Explosion-proof junction box

An explosion-proof junction box and junction box technology, applied in the direction of the casing/cover/support, electrical components, electromechanical devices, etc., can solve the problems of junction box space and safety discount, safety performance cannot be guaranteed, and non-compliance with explosion-proof regulations. , to achieve the effect of reasonable electrical clearance and creepage distance, compact structure and spacious interior space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The invention will be further described below in conjunction with specific drawings.

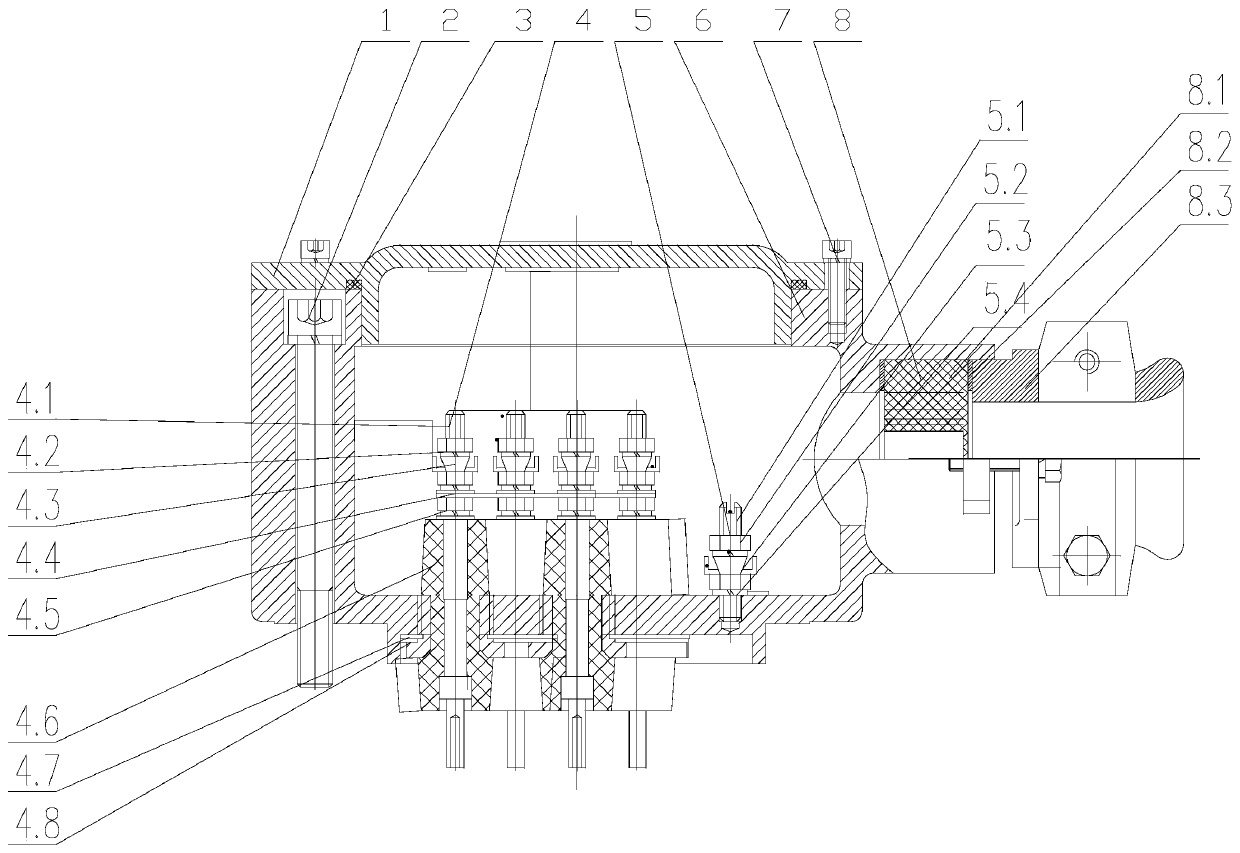

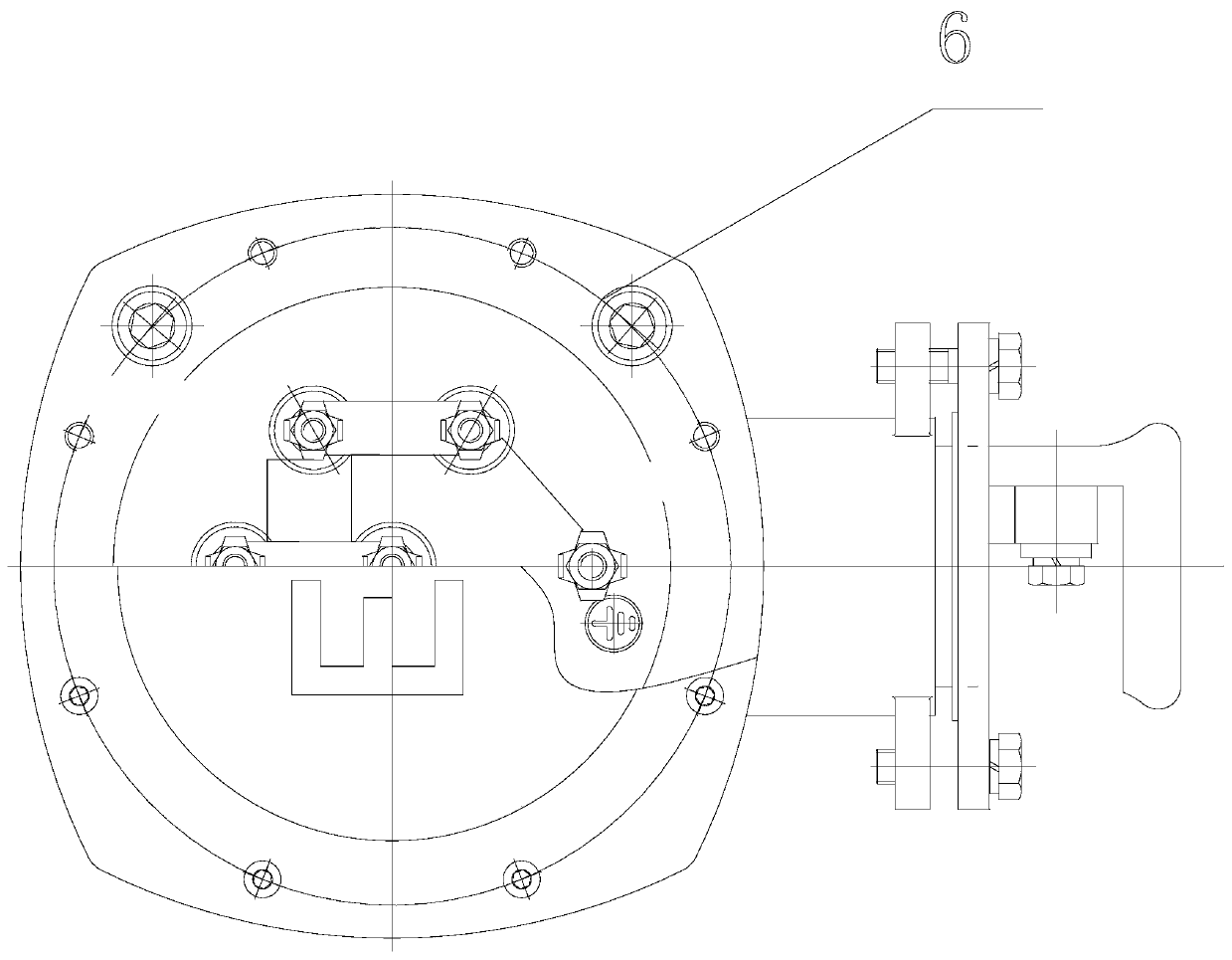

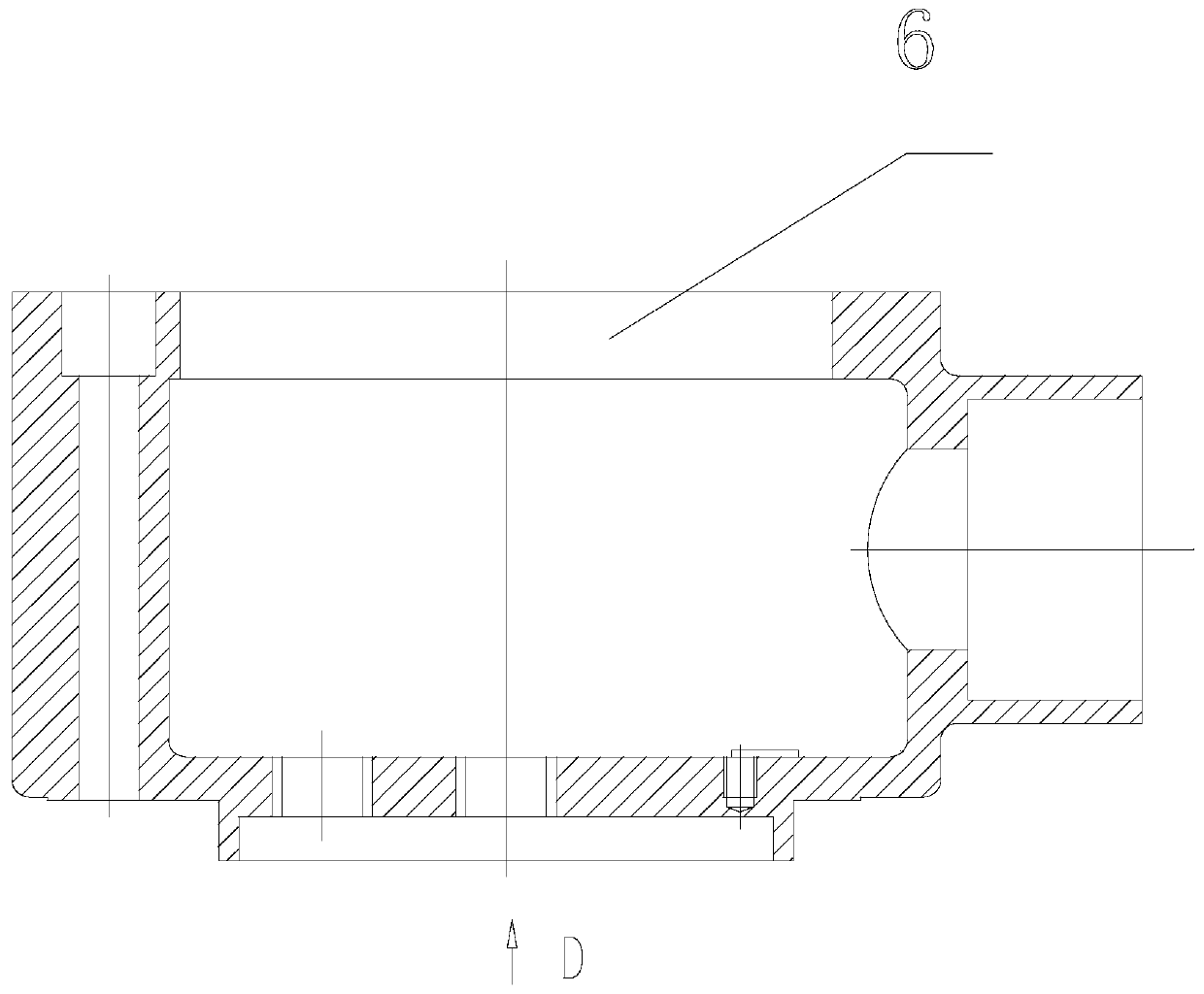

[0024] Such as Figure 1-Figure 6 As shown: the explosion-proof junction box includes a junction box cover 1, a connection terminal 4, a grounding terminal 5, a junction box seat 6 and an outlet part 8, the side wall of the junction box seat 6 is provided with at least one outlet part 8, and the connection terminal 4 and the grounding terminal 5 are installed on the bottom of the junction box seat 6, and the junction box cover 1 and the junction box seat 6 are fastened by the second fastening bolt 7. It is characterized in that: the box body of the junction box seat 6 is composed of four eccentric arc 6.1, the cover body of the junction box cover 1 is composed of four eccentric arcs 1.1, the four eccentric arcs 6.1 of the box seat are matched with the four eccentric arcs 1.1 of the box cover, so The dimensions R1 of the four eccentric arcs of the box seat and the four eccentric arcs ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com