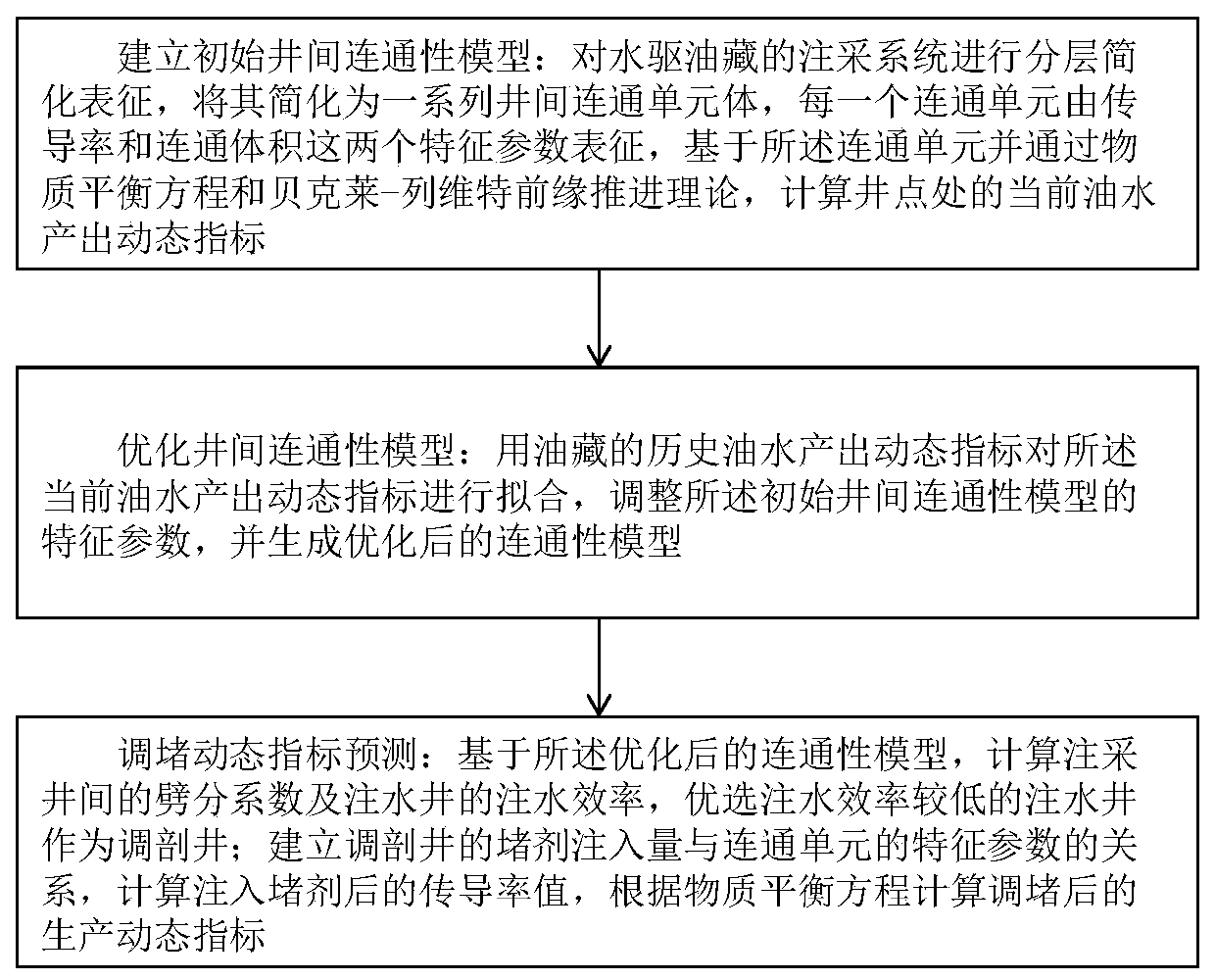

A dynamic profile control and blockage prediction method and system based on inter-well connectivity

A technology for interwell connectivity and dynamic prediction, applied in earthwork drilling, wellbore/well components, special data processing applications, etc., can solve the problem of complex seepage mechanism, inability to calculate quickly, failure to consider shutting down wells and oil well transfer, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

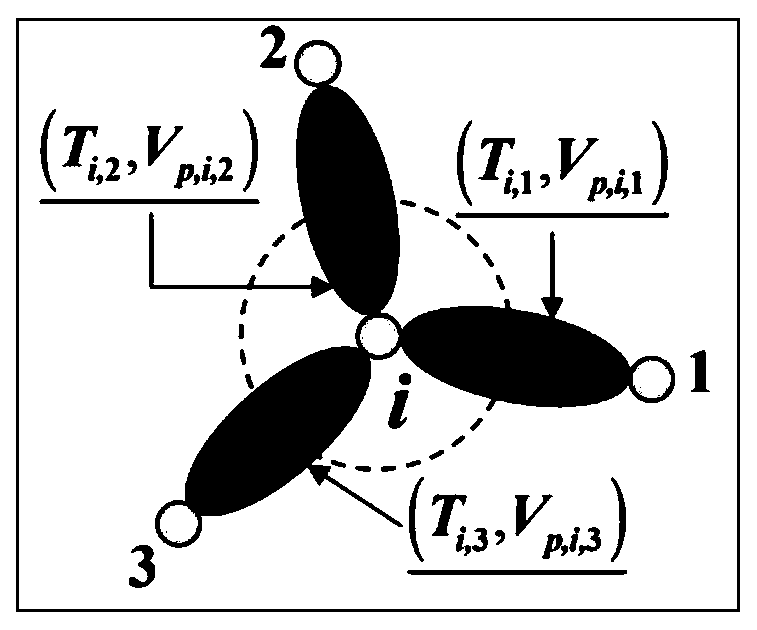

Method used

Image

Examples

Embodiment 1

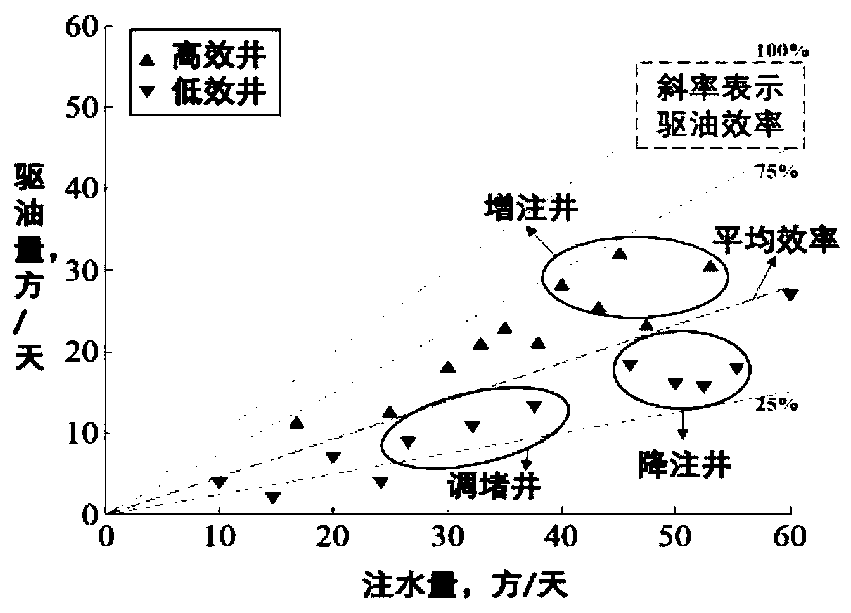

[0136] Embodiment 1 takes a water injection well as an example to briefly introduce the plugging regulation and prediction process. Such as Figure 5 As shown, I1 is a water injection well connected to 4 production wells, and each connected unit in the figure is marked with conductivity and connected volume (unit: ten thousand square meters); Figure 6 is the splitting coefficient from well I1 to 4 production wells at the current moment. Taking Well I1 as the plugging adjustment well, and assuming that the injected plugging dose is 350 m3, the plugging agent input volumes to the four connected units of P1, P2, P3, and P4 wells are 17.5, 122.5, 157.5, and 52.5 m3 respectively. Figure 7 shown. According to the ratio of the amount of plugging into each connected unit to the connected volume, it can be determined that the dimensionless injection multiples of the four connected units are about 0.0088, 0.082, 0.21, and 0.0044; Figure 4 According to the relationship curve shown,...

Embodiment 2

[0138] Example 2 is an example of the concept of heterogeneity. A two-dimensional heterogeneous reservoir model is established using a commercial numerical simulator. Five injection and four production well patterns are used. The reservoir grid is divided into 25×25×1, X, Y and The grid sizes in the Z direction are 25m, 15m and 15m. The real permeability field of the model is as Figure 9 As shown, there are high-permeability areas and low-permeability areas, the average porosity is 0.2, the initial oil saturation is 0.8, and the initial reservoir pressure is 25MPa. The production data of 1800 days of simulated production are used for history matching.

[0139] History matching single well fitting such as Figure 10a~10b As shown, this method has a good consistency with the numerical simulation method. Figure 11 shows the corresponding situation between the splitting coefficient calculated by the model and the real flow field of the model. accuracy. The connected characteri...

Embodiment 3

[0142] Embodiment 3 is an actual calculation example. The plugging adjustment dynamic prediction method proposed by the present invention is applied to an actual low-permeability oil field. This oil field started production in 2011, with a total of 250 wells, of which 80 water injection wells, with an average permeability of 20mD , the average porosity is 0.108, the initial reservoir pressure is 20MPa, and the block connectivity inversion results are as follows Figure 14 . The block fit is as follows Figure 15a , 15b, the fitting correlation coefficient of block accumulative oil production is 94.1%, and the fitting correlation coefficient of block water cut is 88.3%.

[0143] Based on the connectivity calculation results, 13 wells with low water injection efficiency were selected for dynamic optimization of plugging regulation. According to the field experiment and indoor experiment, the scatter point of the plugging agent on the decrease of conductivity is obtained, and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average permeability | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com