Supported solid base catalyst and application thereof

A solid base catalyst and supported technology, which is applied in the field of supported solid base catalysts, can solve the problems of polycarbonate products that are prone to side reactions, such as low quality, high price, etc., and achieve gelation avoidance, good catalytic efficiency, The effect of high molecular weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

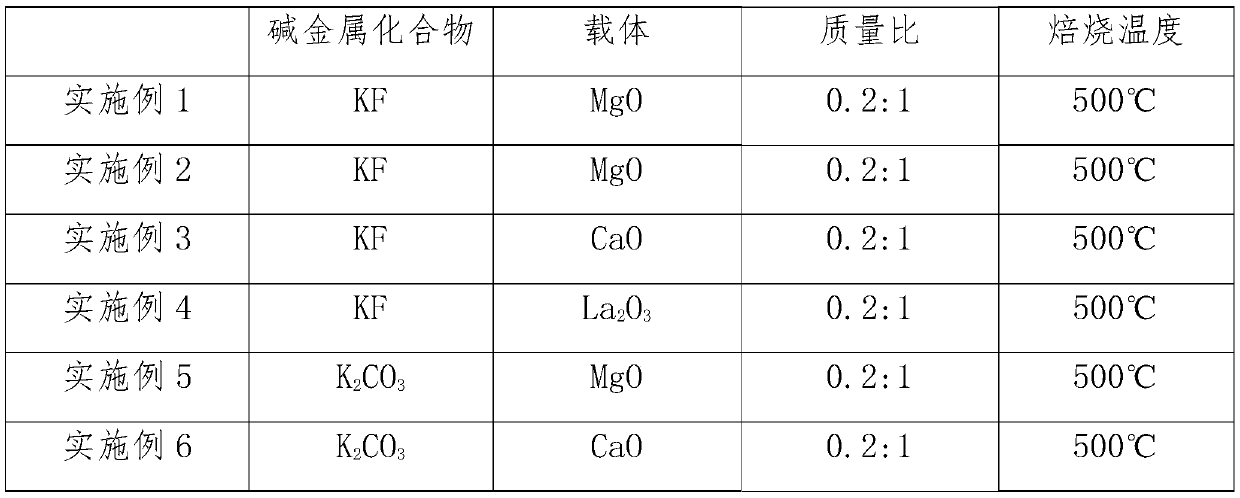

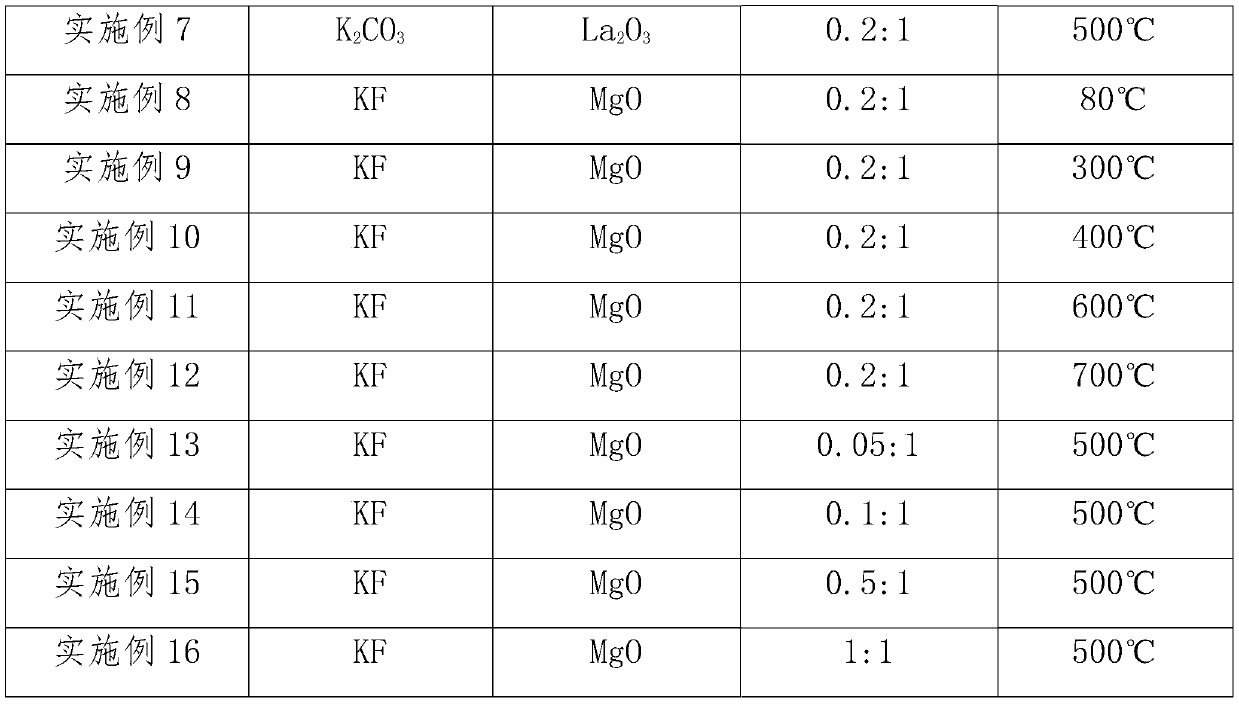

Embodiment 1

[0037] Synthesize 20-KF / MgO-500 catalyst by impregnation method: dissolve KF in deionized water, add MgO to the solution, stir at room temperature for 12 hours, evaporate and dry at 80°C to obtain the precursor (white powder), at 500°C After calcination for 4.0h, 20-KF / MgO-500 can be obtained.

Embodiment 2

[0039] The 20-KF / MgO-500 catalyst was synthesized by ultrasonic impregnation method: KF was dissolved in deionized water, MgO was added to the solution, ultrasonic reaction was conducted for 6 hours, and evaporated and dried at 80°C to obtain the precursor (white powder) at 500°C. After calcination for 4.0h, 20-KF / MgO-500 can be obtained.

Embodiment 3

[0041] Synthesize 20-KF / CaO-500 catalyst by impregnation method: dissolve KF in deionized water, add CaO to the solution, stir at room temperature for 12 hours, and evaporate to dryness at 100°C to obtain the precursor (white powder). At 500°C After calcination for 3.0h, 20-KF / CaO-500 can be obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com