Installation method of steel cofferdam for reinforcing bridge underwater structure

An underwater structure and installation method technology, which is applied to bridges, bridge maintenance, bridge reinforcement, etc., can solve the problems of difficult operation of bridge piers, many guide frame components, and discounted construction efficiency, so as to achieve fast and convenient construction, strengthen structural stability, Quick and easy installation and removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

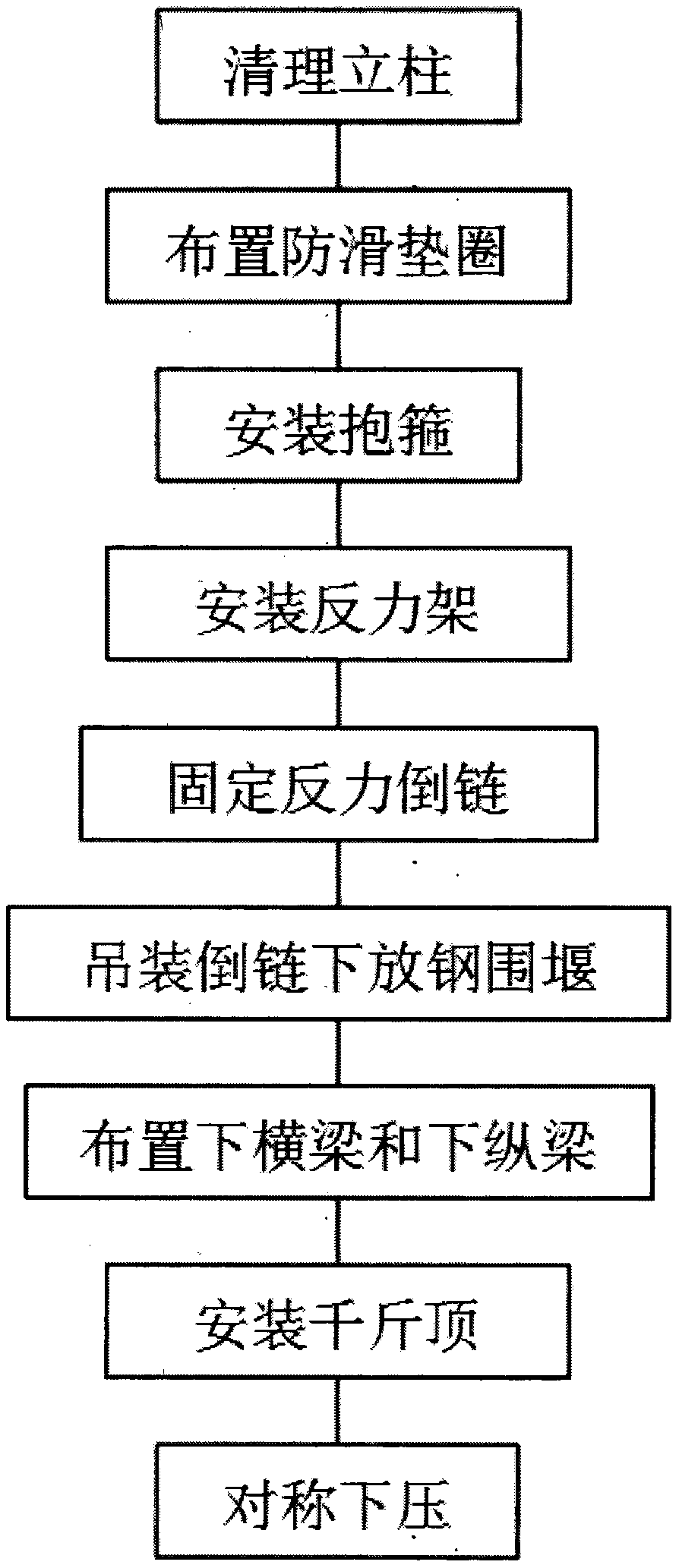

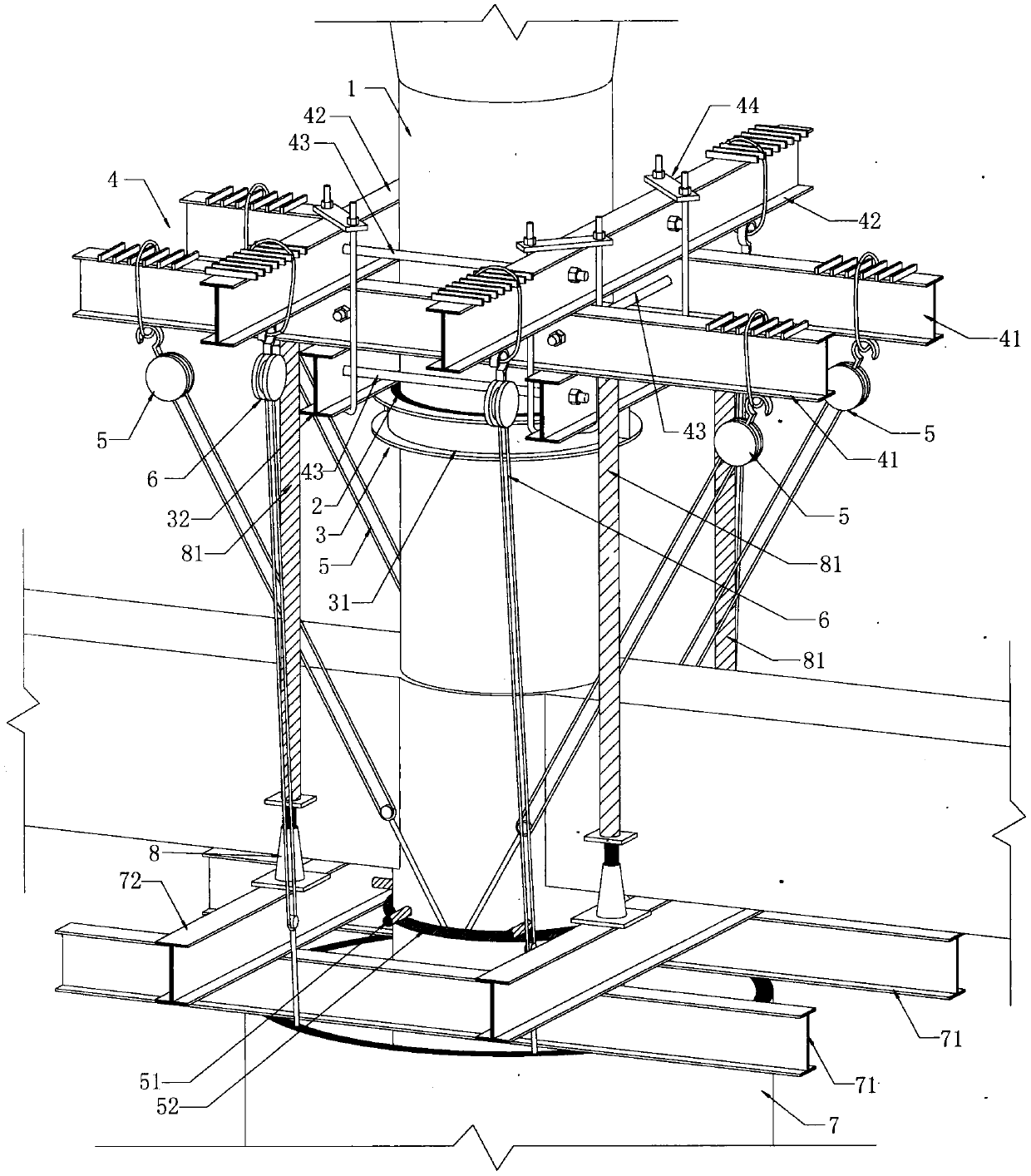

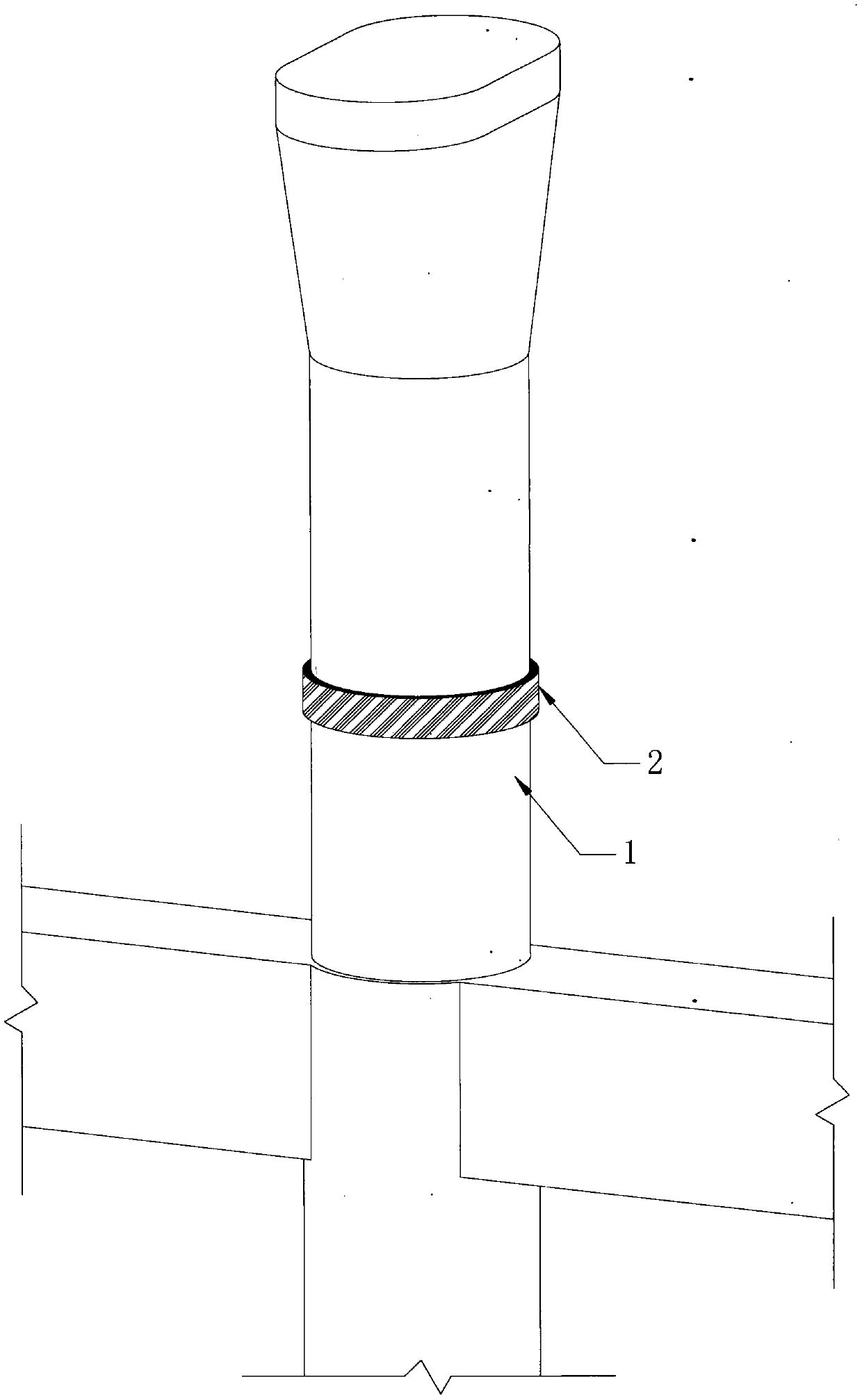

[0038] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation manners of the present invention will now be described with reference to the accompanying drawings. The invention provides a steel cofferdam installation method for strengthening the underwater structure of bridges, which is characterized in that by cleaning the column 1, arranging the anti-slip gasket 2, installing the hoop 3, assembling the reaction force frame 4, fixing the reaction force back chain 5, and lowering the steel Cofferdam 7, arrange beams and longitudinal beams, install jacks 8, press down symmetrically, and complete the quick press down installation of steel cofferdam 7 for strengthening the underwater structure of the bridge, hoop 3 and reaction frame 4 are assembled into a whole through buckle 44, The reaction force inverted chain 5 is connected with the column 1 to form an inverted triangle reaction force syste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com