a wind sorter

A wind separator and support frame technology, applied in the direction of solid separation, separation of solids from solids by air flow, chemical instruments and methods, etc., can solve the problem of large distance between the discharge port and the collection device, powdered materials flying and scattering, etc. problems, to avoid the flying of materials and prolong the length of the pipeline

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

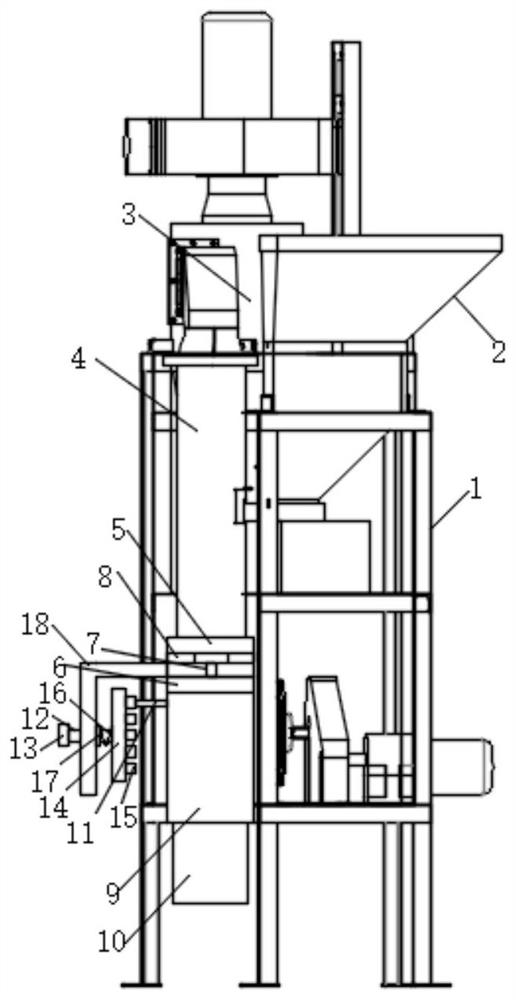

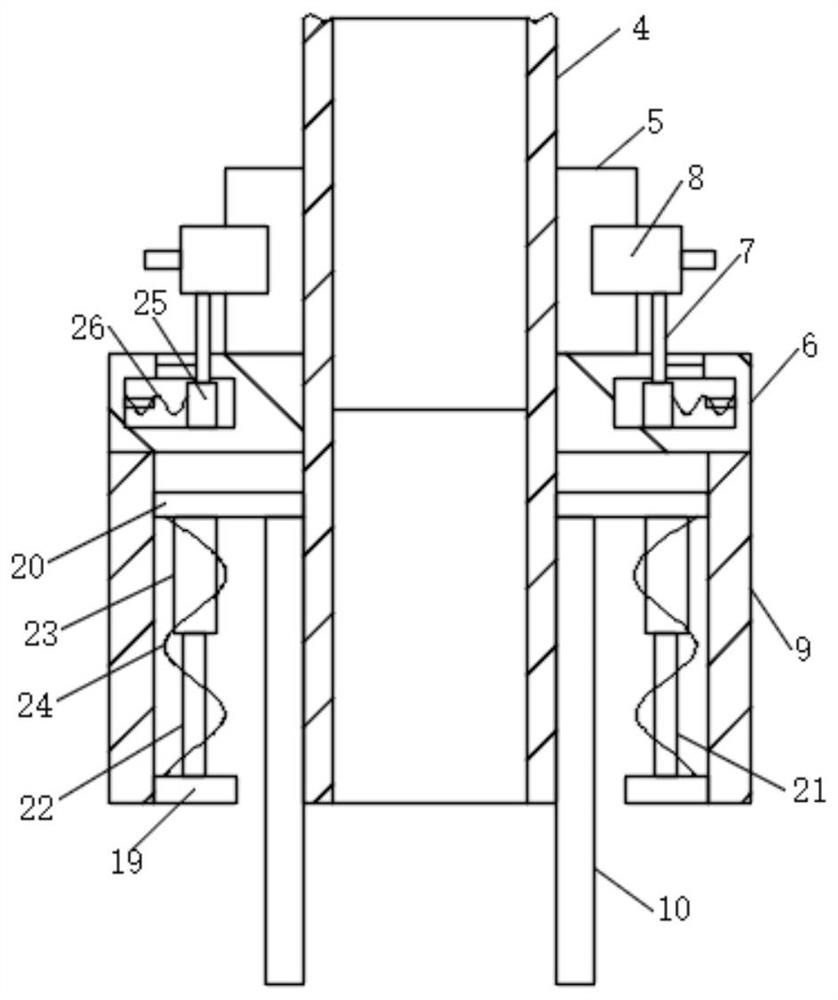

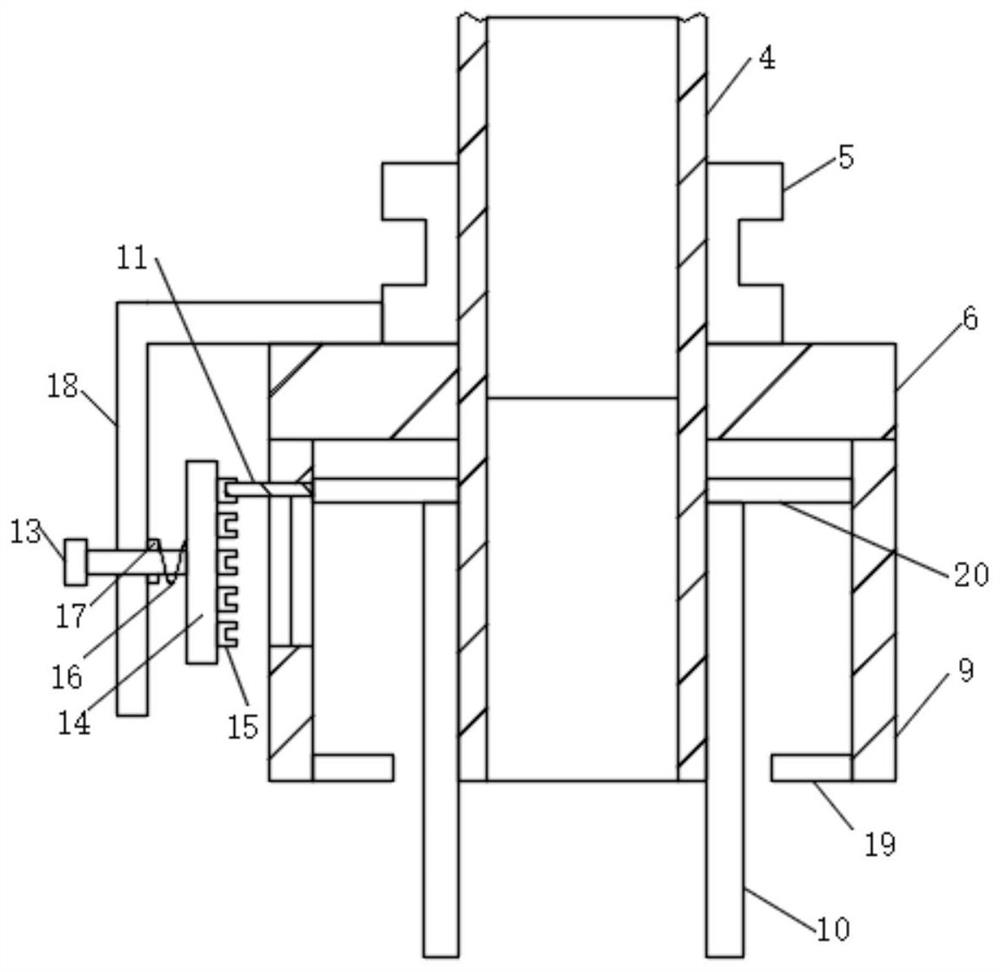

[0023] see Figure 1 to Figure 4 , the present invention provides a technical solution: a winnowing machine, comprising a support frame 1, a feeding funnel 2, a crushing chamber 3 and a conveying pipe 4, the feeding funnel 2 is located at the upper position on the right side of the front end of the support frame 1, and the crushing chamber 3 is located at the rear end of the support frame 1, and the delivery pipe 4 is located at the left side of the front end of the support frame 1. The outer side of the lower end of the delivery pipe 4 is provided with a fixed ring pipe 5 and a stable ring block 6, and the interior of the stable ring block 6 is symmetrically provided with Moving block 25 and the 3rd spring 26, the upper surface of stable ring block 6 is symmetrically provided with connecting rod 7, and connecting rod 7 is in vertical state and can slide, and the top of connecting rod 7 is provided with limit half ring 8, and limit half ring 8 is snapped and connected with the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com