Substrate heating device and substrate heating method

A heating device and heating method technology, applied in the direction of lighting and heating equipment, furnaces, instruments, etc., to achieve the effects of suppressing the reduction of uniformity in the plane, preventing sublimation pollution, and suppressing changes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

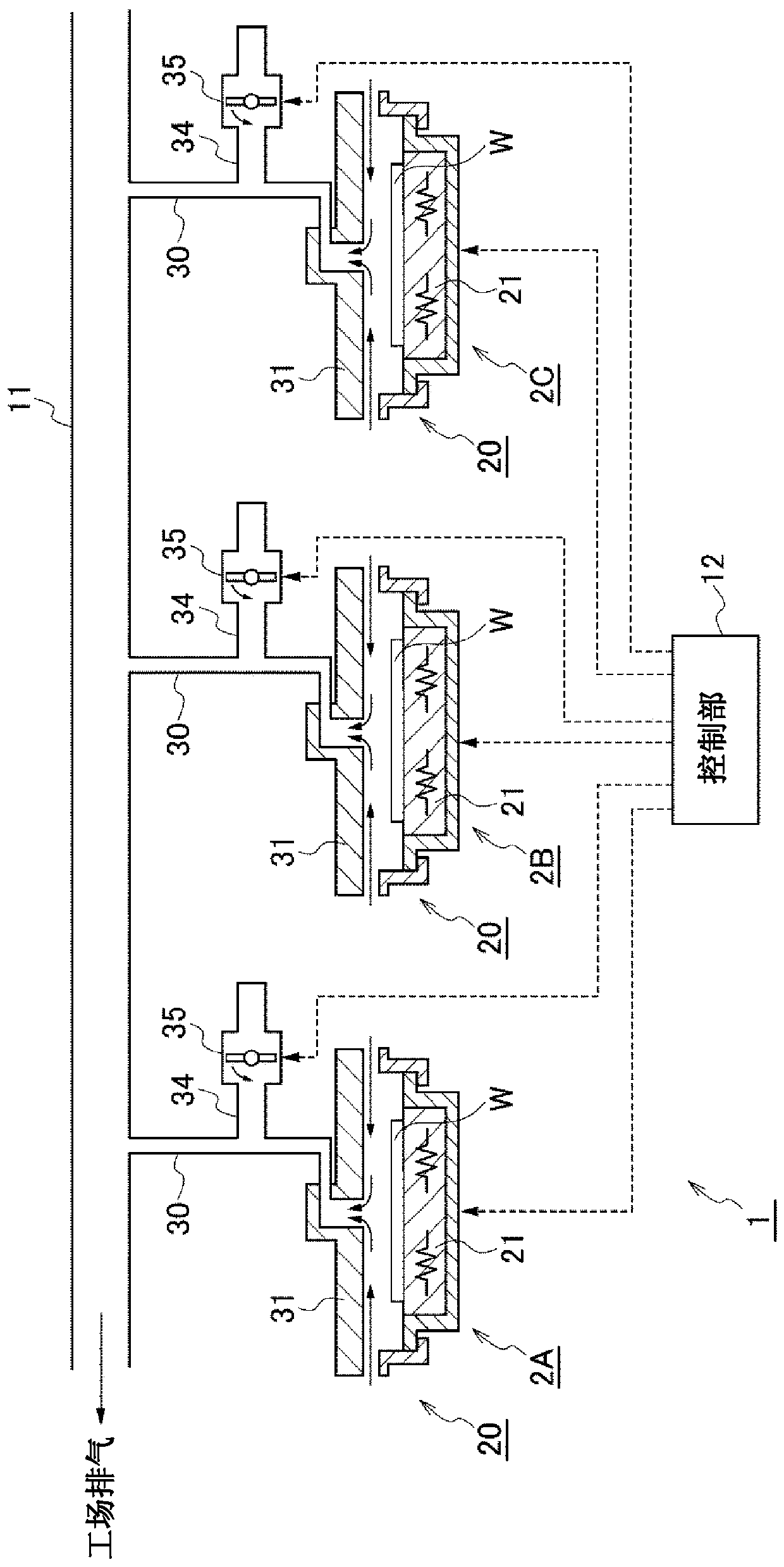

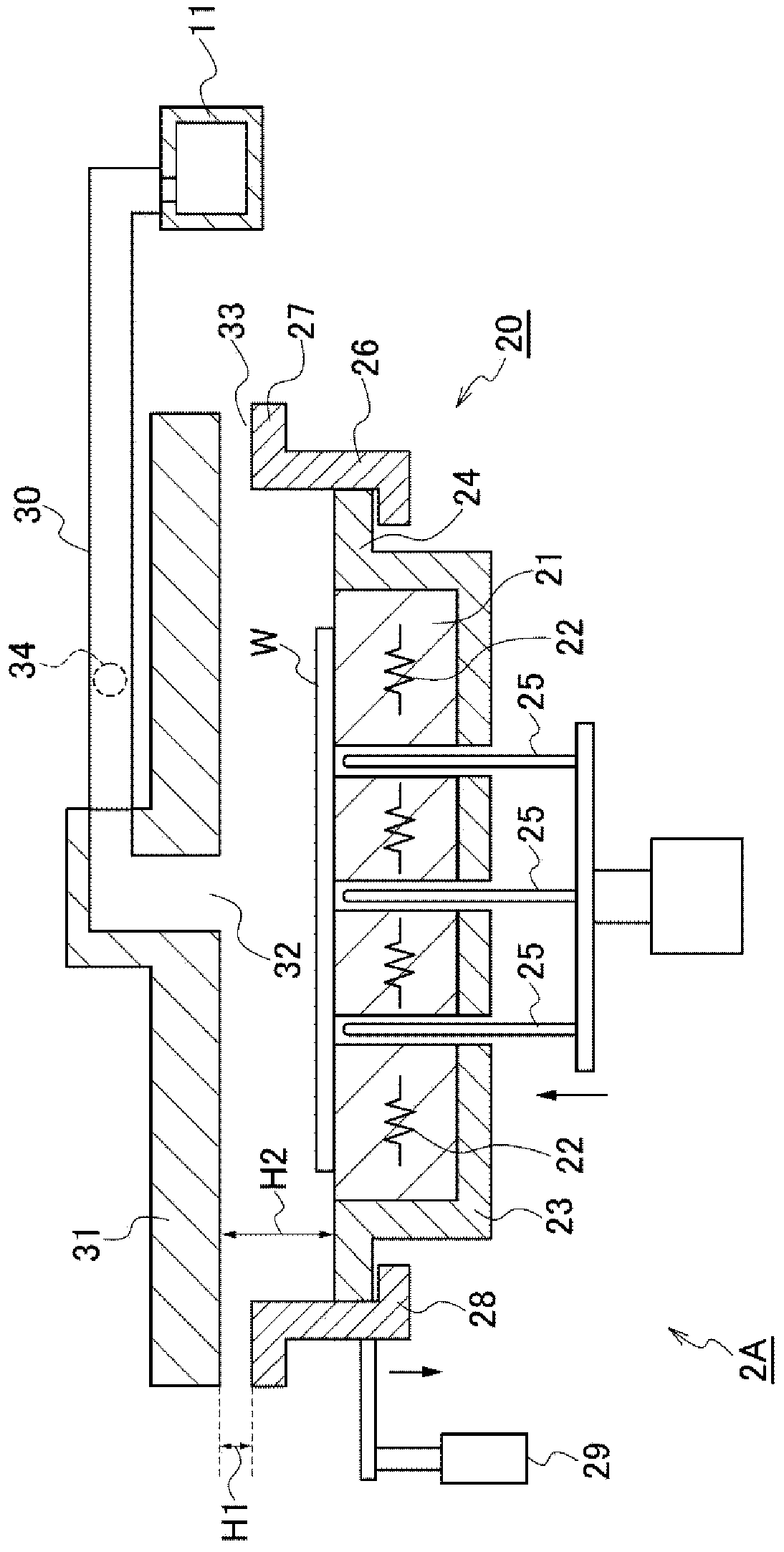

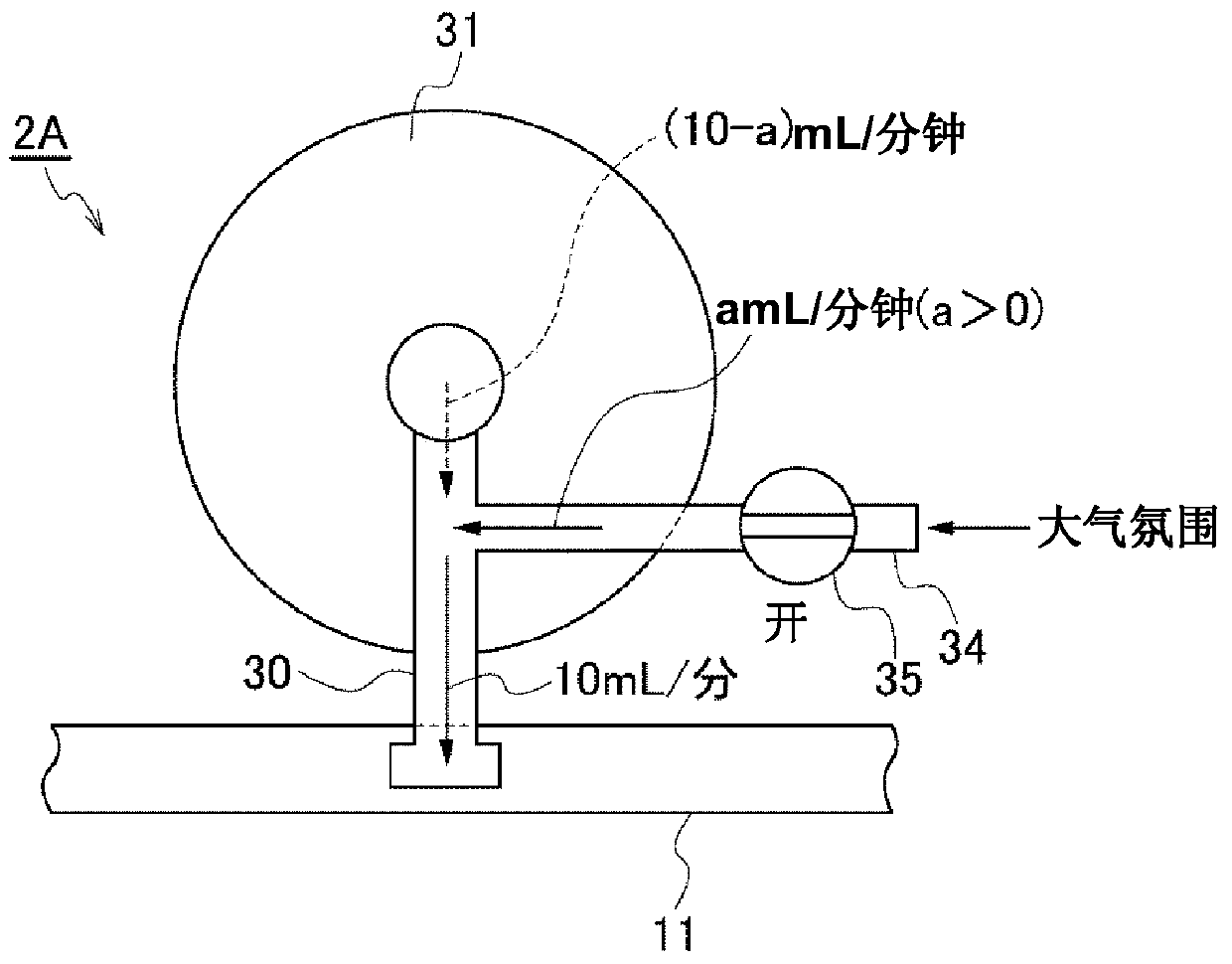

[0055] refer to figure 1 The schematic configuration diagram of FIG. 10 illustrates a wafer W heating apparatus 1 according to an embodiment of the present invention. The heating device 1 heats the wafer W whose surface is coated with a chemical solution on the outside of the heating device 1 . In this example, the diameter of the wafer W is 300 mm. In addition, the chemical solution contains a relatively low molecular weight polymer (low molecular weight polymer) and a cross-linking agent, for example, by heating to 250°C, the cross-linking reaction of the above-mentioned polymer occurs to form a so-called chemical compound containing carbon as a main component. Organic film of SOC film. The content of carbon in the organic film is, for example, 90% or more. In addition, after heat treatment by the heating device 1 on the organic film, a film containing silicon oxide called an SOG film and a resist film are sequentially laminated outside the heating device 1 . The pattern...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com