Double-valve-seat regulating ball valve

A technology of regulating ball and double valve seat, which is applied in the field of regulating valves, can solve the problems of large rotating torque of the valve stem and wear of the valve core of the ball valve, and achieve the effect of reducing the rotating torque, reducing friction and improving the adjustment accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

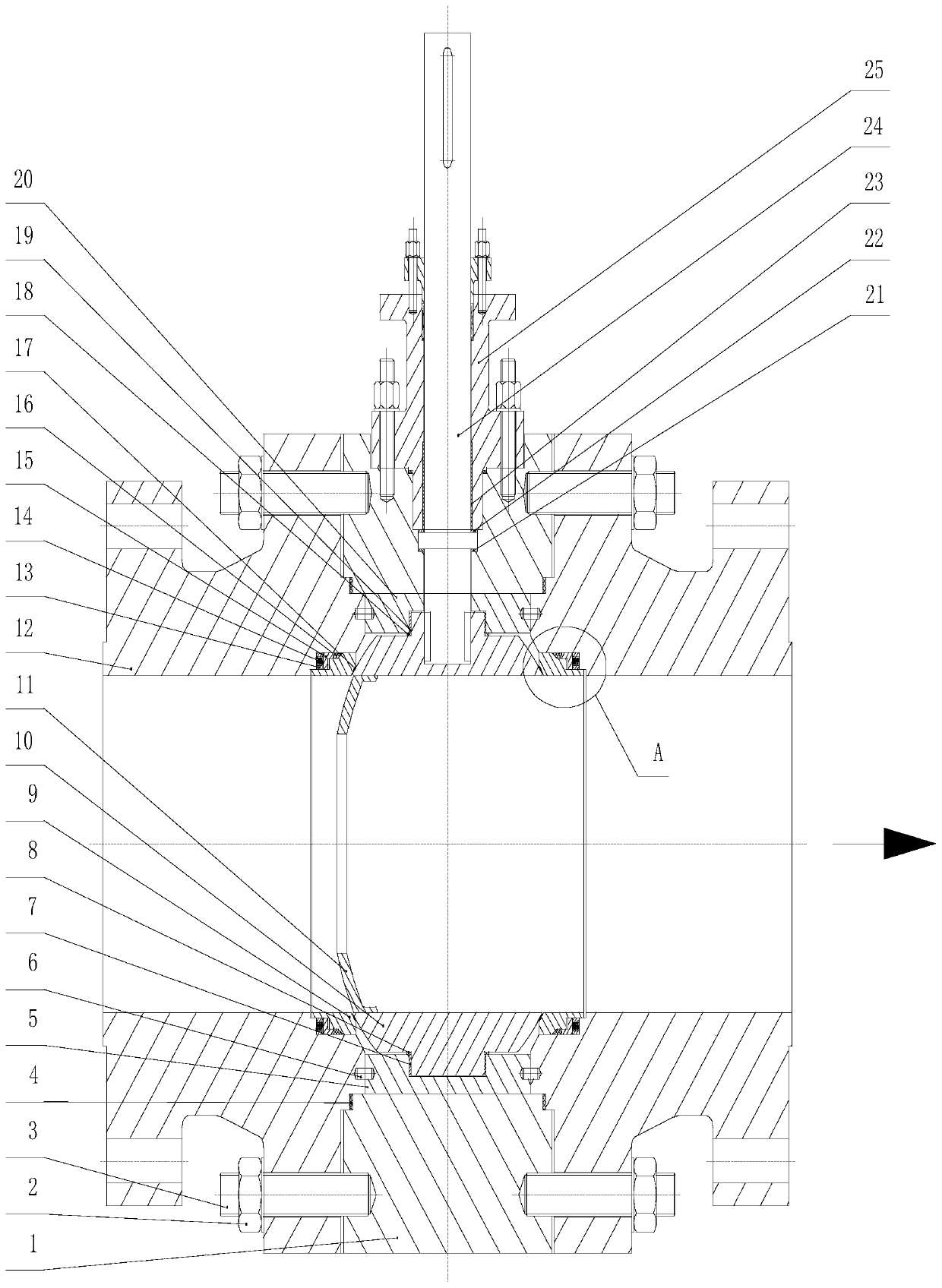

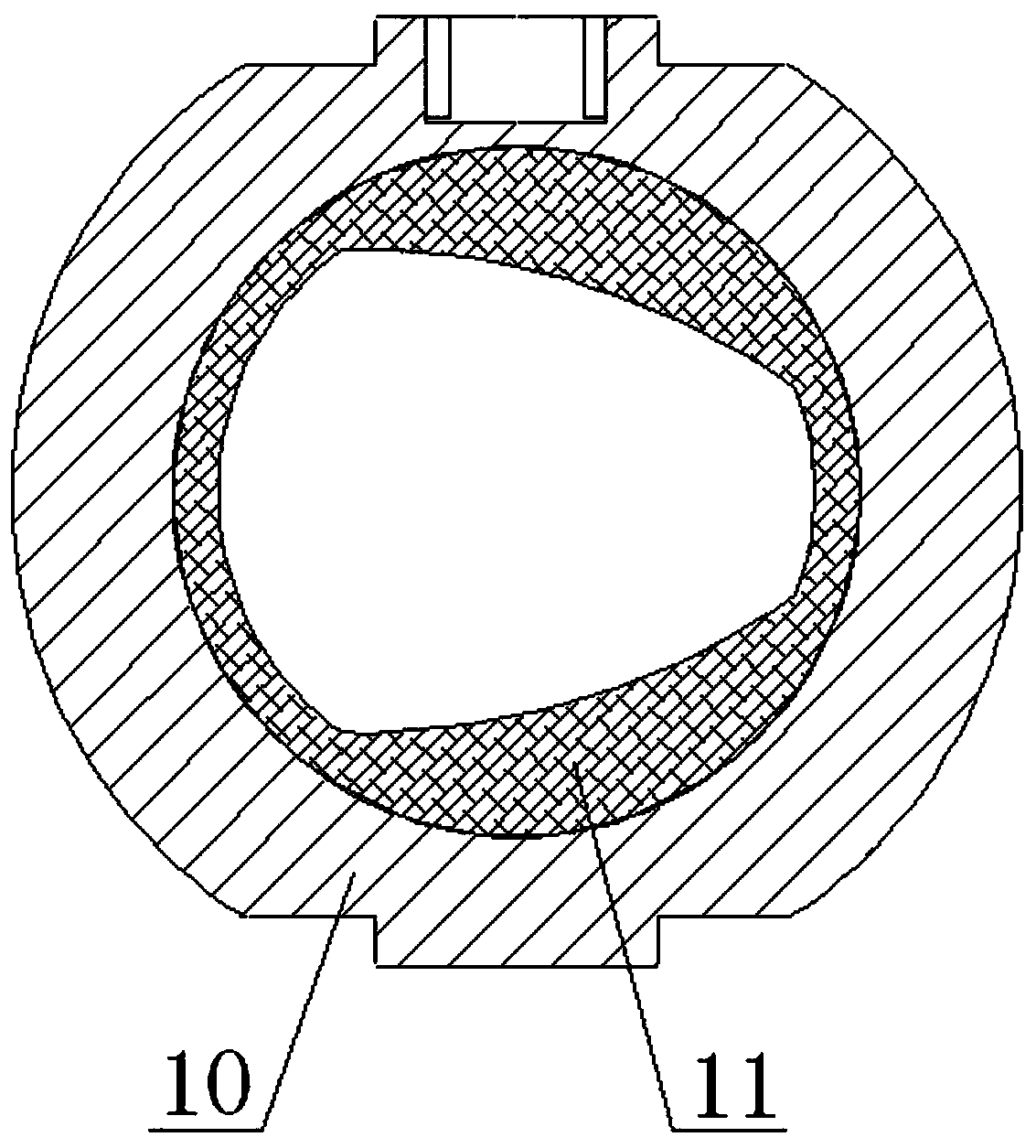

[0029] Such as figure 1 and figure 2 A double-seat regulating ball valve shown includes a valve body, a valve seat, and a valve core. The valve body includes a main valve body 1 and two auxiliary valve bodies 12 respectively fixed on both sides of the main valve body 1; There are two valve seats 9, the valve seats 9 are located between the two auxiliary valve bodies 12, and the two valve seats 9 are located on opposite sides of the valve body in the radial direction; the valve core is located between the two valve seats 9. This embodiment adopts a double valve seat structure, which is suitable for high temperature, high pressure and frequently changing working conditions. It can avoid valve locking caused by deformation of valve trim under high temperature and high pressure working conditions, and significantly improve the two-way sealing performance of the valve.

Embodiment 2

[0031] Such as Figure 1 to Figure 3A double-seat regulating ball valve shown includes a valve body, a valve seat, and a valve core. The valve body includes a main valve body 1 and two auxiliary valve bodies 12 respectively fixed on both sides of the main valve body 1; There are two valve seats 9, the valve seats 9 are located between the two auxiliary valve bodies 12, and the two valve seats 9 are located on opposite sides of the valve body in the radial direction; the valve core is located between the two valve seats 9.

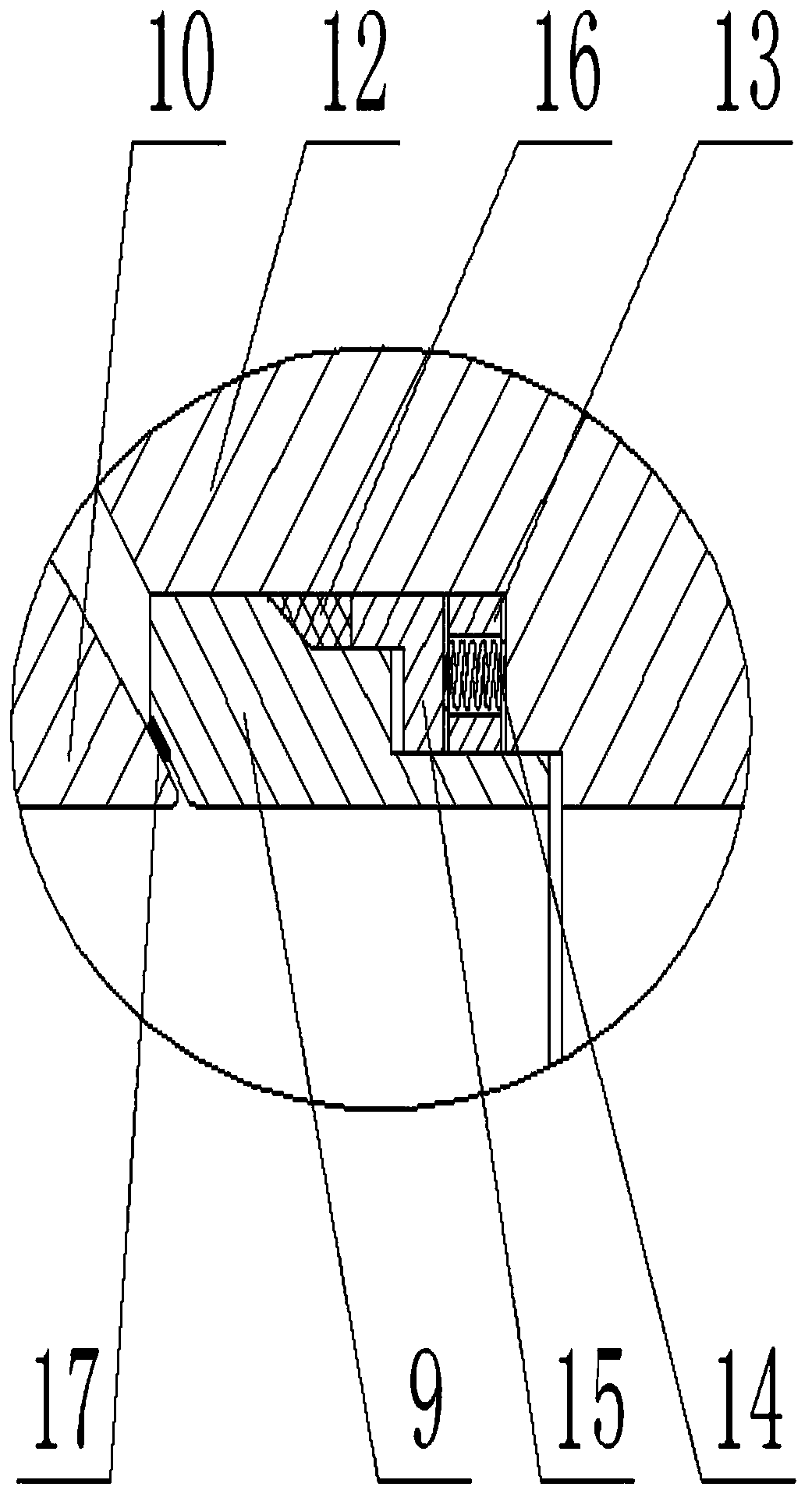

[0032] The main valve body 1 and the auxiliary valve body 12 are fixedly connected by bolts 3 , and a sealing gasket 4 is arranged between the main valve body 1 and the auxiliary valve body 12 . The valve seat 9 is installed in the auxiliary valve body 12 through the valve seat bracket 15; several groups of springs 14 are evenly distributed along the circumferential direction between the valve seat 9 and the auxiliary valve body 12, and the two ends of the ...

Embodiment 3

[0040] Such as Figure 1 to Figure 3 A double-seat regulating ball valve shown includes a valve body, a valve seat, and a valve core. The valve body includes a main valve body 1 and two auxiliary valve bodies 12 respectively fixed on both sides of the main valve body 1;

[0041] There are two valve seats 9, the valve seat 9 is located between the two auxiliary valve bodies 12, and the two valve seats 9 are located on opposite sides in the radial direction of the valve body; the valve core is located between the two valve seats 9 between. The main valve body 1 and the auxiliary valve body 12 are fixedly connected by bolts 3 , and a sealing gasket 4 is arranged between the main valve body 1 and the auxiliary valve body 12 . The valve seat 9 is installed in the auxiliary valve body 12 through the valve seat bracket 15; several groups of springs 14 are evenly distributed along the circumferential direction between the valve seat 9 and the auxiliary valve body 12, and the two ends...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com