CNC metal machining machine with single tool turret, double spindles and double machining efficiency

A technology of metal processing and processing efficiency, applied in metal processing machinery parts, metal processing equipment, manufacturing tools, etc., can solve problems such as uncompetitiveness, increased cost, and bulky volume.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0066] In order to have a further understanding and recognition of the features of the present invention and its characteristics, the following examples are listed and described as follows in conjunction with the drawings:

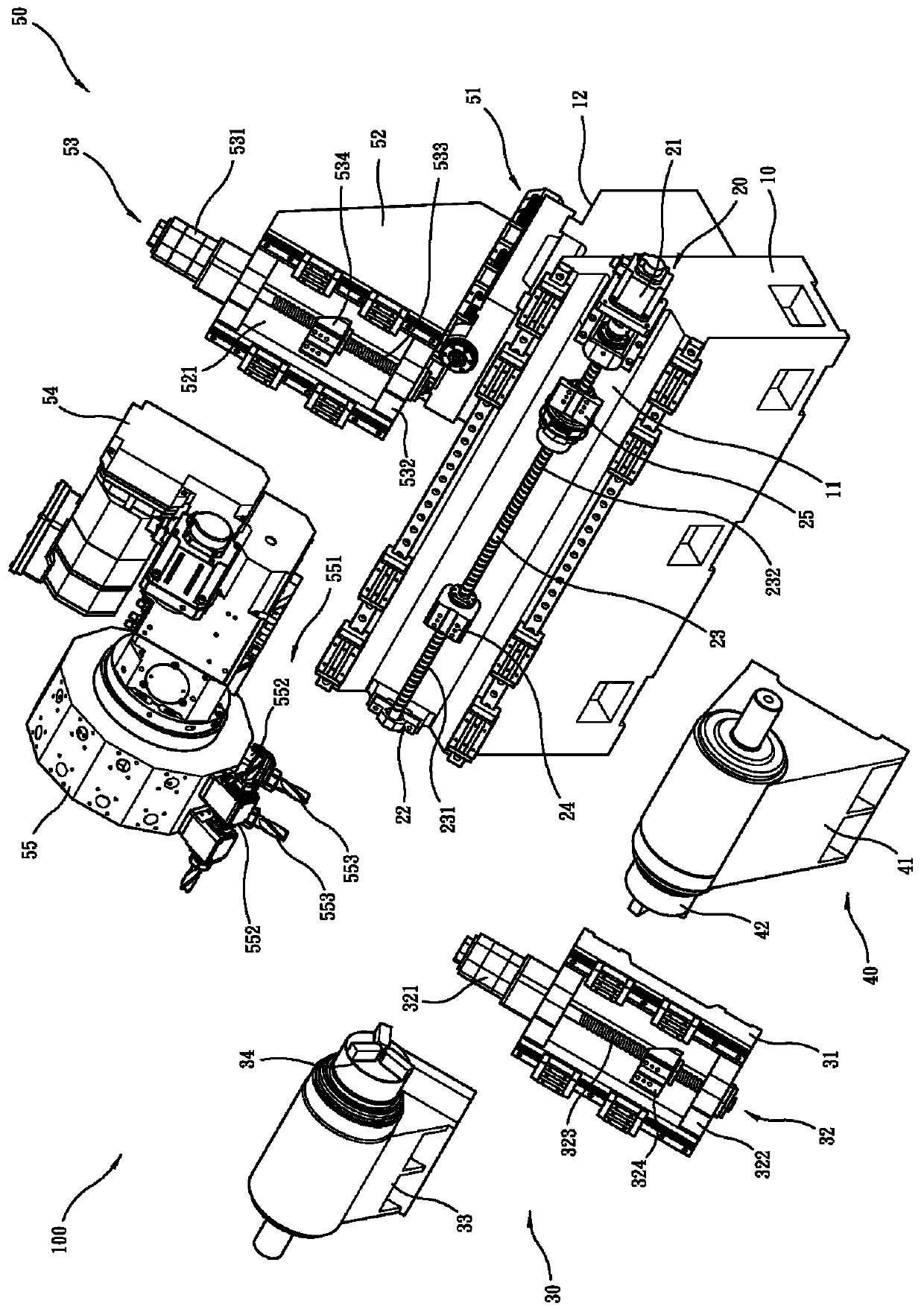

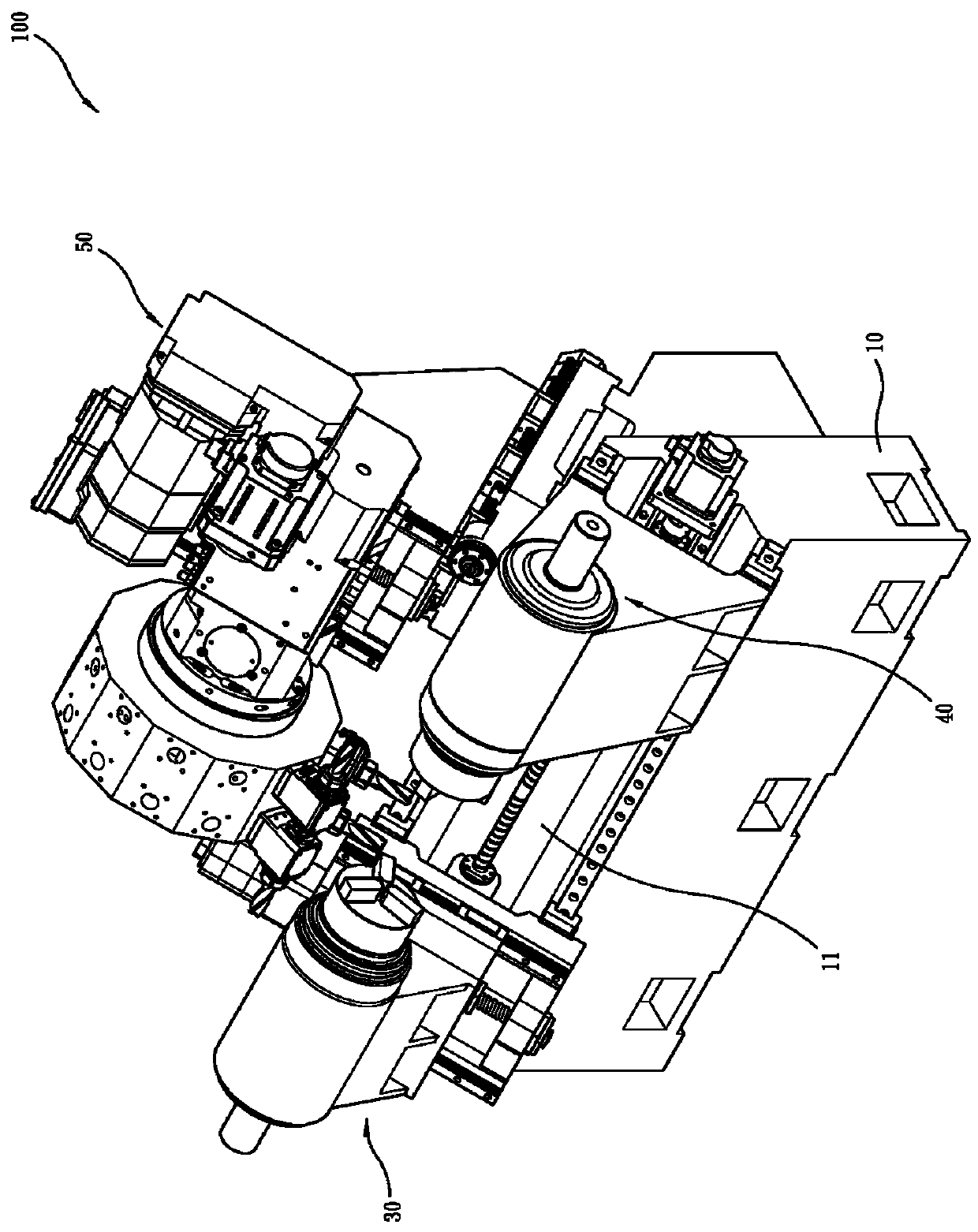

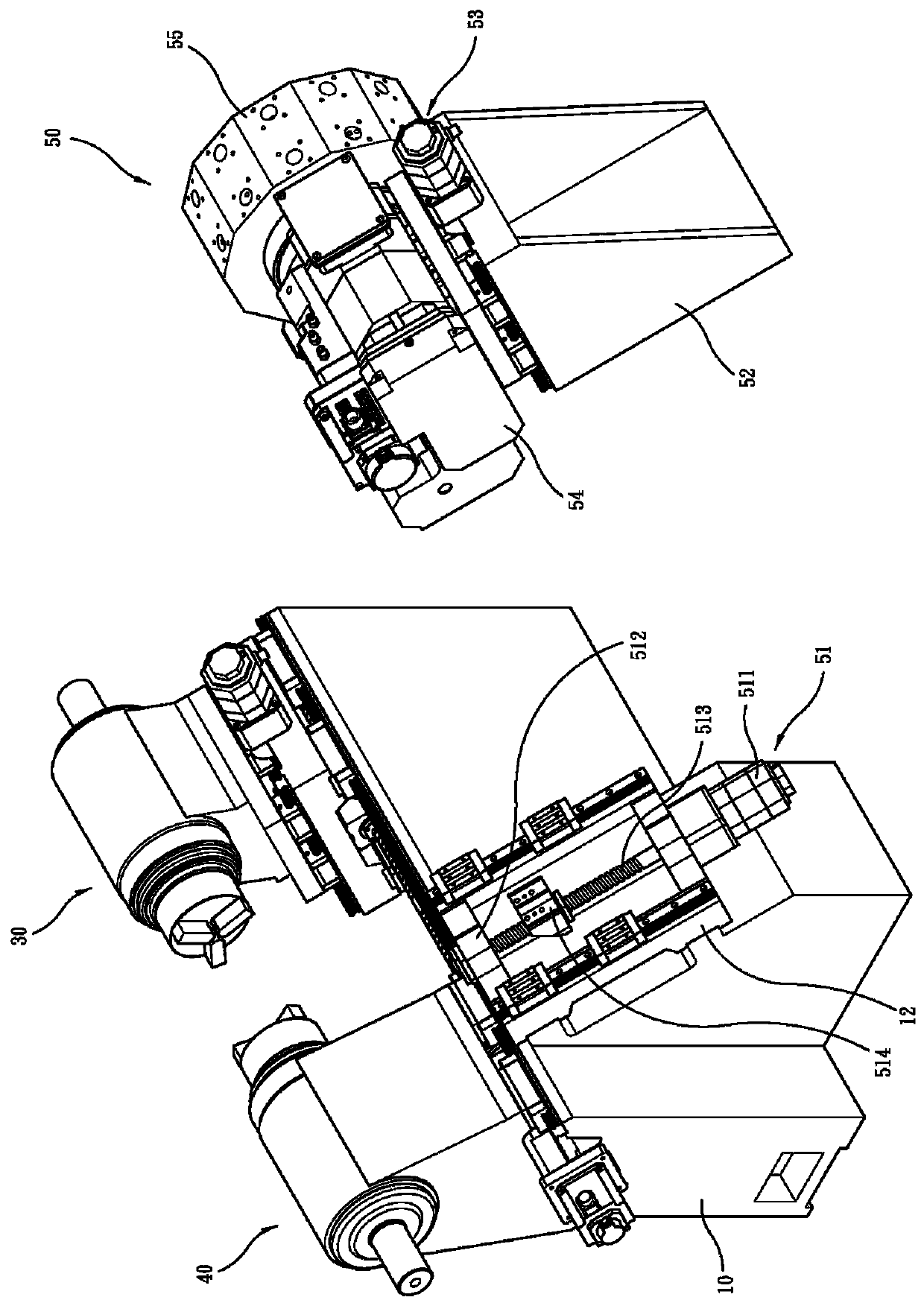

[0067] see Figure 1 to Figure 8 According to the first preferred embodiment of the present invention, a CNC single turret, double spindle and double machining efficiency metal processing machine 100 mainly includes a base 10, a spindle drive source 20, a first spindle unit 30, A second spindle unit 40 and a turret unit 50, wherein:

[0068] see Figure 1 to Figure 3 , the base 10 can be firmly placed on a ground (or plane). The base 10 has a Z-axis installation surface 11 and a Y-axis installation surface 12 perpendicular to the Z-axis installation surface 11 .

[0069] see Figure 1 to Figure 3 , the spindle drive source 20 is arranged on the Z-axis mounting surface 11 of the base 10, the spindle drive source 20 has a drive motor 21, a bearing seat 2...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap