A kind of phosphorus nitrogen zinc two-dimensional supramolecular coated molybdenum disulfide hybrid flame retardant and its application

A molybdenum disulfide and supramolecular technology is applied to the chemical characteristics of fibers, the manufacture of fire-resistant and flame-retardant filaments, and the production of single-component synthetic polymer rayon. It can solve the problems of large addition amount and low flame-retardant efficiency, and achieve reduction The effect of adding amount, improving flame retardant efficiency and good application prospect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Preparation of flame retardant: Dissolve 0.5g of melamine and 0.1g of zinc acetate in 200mL of deionized water, then add 0.1g of molybdenum disulfide nanosheets to the solution and ultrasonically disperse for 2 hours. Add 0.5g phytic acid and stir at 30°C for 4h. Finally, after centrifugal cleaning with deionized water and vacuum drying at 60° C., a phosphorus-nitrogen-zinc two-dimensional supramolecular-coated molybdenum disulfide hybrid material is obtained.

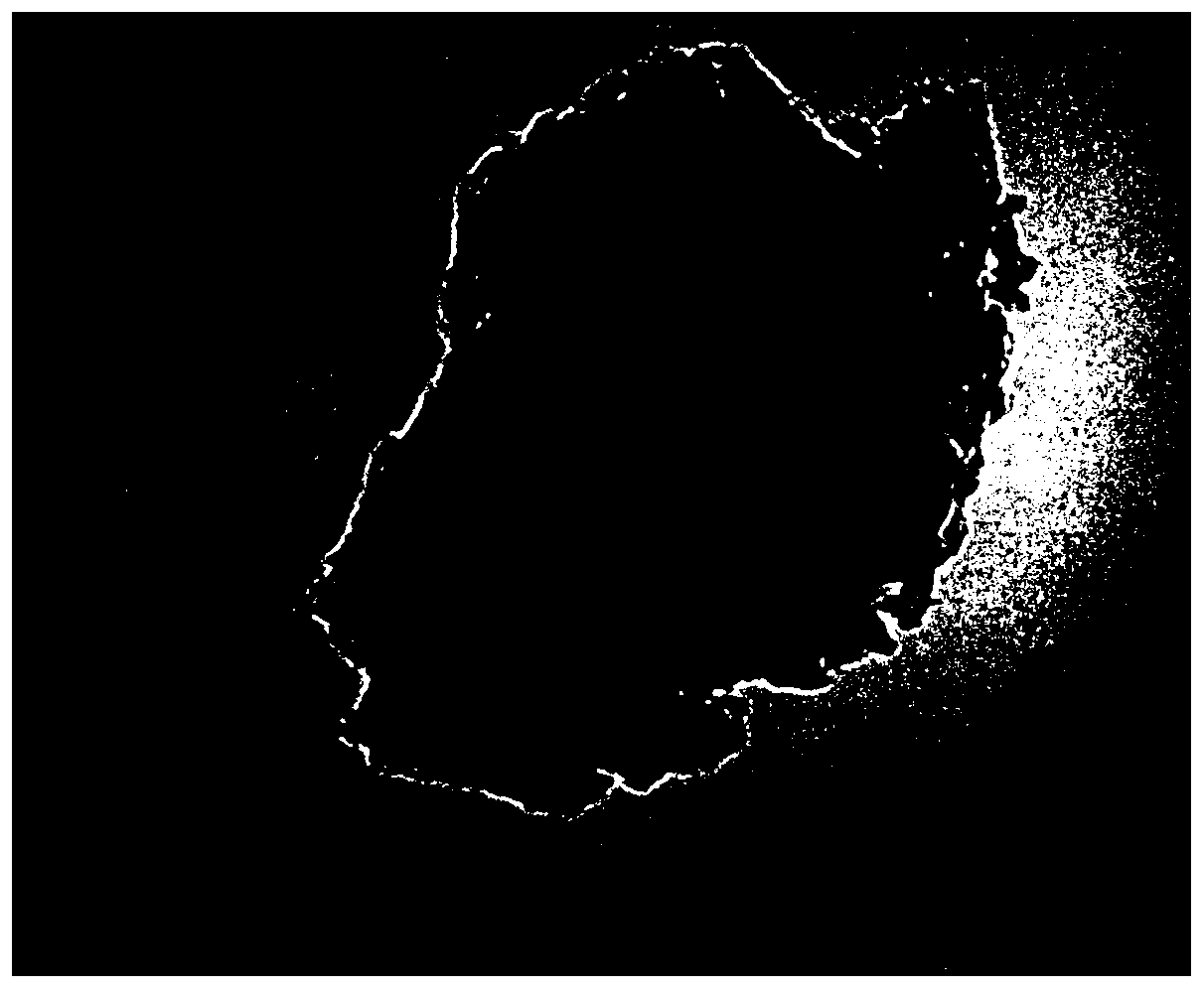

[0028] After SEM and TEM tests, respectively, as figure 1 and 2 As shown, the surface of the obtained hybrid material is rough, and there are massive loads on the surface of the molybdenum disulfide nanosheets, showing an obvious sandwich structure, and the surface sheet-like two-dimensional supramolecules are successfully coated with the molybdenum disulfide nanosheets.

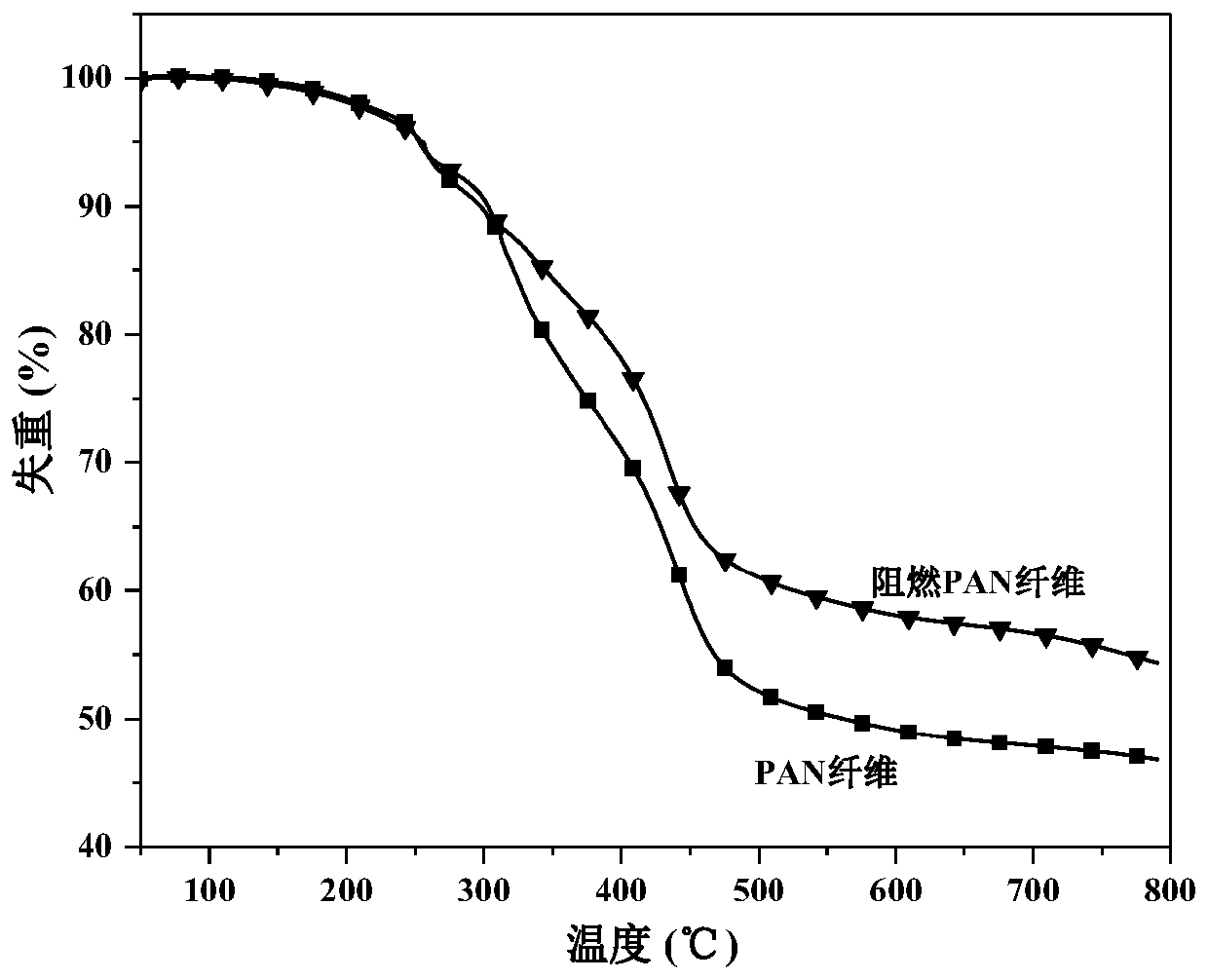

[0029] Preparation of flame retardant polyacrylonitrile fiber: Weigh 0.06g of phosphorus nitrogen zinc two-dimensional supramolecular coate...

Embodiment 2

[0032] Preparation of flame retardant: Dissolve 0.8g of melamine and 0.15g of zinc acetate in 200mL of deionized water, then add 0.2g of molybdenum disulfide nanosheets to the solution and ultrasonically disperse for 2 hours. Add 1g of phytic acid and stir at 30°C for 4h. Finally, after centrifugal cleaning with deionized water and vacuum drying at 60° C., a phosphorus-nitrogen-zinc two-dimensional supramolecular-coated molybdenum disulfide hybrid material is obtained.

[0033] Preparation of flame-retardant polyacrylonitrile fibers: Referring to Example 1, flame-retardant polyacrylonitrile fibers were prepared. The specific performance parameters are shown in Table 1.

Embodiment 3

[0035] Preparation of flame retardant: Dissolve 0.5g of melamine and 0.1g of zinc acetate in 200mL of deionized water, then add 0.1g of molybdenum disulfide nanosheets to the solution and ultrasonically disperse for 2 hours. Add 0.5g phytic acid and stir at 60°C for 4h. Finally, after centrifugal cleaning with deionized water and vacuum drying at 60° C., a phosphorus-nitrogen-zinc two-dimensional supramolecular-coated molybdenum disulfide hybrid material is obtained.

[0036] Preparation of flame-retardant polyacrylonitrile fibers: Referring to Example 1, flame-retardant polyacrylonitrile fibers were prepared. The specific performance parameters are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| limiting oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com