Delivery window assembly

A technology for transferring windows and components, which is applied in windows/doors, building components, door/window applications, etc. It can solve the problems of complex operation, cross-contamination, and inability to continuously transfer items, and achieve cross-infection prevention, good sealing, and energy saving The effect of passing on costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

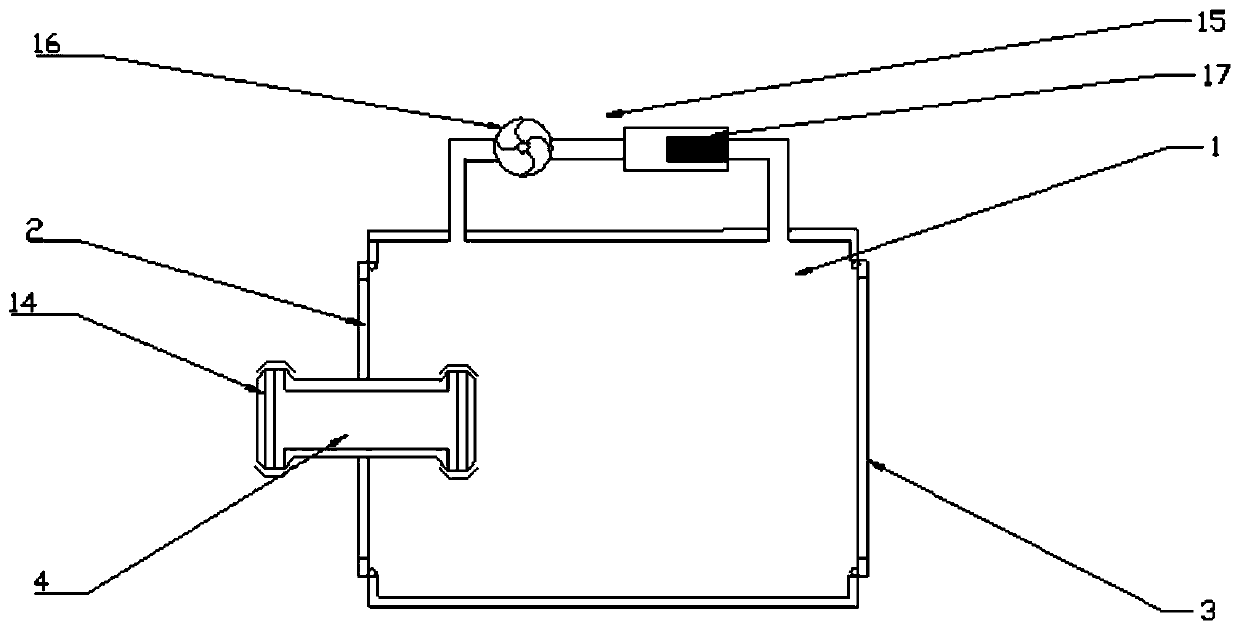

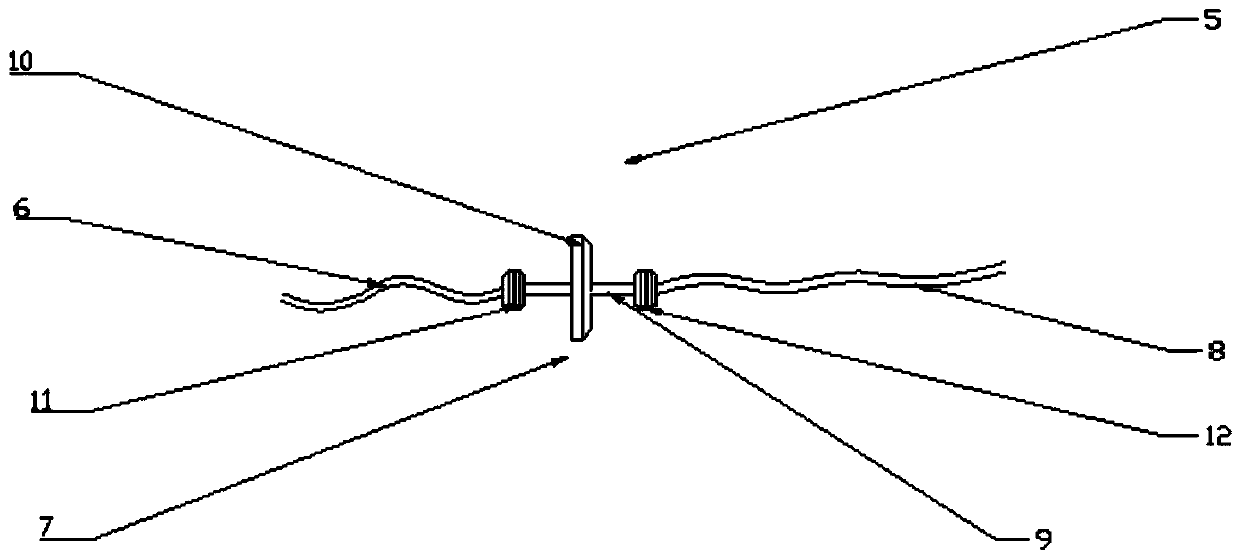

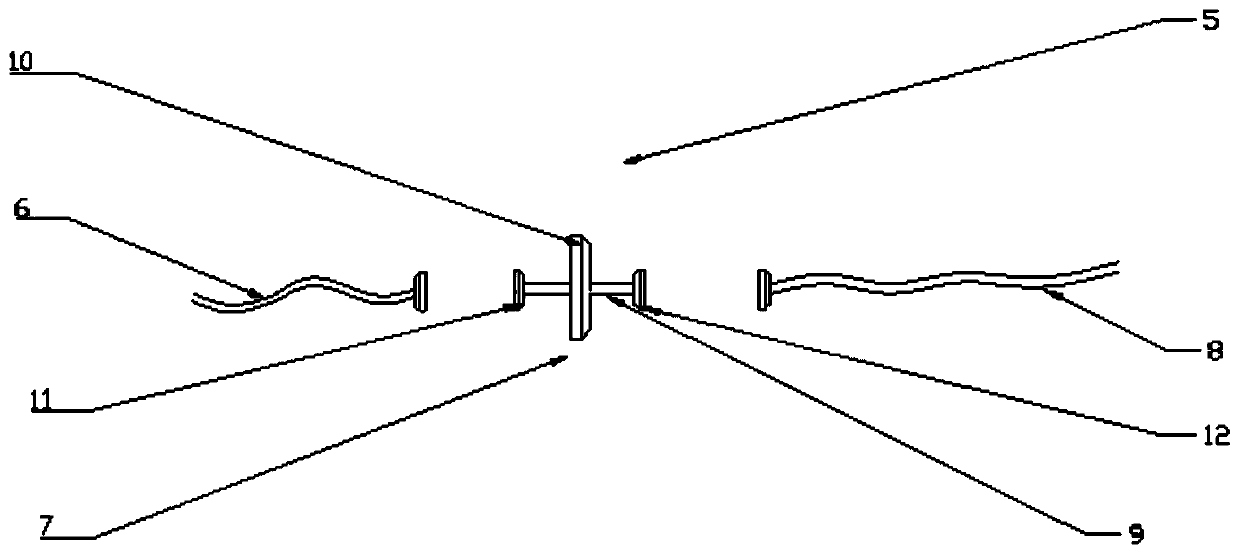

[0032] Such as figure 1 , shown in 4, 5, and 6, a transfer window assembly includes a box body 1, and the box body 1 is located between two isolation areas. In this embodiment, the left side of the box body is the sterile area A, and the right side is the non-sterile area. Bacteria area B. A first cabin door 2 and a second cabin door 3 are installed on the box body 1, and a transfer port 4 is arranged on the first hatch door 2, wherein the transfer port 4 has an opening on the inside and outside sides of the box body 1, and each A matching detachable blocking cover 14 is set at each opening, and in this embodiment the two are connected by a clamp; a sterilizing device 15 is further provided on the box to realize the sterilizing inside the box. Self-cleaning, in this embodiment, the sterilization device 15 is set as a combination of a fan 16 , a filter 17 and a hydrogen peroxide generator 18 . The transfer window assembly further includes a transmission connector 5 that is us...

Embodiment 2

[0037] Such as figure 1 , 3 and Figure 7-9 As shown, a transfer window assembly includes a box body 1, and the box body 1 is located between two isolation areas. In this embodiment, the left side of the box body is a non-sterile area B, and the right side is an aseptic area A. A first cabin door 2 and a second cabin door 3 are installed on the box body 1, and a transfer port 4 is arranged on the first hatch door 2, wherein the transfer port 4 has an opening on the inside and outside sides of the box body 1, and each A matching detachable plugging cover 14 is set at each opening, and the two are connected by threads in this embodiment; a sterilizing device 15 is further arranged on the box body to realize self-cleaning inside the box body. In this embodiment, the sterilization device 15 is configured as a fan 16 and a filter 17 . The transfer window assembly further includes a transmission connector 5 that is used in conjunction with the box body 1 to realize the transmission...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com