A kind of metal sample corrosion test device

A metal sample and corrosion test technology, applied in the direction of measuring devices, weather resistance/light resistance/corrosion resistance, instruments, etc., can solve the problems of high labor intensity, over-corrosion, low efficiency, etc., and achieve the effect of high work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

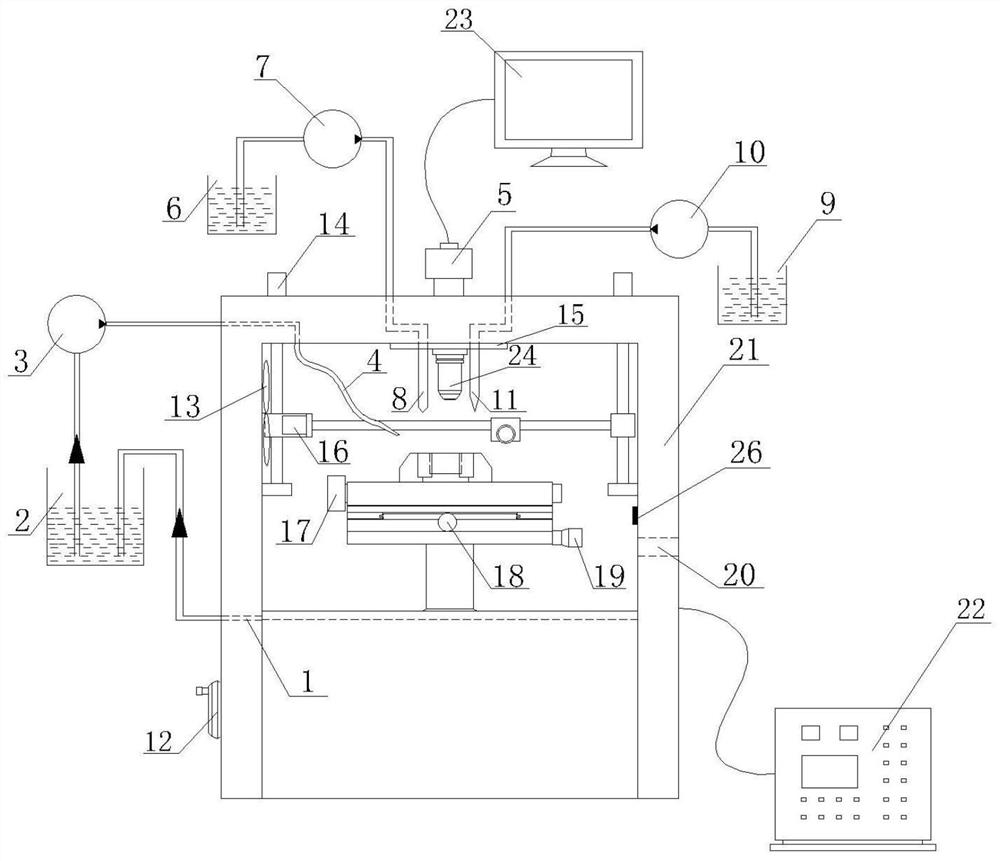

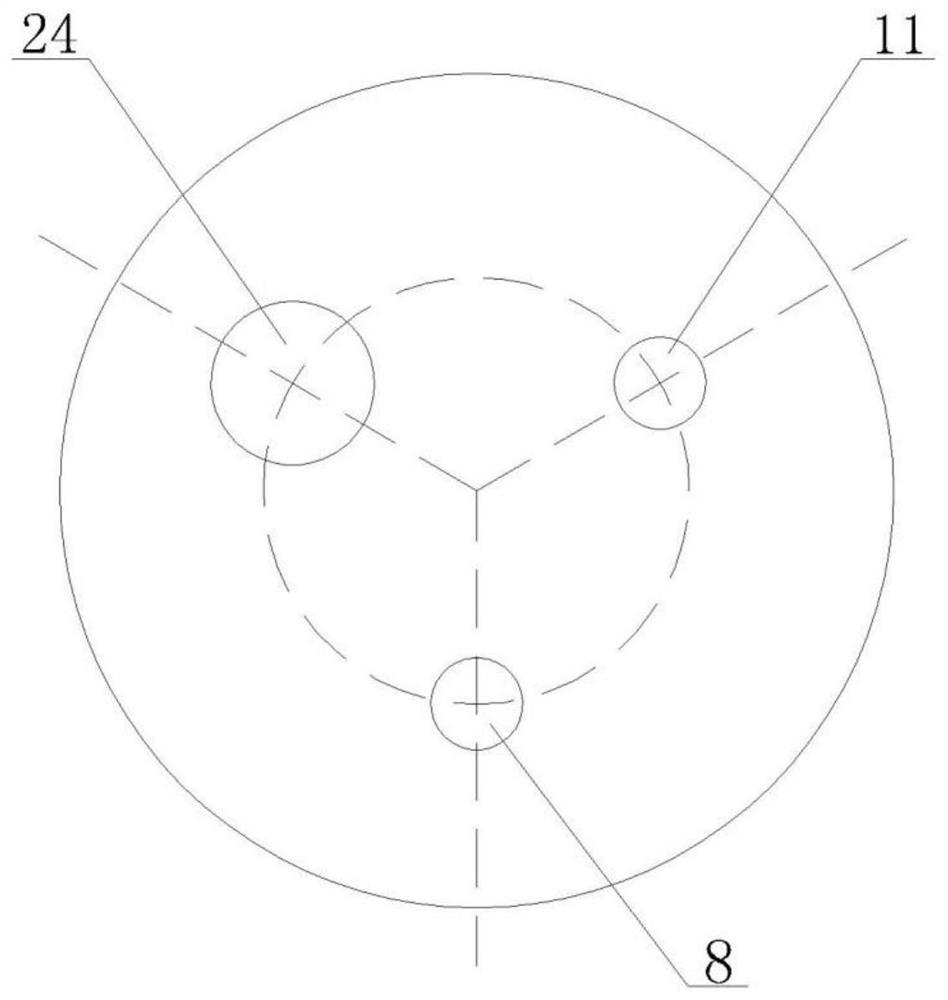

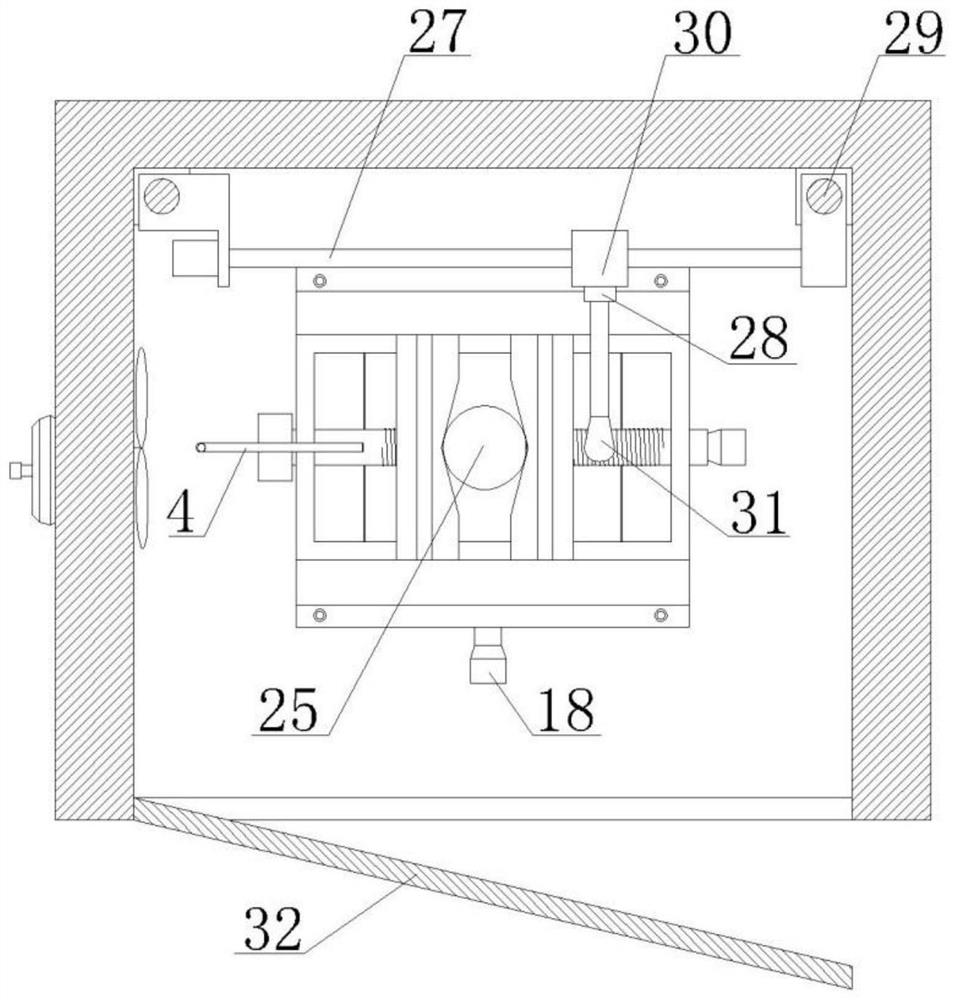

[0027] Combine below Figure 1-3 Describe this embodiment, a metal sample corrosion test device, including alcohol dropper 8, corrosion liquid dropper 11, Z-axis lifting knob 12, lifting motor 14, turntable 15, traverse motor 16, box body 21, objective lens 24. Traversing mechanism 27, rotating wiping motor 28, lifting mechanism 29, connection block 30 with pressure sensor inside, wiping rod 31 and stage, by rationally arranging the steering of turntable 15 and alcohol dropper 8, corrosion liquid dropper 11 and the arrangement of the objective lens 24 can realize functions such as corrosion, flushing, and observation; the present invention realizes functions such as flushing of the metal sample 25, reflux of the corrosion solution, recovery and recycling of the metal sample 25 by rationally setting the layout of the box body 21; the turntable 15 is provided with alcohol dropper 8, corrosion liquid dropper 11 and objective lens 24, and turntable 15 is rotatably connected on the...

specific Embodiment approach 2

[0029] Combine below Figure 1-3 This embodiment will be described. This embodiment will further describe the first embodiment. The alcohol dropper 8, the corrosive liquid dropper 11 and the objective lens 24 are arranged on the turntable 15 in a circular shape with the rotation axis of the turntable 15 as the center line. The distance from the object lens 24 to the centerline of rotation of the rotating disk 15 is equal to the distance from the alcohol dropper 8 to the centerline of rotation of the rotating disk 15, and the distance from the object lens 24 to the centerline of rotation of the rotating disk 15 is equal to the center of rotation of the corrosion dropper 11 to the rotating disk 15 line distance; when the turntable 15 rotates around its own axis, the turntable 15 can only rotate in the path of corrosion dropper 11→alcohol dropper 8→objective lens 24 and objective lens 24→alcohol dropper 8→corrosion dropper 11 , cannot be turned over.

specific Embodiment approach 3

[0031] Combine below Figure 1-3 Describe this embodiment mode, this embodiment mode will further explain Embodiment 2, the metal sample corrosion test device also includes a flushing water backflow hole 1, a water tank 2, a first peristaltic pump 3 and a universal water nozzle 4, and the flushing water backflow The hole 1 is set at the bottom of the tank main body 21, the first peristaltic pump 3 and the water tank 2 are connected through a tube, the first peristaltic pump 3 and the universal water nozzle 4 are connected through a tube, and the universal water nozzle 4 is set in the tank main body 21 , the flushing water return hole 1 is connected to the water tank 2 through a pipe; the electric control box 22 is electrically connected to the first peristaltic pump 3, and the electric control box 22 can realize the metal sample 25 by controlling the start of the first peristaltic pump 3 For flushing, the flushing water flows back to the water tank 2 through the flushing water r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com