Frame part boxing method and auxiliary boxing device

A part and frame type technology, which is applied in the field of frame type parts packing method and auxiliary packing device, can solve the problems of long transformation period, large site demand area and high energy consumption, and achieves low energy consumption, small site demand, retrofit less required effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049]In order to further elaborate the technical means and effects that the present invention adopts for reaching the intended invention purpose, below in conjunction with the accompanying drawings and preferred embodiments, the specific implementation, structure, features and effects of the present invention are described in detail as follows:

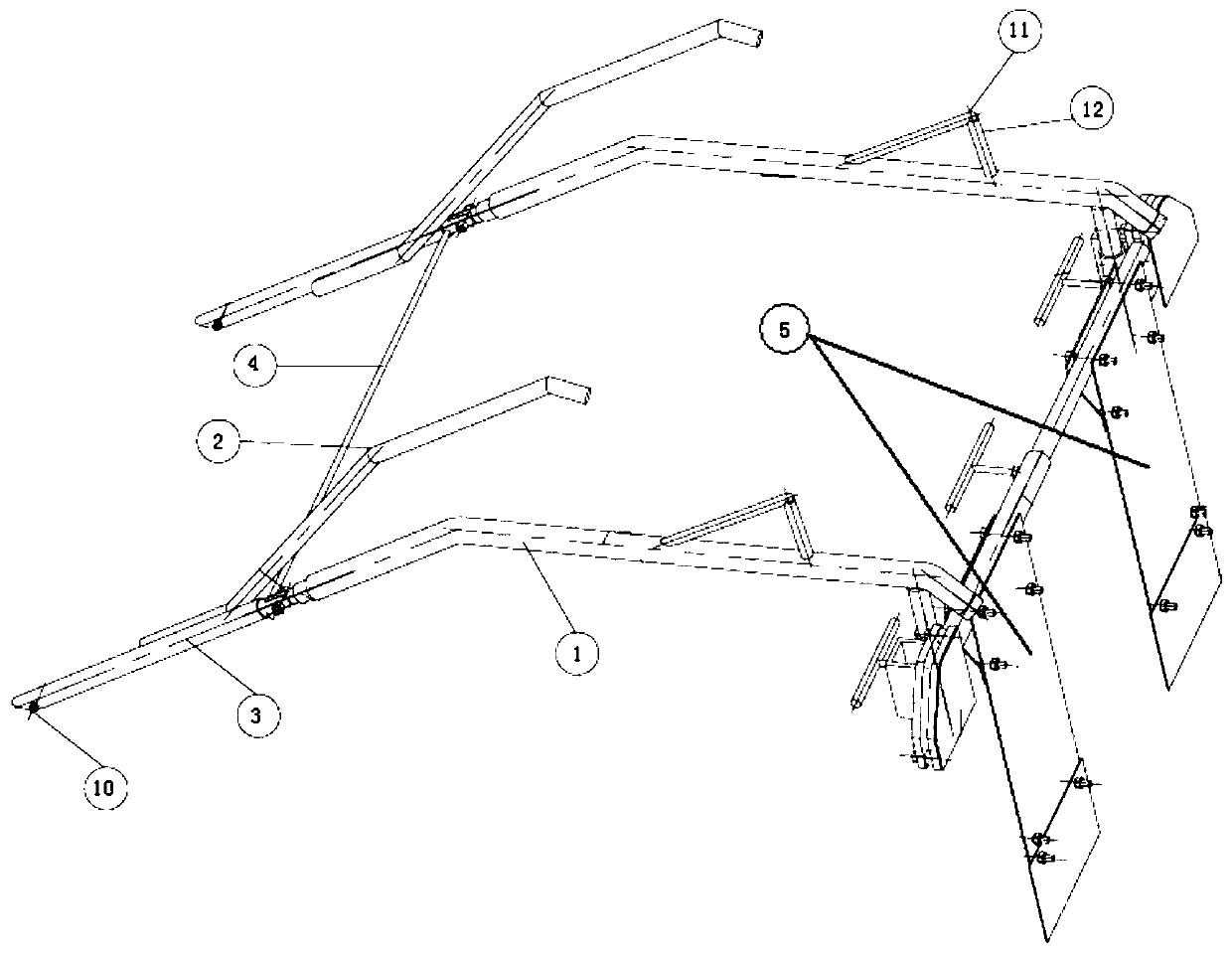

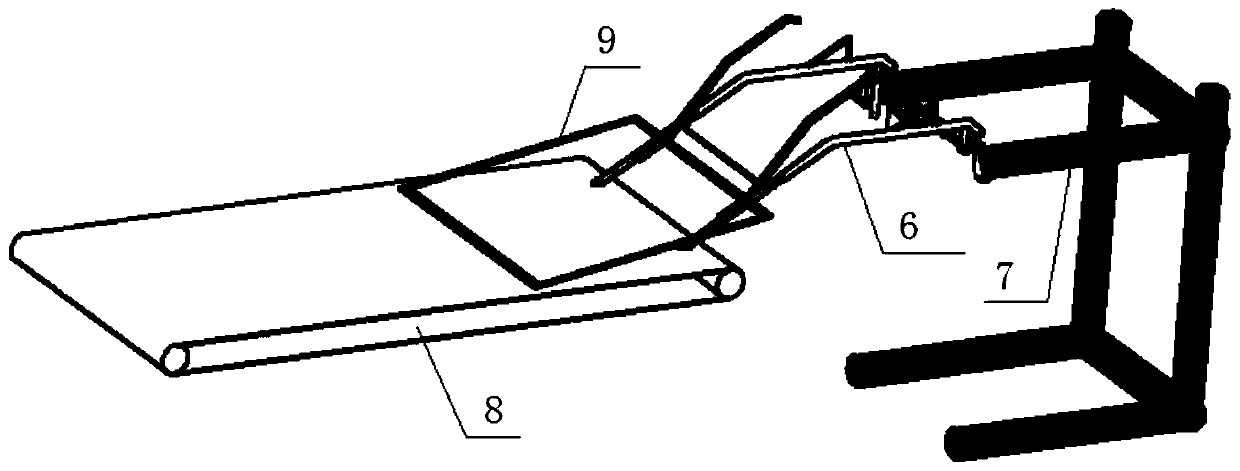

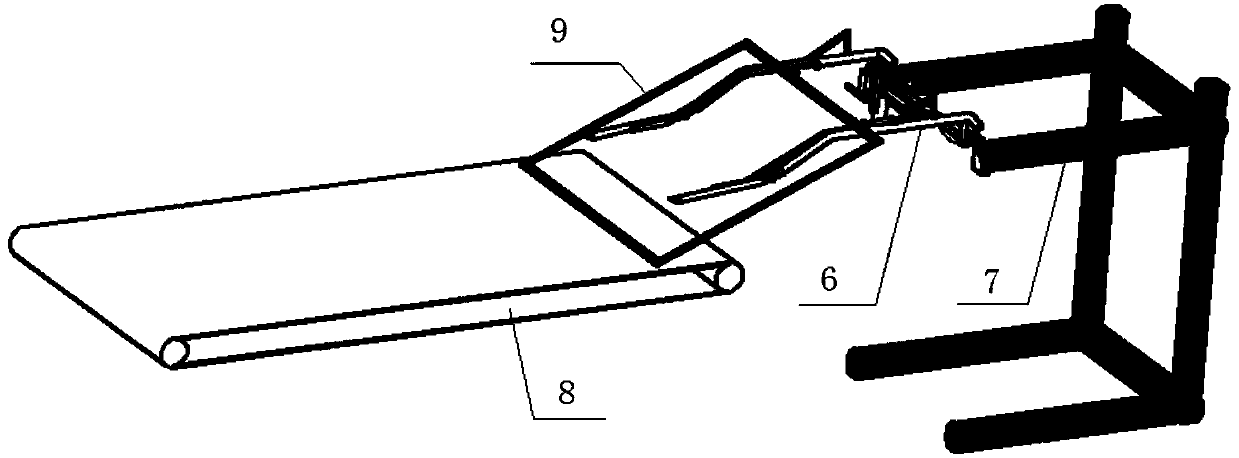

[0050] Such as figure 1 As shown, the auxiliary box-packing device of the present invention includes two sets of identical device main bodies, and the two sets of device main bodies are parallel to each other and fixedly connected by parallel rods 4 perpendicular to the rods of the device main body.

[0051] Each set of device main body comprises: the first rod 1, the second rod 2, the third rod 3, and the connecting device 5, the connecting device 5 is arranged on the first rod 1, for connecting the first rod 1 is connected on the part mounting device 7. The second rod 2 is fixedly connected to the third rod 3, and the connection p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com