Feeding device

A feeding device and feeding technology, which is applied in packaging and other directions, can solve the problems of affecting packaging, low labor efficiency, and large gap in the size of open plugs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

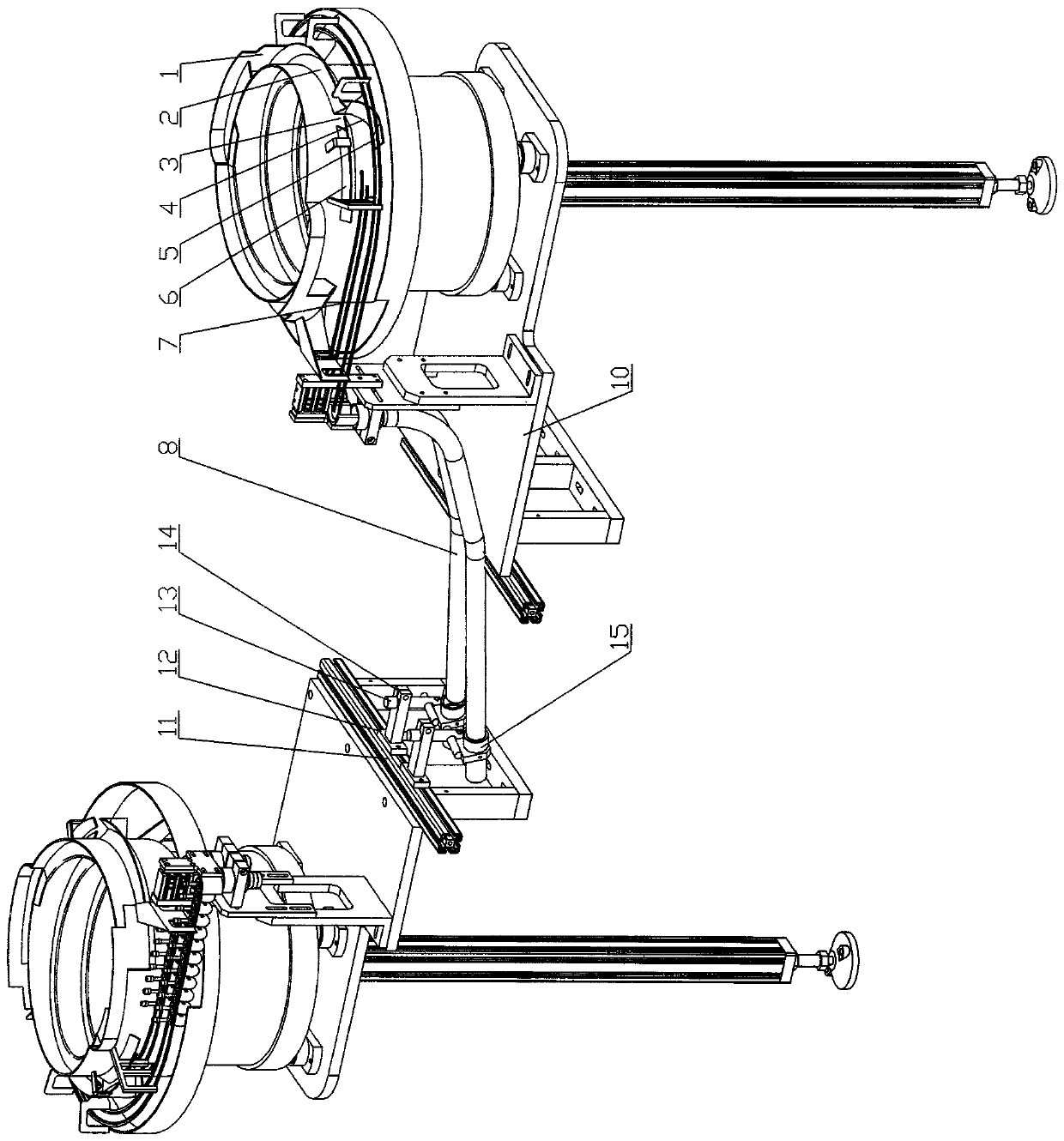

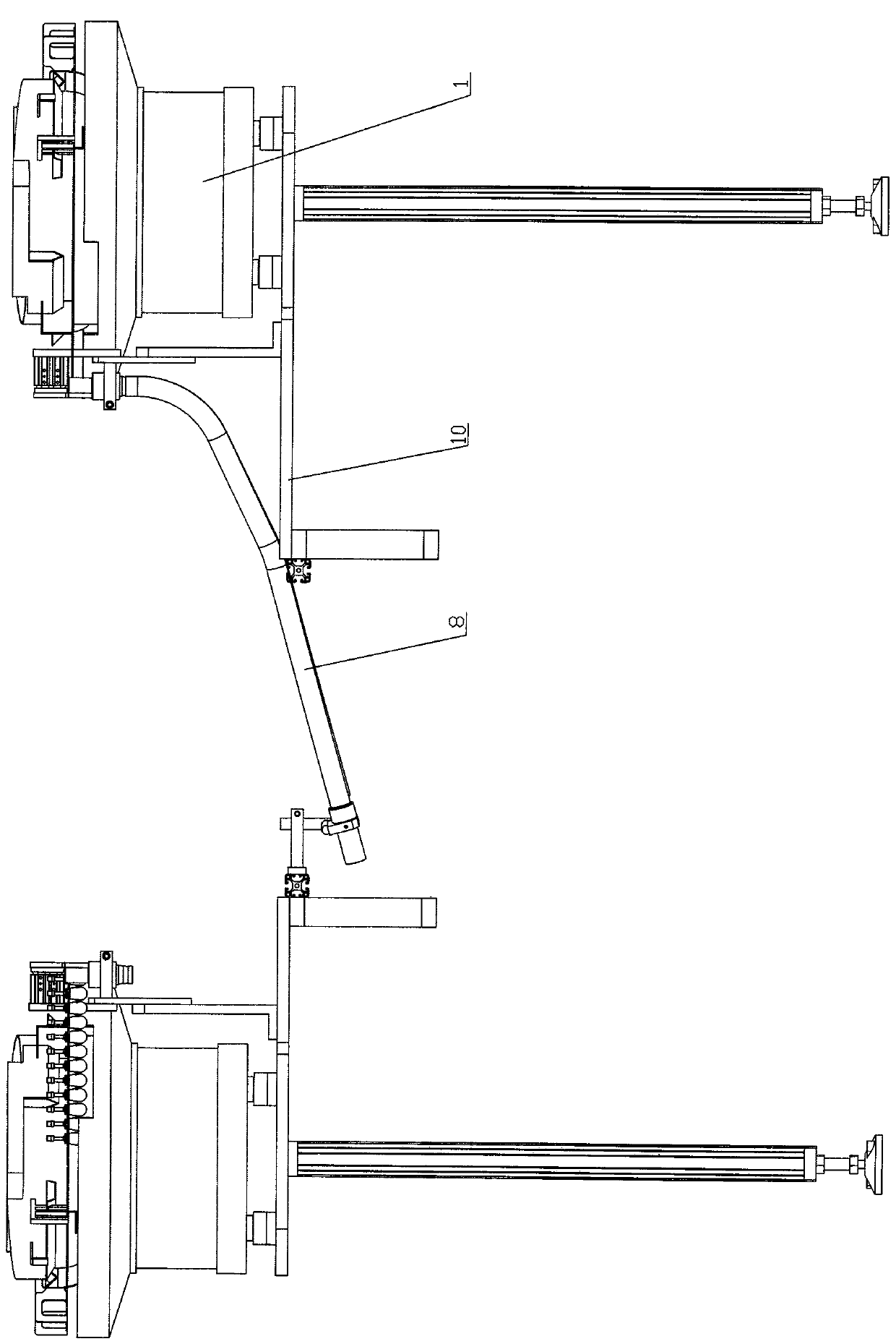

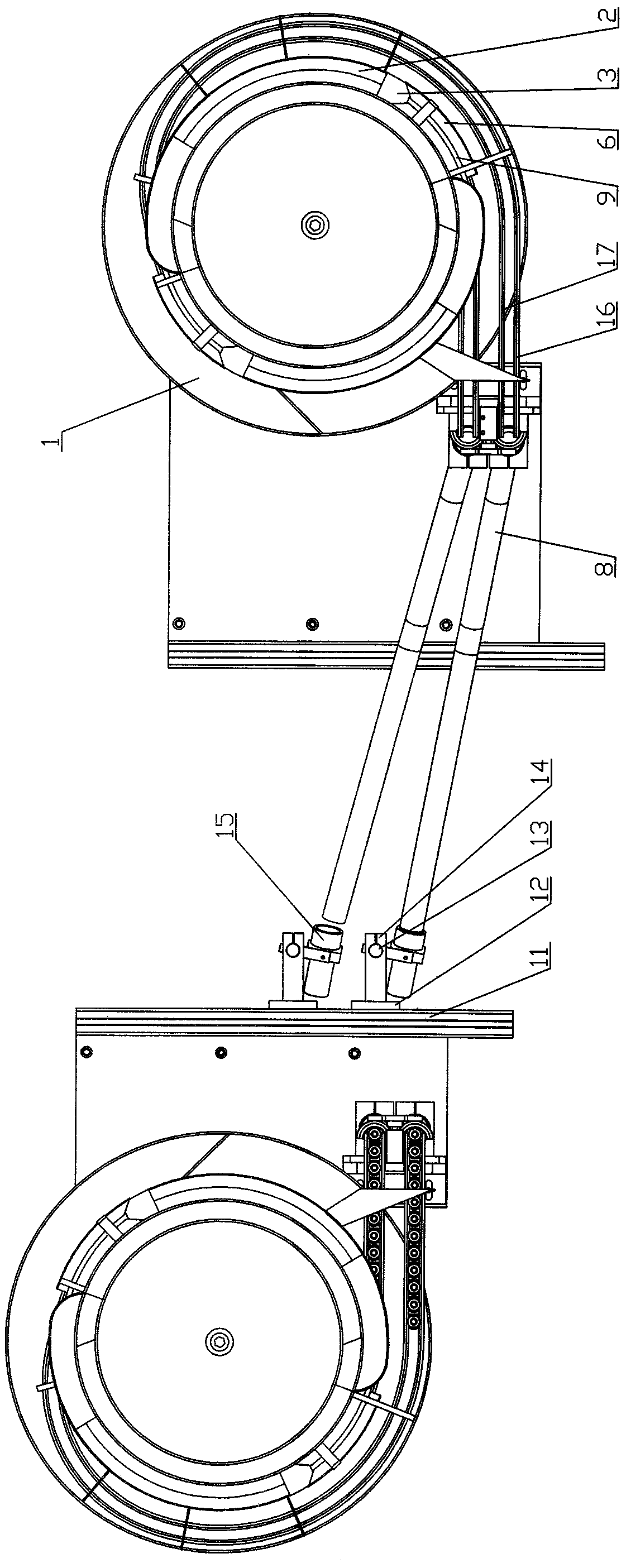

[0019] The following describes the relevant details and working principles of the embodiments and embodiments of the present invention in conjunction with the accompanying drawings. This kind of feeding device includes a frame 10 and a vibrating plate. The vibrating plate 1 includes a feeding track 2 and a U-turn component. The U-turn component includes a baffle 6, a feeding rail 7 and a guide plate 4, and the baffle is connected to There is a blanking space 3 between the feed rails, the guide plate 4 is arc-shaped, and the upper end of the guide plate is connected with the discharge end of the feed rail 2. The guide plate and the feed rail can be in a connection relationship. There is no need to connect between them. After the material comes out of the feeding track 2, the bottom of the material gradually moves down along the guide plate 4; the feeding guide 7 is arranged under the baffle 6, and the feeding guide 7 and the concave of the material The groove part 23 matches; se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com