Early warning method for judging defect of kinematic pair of mechanical equipment through variable value

A technology of mechanical equipment and kinematic pair, which is applied to the early warning of mechanical equipment kinematic pair defects and the early warning field of variable value judgment of mechanical equipment kinematic pair defects. The effect of avoiding the phenomenon of missed alarm

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] The present invention is implemented on the coal crusher equipment of a power plant in a certain city in Liaoning, China, and monitors the coal crusher equipment bearings.

[0053] (1) Obtain the ambient temperature T of the kinematic pair of the coal crusher hi

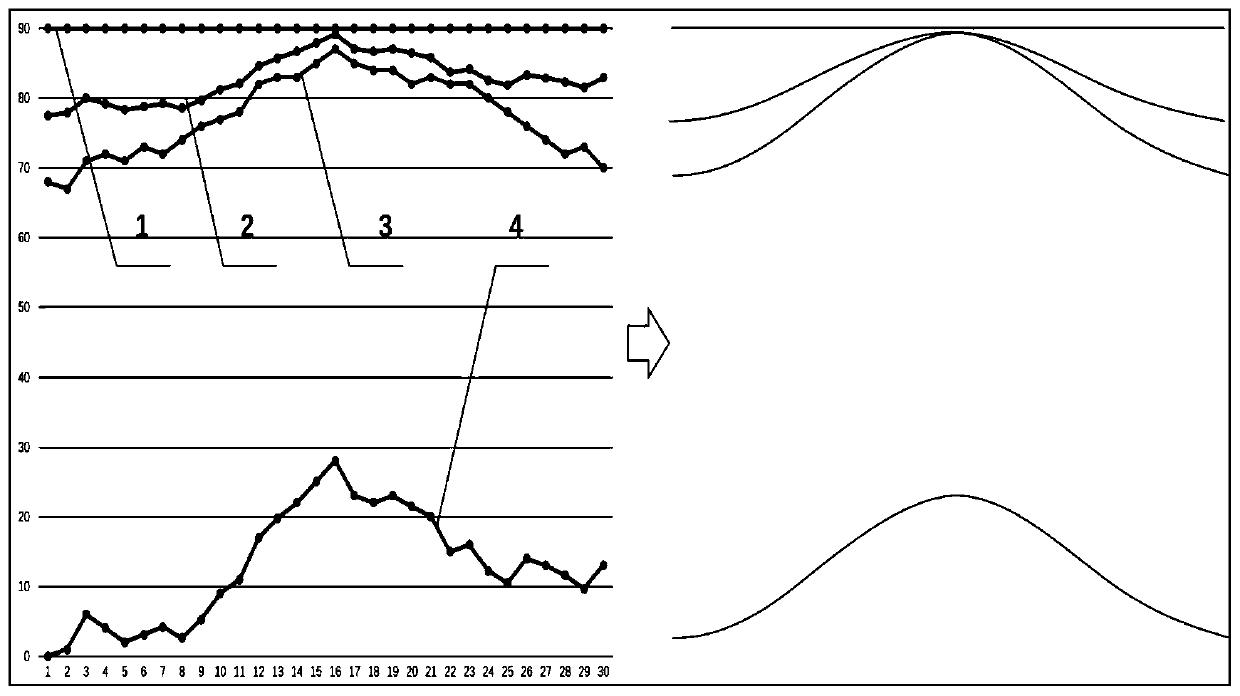

[0054] Select the upper bearing end cover of the non-operating coal crusher equipment that is mutually prepared with the running coal crusher equipment as the effective point of the ambient temperature, and obtain the ambient temperature T of the coal crusher equipment through the measurement of the effective point of the ambient temperature hi , see figure 1 Curve 4 in

[0055] (2) Obtain the working temperature T of the motion pair fi

[0056] Select the bearing end cover of the running coal crusher equipment as the effective point of the working temperature of the kinematic pair, and obtain the working temperature T of the kinematic pair by measuring the effective point of the kinematic pair fi , see ...

Embodiment 2

[0064] The invention is implemented on the belt conveyor driven roller equipment of a power plant in a certain city in Jilin, China, to monitor the belt conveyor driven roller bearings.

[0065] (1) Obtain the ambient temperature T of the kinematic pair of the driven roller equipment of the belt conveyor hi

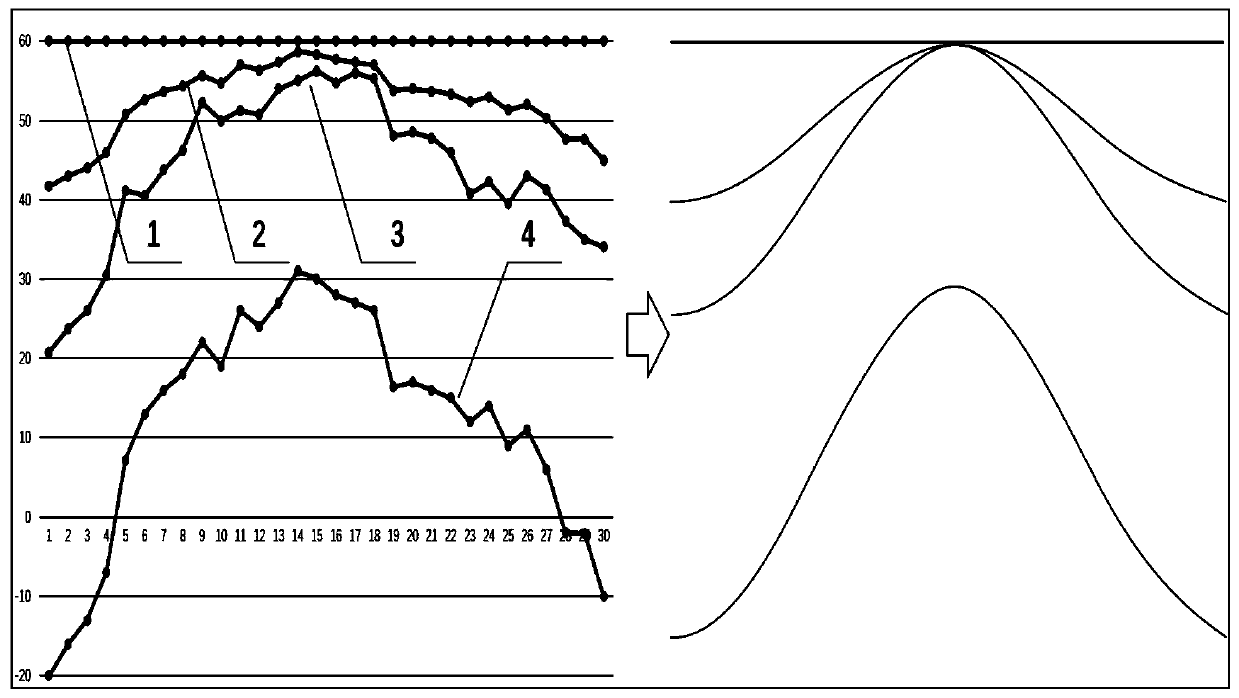

[0066] Select the upper bearing end cover of the non-operating belt conveyor driven pulley equipment that is mutually prepared with the driven pulley equipment of the belt conveyor as the effective point of the ambient temperature, and obtain the ambient temperature T of the driven pulley equipment of the belt conveyor by measuring the effective point of the ambient temperature hi , see figure 2 Curve 4 in

[0067] (2) Obtain the working temperature T of the motion pair fi

[0068] Select the bearing end cover on the driven pulley equipment of the running belt conveyor as the effective point of the working temperature of the kinematic pair, and obtain the working tem...

Embodiment 3

[0076] The invention is implemented on a cantilever belt reducer of a bucket wheel stacker and reclaimer in a certain port of a certain city in Hebei, China, and monitors the high-speed shaft of the reducer.

[0077] (1) Obtain the ambient temperature T of the motion pair of the reducer hi

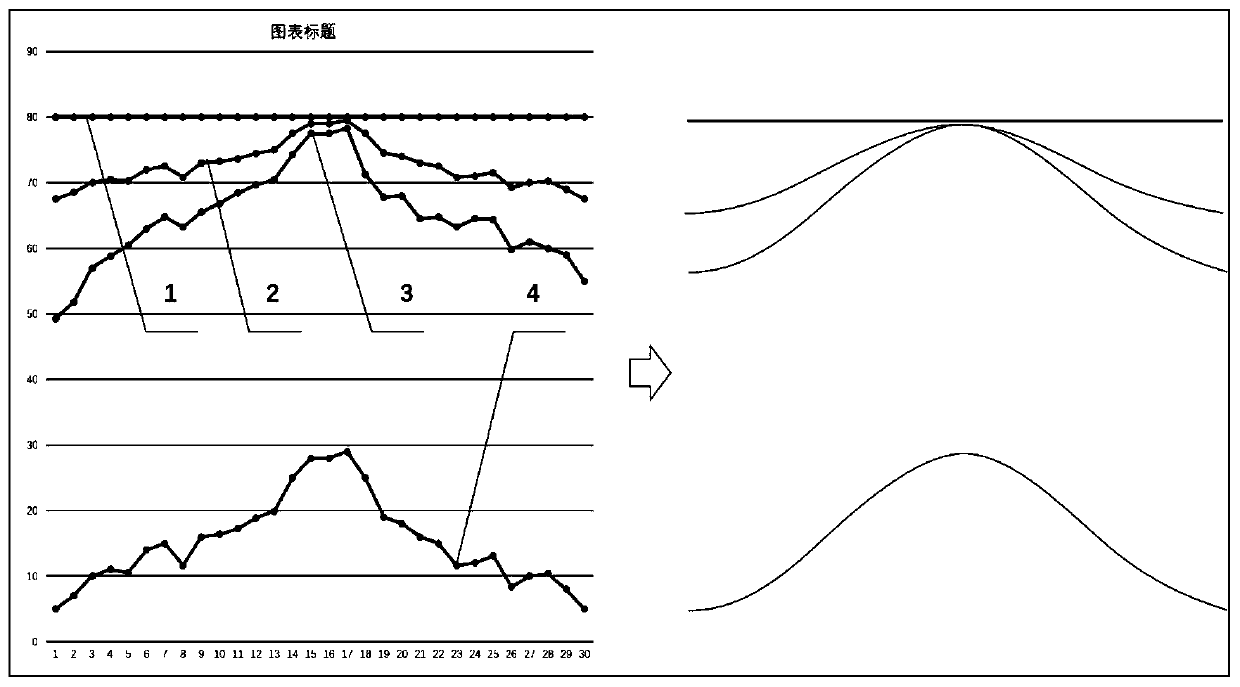

[0078] The steel structure of the support seat of the reducer is selected as the effective point of the ambient temperature, and the ambient temperature T of the reducer is obtained by measuring the effective point of the ambient temperature hi , see image 3 Curve 4 in

[0079] (2) Obtain the working temperature T of the motion pair fi

[0080] Select the end cover of the high-speed shaft bearing of the reducer as the effective point of the working temperature of the kinematic pair, and obtain the working temperature T of the kinematic pair by measuring the effective point of the kinematic pair fi , see image 3 Curve 3 in

[0081] (3) Obtain the design temperature T of the kinemat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com