Method and device for unclassified flotation of ilmenite

A flotation device and full-grain grade technology, applied in flotation, solid separation, etc., can solve the problems of large amount of reagent addition, short mineral-medicine action time, poor effect, etc., to optimize the flotation process and improve the effect of reagents Effect, effect of simplifying the flotation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

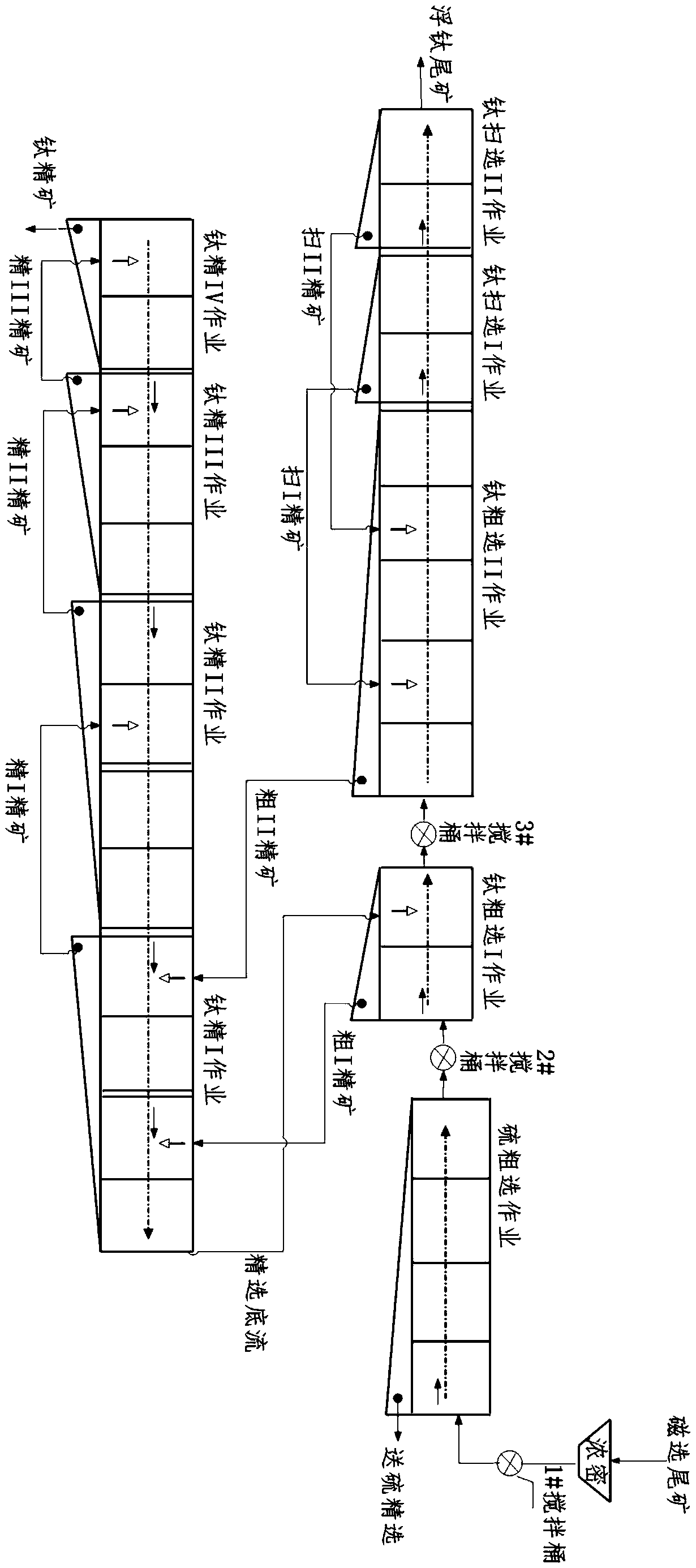

[0032] The present embodiment provides a kind of flotation method of ilmenite full-grain grade, such as figure 2 As shown, the magnetic separation tailings are used as flotation feed, after being concentrated, they are stirred and mixed with the flotation agent that is beneficial to sulfur separation and inhibits titanium separation in the 1# mixing tank, and then carry out sulfur roughing to remove ferro-titanium sulfur in mines;

[0033] The desulfurization tailings enter the 2# stirring tank and the 3# stirring tank in turn, and in the 2# stirring tank and the 3# stirring tank, the titanium flotation agent (especially the collector) which is beneficial to the separation of titanium is mixed with the ore pulp, and the effect is In this embodiment, the linear speed of the impellers in the 2# agitation tank and the 3# agitation tank is controlled at 5m / s~8m / s, which is realized by selecting the impeller diameter and rotation speed of the corresponding agitation tank. Specific...

Embodiment 2

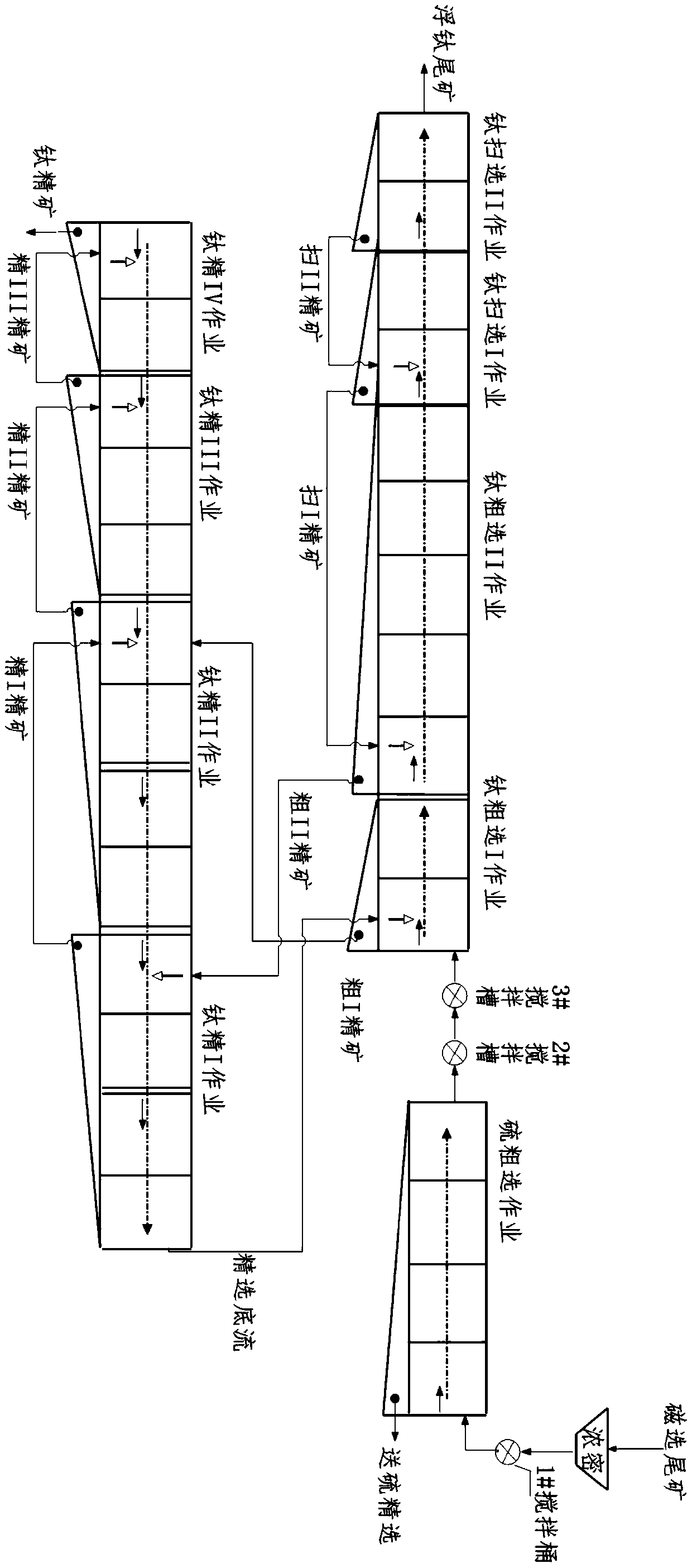

[0047] A kind of flotation method of ilmenite full-grain grade. The difference from Example 1 is that the "gradient decrease" strong acid system is adopted in the flotation process. According to the pulp characteristics of different processes, sulfuric acid is added step by step to adjust the pH value. Primarily used to suppress gangue minerals. Among them, the main purpose of the roughing process is to ensure the yield of the flotation process, and the pH value is 2.8; the pH value of the sweeping process is higher than that of the roughing process due to the lower grade of the selected minerals, and the pH value is 3.0; the beneficiation operation is mainly used to reduce gangue entrainment , the pH value of different beneficiation stages gradually decreases and the mineral grade is increased. The pH value of the titanium beneficiation I process is 2.5, the pH value of the titanium beneficiation II process is 2.3, the pH value of the titanium beneficiation III process is 2.2,...

Embodiment 3

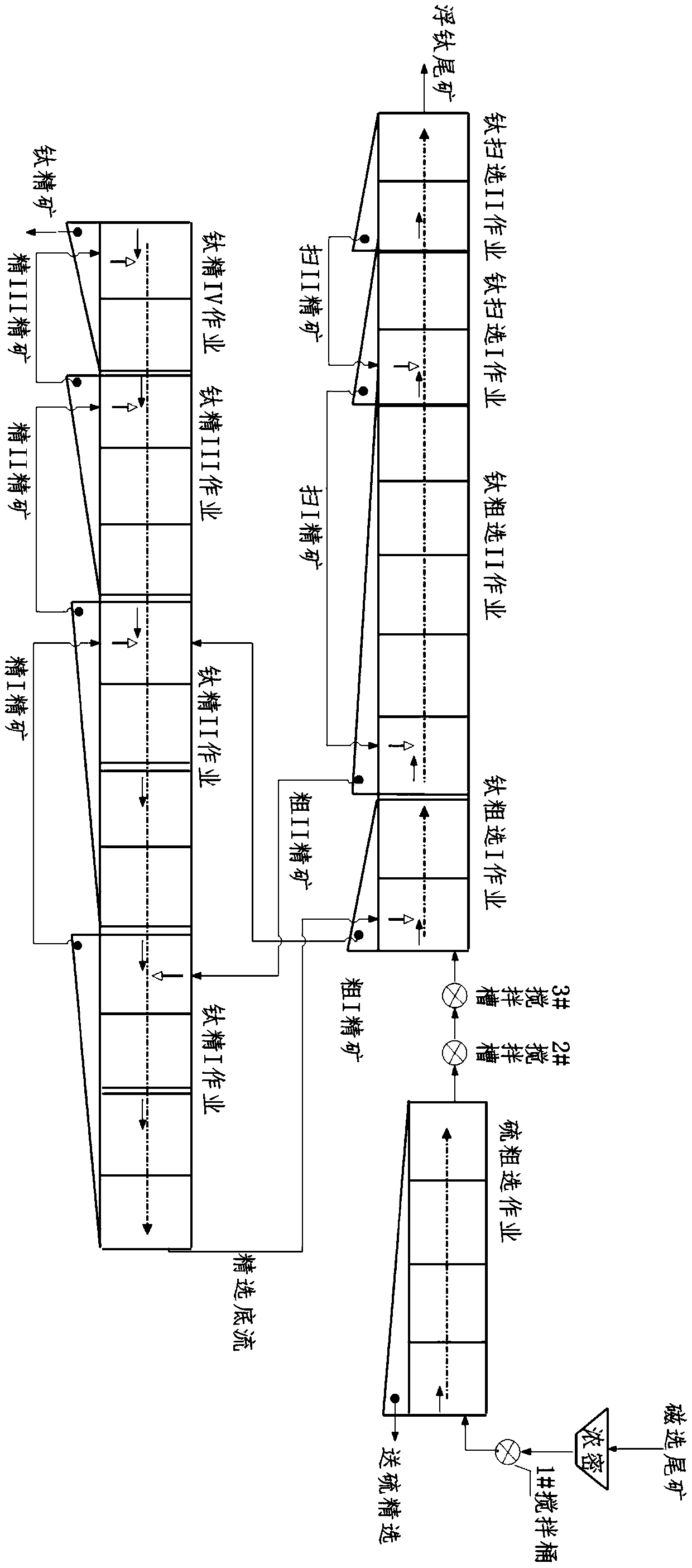

[0049] A kind of flotation method of ilmenite full-grain grade. The difference from Example 1 is that the "gradient decrease" strong acid system is adopted in the flotation process. According to the pulp characteristics of different processes, sulfuric acid is added step by step to adjust the pH value. Primarily used to suppress gangue minerals. Among them, the main purpose of the roughing process is to ensure the yield of the flotation process, and the pH value is 3.0; the pH value of the sweeping process is higher than that of the roughing process due to the lower grade of the selected minerals, and the pH value is 3.2; the beneficiation operation is mainly used to reduce gangue entrainment , different beneficiation stages gradually reduce the pH value and increase the mineral grade. The pH value of the titanium beneficiation I process is 2.8, the pH value of the titanium beneficiation II process is 2.5, the pH value of the titanium beneficiation III process is 2.4, and the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com