Oil absorbing device and method for surface oil layer treatment

An oil layer and oil suction pipe technology, which is applied in the field of oil-water separation, can solve the problems of inability to realize low-cost recovery, and the oil product stays in the removal and processing stage, and achieves the effects of good oil product collection effect, low cost and simple structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

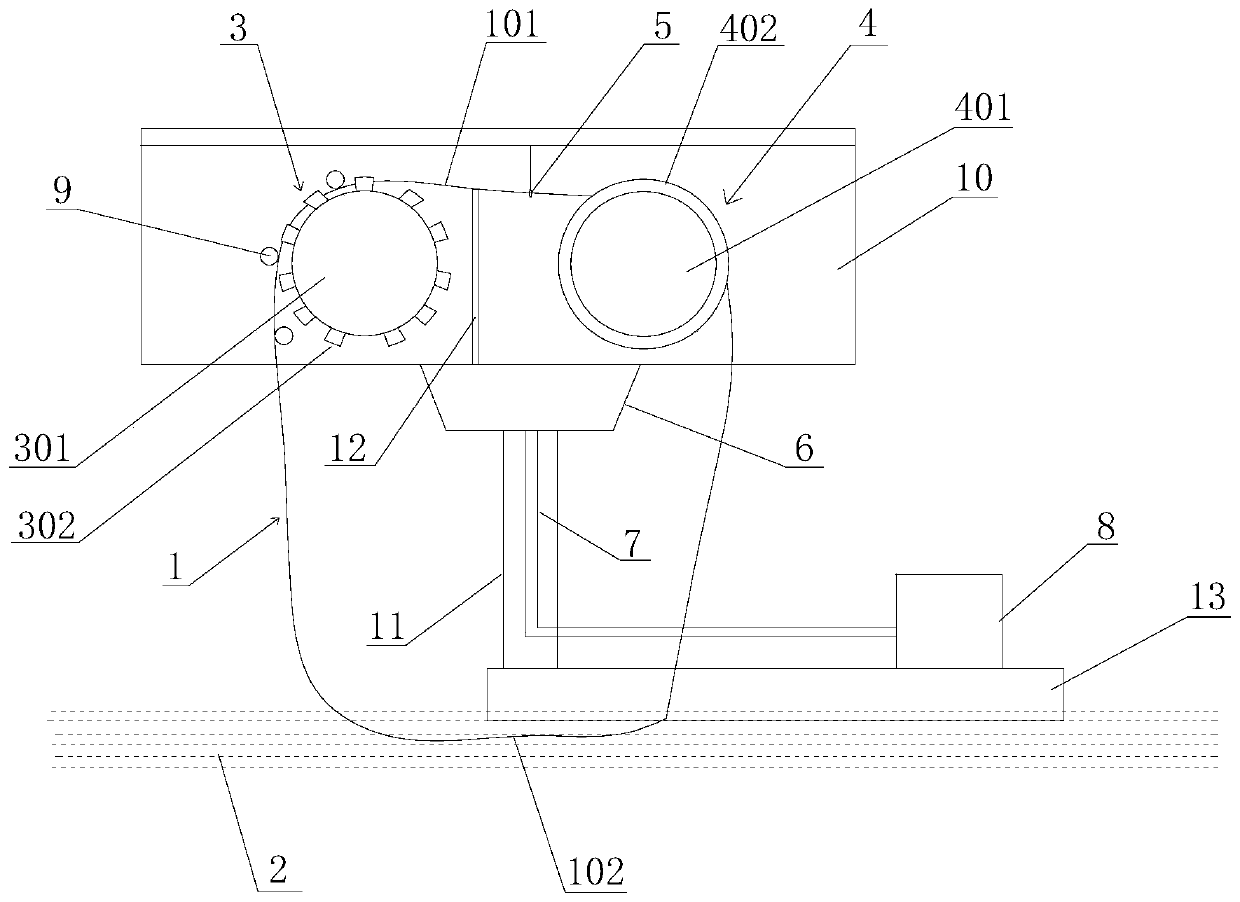

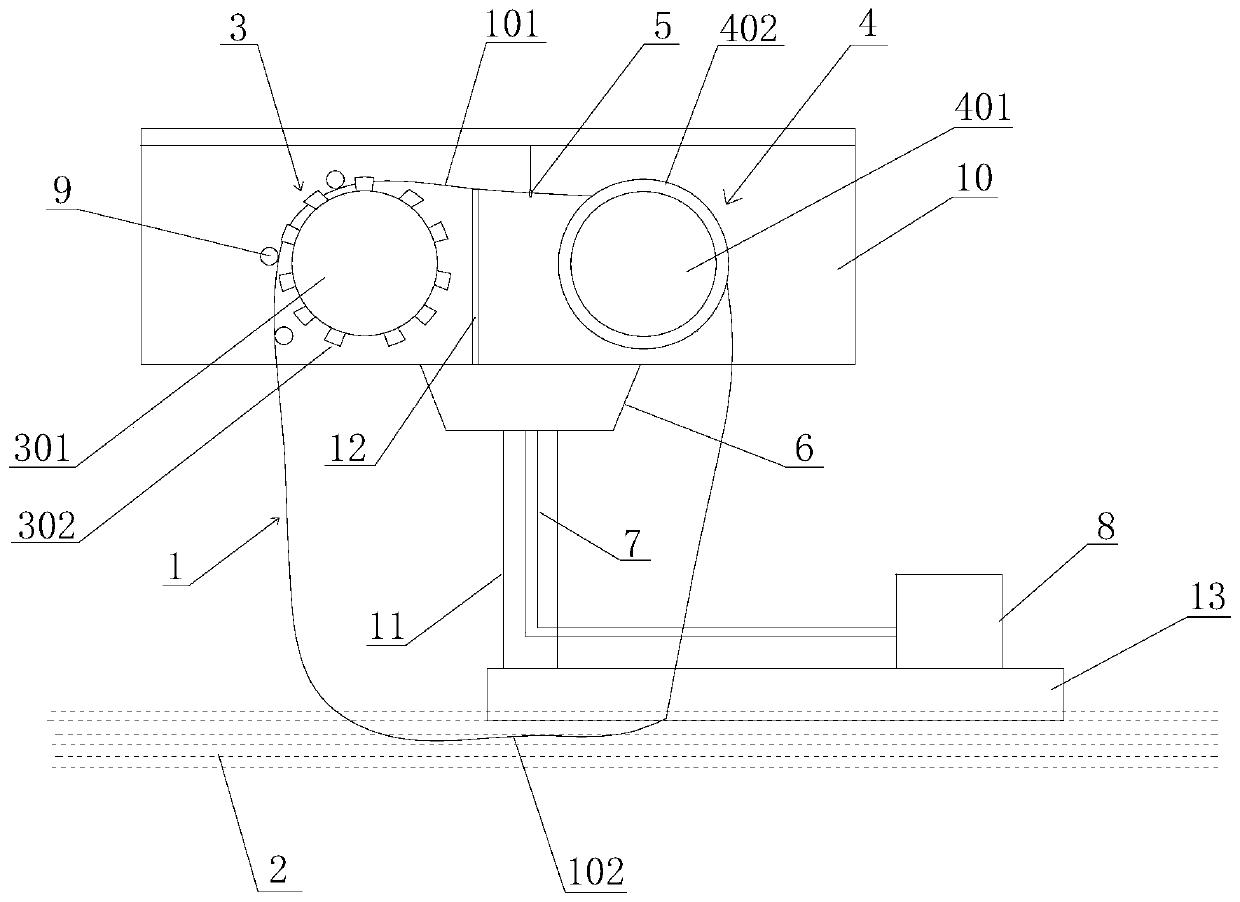

[0025] With reference to the accompanying drawings, an oil suction device for surface oil layer treatment includes an oil suction pipe 1 for carrying oil on the surface and a driving device for driving the oil suction pipe to rotate circularly. The oil suction pipe 1 is in a closed ring shape, the top section 101 of the oil suction pipe is connected to the driving device, and the bottom section 102 of the oil suction pipe sags naturally under its own gravity and is in the oil-water interface layer 2 . The driving device includes a driving wheel 3 and a driven wheel 4 , the driving wheel 3 is in transmission connection with the driving motor, and the top segment body 101 of the oil suction pipe rides on the driving wheel 3 and the driven wheel 4 . An oil drain ring 5 is arranged between the driving wheel and the driven wheel, and the oil drain ring 5 is set on the outside of the oil suction pipe, and an oil pan 6 is arranged at the bottom of the oil drain ring, and the bottom of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com