A speed-adaptive air volume adjustment method for reciprocating compressors

A gas volume adjustment and compressor technology, which is applied to mechanical equipment, machines/engines, liquid variable capacity machinery, etc., can solve problems such as difficult real-time adjustment of gas volume, inaccurate gas volume control, and poor adjustment effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] The principle and implementation of the present invention will be described in detail below in conjunction with the accompanying drawings.

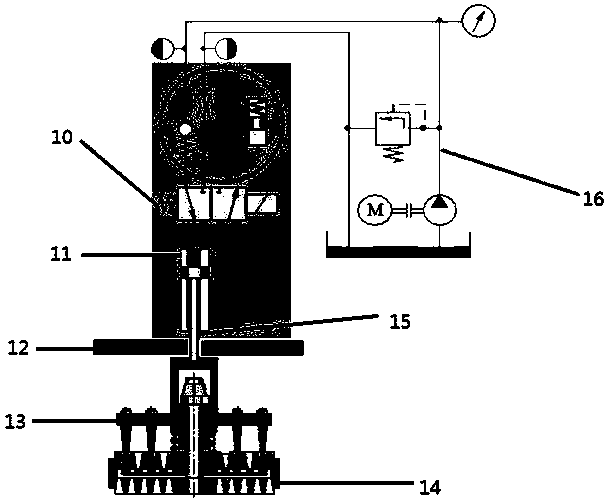

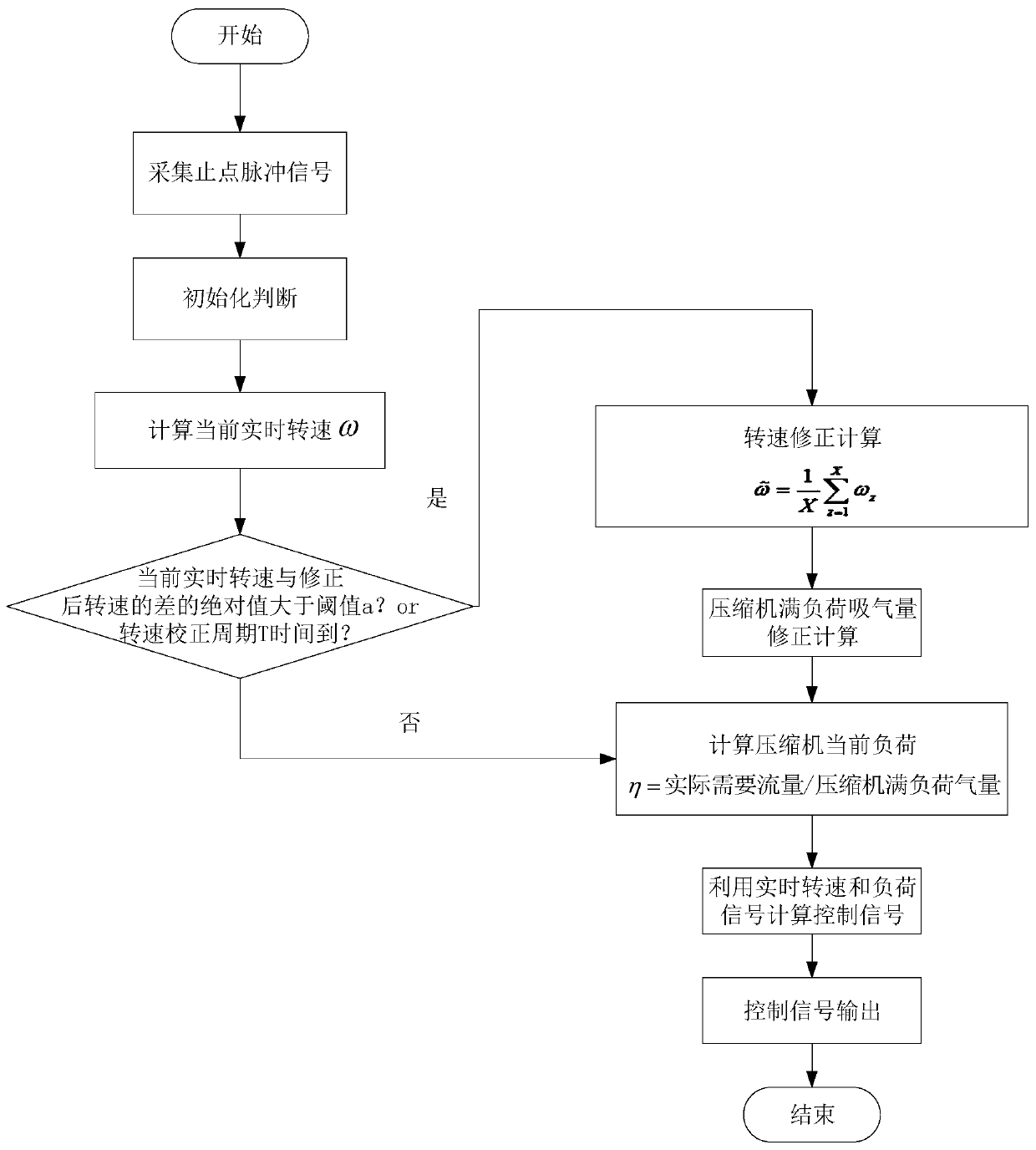

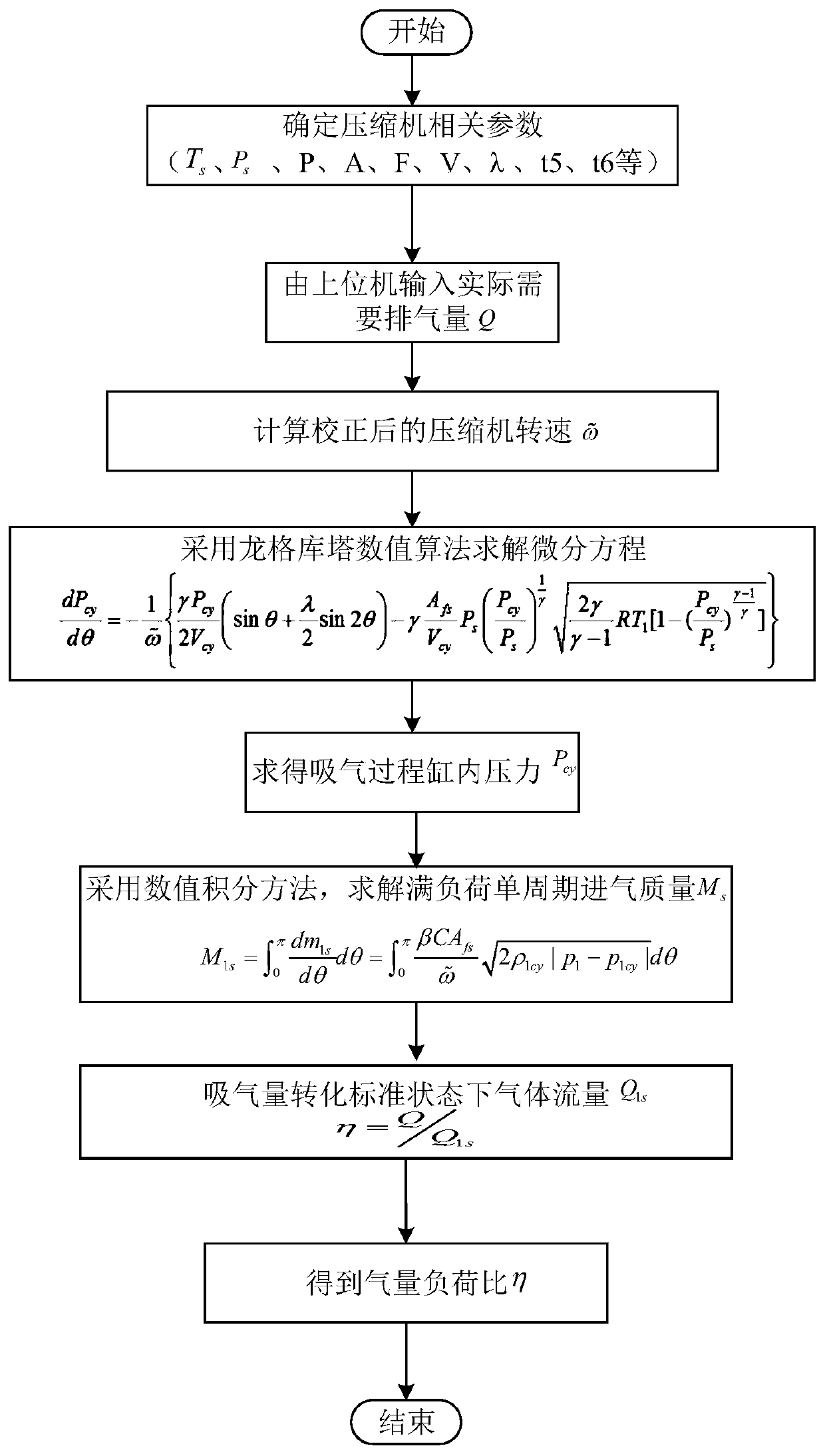

[0052] The present invention relates to a speed-adaptive reciprocating compressor gas volume adjustment method, its main logic flow chart is shown in Figure 1, which mainly includes stop pulse signal acquisition, current real-time speed calculation, average running speed correction, primary load ratio Adaptive correction, control signal adaptive calculation output and other parts. Specifically implemented in a two-stage two-cylinder natural gas reciprocating compressor, all the intake valves of the first and second stages of the compressor are equipped as follows figure 2 The executive unloader device shown in the figure adjusts the load of the unit by adjusting the ejection control signal and the timing of the ejection signal output to achieve the effect of controlling the exhaust volume. The unit displacement control method of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com