Oven

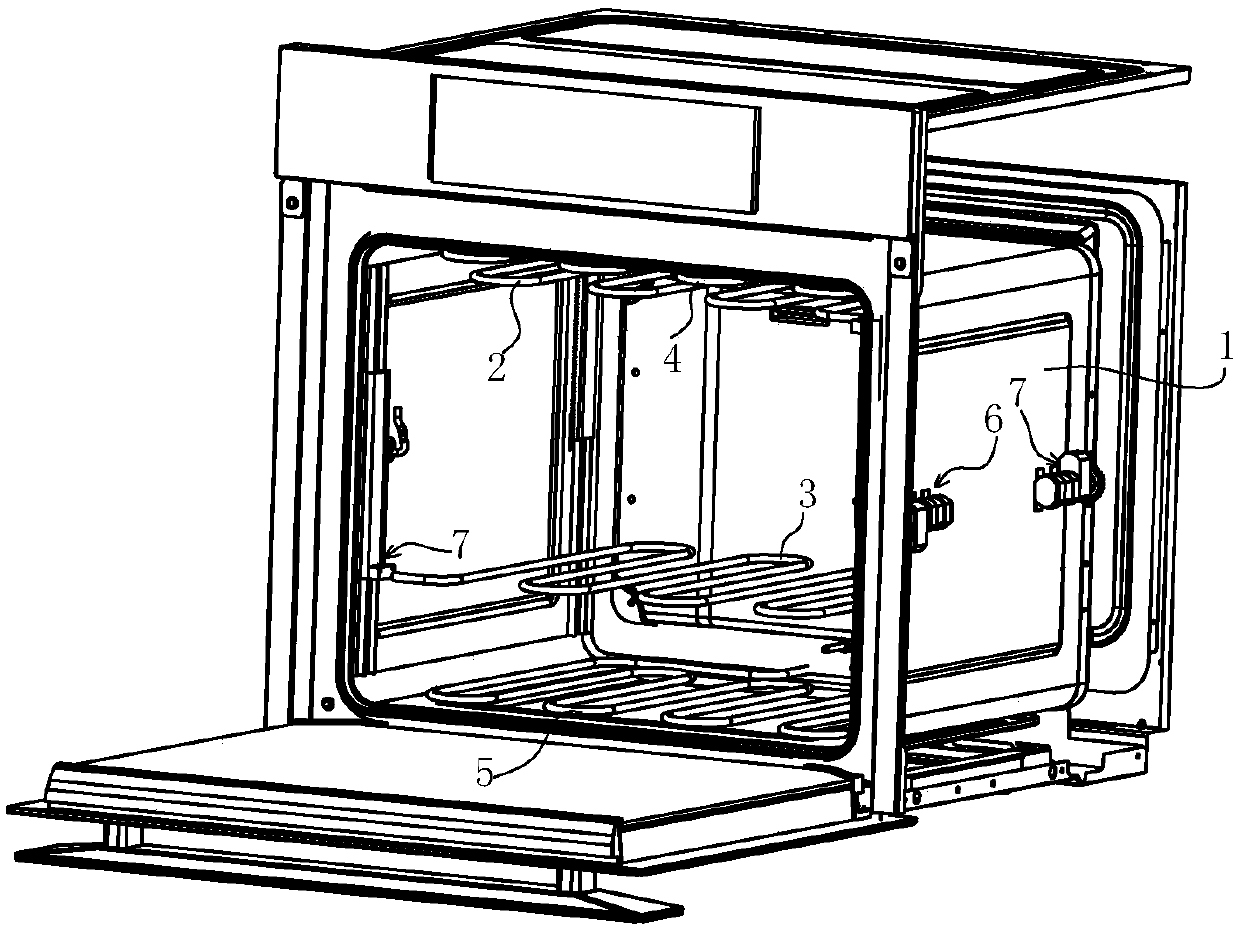

An oven and heating tube technology, applied in the oven field, can solve the problems of poor color consistency, poor baking effect at the bottom of the food, poor preheating time, etc., and achieve the effect of consistent baking effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

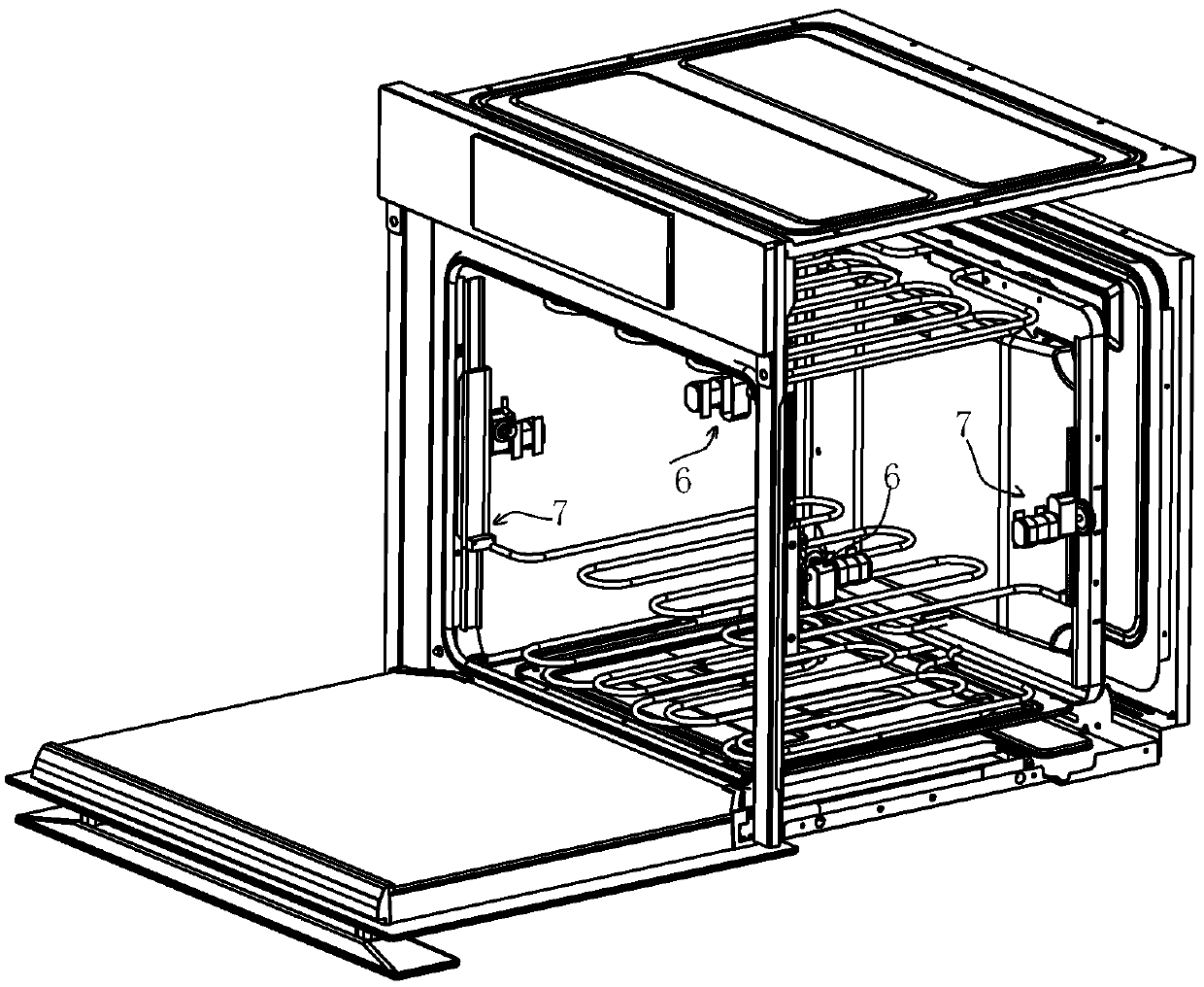

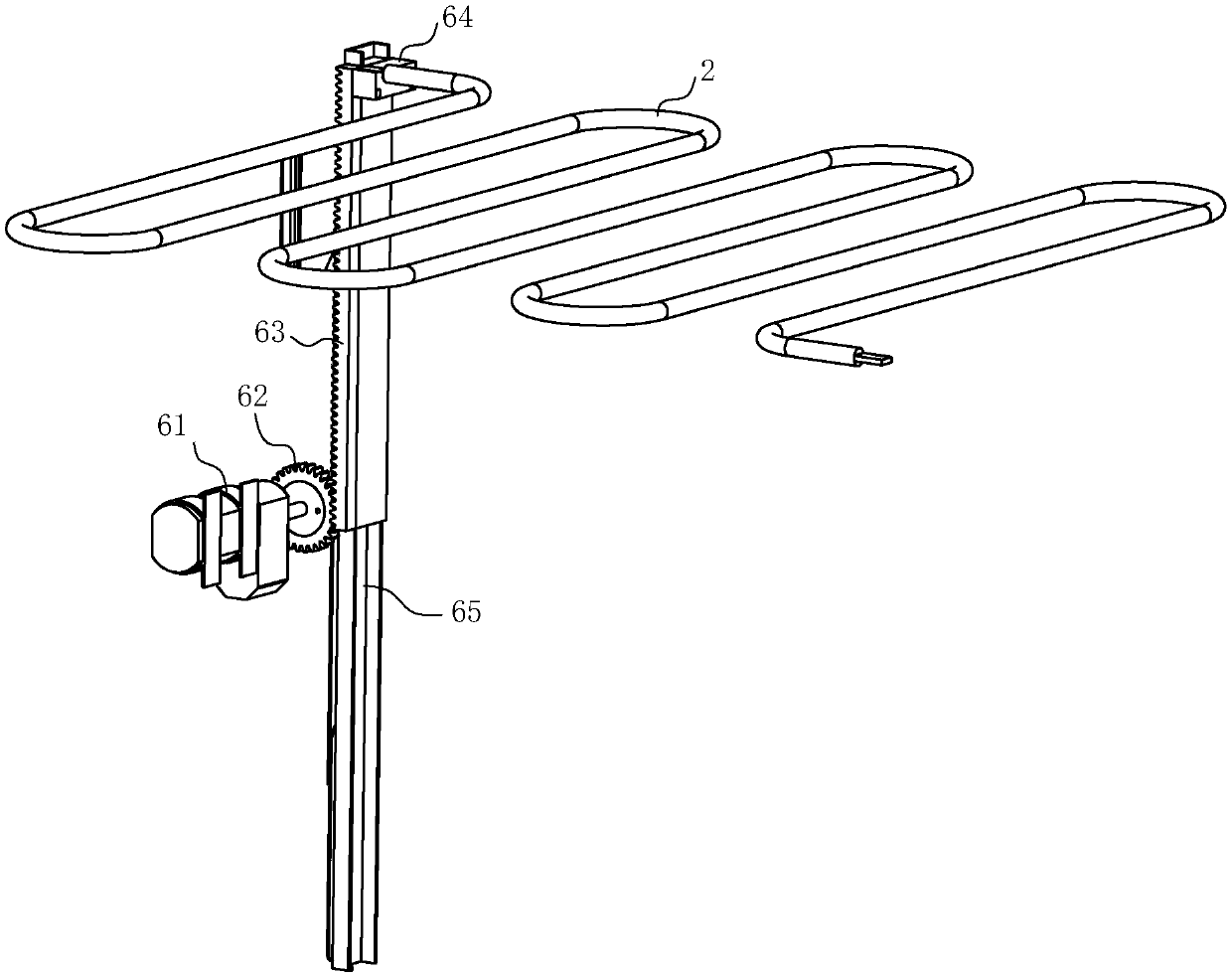

[0054] Different from Embodiment 1, the first lifting drive mechanism includes a first drive motor and a screw 66 that is connected to the first drive motor and driven to rotate by the first drive motor. The nut 67 that moves up and down, and the two ends of the upper moving heating tube 2 are respectively fixed on the two nuts 67; the first driving motor and 61 are arranged outside the inner container, and the screw rod 66 and the nut 67 are arranged inside the inner container, see Figure 5 , 6 shown.

[0055] The second lifting drive mechanism 7 includes a second drive motor and 71 connected with the second drive motor and driven by the second drive motor to rotate the second screw 76, the thread is sleeved on the second screw and can be up and down along the second screw The second nut 77 that moves, the two ends of the moving heating tube 3 are respectively fixed on the two second nuts 77; the second drive motor and 71 are arranged outside the inner container, and the se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com