Waste tire recycling detecting repairing device facilitating retreading

A technology for waste tires and blocking devices is applied in the field of waste tire recycling detection and repair devices, which can solve the problems of difficult sorting, danger, laborious manual maintenance, etc., and achieve the effects of simple and convenient sorting and handling, ensuring conveying stability, and ensuring driving stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

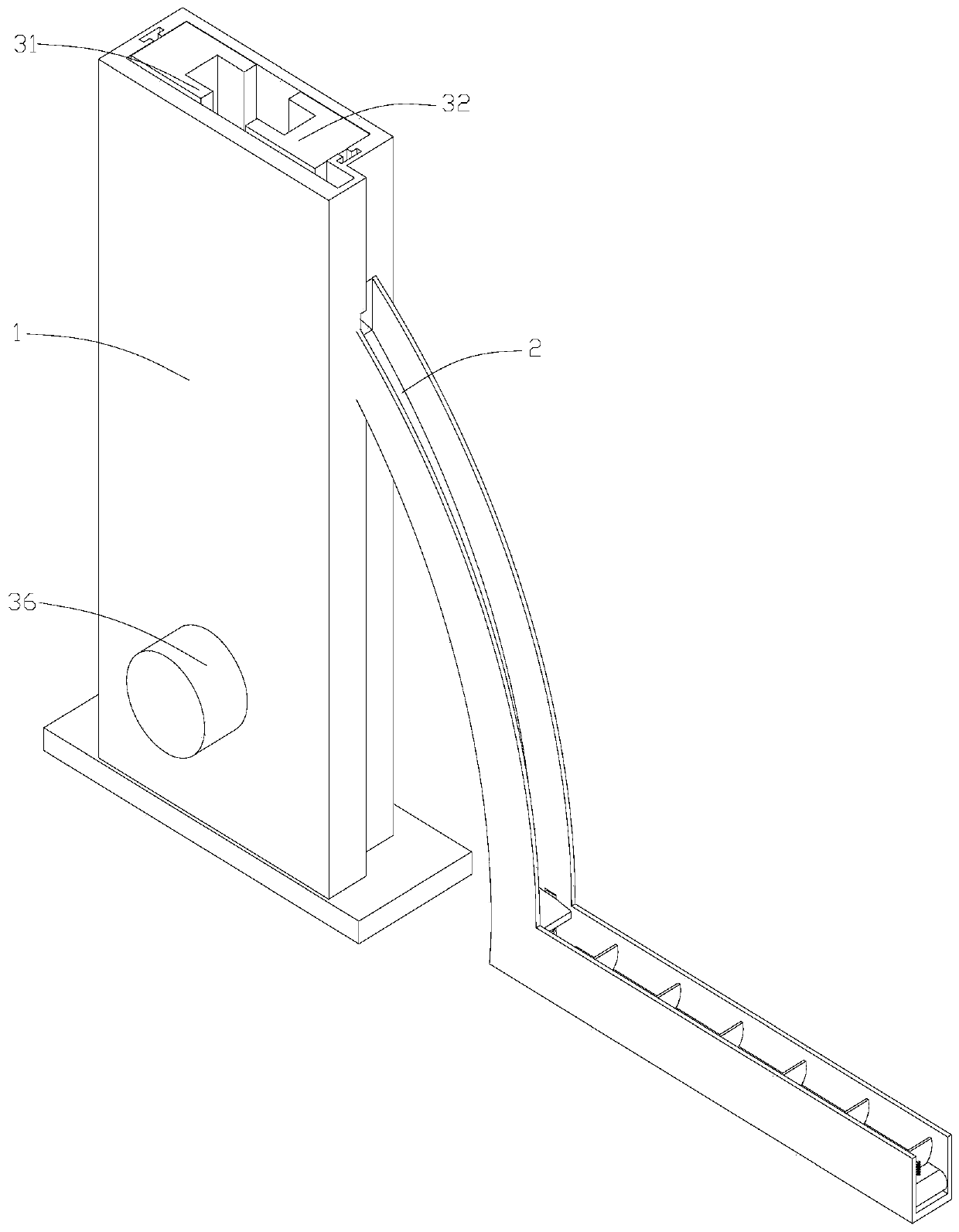

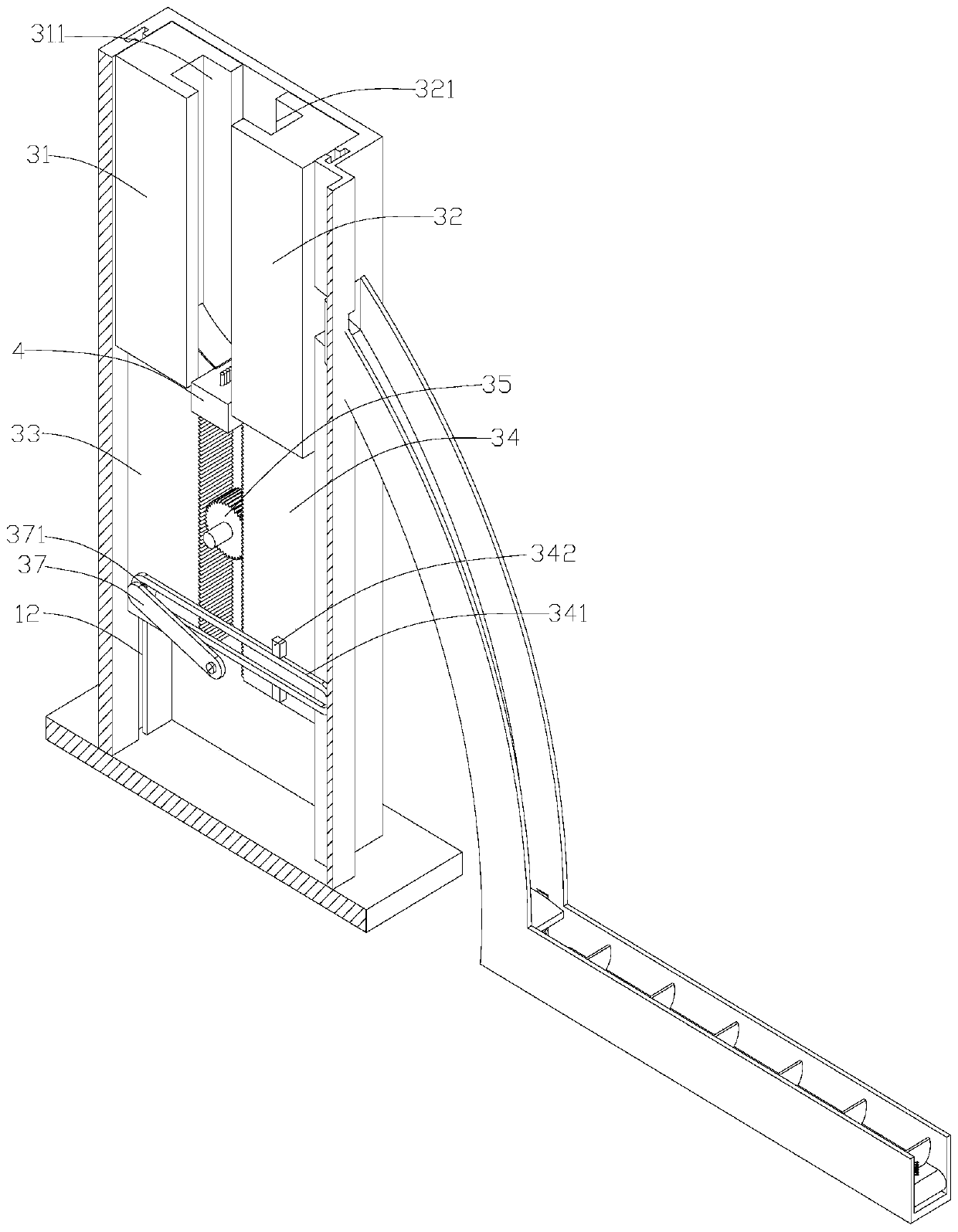

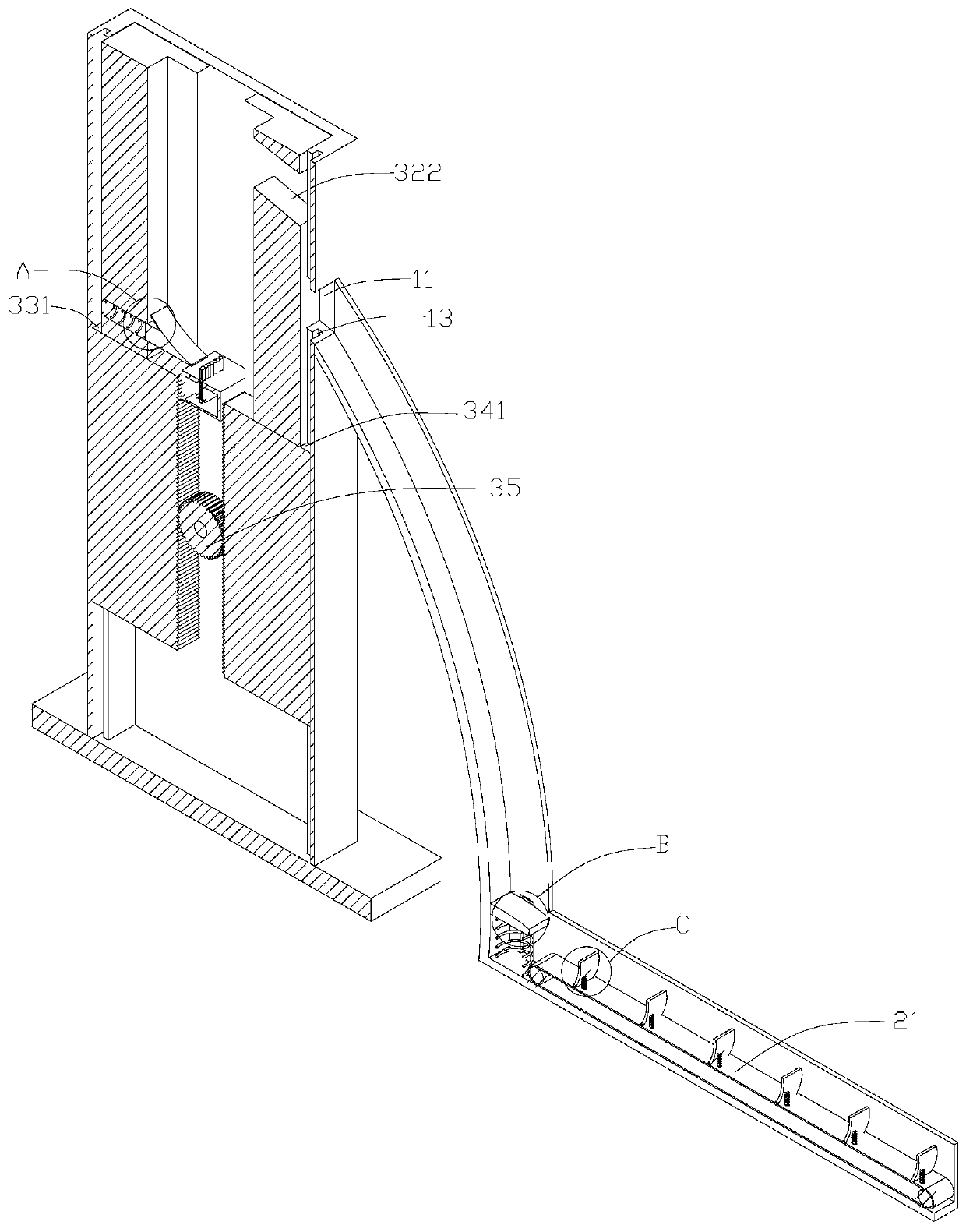

[0026] Such as Figure 1-11 As shown, a waste tire recovery, detection and repair device that is convenient for retreading includes a fixed housing 1 and a feeding channel 2 for transporting the waste tires after the detection and filling. The fixed housing 1 is provided with a control The first control block 31 and the second control block 32 that the waste tire after grinding rotates, the first drive block 33 and the second drive block 34 that are used to drive the first control block 31 and the second control block 32 and are used for The tire repairing device for detecting and filling the polished waste tires, through the setting of the above structure, the ground waste tires can be clamped by the first control block and the second control block, so as to avoid the separation of the waste tires and ensure that the waste tires are The stability of the tire repair, and the setting of the first driving block and the second driving block, so that the waste tire can realize the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com