Method of evaluating debonding of honeycomb sandwich structure at high temperature

A technology of honeycomb interlayer and debonding, which is applied in the direction of measuring devices, instruments, scientific instruments, etc., can solve the problems such as the evaluation method of debonding of honeycomb sandwich structure that does not exist yet, and achieve good evaluation results, easy implementation, and simple system construction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described below with reference to the accompanying drawings and embodiments.

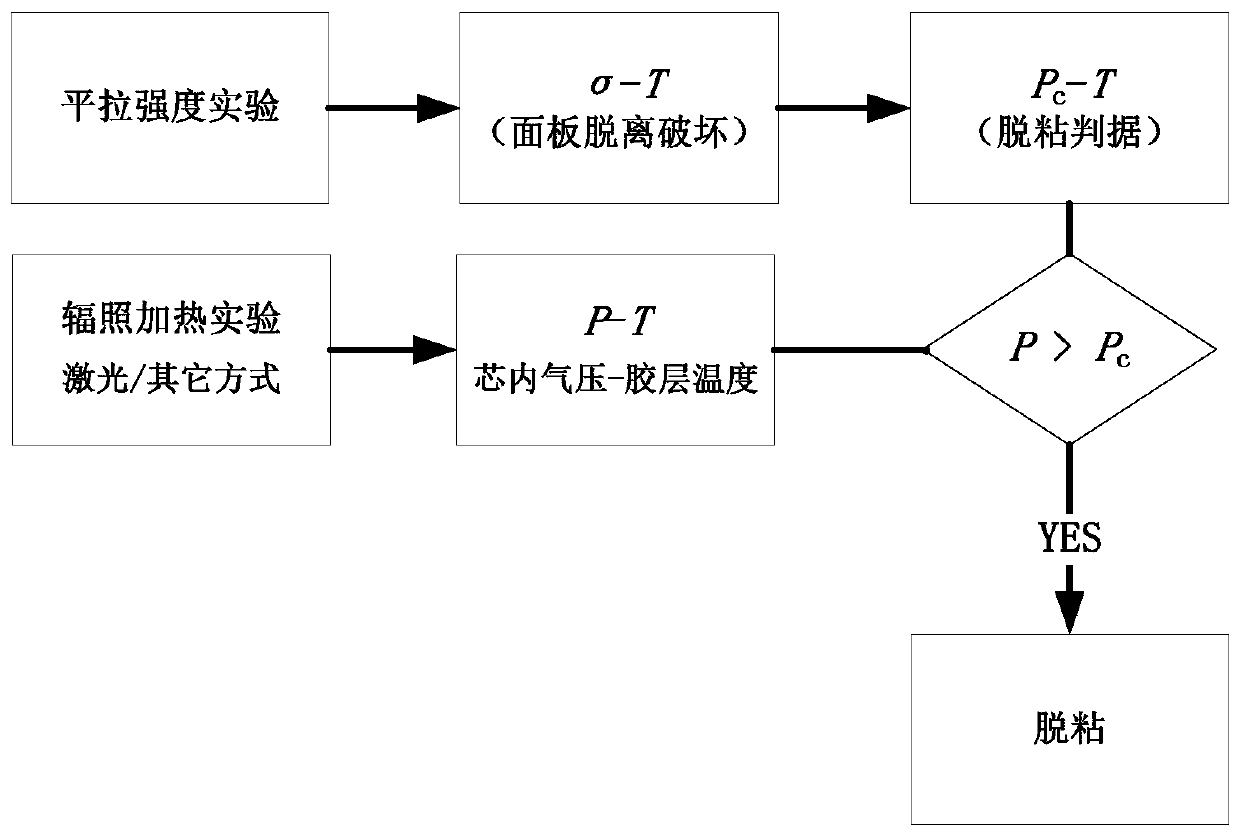

[0033] see figure 1 , a honeycomb sandwich structure debonding evaluation method at high temperature, the main steps are:

[0034] Step 1) Select the honeycomb sandwich structure sample; the honeycomb sandwich structure sample is selected from the honeycomb sandwich structure to be evaluated in the same process or the same factory batch;

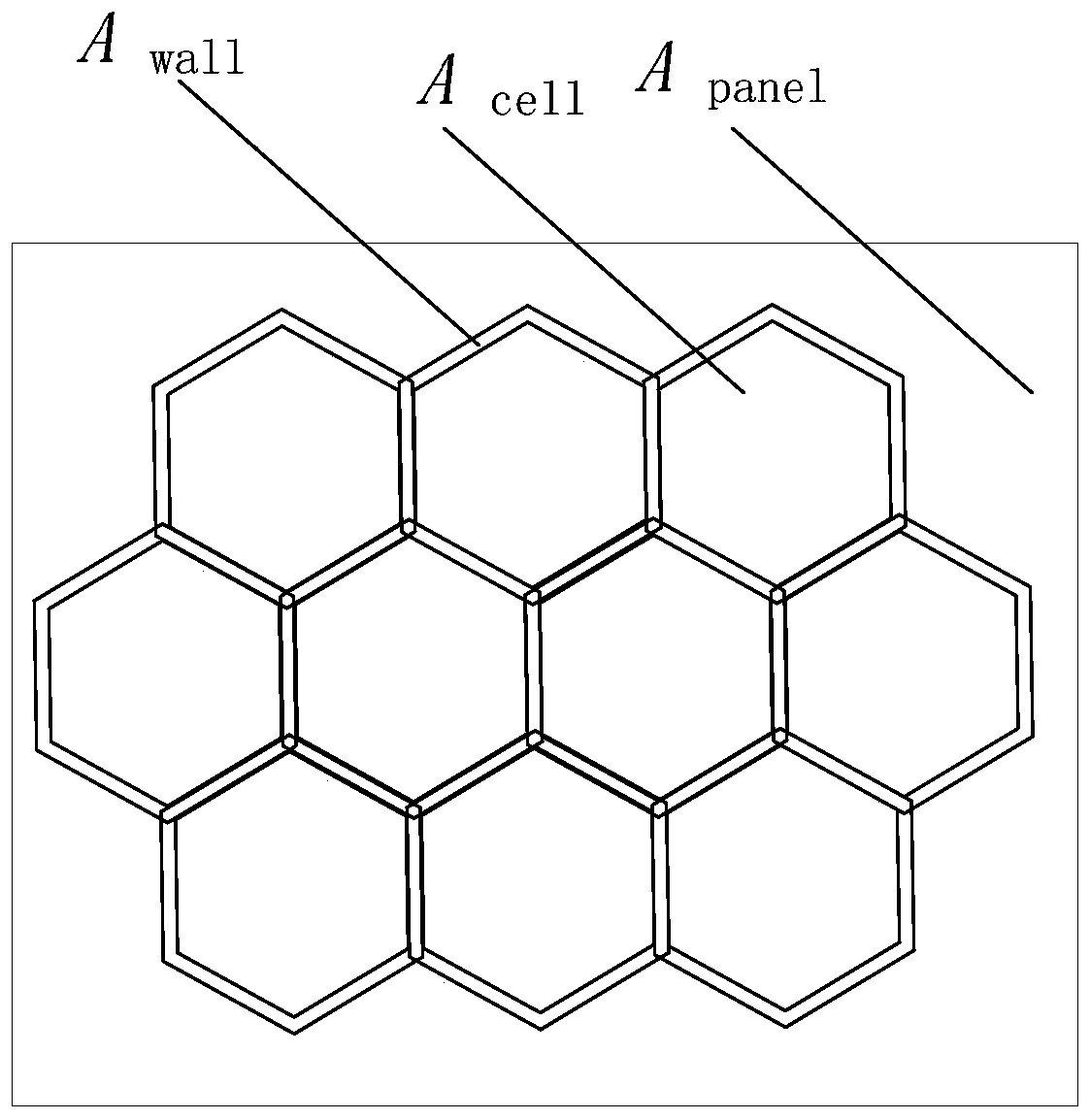

[0035] Step 2) Perform a flat tensile strength test on the honeycomb sandwich structure sample to obtain the strength σ(T) of the adhesive layer between the faceplate and the honeycomb core of the honeycomb sandwich structure;

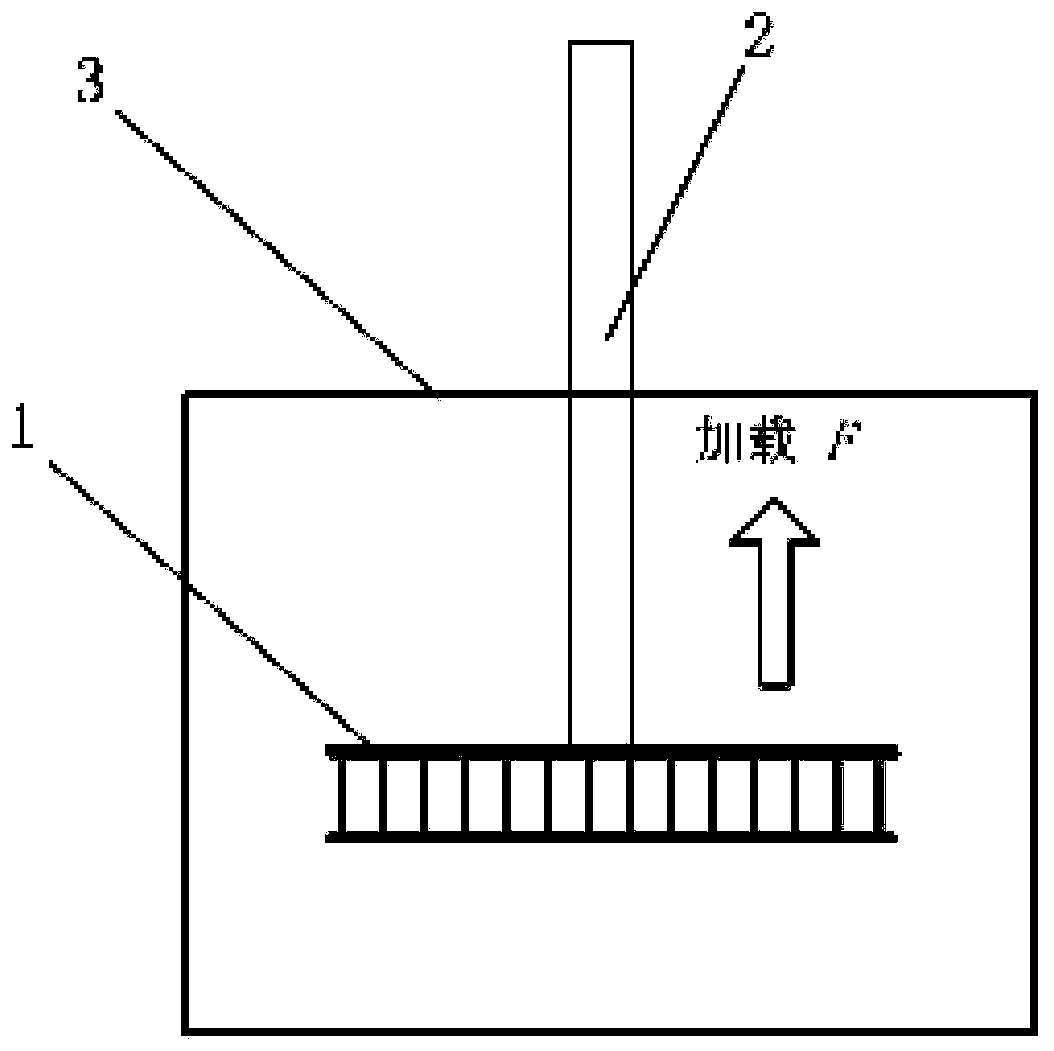

[0036] see figure 2 , set the temperature T of the heating furnace 3, and use the heating furnace 3 to heat the honeycomb sandwich structure sample to thermal equilibrium; pass the mechanical loading rod 2 through the high temperature resistant adhesive layer 1 (it needs to be explained that ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com