Cold-patch additive material and preparation method and application thereof

An additive material and cold patching technology, applied in building insulation materials, building components, buildings, etc., can solve the problems of road surface damage, low initial strength of cold patched asphalt mixture, and inability to resist vehicles, etc., to improve storage and workability , good durability and bonding performance, and the effect of saving secondary repair costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

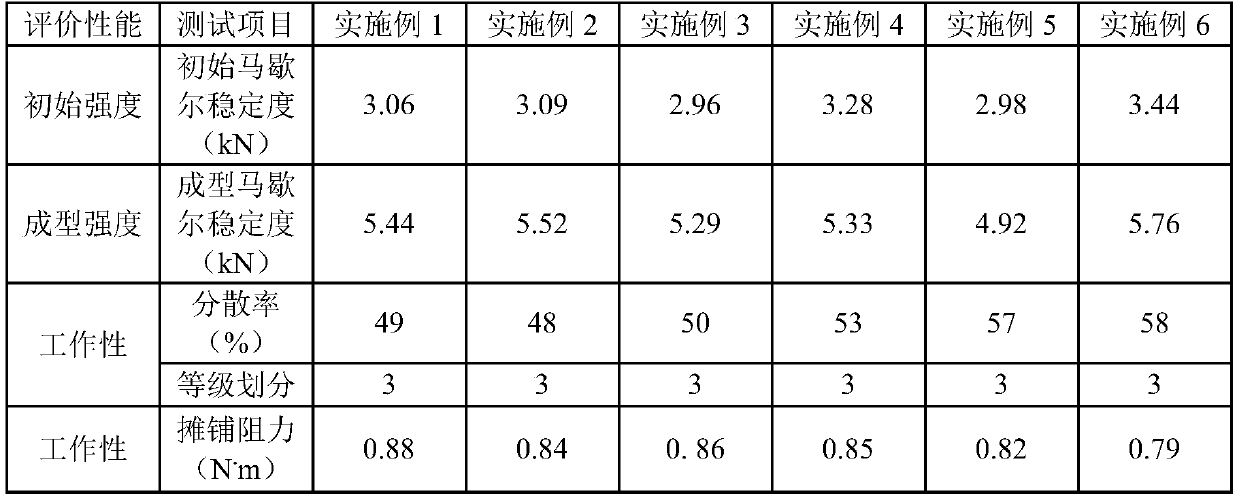

Examples

preparation example Construction

[0023] The preparation method of the cold patching additive material of the present invention comprises the following steps,

[0024] Step 1, in terms of mass percentage, respectively weighing 17%-20% of trichlorethylene, 11%-16% of SBS, 13%-21% of clear oil, 42%-46% of diesel oil, and 9%-13% of EVA;

[0025] Step 2, according to the mass percentage in step 1, add SBS to the trichlorethylene, fully stir on the high-speed shear until there is no solid residue in the trichlorethylene, generally at a stirring speed of 1000 to 2000 rpm Stir in the container for 20-30 minutes to prepare prepolymer A, which can improve the cohesiveness of modified asphalt mixture;

[0026] Step 3, according to the mass percentage in step 1, add EVA to the diesel oil, fully stir on the high-speed shearing instrument until there is no solid residue in the diesel oil, generally stir in a stirrer with a speed of 1000-2000 rpm for 20- It takes only 30 minutes to prepare prepolymer B. Prepolymer B can im...

Embodiment 1

[0029] The cold repair additive of the present invention is prepared from trichlorethylene, SBS, clear oil, diesel oil and EVA, and its mass percentage composition is: 20% of trichlorethylene, 16% of SBS, 13% of clear oil, 42% of diesel oil and 9% of EVA.

[0030] The preparation method of the cold patch additive material comprises the following steps,

[0031] Step 1, by mass percentage, take respectively 20% of trichlorethylene, SBS 16%, clear oil 13%, diesel oil 42% and EVA 9%;

[0032]Step 2, according to the mass percentage in step 1, add SBS in the trichlorethylene solution, fully stir in the high-speed shearing instrument, until there is no solid residue in the trichlorethylene, generally in a stirrer with a rotating speed of 1000 rpm Stir in medium for 30 minutes to obtain prepolymer A;

[0033] Step 3, according to the mass percentage in step 1, add EVA in the diesel oil, fully stir in the high-speed shearing instrument, until there is no solid residue in the diesel ...

Embodiment 2

[0037] The cold repair additive of the present invention is prepared from trichlorethylene, SBS, clear oil, diesel oil and EVA, and its mass percentage is composed of: trichloroethylene 17%, SBS 11%, clear oil 21%, diesel oil 42%,

[0038] EVA9%.

[0039] The preparation method of the cold patch additive material comprises the following steps,

[0040] Step 1, by mass percentage, take respectively 17% of trichlorethylene, SBS 11%, clear oil 21%, diesel oil 42% and EVA 9%;

[0041] Step 2, according to the mass percentage in step 1, add SBS in the trichlorethylene solution, fully stir in the high-speed shearing instrument, until there is no solid residue in the trichlorethylene, until there is no solid residue in the trichlorethylene, generally Stir in a stirrer at 1400 rpm for 25 minutes to obtain prepolymer A;

[0042] Step 3, according to the mass percentage in step 1, add EVA in the diesel oil, fully stir in the high-speed shearing instrument, until there is no solid resi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com