Coating device for surface coating

A surface coating and movable plate technology, which is applied to the device and coating of the surface coating liquid, can solve the problems of surrounding environmental pollution, high labor intensity, less than 50%, and achieve low technical requirements and coating quality High and wide application effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

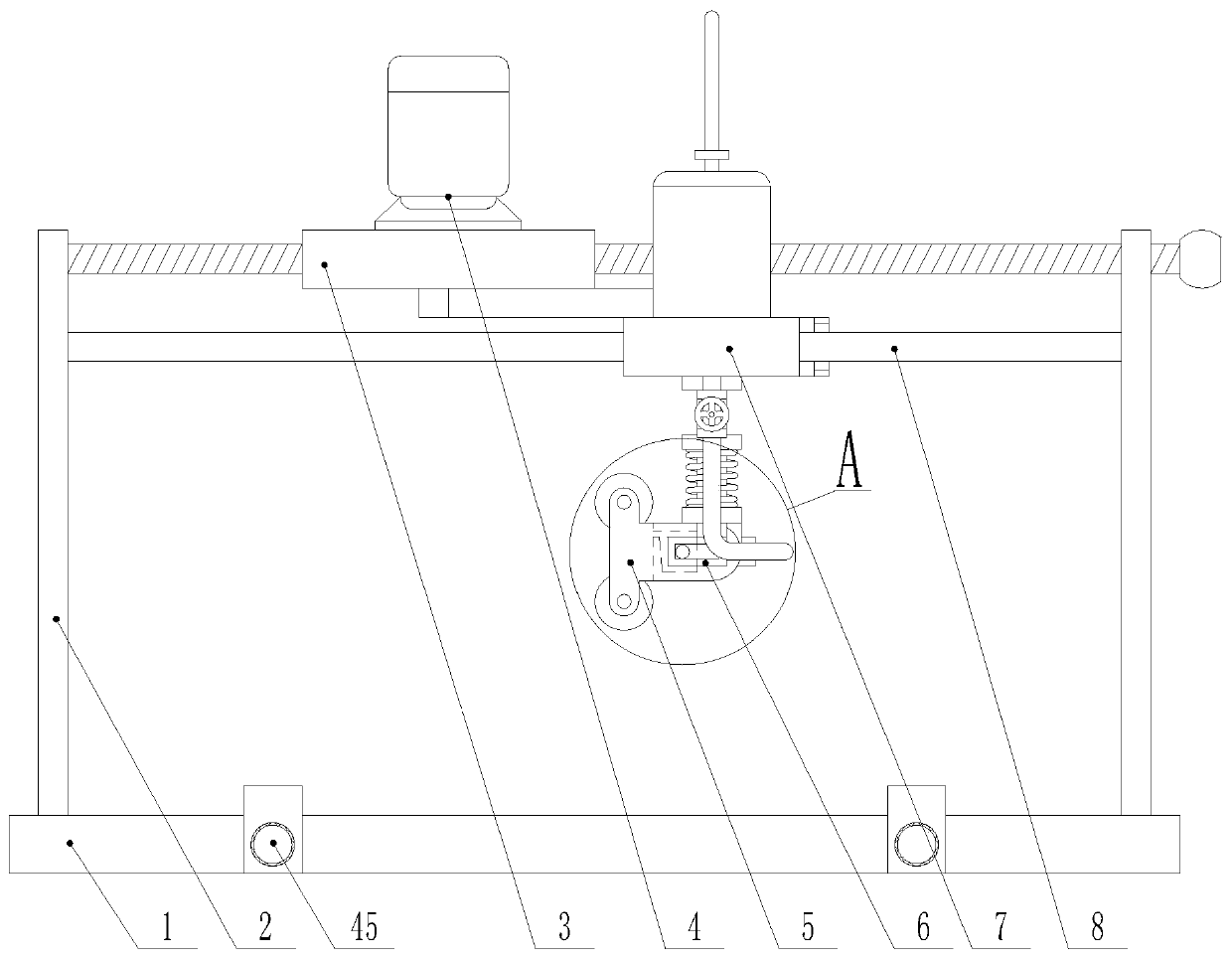

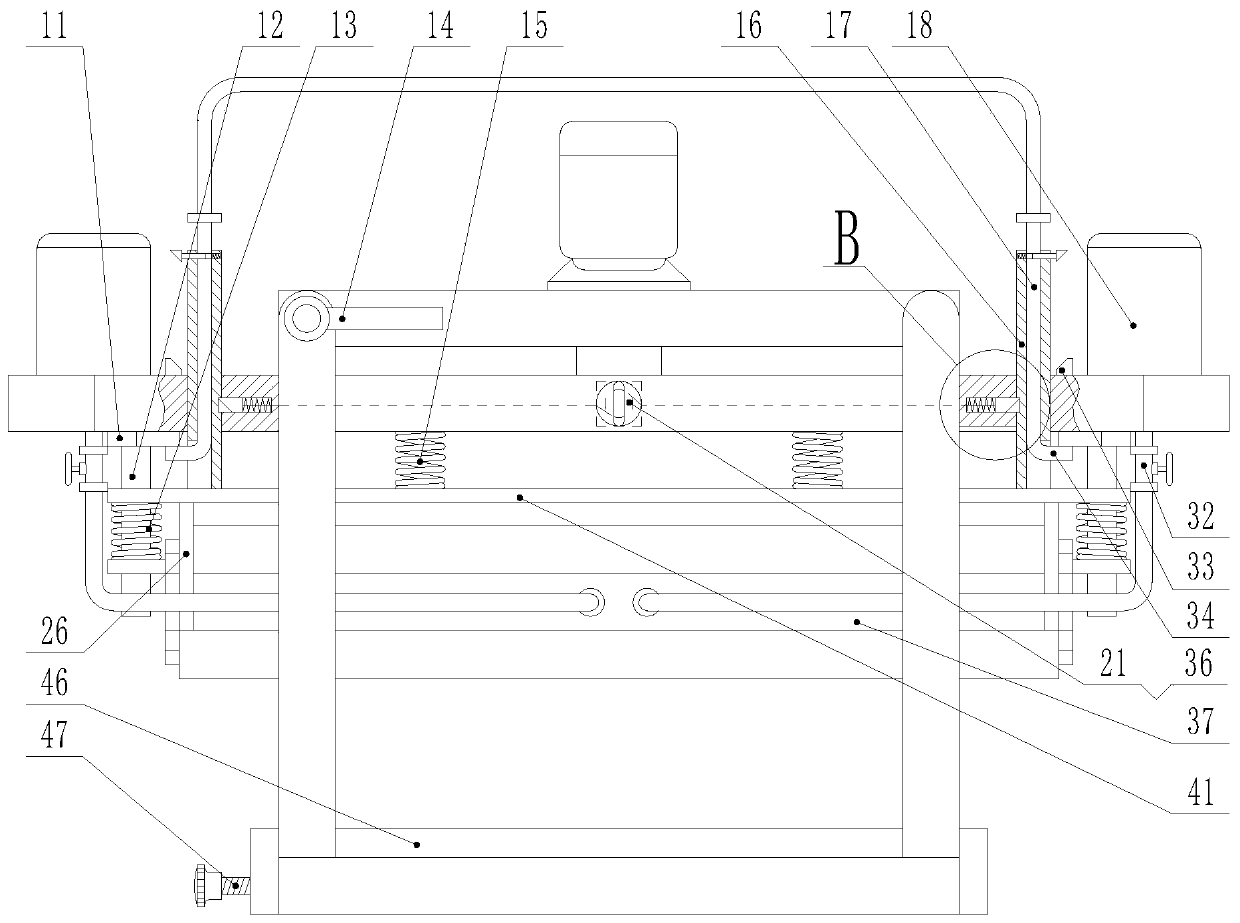

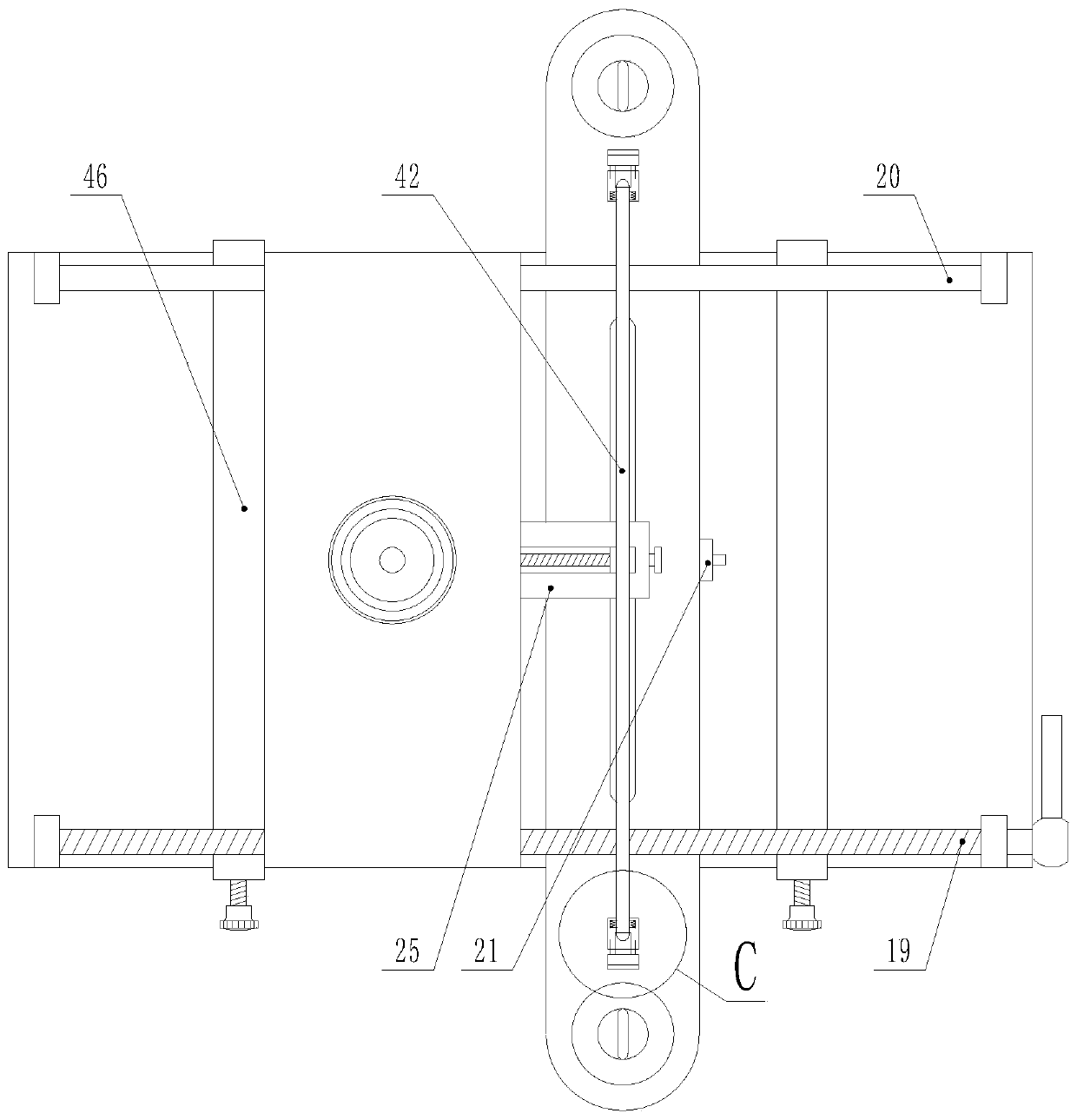

Image

Examples

Embodiment 1

[0041] In Embodiment 1, the height of the platen 1 cannot be adjusted, and the first compression spring 15 can only be compressed when it is necessary to coat plates of different thicknesses. In embodiment 2, such as Figure 10 and 11 As shown, the platen 1 is provided with a rectangular groove, the third lead screw 49 and the fifth guide rod 52 are arranged in the rectangular groove of the platen 1, and the wall at the right end of the platen 1 rectangular groove A through hole is provided, and one end of the third lead screw 49 is rotationally connected with the left end wall of the rectangular groove of the platen 1, and the right end passes through the through hole on the right end wall of the platen 1 and is connected with the second handle 50.

[0042] The two ends of described fifth guide bar 52 are respectively fixedly connected with the walls at both ends of the rectangular groove of platen 1, threaded holes are provided on the first movable block 53, through holes a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com