3D spacer fabric reinforced pu composite and its use

A spacer fabric, composite material technology, applied in other household appliances, knitting, application and other directions, can solve the use of undisclosed 3D spacer fabric reinforced PU composite materials, the unusable composition, mechanical properties toughness, elongation and hardness problems, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

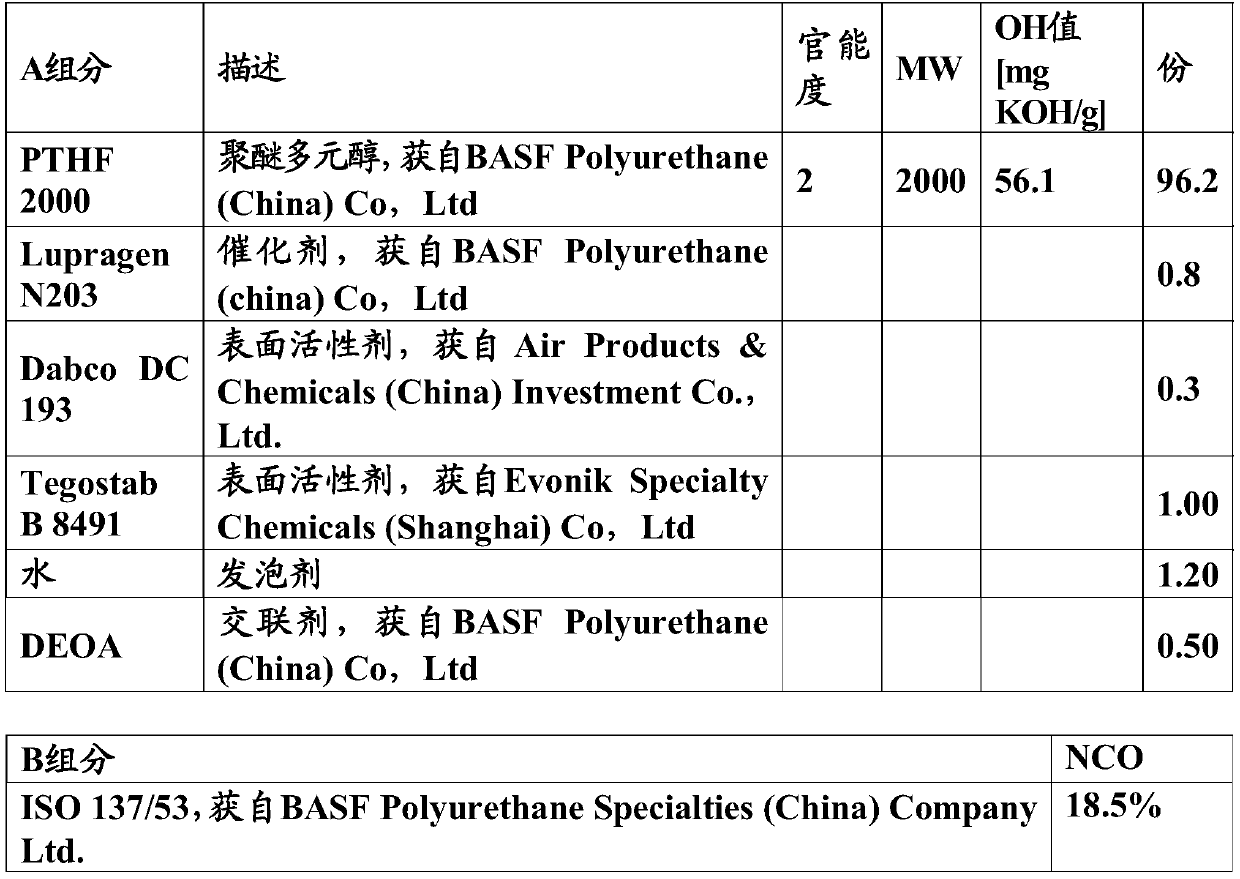

Method used

Image

Examples

Embodiment

[0070] 1. Measurement method

[0071] During the experiments, the toughness, density, hardness and mechanical properties of the 3D fabric-reinforced PU composites were measured.

[0072] The density of the 3D fabric-reinforced PU composite was measured from the top layer to the bottom layer by using a DPX300LTE density analyzer. According to the test standard, a sample with a size of 5cm (length) x 5cm (width) x 1cm (thickness) should be prepared, then placed in the chamber and scanned by X-rays. Thus, a density profile is obtained.

[0073] The hardness of the 3D fabric-reinforced PU composites was measured in the direction of spaced yarns according to the test standard of ASTM D 2240 by using an Asker C durometer obtained from KOBUNSHI KEIKI Co, Ltd.

[0074] The tensile strength of the 3D fabric-reinforced PU composites was measured in the direction of spaced yarns according to the test standard of DIN 53504 by using a Zwick / Roell testing machine obtained from Zwick Roell...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com