Wastewater treatment equipment for meat processing

A wastewater treatment and meat processing technology, which is applied in animal processing wastewater treatment, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc., can solve the problems of low practicability and poor mixing effect, and improve practicality High performance, convenient rotation, and improved stirring effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

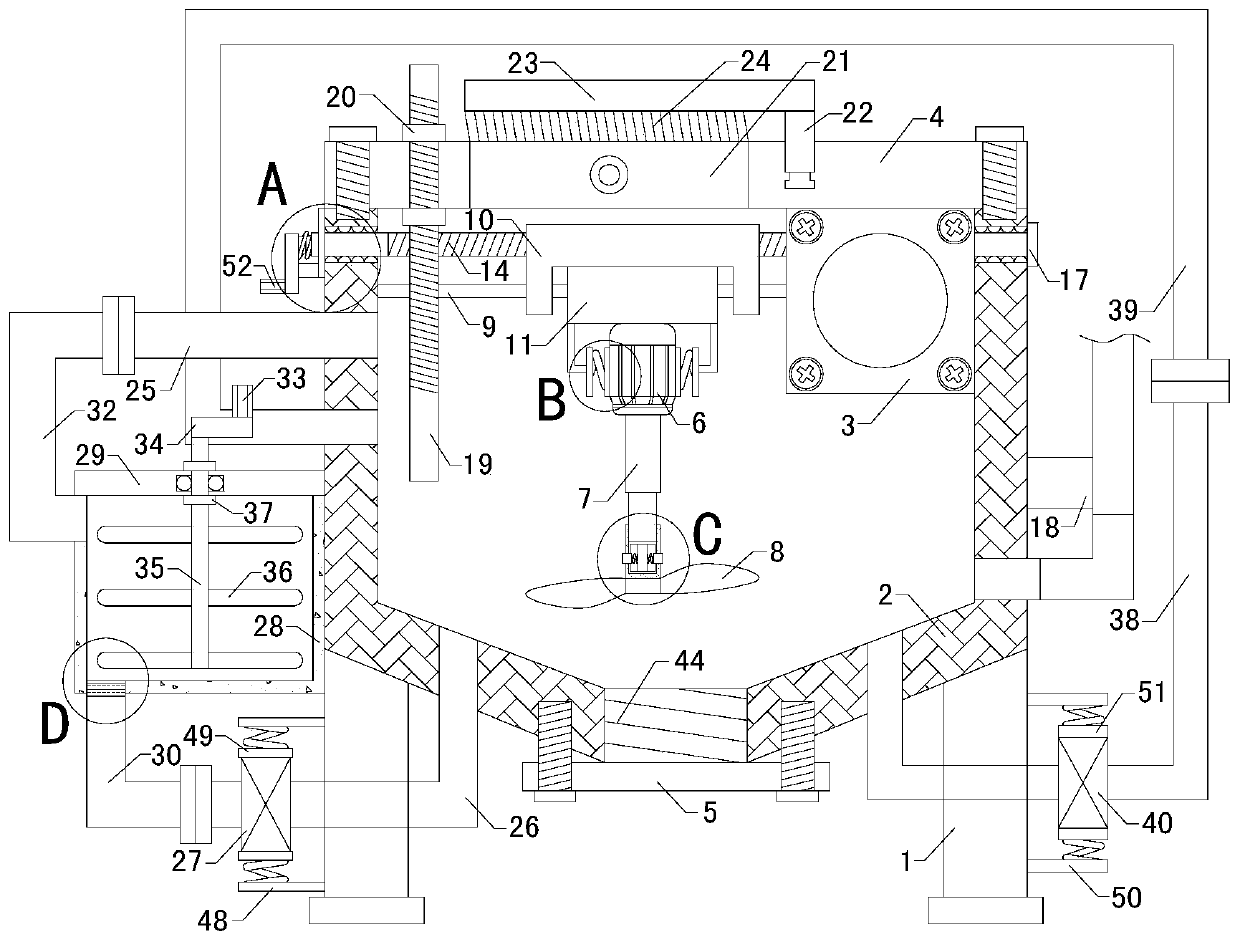

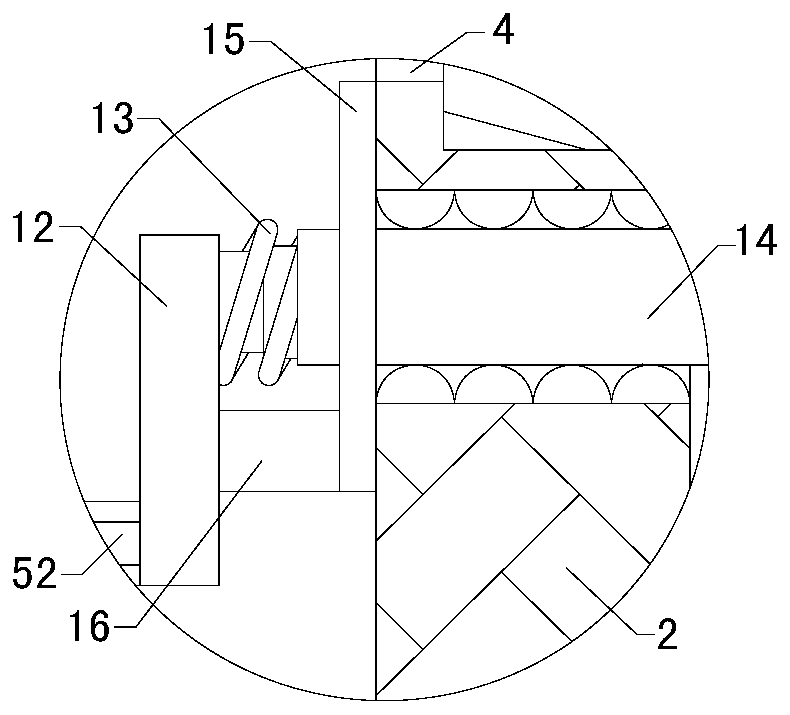

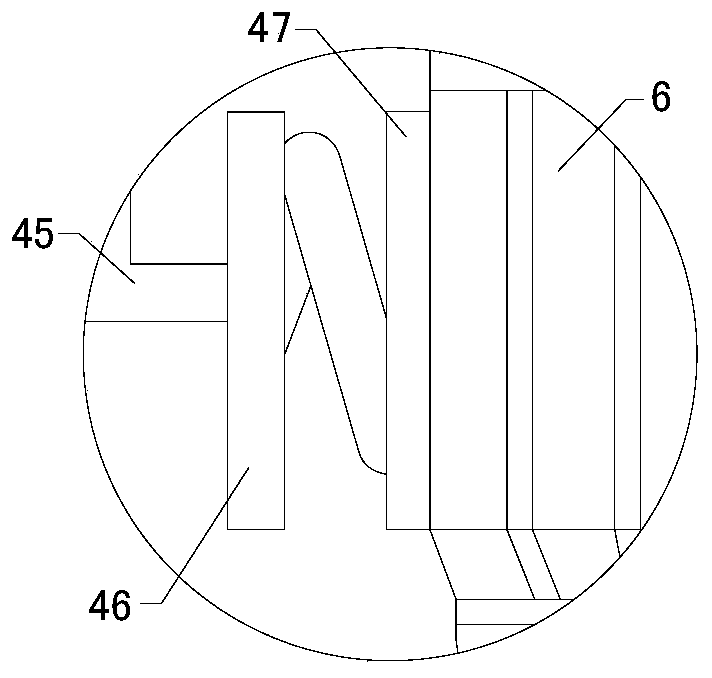

[0022] like Figure 1 to Figure 5As shown, a kind of meat processing wastewater treatment equipment of the present invention comprises two groups of side panels 1 and a working box 2, the tops of the two groups of side panels 1 are installed on the left and right sides of the bottom of the working box 2 respectively, and the working box 2 There is a working cavity inside, a maintenance port is connected to the top of the working box 2, and a maintenance cover 3 is screwed on the maintenance port, and a feeding port is connected to the top of the front side of the working box 2, and a screw is installed on the feeding port. Feeding cover 4, the bottom end of working box 2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com