A reactive filter material for coking wastewater treatment and its preparation and use method

A coking wastewater and reactive technology, applied in chemical instruments and methods, water/sewage treatment, reduced water/sewage treatment, etc., can solve problems such as high investment and operating costs, increased use costs, sintering and ironmaking process hazards, etc. , to achieve the effect of reducing the processing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

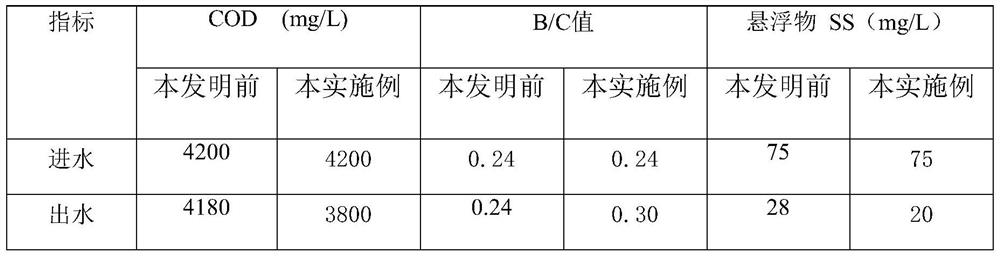

Embodiment 1

[0038] A reactive filter material, its raw materials are: coking coke powder, rolled iron oxide scale and blast furnace dedusting ash, the volume ratio of the three raw materials is: coking coke powder: hot-rolled iron oxide scale: blast furnace dedusting ash = 1:1:1; add binder, and its addition amount is added according to the ratio of the total volume of the above three raw materials, that is, the total volume of the three raw materials: binder = 1:1.3; the particle size of the coking coke powder The diameter is 100-200 mesh, the particle diameter of the blast furnace dust is 100-200 mesh, and the particle diameter of the rolled oxide scale is 0.5-2 mm.

[0039] Preparation:

[0040] 1) Pretreatment of raw materials:

[0041]Take the silicon steel oxide iron scale and pulverize it, sieve it, and take the sieved particles with a particle size of 0.5-1mm. After washing with water for many times to remove salt and impurities until it is clean, use lye with a concentration of ...

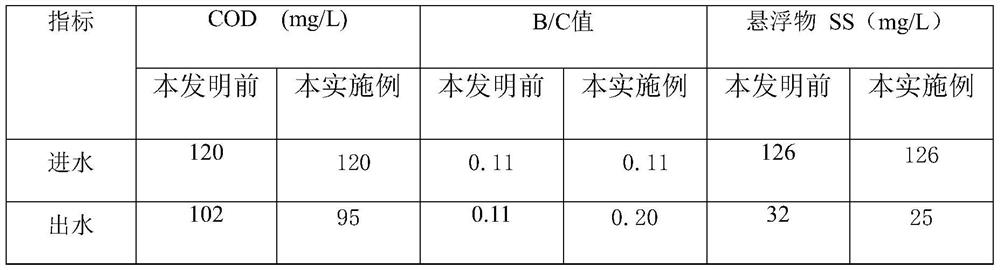

Embodiment 2

[0058] A reactive filter material, its raw materials are: coking coke powder, rolled iron oxide scale and blast furnace dedusting ash, the volume ratio of the three raw materials is: coking coke powder: hot-rolled iron oxide scale: blast furnace dedusting ash = 1.2: 1.6: 1; add binder, and its addition amount is added according to the ratio of the total volume of the above three raw materials, that is, the total volume of the three raw materials: binder = 1: 2.1; the particle size of the coking coke powder The diameter is 100-200 mesh, the particle diameter of the blast furnace dust is 100-200 mesh, and the particle diameter of the rolled oxide scale is 0.5-2mm.

[0059] Preparation:

[0060] 1) Pretreatment of raw materials:

[0061] Take the silicon steel oxide iron scale and crush it, sieve it, and take the sieved particles with a particle size of 1-2 mm. After washing with water for many times to remove salt and impurities until it is clean, use lye with a concentration o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com