Heating washing device used for toilet

A technology for utensils and toilets, applied in the field of sanitation facilities, can solve problems such as electricity safety, residual washing liquid, and low heating efficiency, and achieve the effects of ensuring safe use, improving safety performance, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

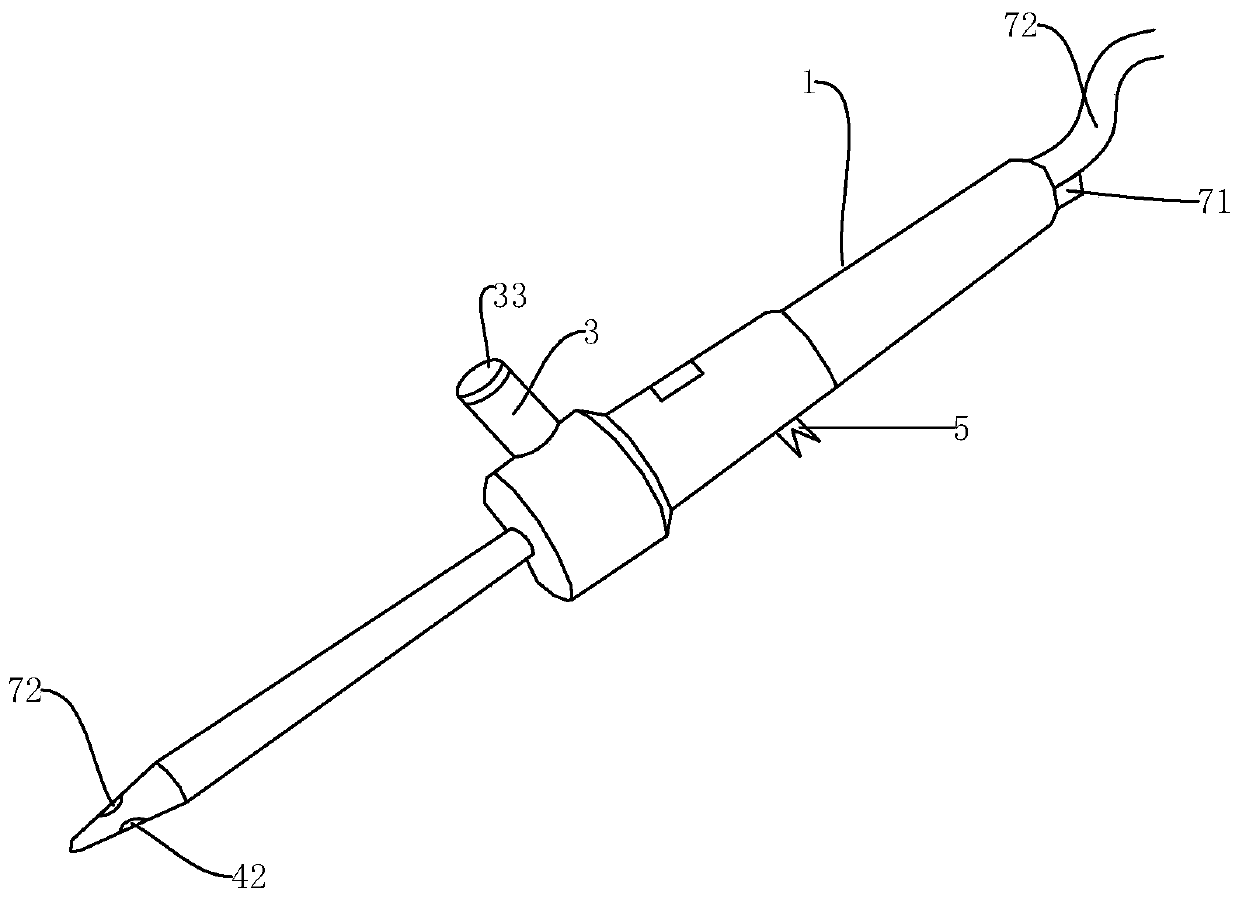

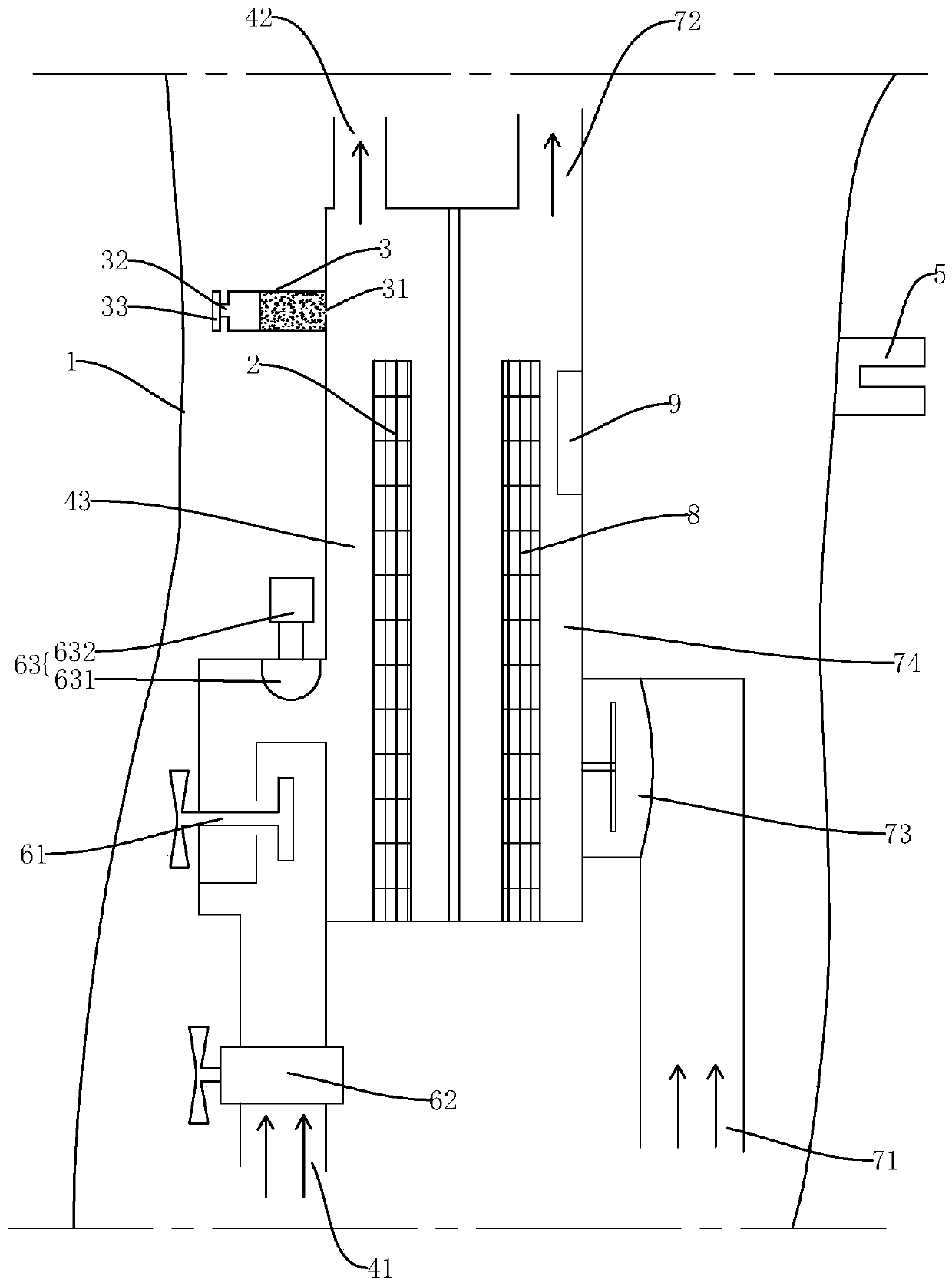

[0031] like Figure 1-Figure 4 As shown, a heating and cleaning appliance for a toilet includes a housing 1, a first heating component 2, and a liquid storage cavity 3. The specific shape of the housing 1 is not limited here, and it can preferably be similar to a commonly used shower head, and A handle is provided on the surface of the housing 1 , and a heat insulating material, such as heat insulating silica gel, etc. may be provided on the surface of the housing 1 to improve the user's comfort during use.

[0032] The housing 1 is provided with a water inlet 41 that can communicate with an external water supply source, a water outlet 42 that outputs water, and a water delivery inner chamber 43 that communicates with the water inlet 41 and the water outlet 42 respectively;

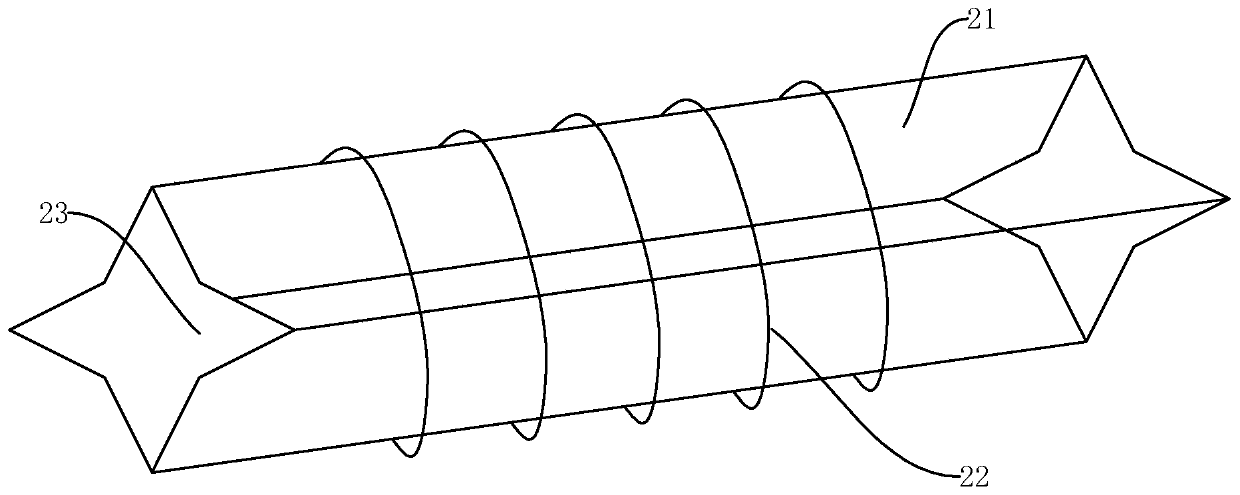

[0033] The first heating component 2 is arranged in the water delivery cavity 43 to heat the water body to be delivered;

[0034] The liquid storage chamber 3 can store washing liquid and air. The liquid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com