Cutting and edge grinding integrated equipment

An integrated, equipment technology, applied in grinding/polishing equipment, machine tools suitable for grinding workpiece edges, glass manufacturing equipment, etc., can solve the problems of glass substrate damage, low efficiency of glass substrate cutting and grinding production lines, etc., to improve efficiency and good rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to explain in detail the technical content, structural features, achieved goals and effects of the technical solution, the following will be described in detail in conjunction with specific embodiments and accompanying drawings.

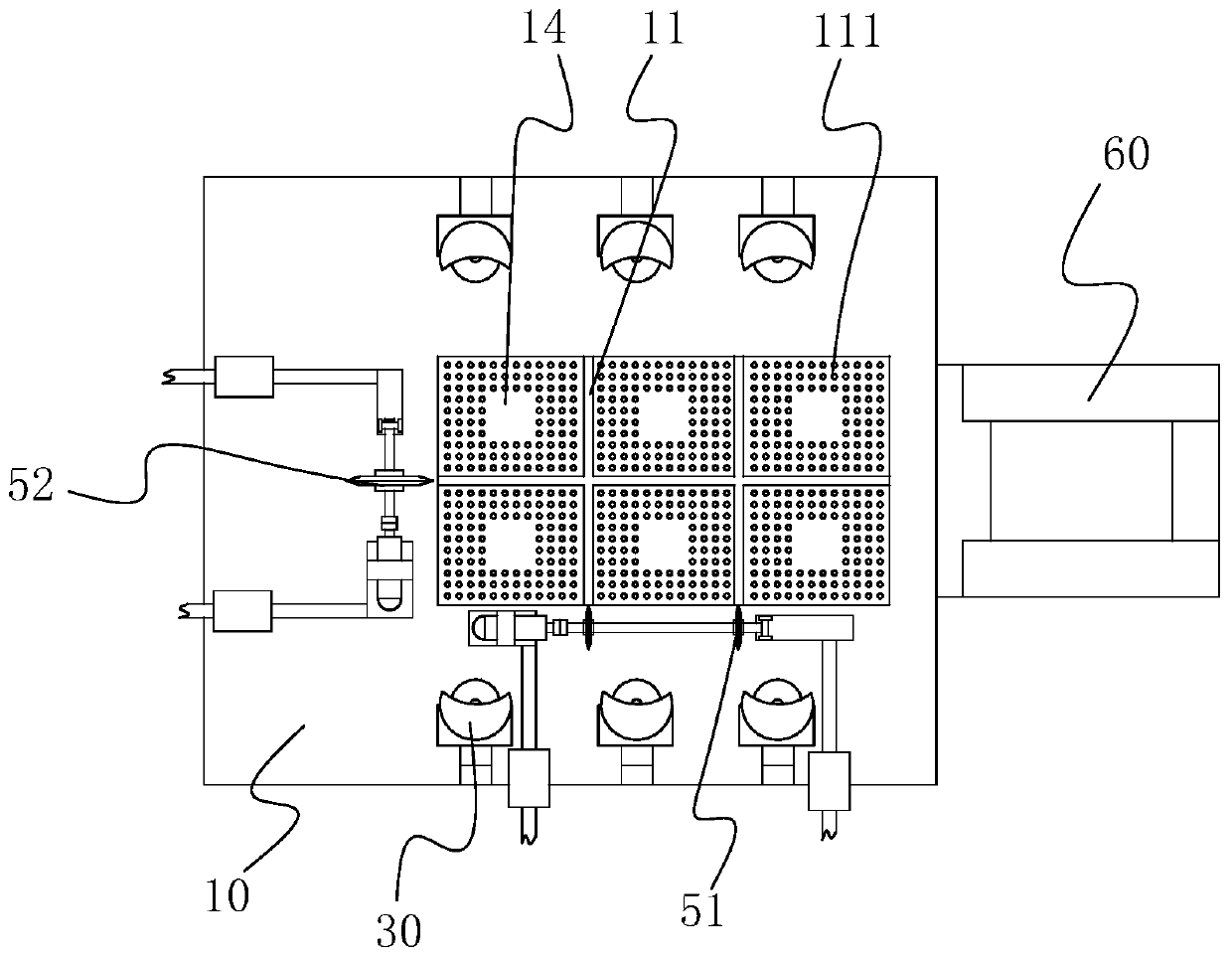

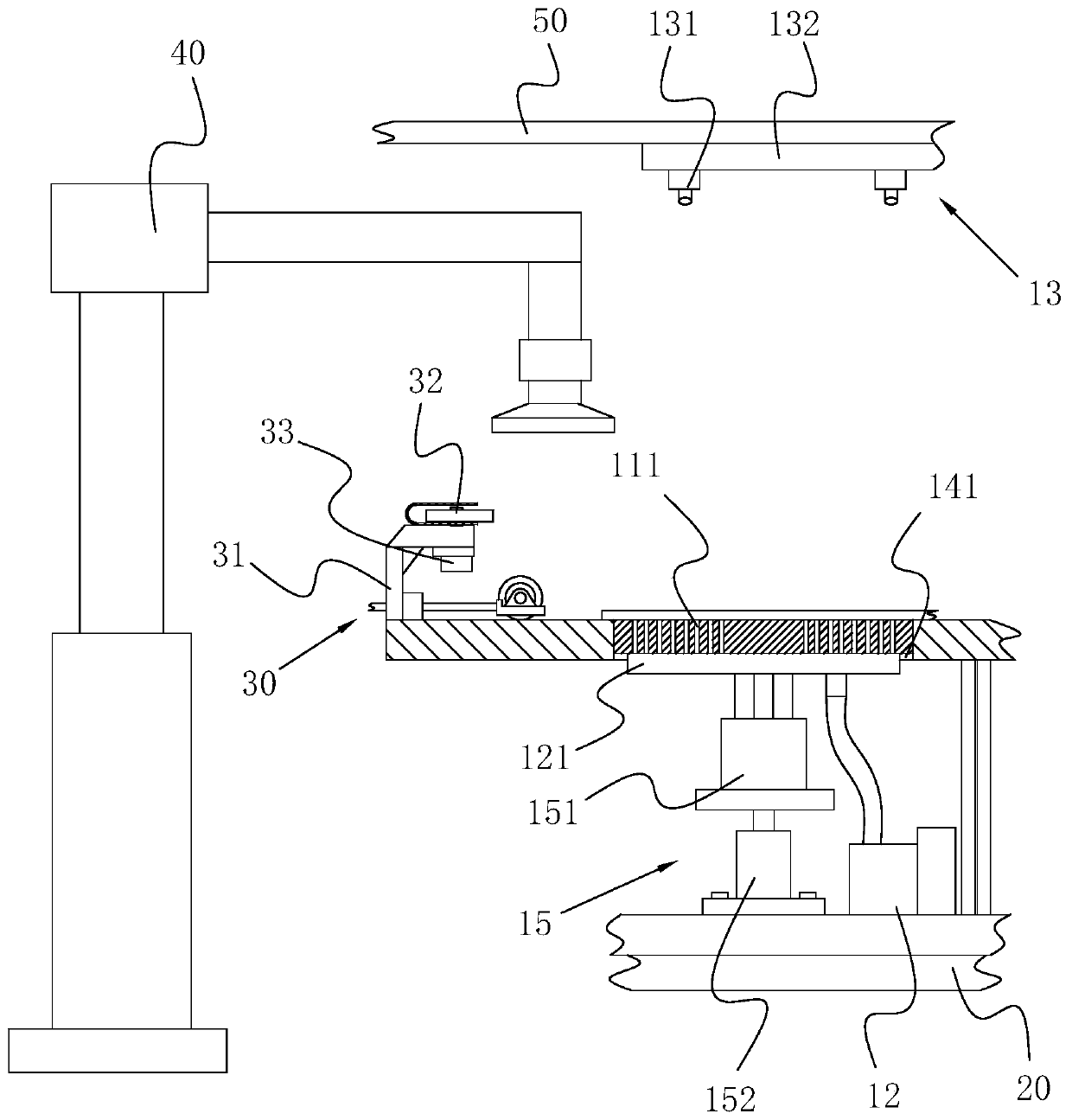

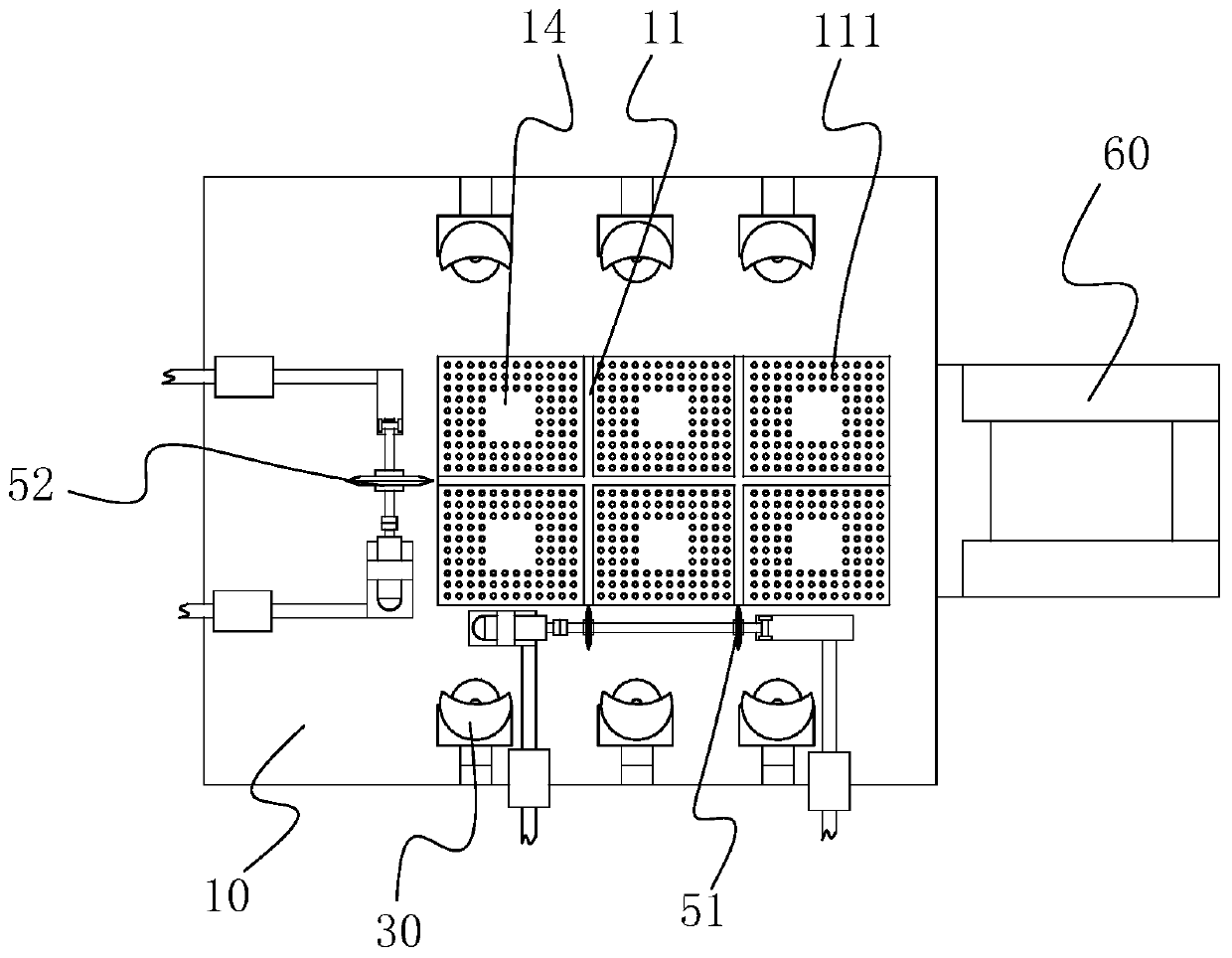

[0026] see figure 1 and figure 2 , this embodiment provides an integrated equipment with cutting and edging, including a carrier 10 , a grinding slide 20 , a grinding mechanism 30 , a gripper mechanism 40 and a frame 50 . The gripper mechanism is used to place the mother substrate of the glass substrate on the stage, and the daughter substrate of the polished glass substrate can also be transported and transported. Specifically, the gripper mechanism includes a vacuum chuck, a vacuum pump, and a mechanical arm. The vacuum chuck is connected to the vacuum pump tube through a pipeline, and then the vacuum pump is used to evacuate the vacuum chuck, and then the glass substrate is adsorbed and grasped. The pipes in the room are arrange...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com