Leather nail-hanging structure for door panel

A peg and leather technology, which is applied to leather goods holders, textiles, papermaking, sewing equipment, etc., can solve the problems of unsatisfactory production quality and production efficiency, low efficiency of line operation, and low product consistency. Good economic benefit, simple structure and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Below in conjunction with accompanying drawing and embodiment the technical solution of the present invention is further described:

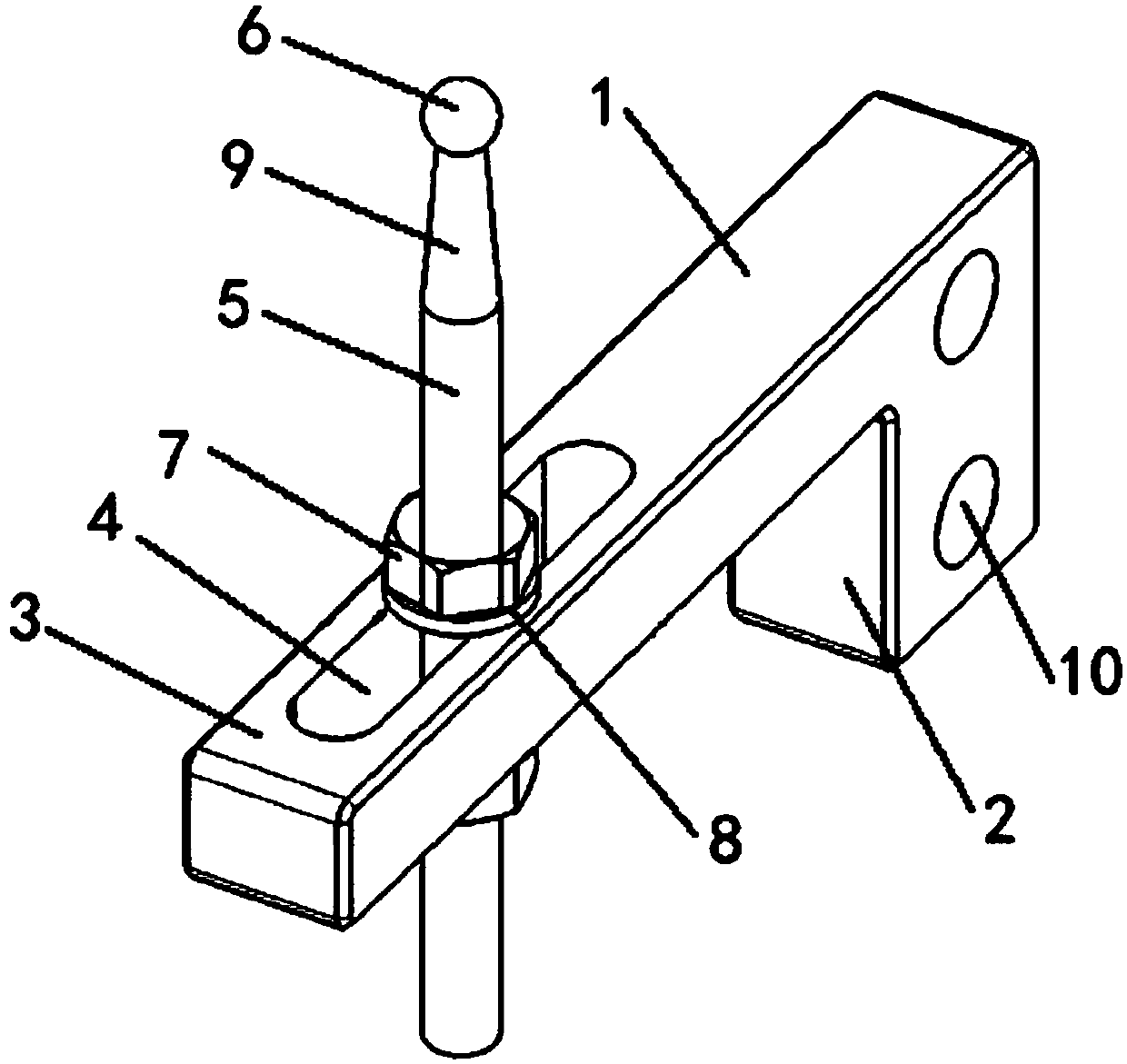

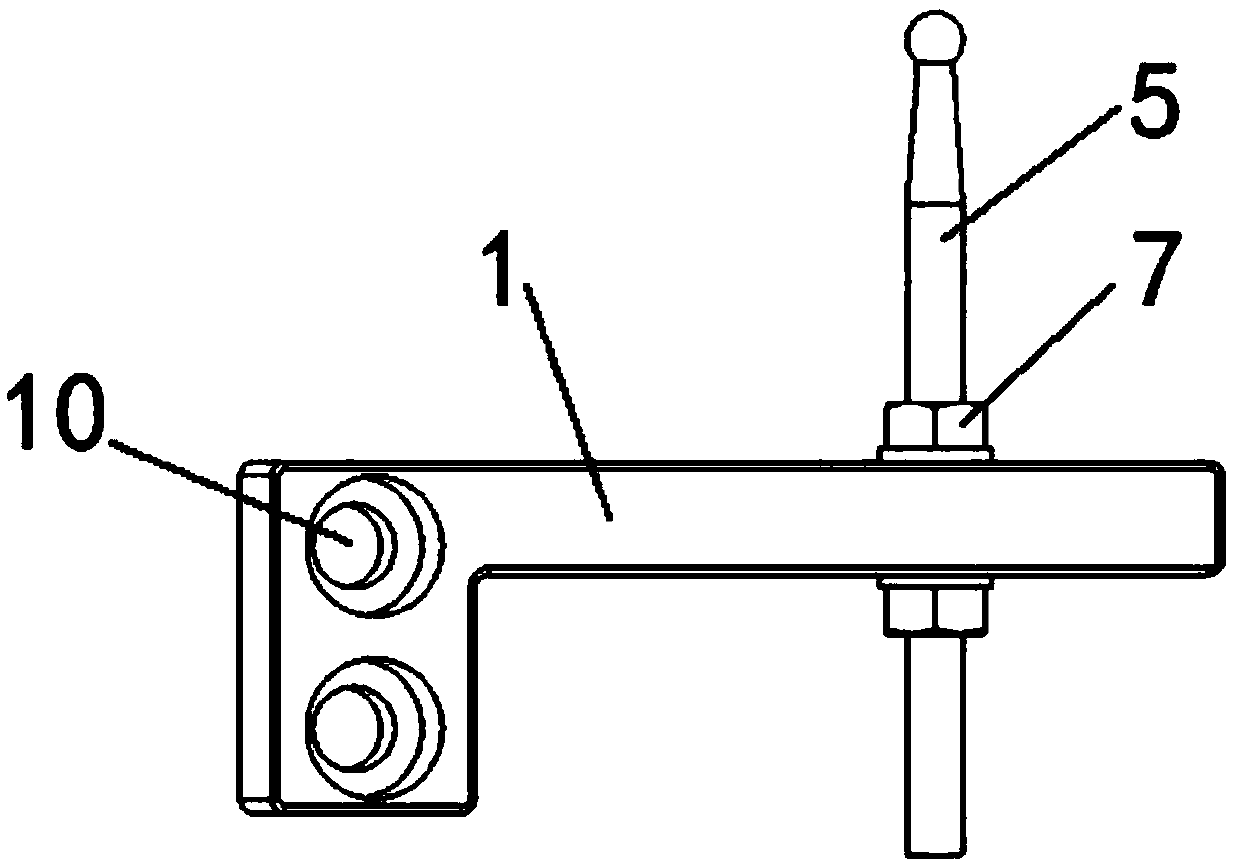

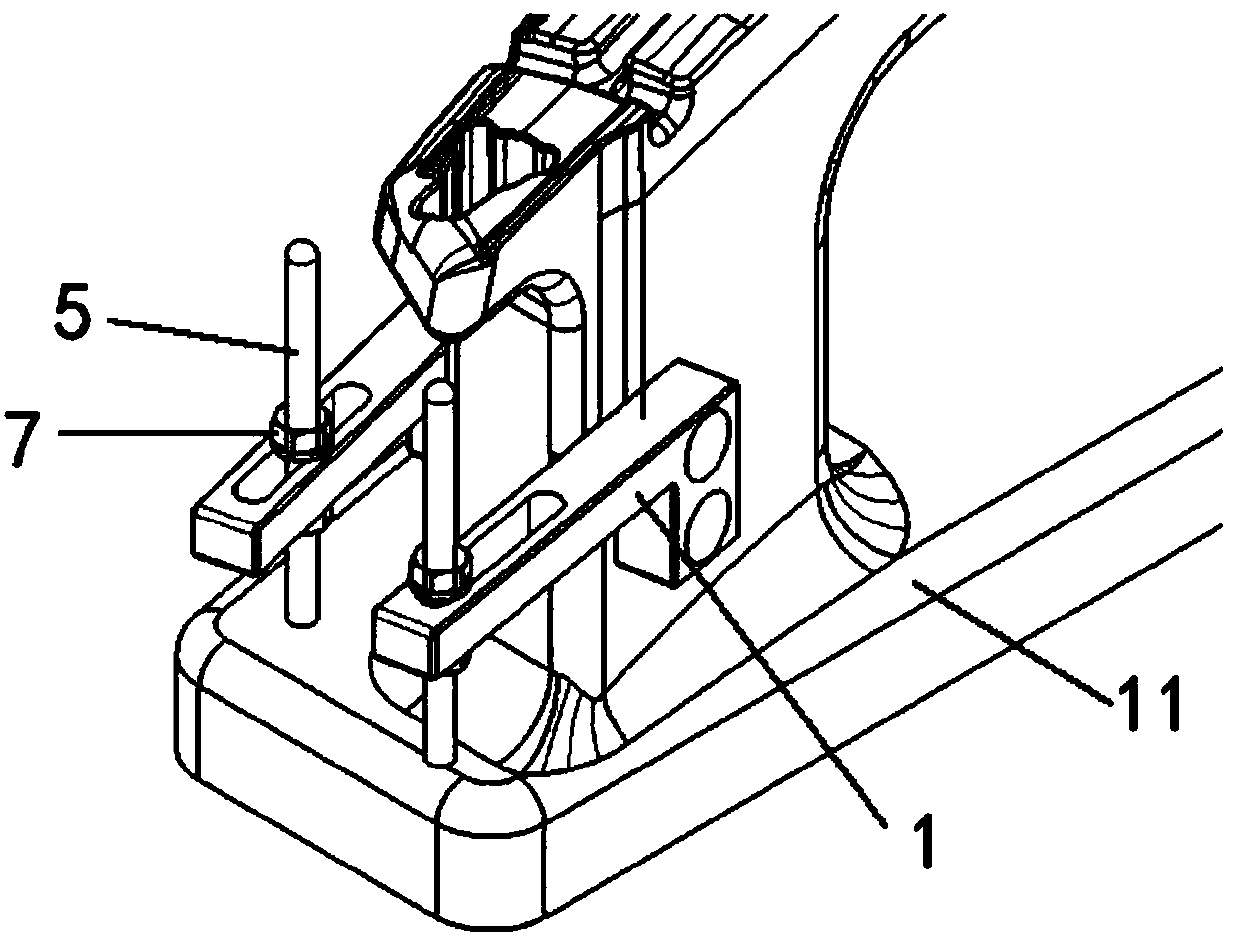

[0016] Such as Figure 1 to Figure 3 As shown, the present invention provides a leather peg structure for a door panel, including a mounting bracket 1 and a limit assembly, wherein the mounting bracket 1 includes a mounting bracket 2 and an adjusting pole 3, and the mounting bracket 2 is connected to the alignment tool 11 , the adjusting pole 3 is provided with a strip-shaped through-hole 4 penetrating up and down, the strip-shaped through-hole 4 is arranged along the length direction of the adjusting pole 3, the limit assembly includes a peg 5, and the peg 5 is used for hanging the leather hanging hole One end of one end is provided with spherical hanging joint 6, and the two ends of peg 5 passing through bar-shaped through hole 4 are all provided with limit nut 7, and limit nut 7 is pressed against adjustment strut 3 under the working s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com