Inner oil sump with bimetallic-strip temperature control structure

A technology of bimetal sheet and oil pan, applied in the direction of oil pan, engine lubrication, engine components, etc., can solve the problems of opening lag, easy damage, high cost, etc., to prevent oil cracking, ensure normal driving, and install quickly Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

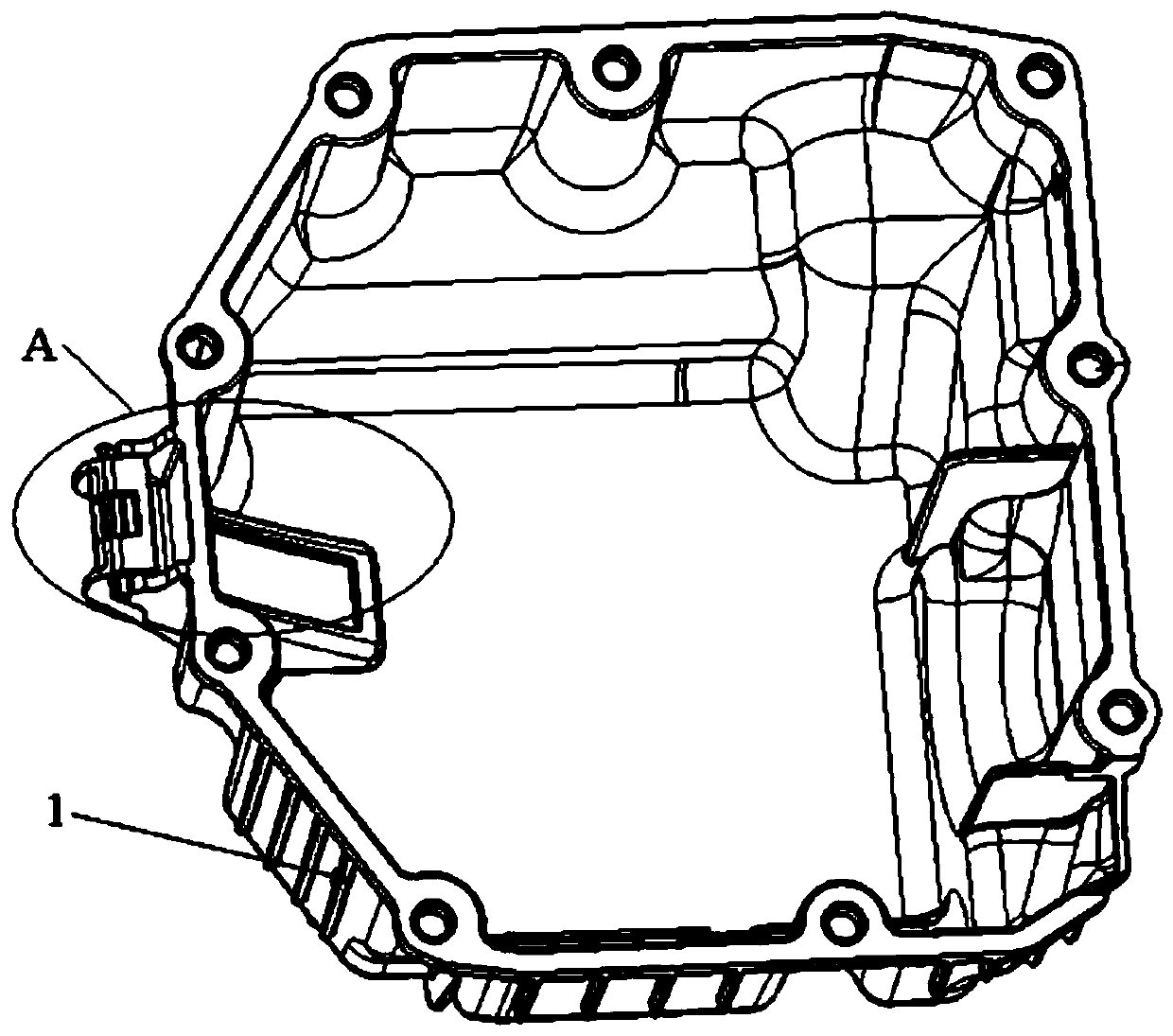

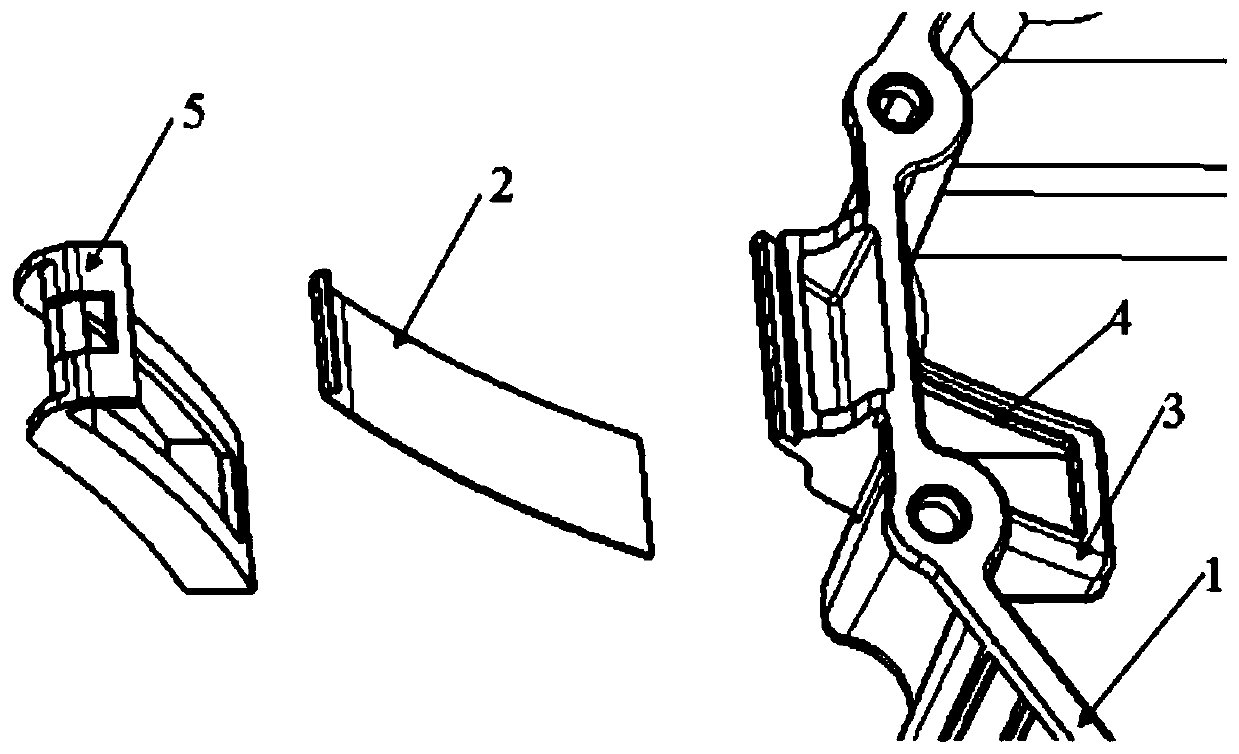

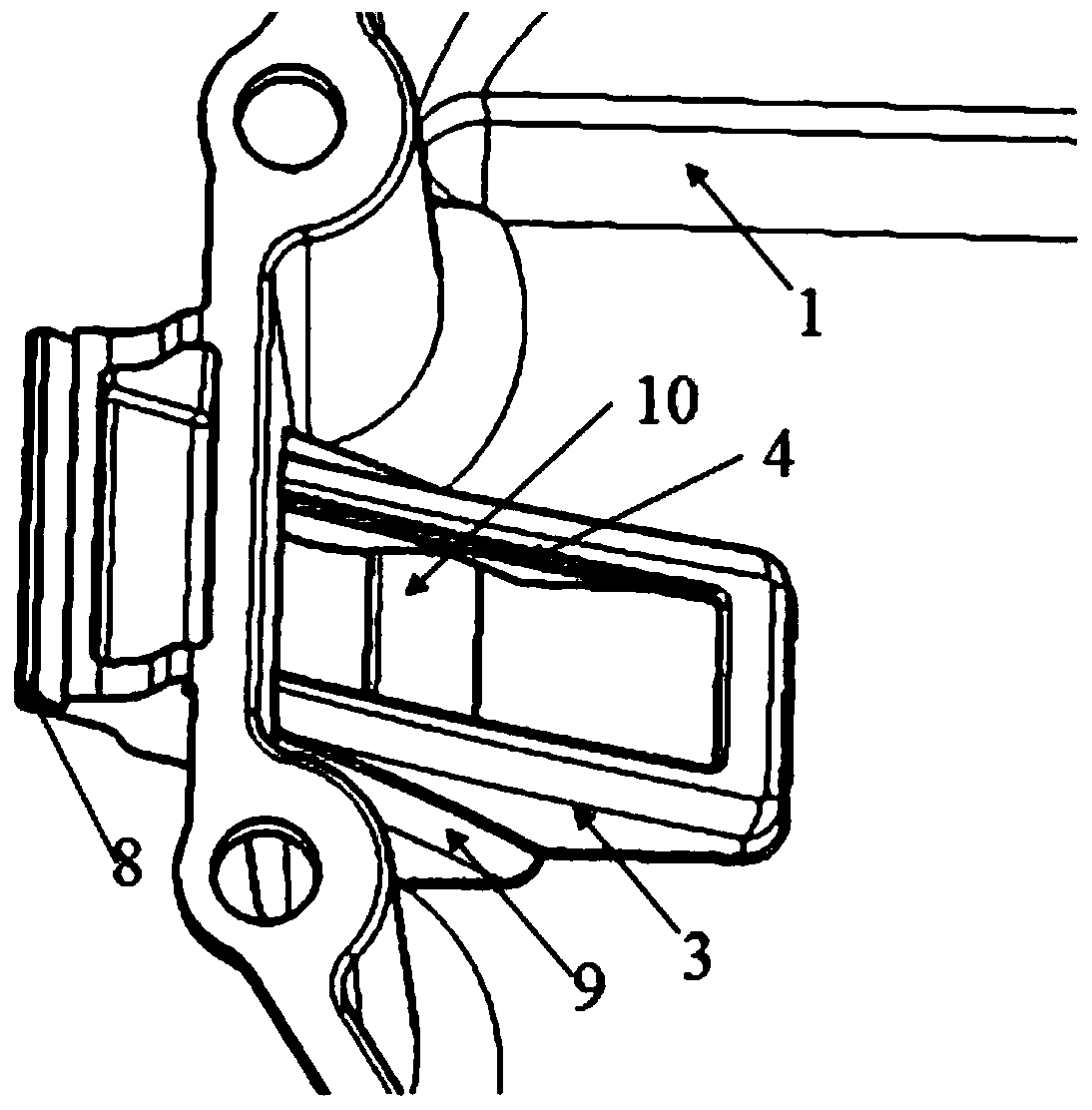

[0035] Such as Figure 1-7 As shown, the present invention provides an inner oil pan with a bimetal temperature control structure, including a casing 1 and a bimetal assembly, the bimetal assembly includes a claw 5 and a bending deformation along the length direction when heated. The bimetal 2, the housing 1 is concave from the side downwards to form the installation groove 3 on both sides of the groove wall to limit the bimetal 2 in the width direction, and the bottom of the installation groove 3 is provided with a drain hole 4 and the bimetal 2 is at room temperature The bottom of the fitting groove closes the drain hole 4; the mounting groove 3 is also provided with a claw 5 that fixes the top of the bimetal 2, and the claw 5 extends toward the tail end of the bimetal 2 and gradually moves away from the drain hole 4. When the bime...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com