Turning mechanism of pedestal pan cover plate

A turning mechanism and toilet technology, applied in the field of bathroom installations, can solve problems such as poor orientation, non-stop rotation, and inconvenient racks, and achieve the effect of small overall height and large turning angle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] The following examples will be combined with the above picture The present invention is further described in detail.

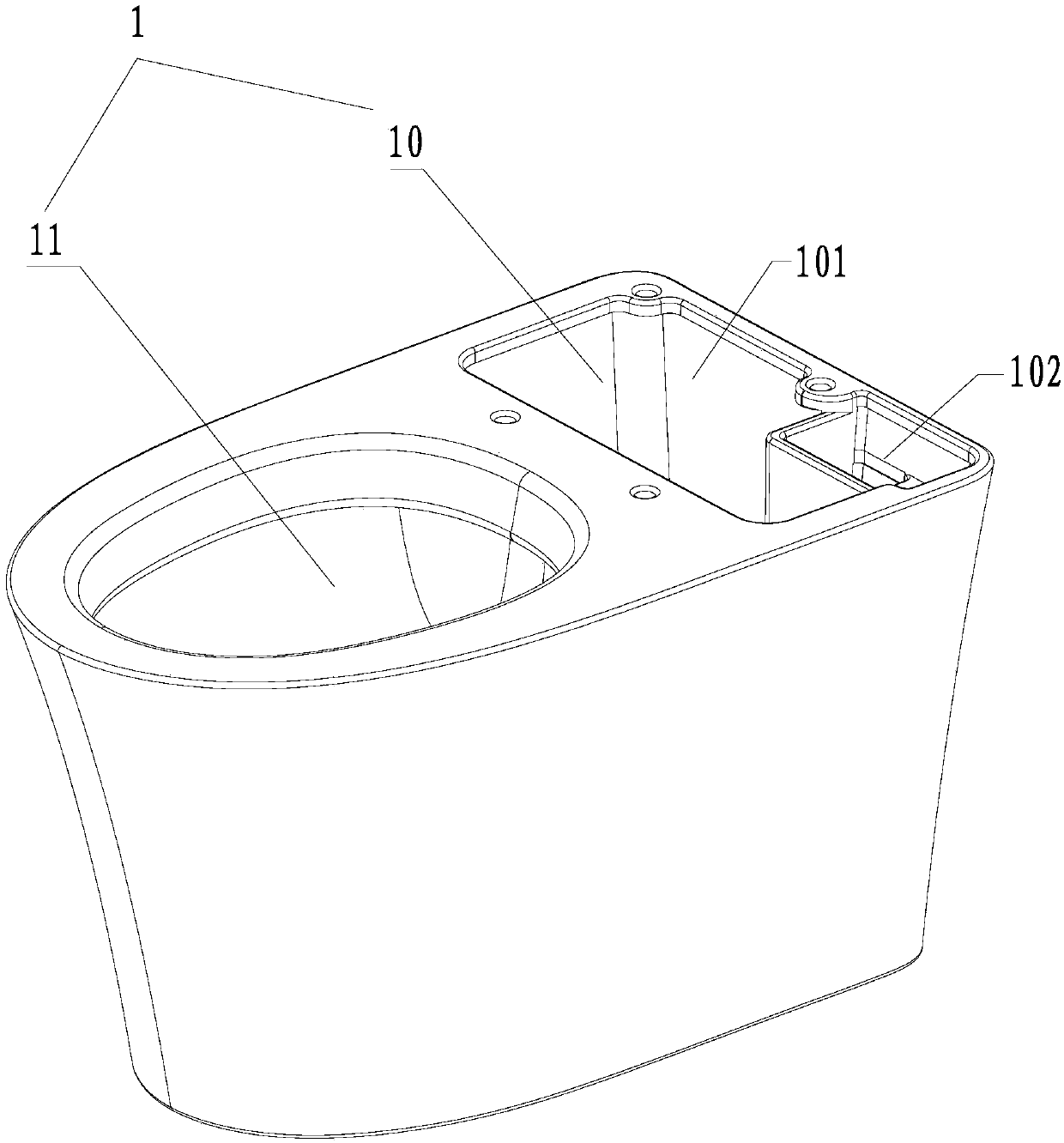

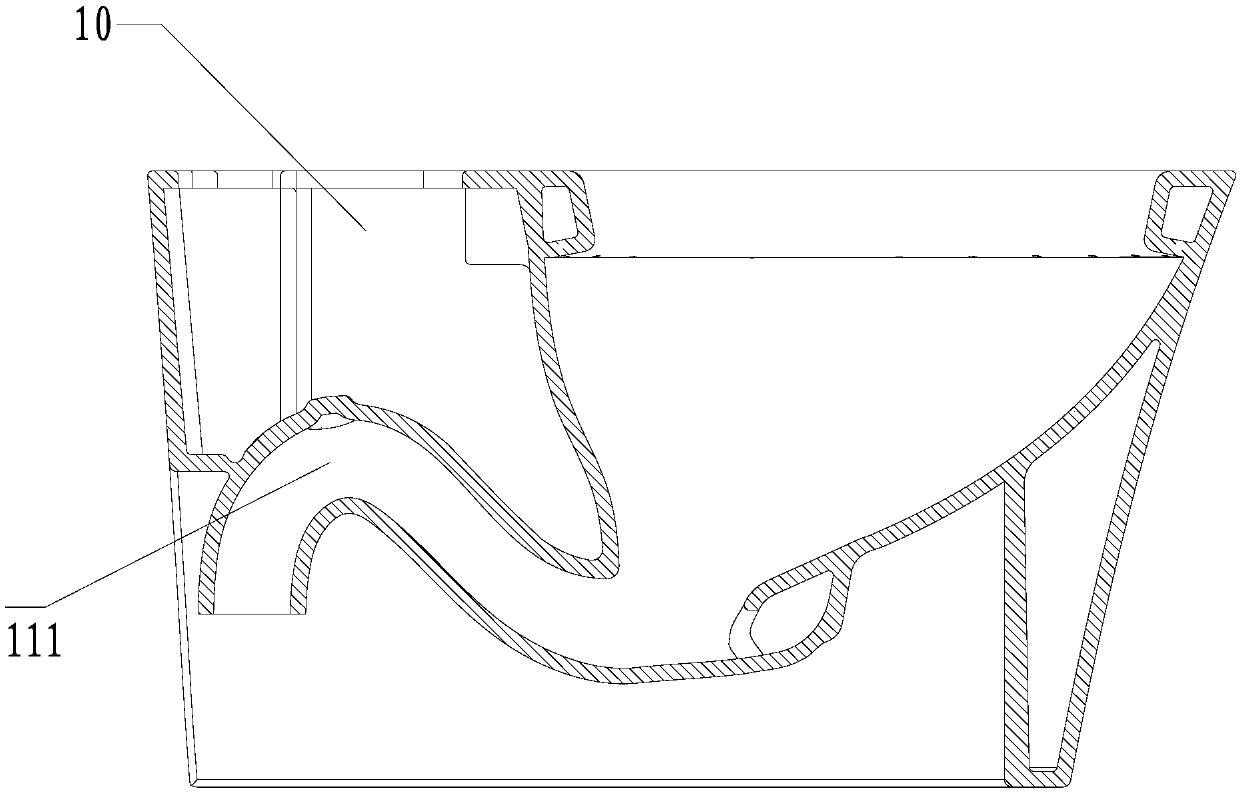

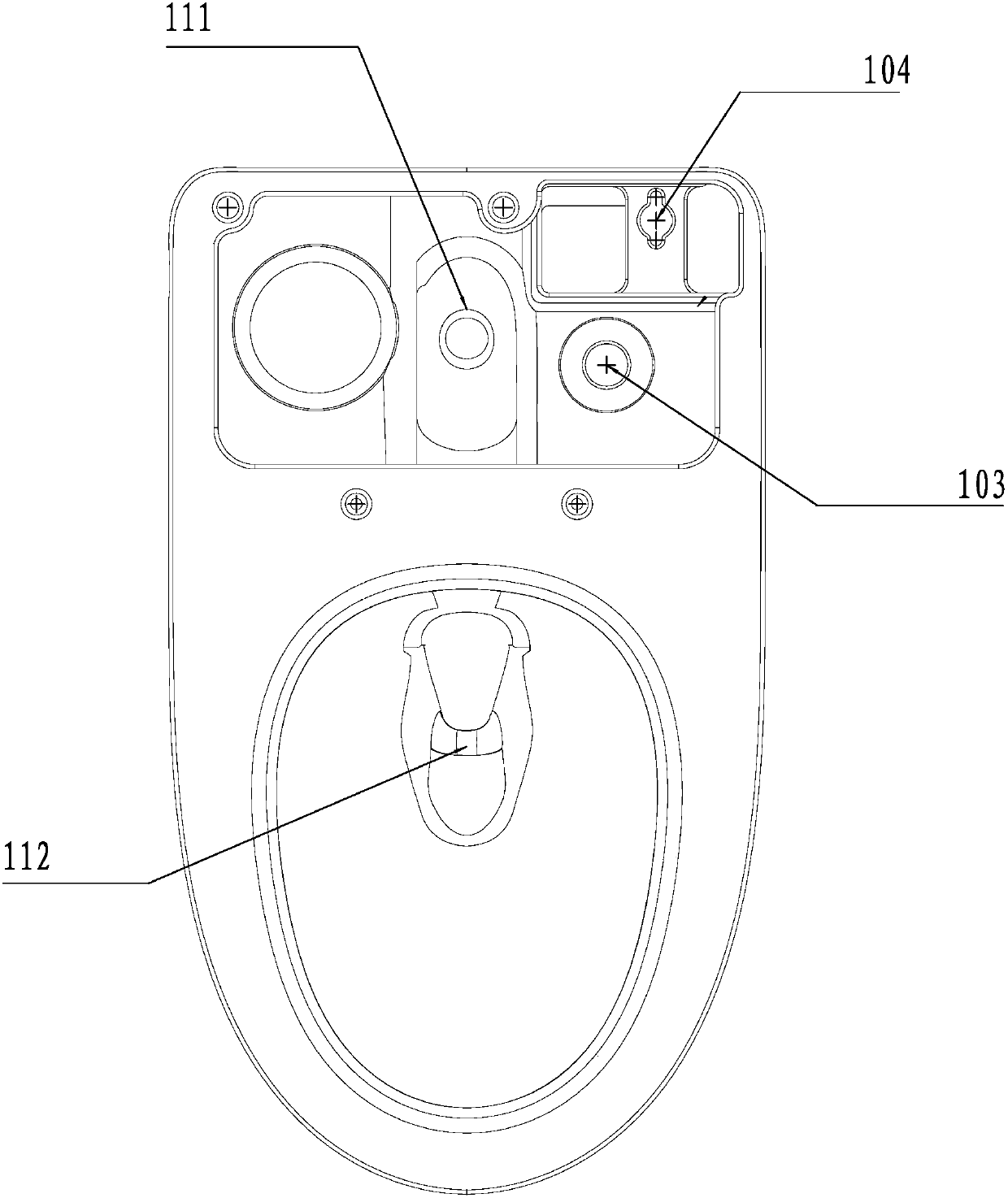

[0049] refer to Figure 1-27 , a toilet, specifically comprising a bucket body 1 and a cover plate 2. The barrel body further includes a toilet tank 10 and a toilet seat body 11; the toilet tank 10 has a second accommodating space 102 for placing the water stop valve 3 and a first accommodating space 101 for storing water; The bottom of the second accommodating space 102 has a second relief hole 104, and the water inlet end 41 of the straight pipe 4 passes through the second relief hole 104 and is connected with the water stop valve 3, so that the The upper surface of the water stop valve 3 faces the opening surface of the water tank 10 . The upper surface of the water stop valve 3 has an operating member 31 for controlling the water stop valve 3 to stop water or pass water. Therefore, in this embodiment, a second accommodating space 102 is speciall...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com