Bearing processing pickling device

A technology of pickling device and bearing processing, applied in the field of bearing processing pickling device, can solve the problems of low efficiency of pickling process and no automatic feeding function, etc., and achieve the effect of speeding up pickling efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

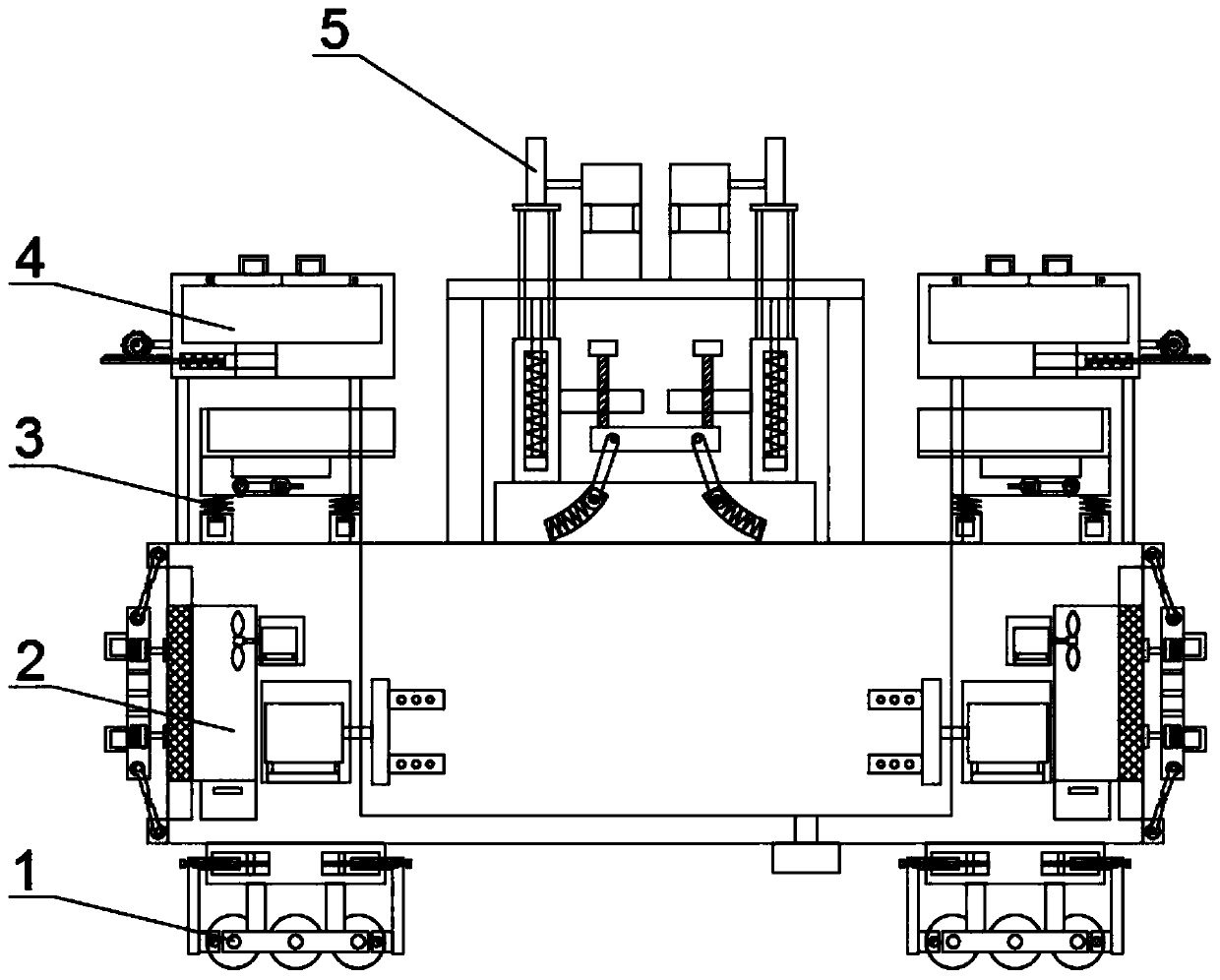

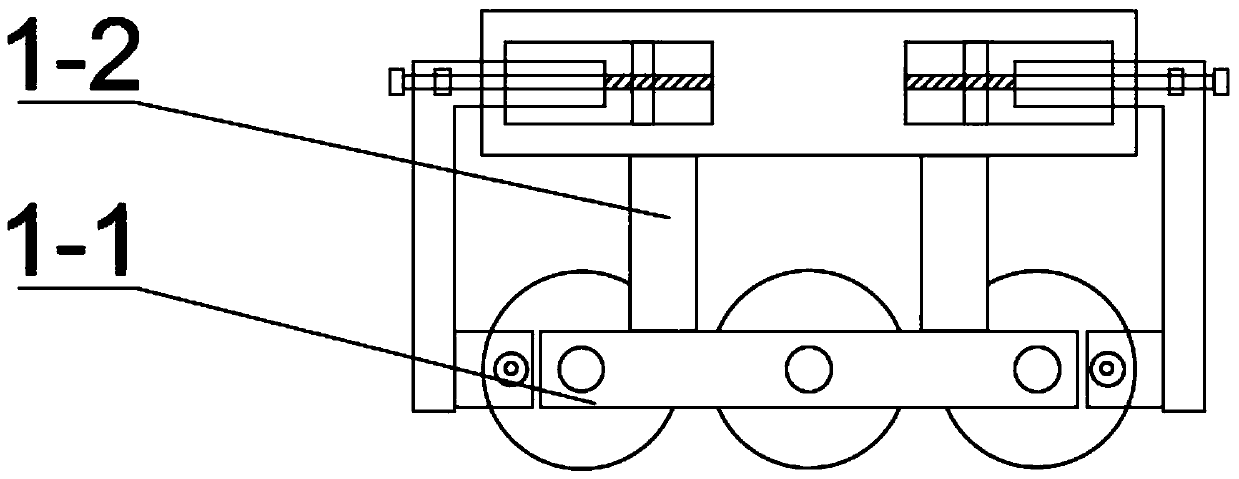

[0048] Combine below figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 , Figure 8 , Figure 9 , Figure 10 , Figure 11 , Figure 12 , Figure 13 , Figure 14 , Figure 15 , Figure 16 , Figure 17 , Figure 18 Describe this embodiment. The present invention relates to a pickling device, more specifically a pickling device for bearing processing, including a moving wheel mechanism 1, a body mechanism 2, a vibrating feeding mechanism 3, a bin mechanism 4, a clamping Mechanism 5, the device can be moved, the device can be parked, the device can remove dust, the device can clean the dust, the device can clamp the workpiece that needs to be pickled, the device can immerse the workpiece that needs to be pickled into the pickling chamber, and the device can speed up the pickling Efficiency, the device can automatically add compounding agent.

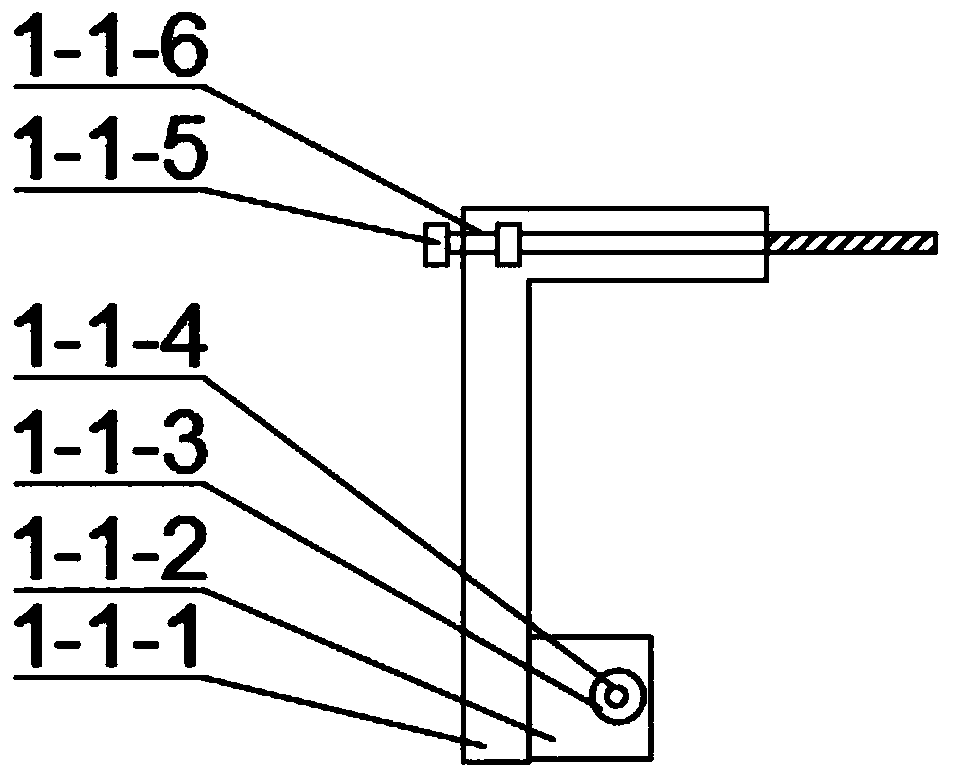

[0049] The mobile wheel mechanism 1 includes a parking mechanism 1-1 and a wheel mechanism 1-...

specific Embodiment approach 2

[0067] Combine below figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 , Figure 8 , Figure 9 , Figure 10 , Figure 11 , Figure 12 , Figure 13 , Figure 14 , Figure 15 , Figure 16 , Figure 17 , Figure 18 This embodiment will be described. This embodiment will further describe the first embodiment, and the number of the moving wheel mechanisms 1 described above is four.

specific Embodiment approach 3

[0068] Combine below figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 , Figure 8 , Figure 9 , Figure 10 , Figure 11 , Figure 12 , Figure 13 , Figure 14 , Figure 15 , Figure 16 , Figure 17 , Figure 18 This embodiment will be described. This embodiment will further describe the first embodiment. The material of the hammer head 2-1-3-8 is high manganese steel.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap