Cassette clamping mechanism

A technology of splint and clamping arm, which is applied in the design of semiconductor manufacturing field, can solve the problems of inability to effectively identify the position and height of the crystal boat, cannot be clamped, and damage the crystal boat, etc., and achieve the limit automatic alarm function and safe shutdown. Effective and precise gripping effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

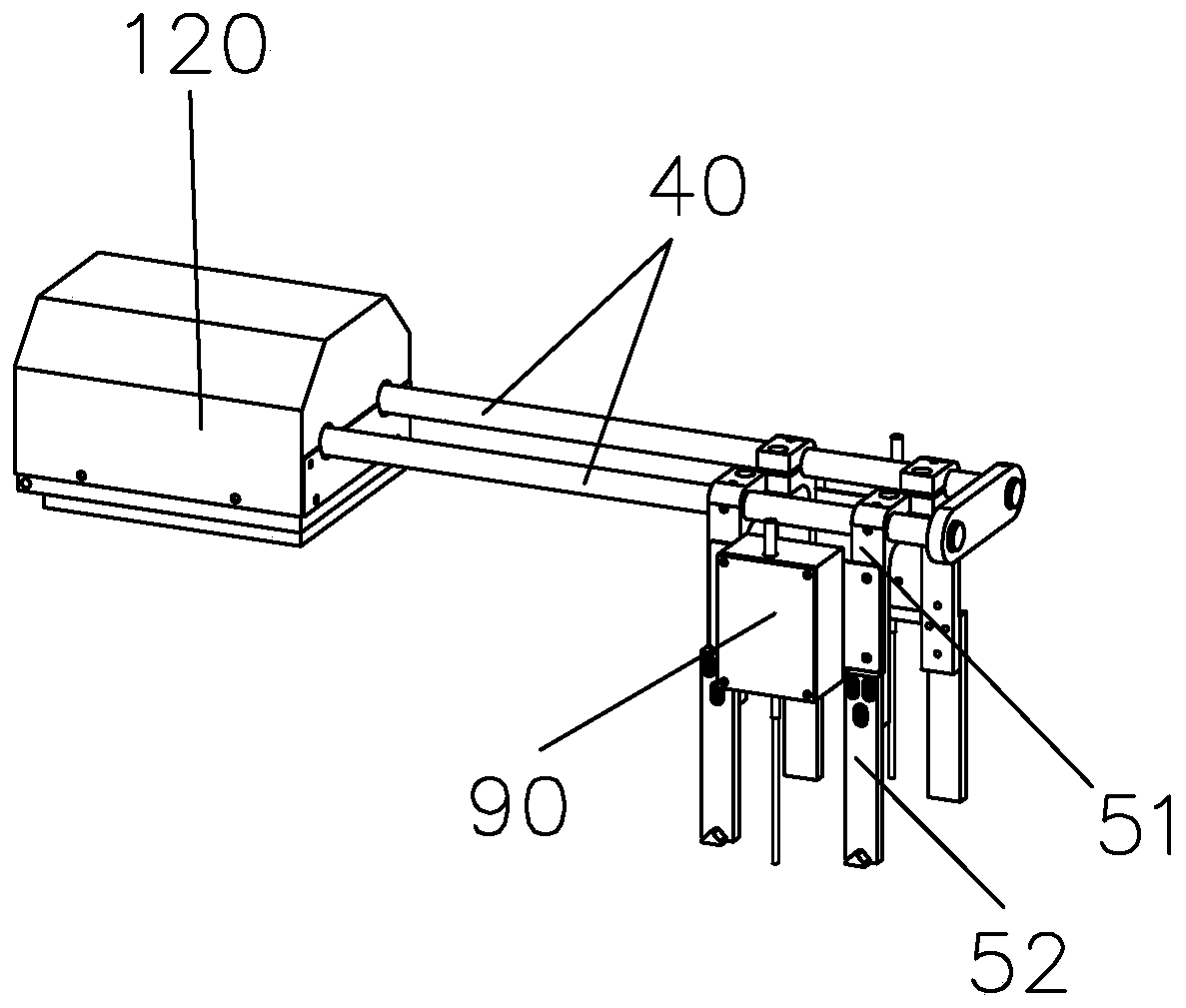

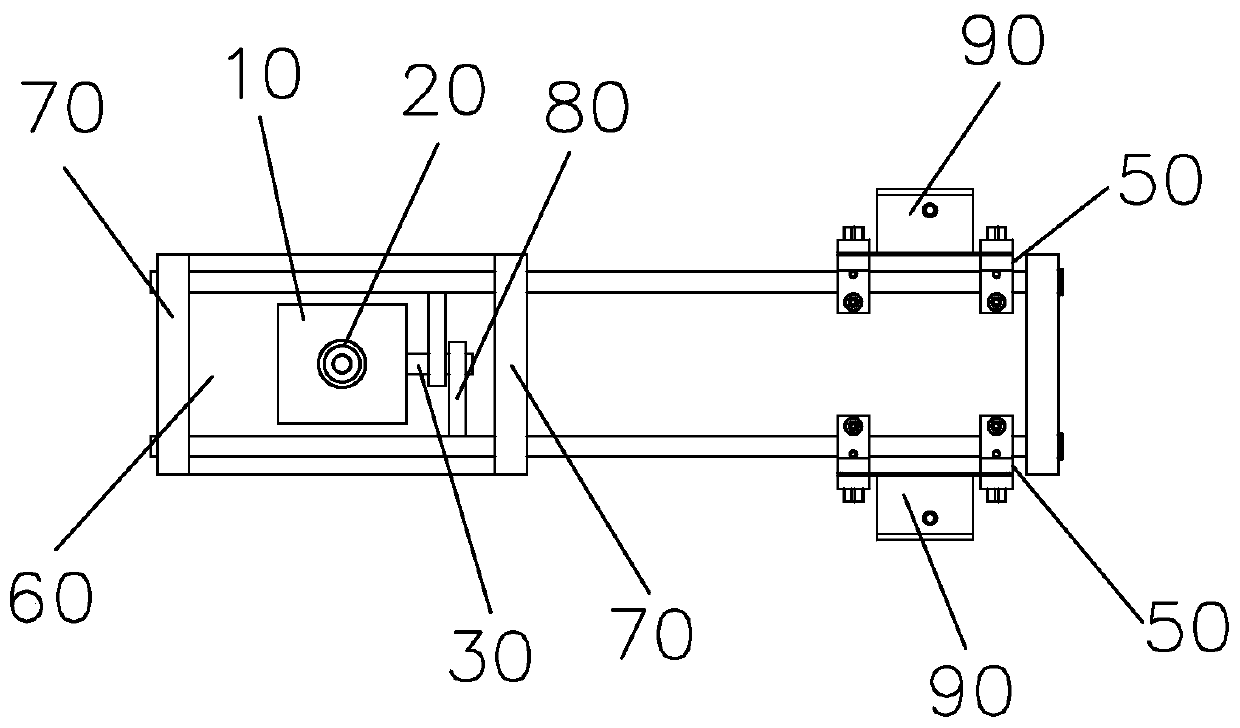

[0024] figure 1 and 2 The wafer clamping mechanism shown includes a screw stepping motor 10, a bushing 20, a connecting shaft 30, two shafts 40 and a pair of clamping arms 50, and the screw stepping motor 10 is fixed on a bottom plate 60 , two parallel bearing seats 70 are arranged on the bottom plate 60 . The shaft sleeve 20 is installed on the screw shaft of the screw stepping motor 10, the connecting shaft 30 is perpendicular to the screw shaft, and the shaft sleeve 20 lifts together with the connecting shaft 30 when lifting along the screw shaft; the two shaft rods 40 and the The connecting shaft 30 is parallel and arranged on both sides of the connecting shaft 30 respectively, and the shaft rod 40 is inserted into the bearing hole of the bearing seat 70, and one end of the shaft rod 40 is provided with a connecting plate 80 which is movably sleeved on the connecting shaft 30, and a pair of clips The holding arms 50 are respectively fixed on the other ends of the two sha...

Embodiment 2

[0029] This embodiment is based on Embodiment 1.

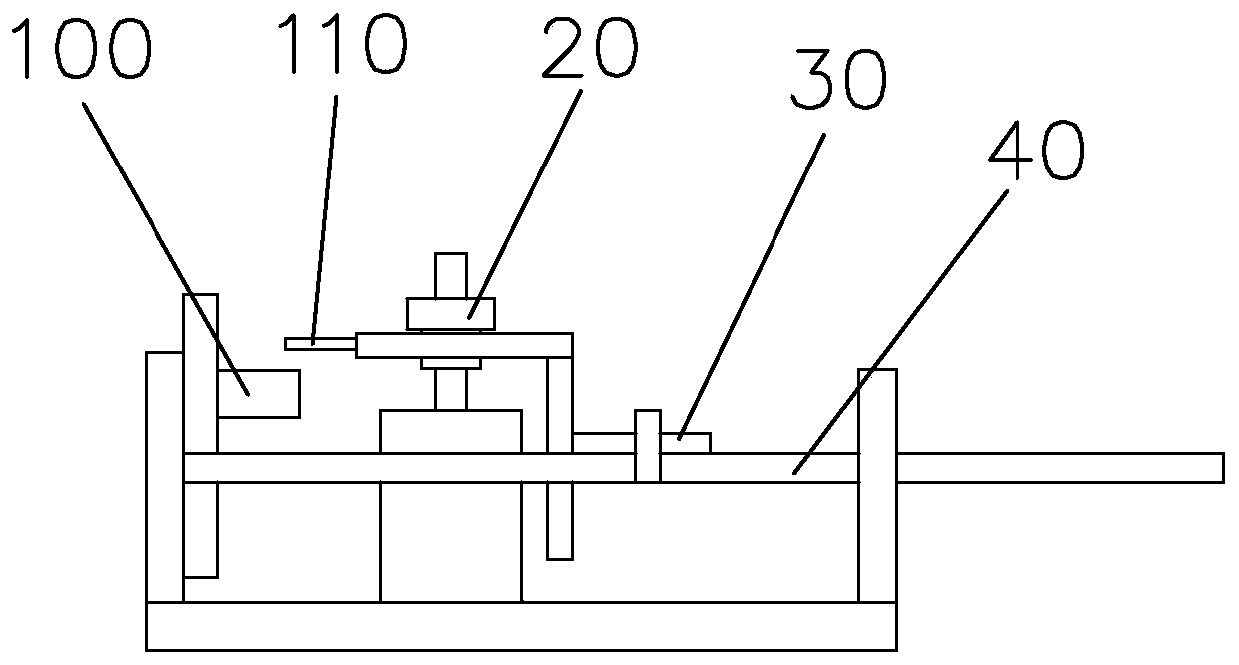

[0030] A photoelectric switch 100 is arranged on the side of the screw stepping motor 10 , and a positioning block 110 used in conjunction with the photoelectric switch 100 is arranged on the bushing 20 . The screw stepping motor 10 reads the positioning pulse in the PLC, and cooperates with the photoelectric switch 100 to effectively and accurately grip the wafer boat and basket, and realize the limit automatic alarm function and safe shutdown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com