A dual-jet multi-color 3D printer

A technology of 3D printers and print heads, applied in the direction of 3D object support structures, coating devices, manufacturing tools, etc., can solve problems such as not being able to satisfy consumers, and achieve the effects of high practicability, avoiding scratches, and avoiding color luster

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

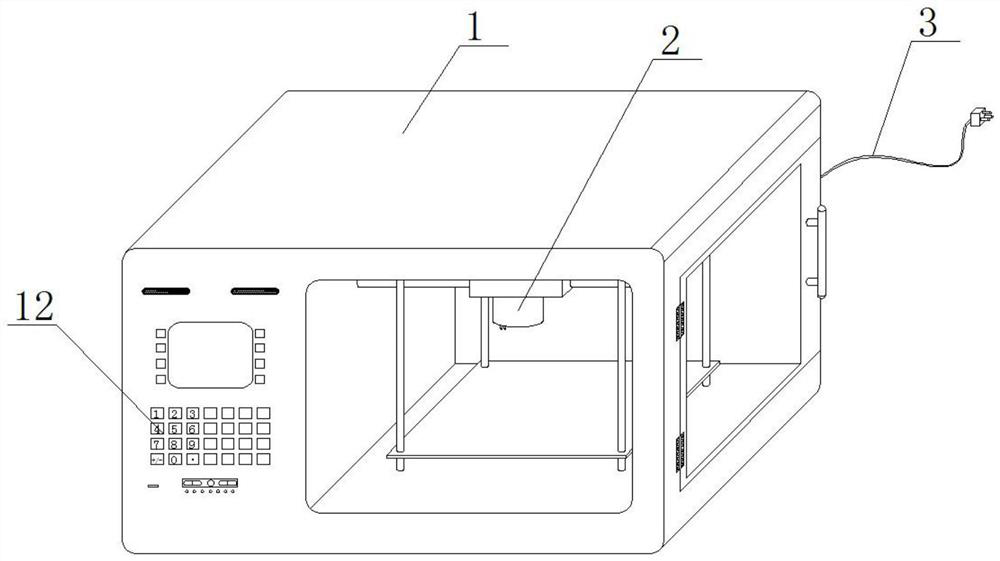

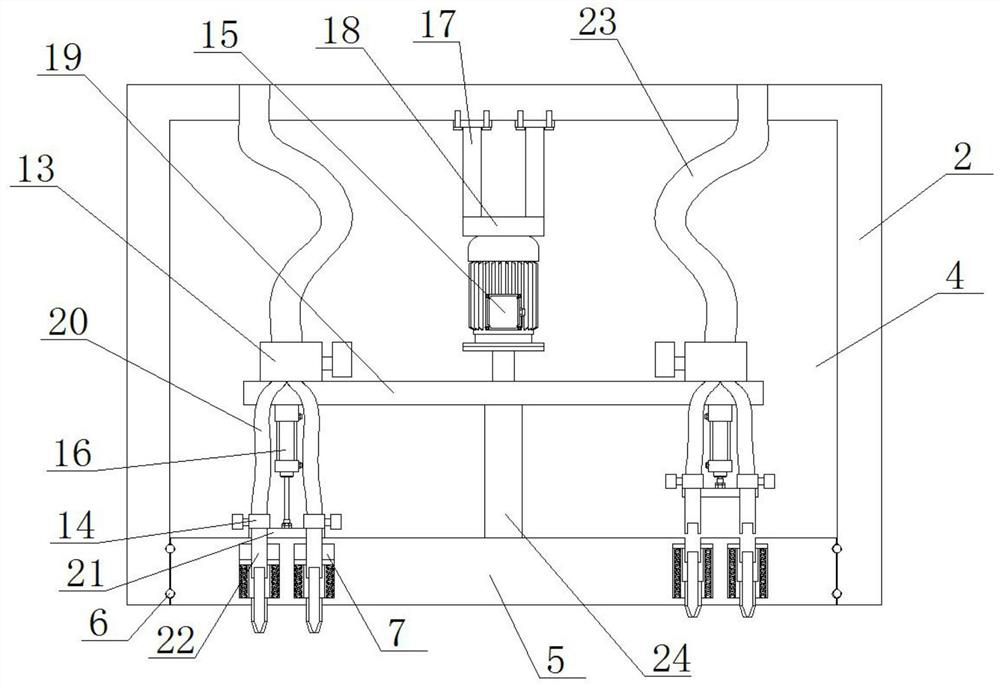

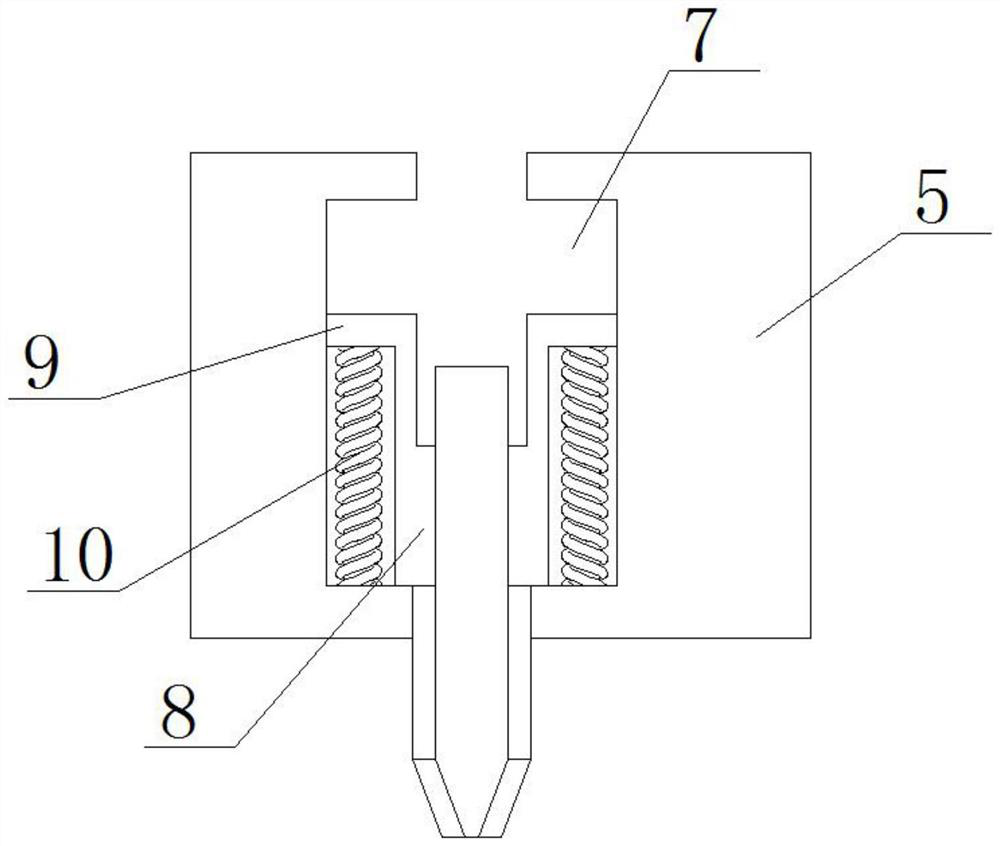

[0020] see Figure 1 to Figure 5 , the present invention provides a technical solution: a double-jet multi-color 3D printer, including a 3D printer body 1 and an intelligent processing system, the rear side of the 3D printer body 1 is connected to a power cord 3, and the inside of the 3D printer body 1 A print head 2 is provided, the bottom of the print head 2 is provided with a circular groove 4, and a rotating base 5 is installed in the opening end of the circular groove 4, and the inner wall between the rotating base 5 and the circular groove 4 Balls 6 are installed between them, and several groups of medium-sized through-holes 7 are opened on the rotating base 5, and the number of each group of medium-sized through-holes 7 is 2, and movable no...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com