Preparation method for fracture physical simulation test piece of coal-measure composite reservoir

A physical simulation and reservoir technology, applied in the preparation of test samples, etc., can solve the problems of not enough to guide the extension and expansion of fractures, different contact interfaces, etc., and achieve the effect of improving reliability, simple steps, and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Embodiments of the present invention will be further described below in conjunction with accompanying drawings:

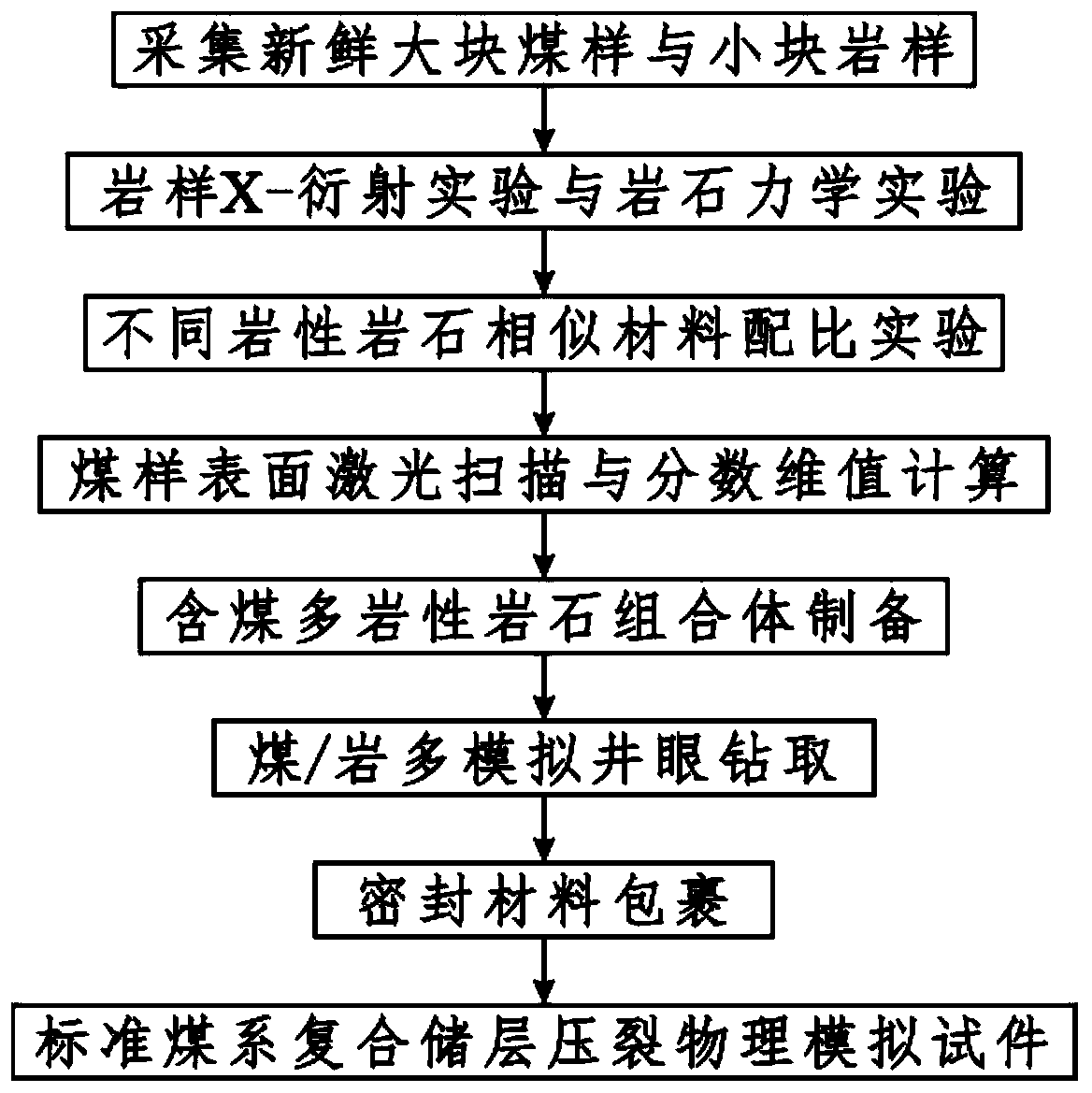

[0027] Such as figure 1 As shown, the coal-measure composite reservoir fracturing physical simulation test piece preparation method of the present invention comprises the following steps:

[0028] Step 1. Collect large fresh coal samples and small rock samples of different lithology in the mine, and mark the sampling orientation and horizon. The size of large coal samples is above 5cm×30cm×30cm, and the size of coal is about 30cm×30cm The surface of the sample is a natural cross-section to ensure that the interface between the coal and the rock is an irregular contact surface, and the size of the small rock sample should be greater than 8cm×8cm×8cm; the different lithology rock layers include sandstone layers, argillaceous sandstone layers, and sandy mudstone layers and mudstone formations;

[0029] Step 2, use a laser scanner to scan the natural section o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap