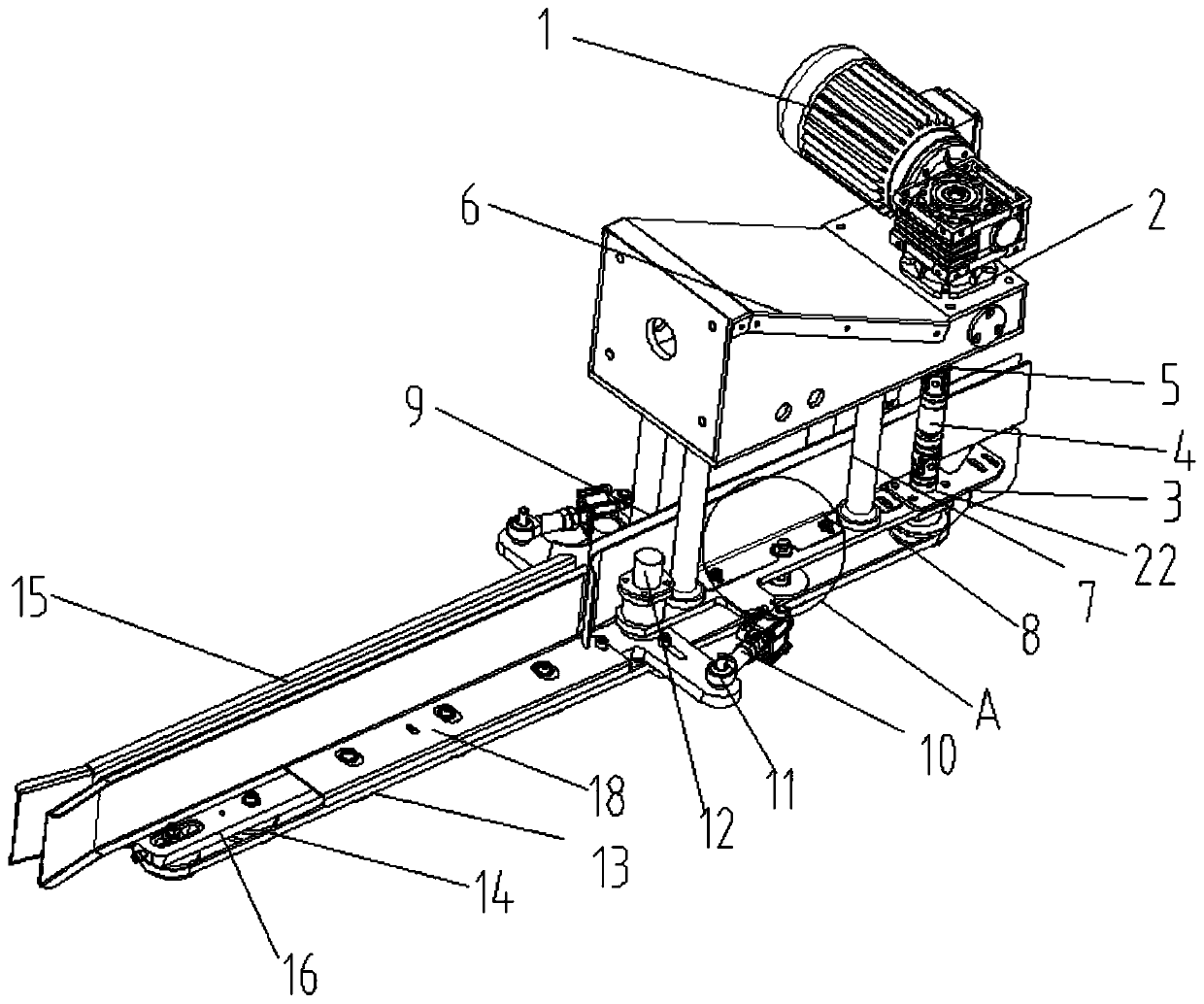

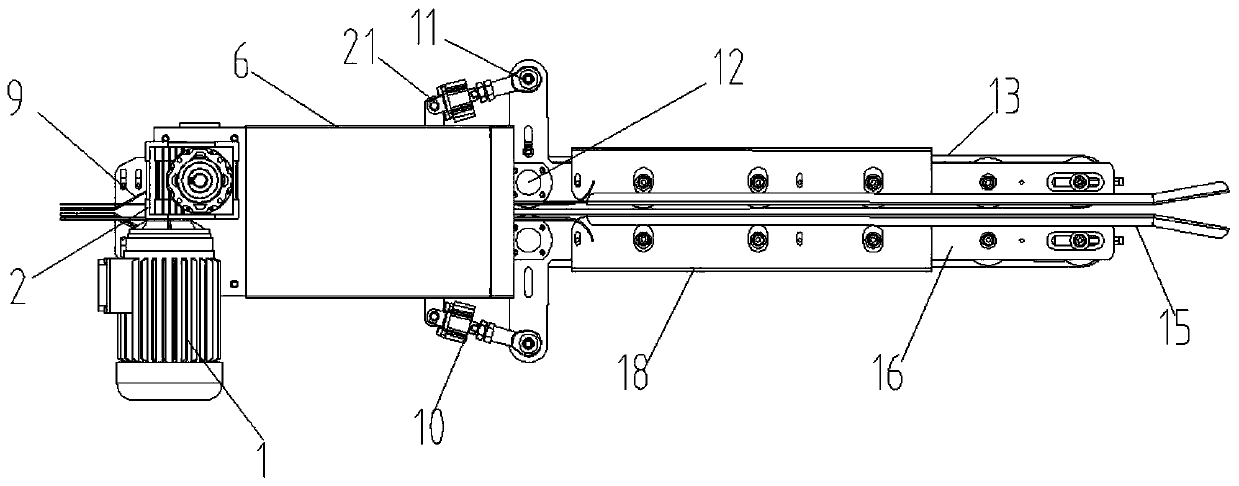

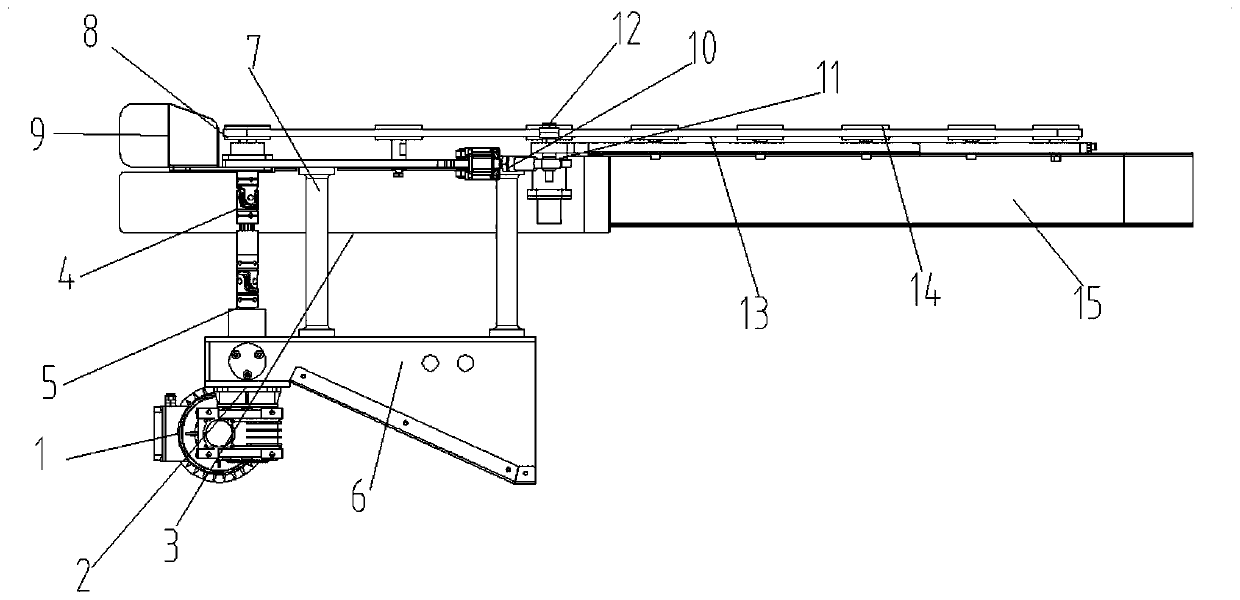

Bag clamping and shaping device of packing machine

A shaping device and machine-clamping bag technology, used in packaging, transportation packaging, transportation and packaging, etc., can solve the problems of easy deformation, affecting the packaging bag, and the M angle is easy to return to its original shape, so as to achieve beautiful packaging and avoid re-deformation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0021] Embodiment: After the M bag has packed the object and is pinned by the pin device, start the deceleration motor 1, so that the motor shaft 5 drives the driving wheel 8 to rotate, and its driving wheel 8 drives the driven wheel 14 to rotate through the belt 13, and the M bag is transported on the conveying device To one side of the guide plate 15, and continue to travel between the pulley mounting plates 16, clamp the mouth of the M bag by the belt 13 and transport it to the bag sealing machine for sealing.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com