A kind of quick-frozen food intelligent production equipment and production process

A technology for quick-frozen food and production equipment, which is applied in the fields of processing meat, food science, meat extrusion, etc., can solve the problems of big difference in the shape of meatballs, troubles in purchasing and selling, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] In order to further explain the technical solutions of the present invention, the following specific embodiments are described in detail.

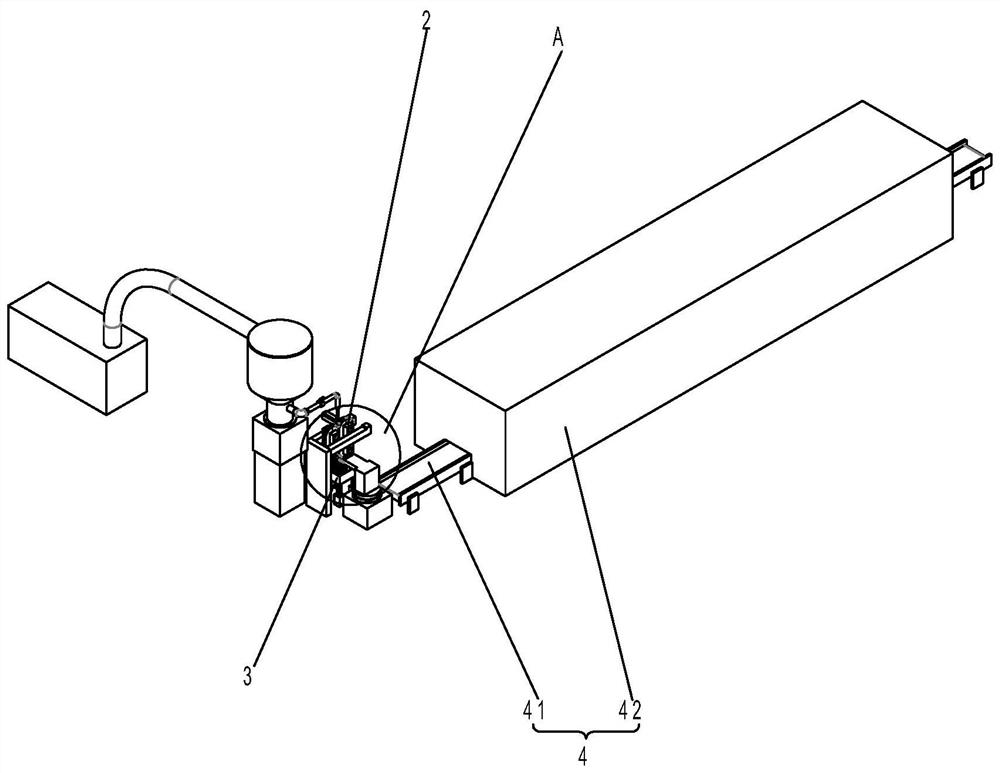

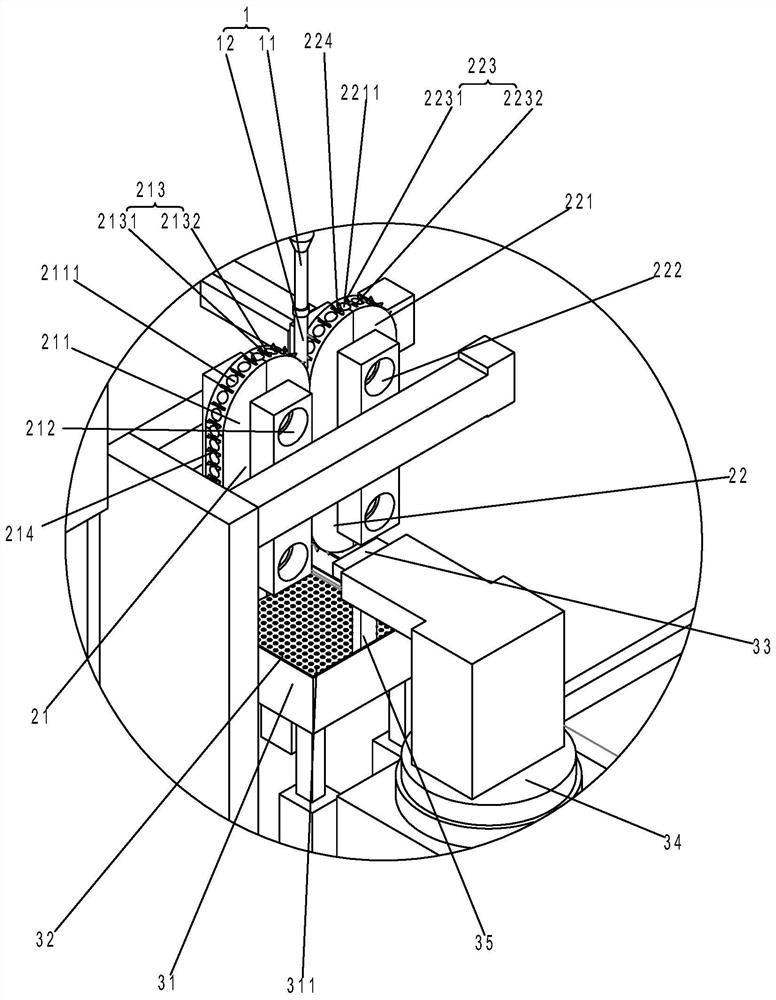

[0036] like figure 1 and figure 2 As shown, an intelligent quick-frozen food production equipment of the present invention includes a conveying device 1 for conveying fillings, a forming device 2 for shaping the fillings to form balls, and a heat setting device 3 for shaping the balls; the conveying device The output end of 1 and the input end of the molding device 2 are connected together, and the output end of the molding device 2 is connected with the input end of the heat setting device 3; The receiving part 32 for receiving the shaped balls, and the lift driving device 33 for driving the receiving part 32 to rise and fall; the upper surface of the hot water accommodating part 31 forms a hot water accommodating cavity, and the receiving part 32 is arranged in the hot water accommodating cavity Inside; the conveying device 1, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com