Portable bridge crack width measuring instrument

A crack width, portable technology, applied in the direction of mechanical gap measurement, etc., can solve the problems of poor accuracy, large limitations, high degree of personal subjectivity, etc., and achieve the effect of facilitating popularization and application, ensuring accuracy, and being easy to carry

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

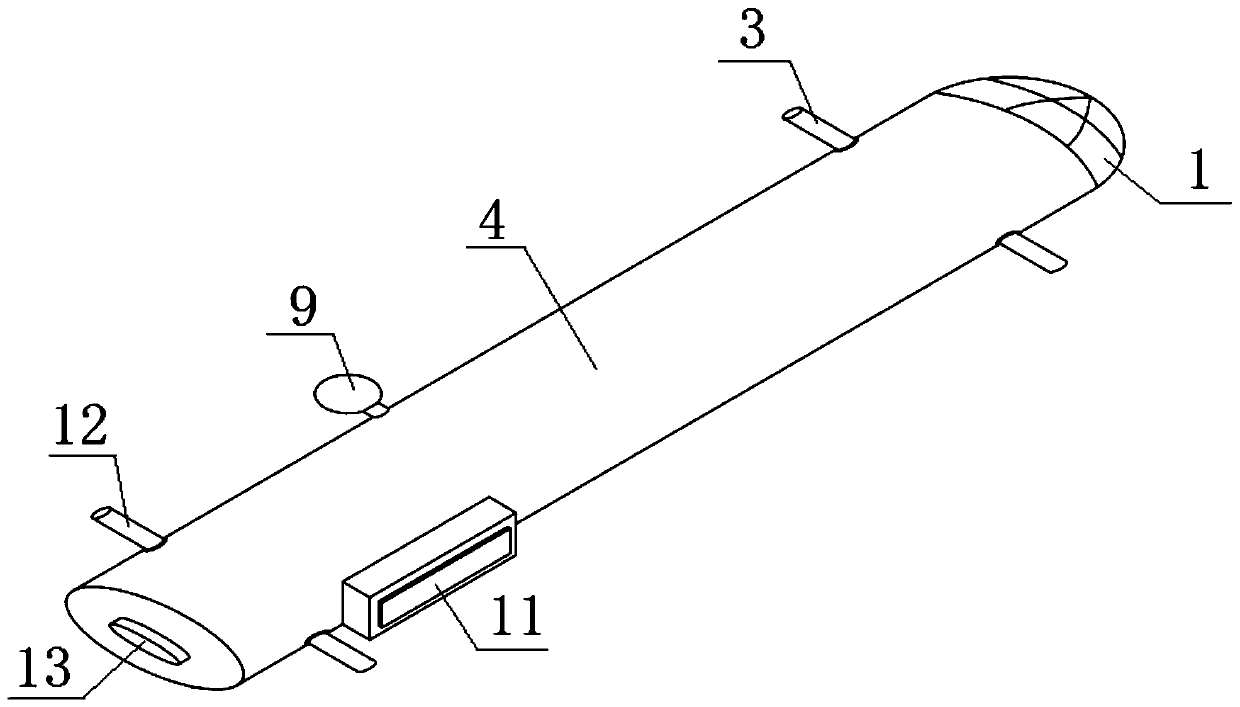

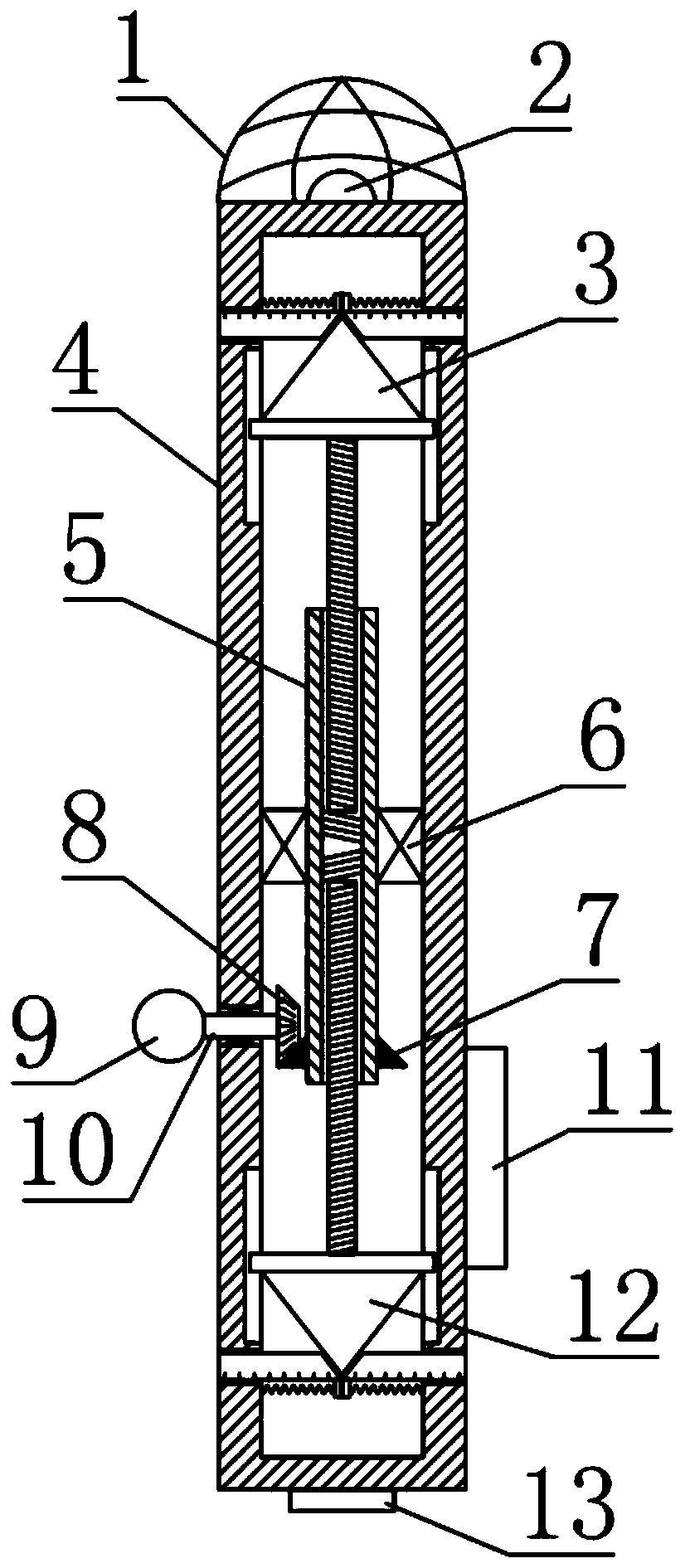

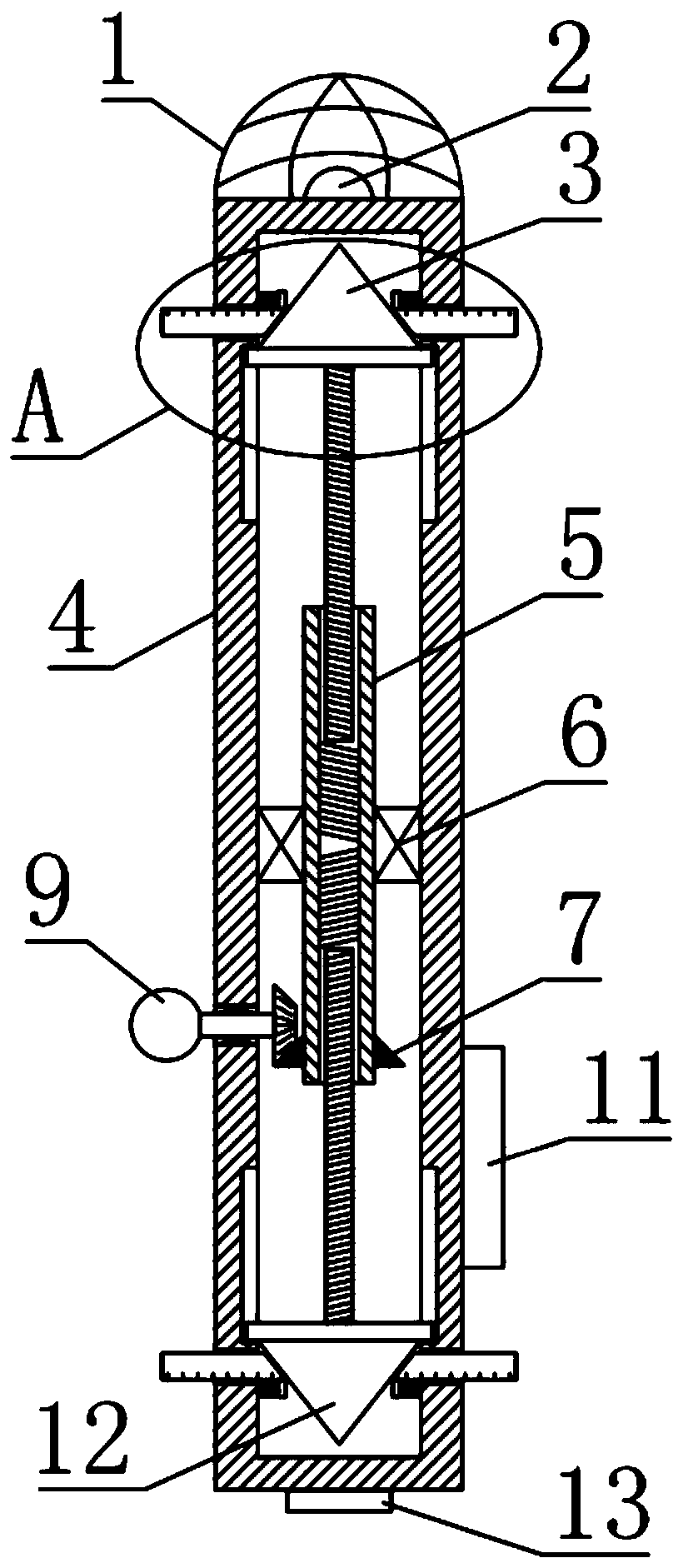

[0029] see Figure 1-4 , in an embodiment of the present invention, a portable bridge crack width measuring instrument includes a cylinder 4, one end of the cylinder 4 is a measuring end, and a measuring assembly 3 is arranged inside the measuring end of the cylinder 4, and the cylinder 4 The other end is the observation end, the observation end of the cylinder 4 is provided with an observation assembly 12, the measurement assembly 3 and the observation assembly 12 all include a measuring rod 14 that can extend from the side wall of the cylinder 4, the cylinder The observation end of 4 is also provided with a control assembly that can make the measurement assembly 3 and the measurement rod 14 of the observation assembly 12 protrude synchronously.

[0030] Further, the barrel 4 may be a cylindrical barrel structure with both ends closed, or other structures.

[0031] Further, in order to facilitate observation of the inside of the crack, a spotlight 2 is installed at the measu...

Embodiment 2

[0033] see Figure 2-4 , the difference between this embodiment and embodiment 1 is:

[0034]In this embodiment, the measurement assembly 3 and the observation assembly 12 both include a top block 17 arranged on the inside of the cylinder body 4, and the two top blocks 17 are arranged symmetrically. The front view of the top block 17 is in the shape of an isosceles triangle. A guide plate 18 is installed and fixed at the inner end of the cylinder body 4. A chute 22 that is slidably connected with the guide plate 18 is provided on the inner side wall of the cylinder body 4. The guide plate 18 can slide along the chute 22. The inner side of the guide plate 18 A screw rod 21 is installed and fixed; the control assembly includes a rotating ball head 9, a rotating rod 10, a driving bevel gear 8, a driven bevel gear 7, a bearing 6 and a threaded cylinder 5, and the inner middle part of the cylinder body 4 rotates through the bearing 6 A threaded barrel 5 is installed, and the threa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com