Automatic roll sealing device for sealing cover of connecting rod type snap-action thermostat

A sudden jump thermostat and connecting rod technology, applied in the direction of electrical components, electric switches, circuits, etc., can solve the problems of lower production yield and poor sealing quality, and achieve reliable packaging, high sealing quality and low energy consumption. low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

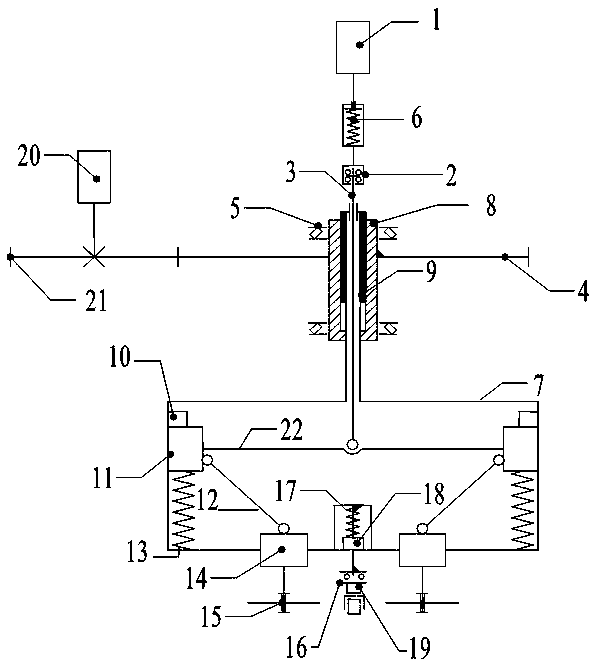

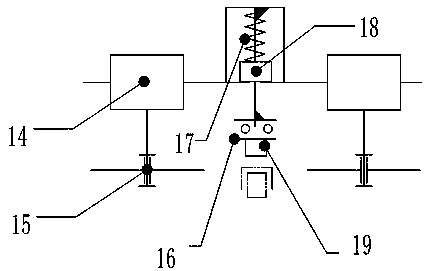

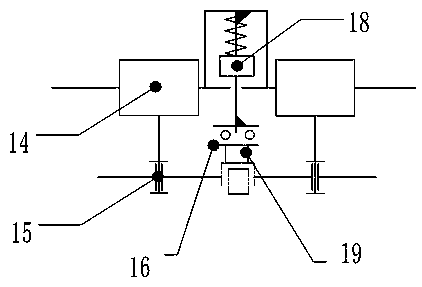

[0020] Such as figure 1 , figure 2 As shown, the motor 20 main shaft of the present invention is equipped with a pinion 21, the pinion 21 and the bull gear 4 form a gear pair, the support shaft 8 is contained in the center hole of the bull gear 4, rotates together with the bull gear 4, and opens the outer spline One end of the spline shaft 9 is installed in the support shaft 8, and can slide up and down in the inner spline groove of the support shaft 8, and one end of the spline shaft 9 without external splines is connected with the rotating matrix shell 7;

[0021] The extension rod of the cylinder 1 is connected in series with the pressure rod bearing 2 through the adjustment spring 6, one end of the pressure rod 3 is connected with the pressure rod bearing 2, and the other end of the pressure rod 3 passes through the center hole of the spline shaft...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com