Multi-connected long blade precision casting wax mold combination correction tool

A technology of precision castings and long blades, which is applied in the field of combined correction tooling for multi-connected long blades precision casting wax models, can solve the problems of affecting the dimensional accuracy of castings, secondary deformation, and low combination efficiency, so as to improve dimensional accuracy and pass rate, Effects that avoid re-distortion and facilitate precise composition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to make the technical means, creative features, achievement goals and effects realized by the present invention easy to understand, the present invention will be further described below with reference to the specific embodiments.

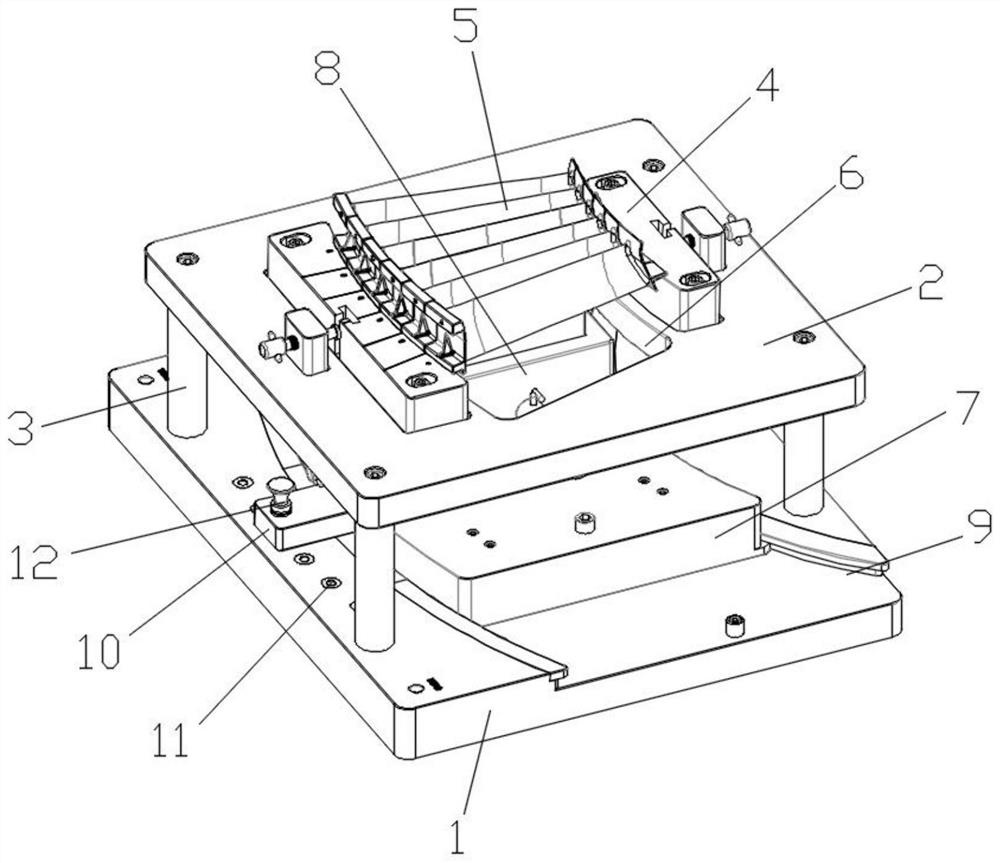

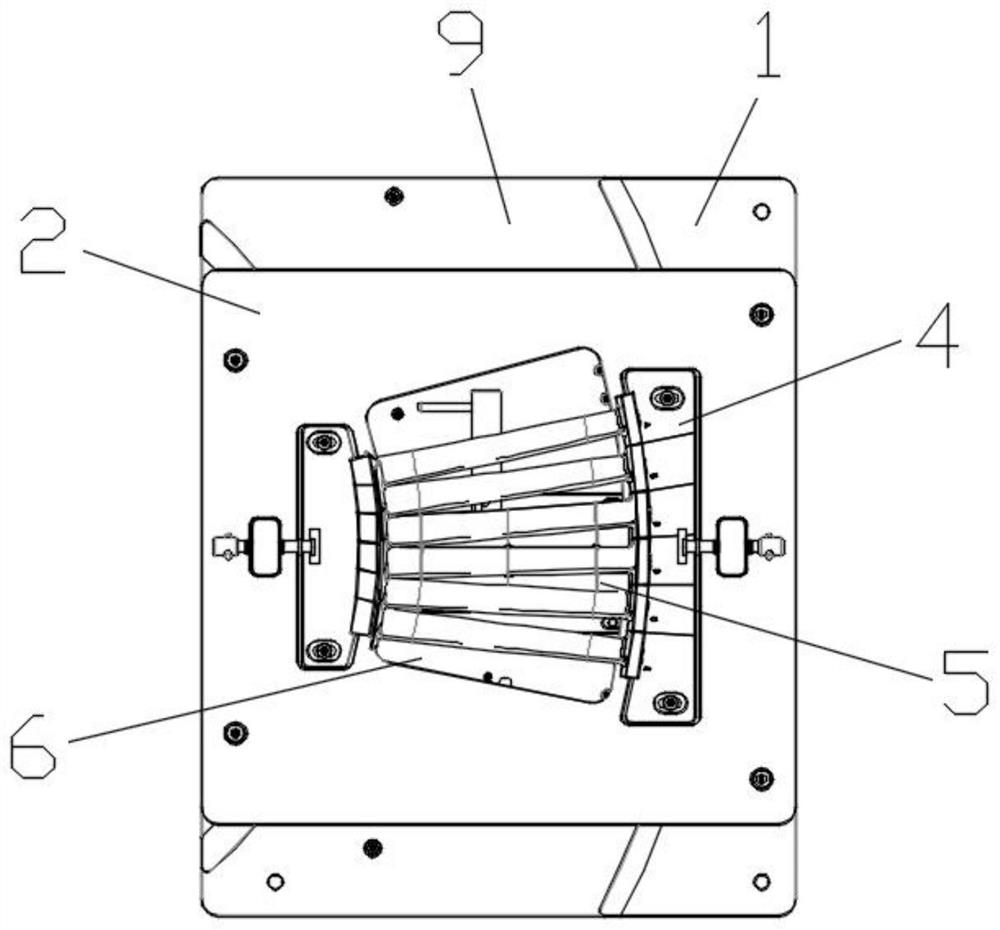

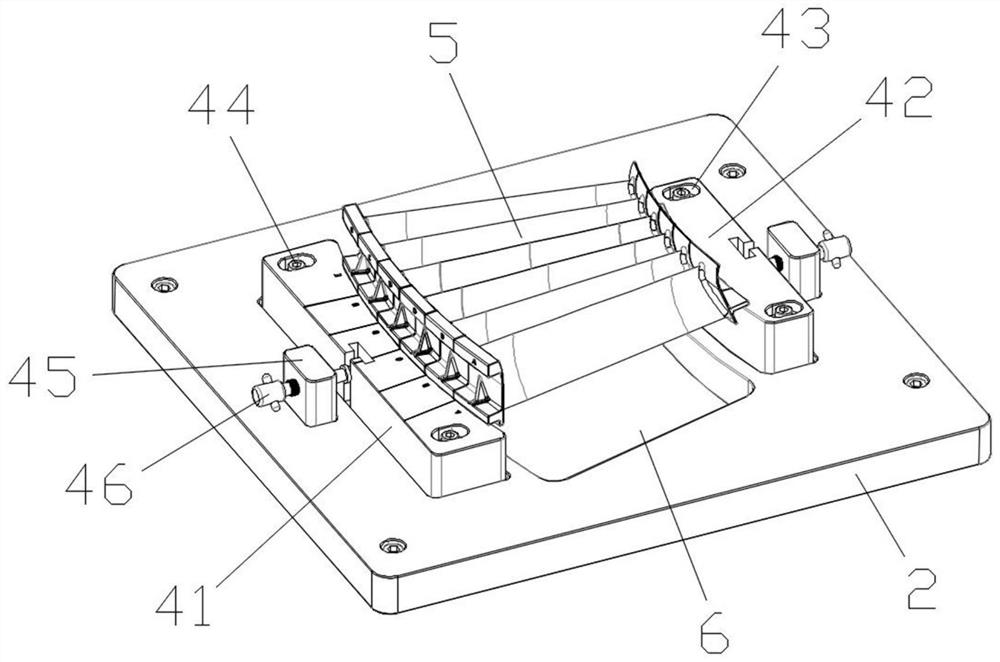

[0021] like Figure 1-2 As shown, a multi-unit long blade precision casting wax mold combination correction tooling includes a lower plate body 1 and an upper plate body 2, and the upper plate body 2 and the lower plate body 1 are fixedly connected by a column 3, and the upper plate body 2 and the lower plate body 1 are fixedly connected. A blade support 4 is installed on the top surface of the plate body 2, a blade wax mold 5 is placed on the blade support 4, a through groove 6 is opened on the upper plate body 2, and a translation seat 7 is slidably connected to the lower plate body 1. , a six-point positioning assembly 8 is installed on the translation base 7 , and the six-point positioning assembly 8 passes through the through gr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com