Grinding device for domestic rusted steel pipe

A rusty steel, household technology, applied in the direction of grinding/polishing equipment, grinding/polishing hand tools, metal processing equipment, etc., can solve the problems of inconvenient use, power consumption, high cost, etc., and achieve convenient sliding and use The effect of convenience and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be clearly and completely described below in conjunction with the accompanying drawings and embodiments.

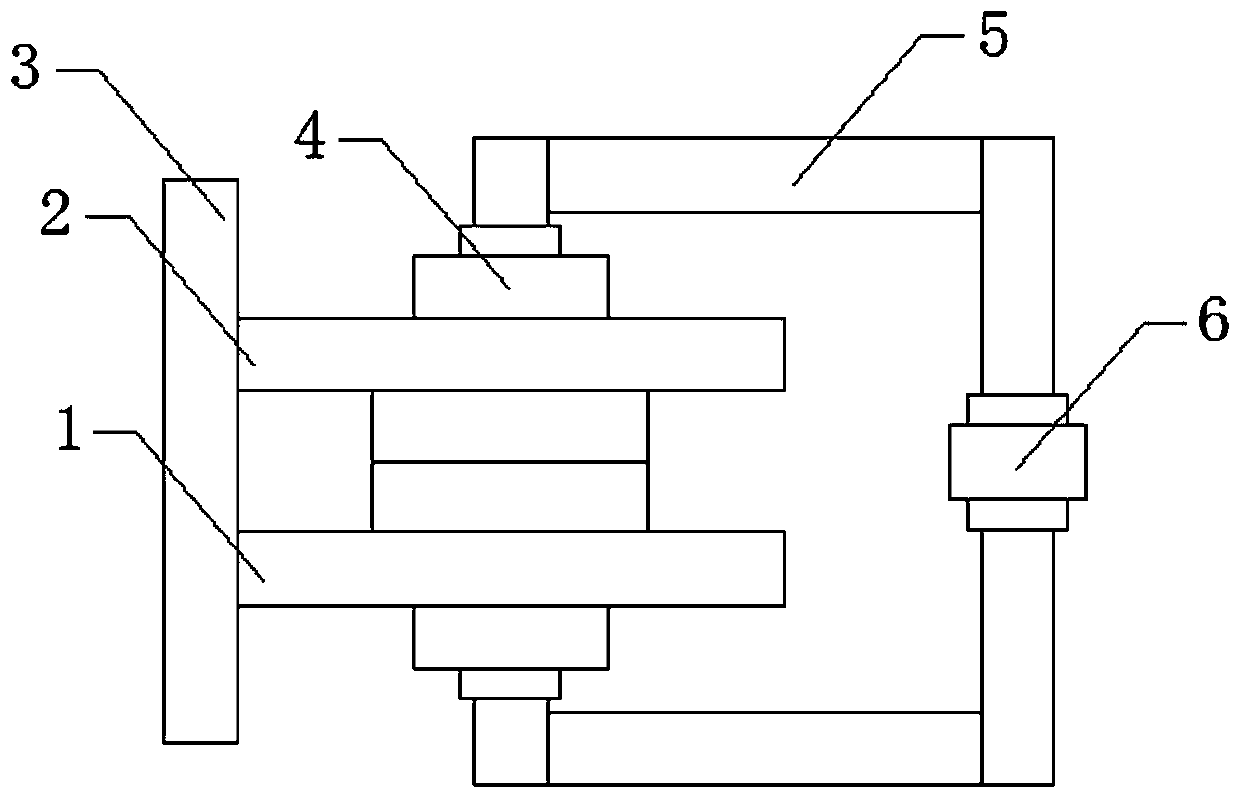

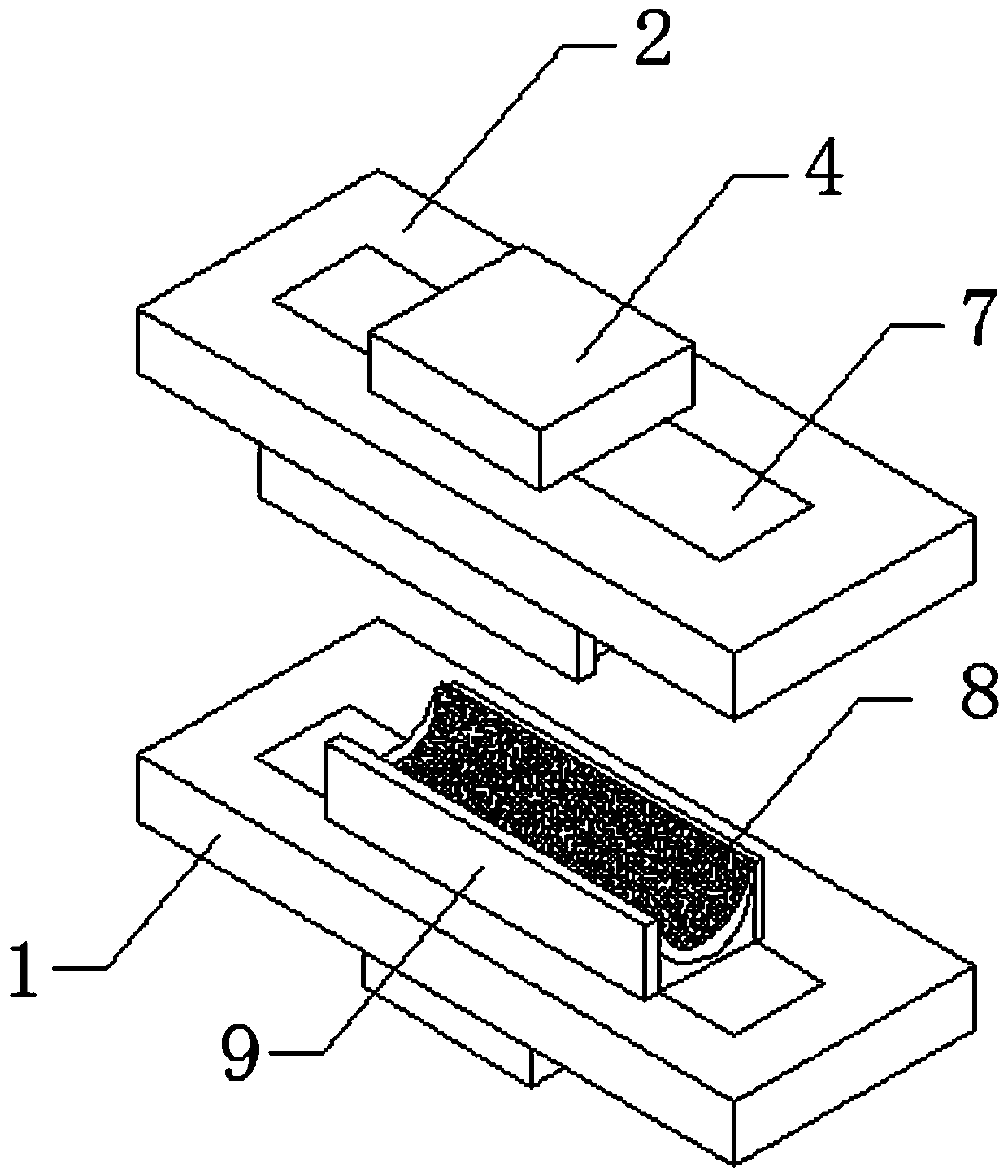

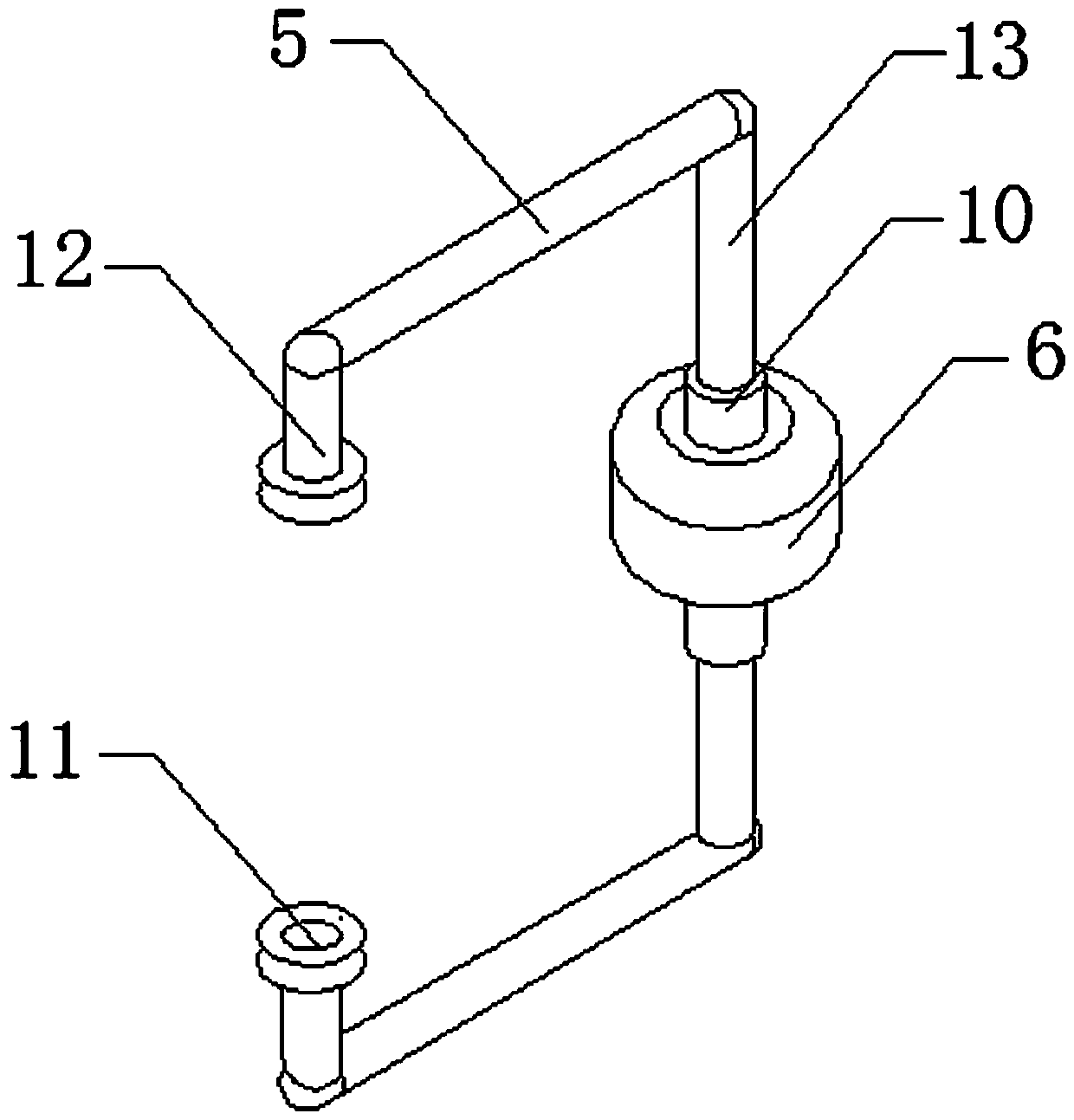

[0019] see Figure 1-Figure 5 , this embodiment includes a first clamping plate 1, a second clamping plate 2 and a grinding block 9, two grinding blocks 9 arranged in parallel are arranged between the first clamping plate 1 and the second clamping plate 2, and the inner walls of the two grinding blocks 9 are embedded Steel wire bristles 8, the first clamping plate 1 and the second clamping plate 2 inside are all provided with chute 7, the first clamping plate 1 and the second clamping plate 2 outsides are all provided with slide block 4, and slide block 4 side is provided with fixed seat 11, fixed Seat 11 outer side is socketed fixed rod 12, and fixed rod 12 one ends install the connecting rod 5 that is horizontally arranged, and connecting rod 5 one ends install the pull bar 13 that is vertically set, and pull rod 13 one ends are provide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com