A kind of cnt-sio 2 /nbr material preparation method and atomizing spray gun

An atomizing spray gun and atomizing nozzle technology, applied in the field of rubber mixing, can solve the problems of re-agglomeration of fillers, reduce compatibility, large water consumption, etc., and achieve the effects of improving dispersibility, low production cost, and small rolling resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

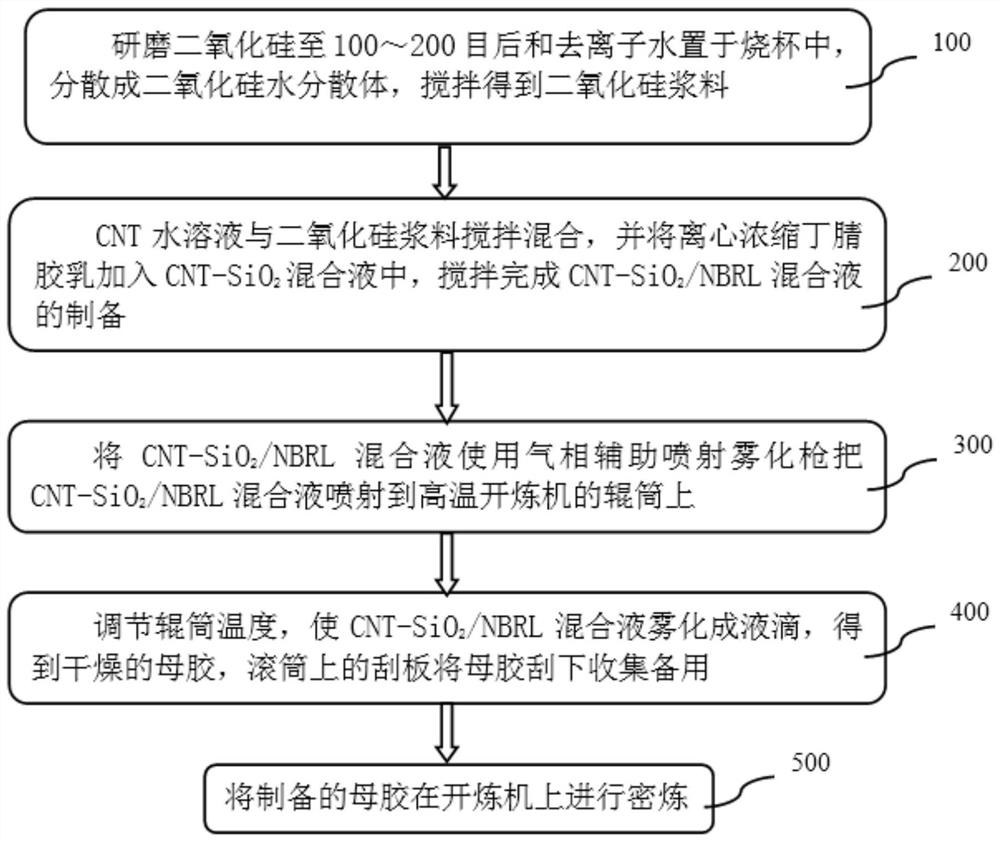

[0049] like figure 1 As shown, the present invention provides a CNT-SiO 2 / NBR composite material preparation method, is characterized in that: comprise the steps:

[0050] S100, use a ball mill to grind silicon dioxide to 100-200 meshes, place the ground silicon dioxide and deionized water in a beaker, and use a high-speed shearing machine to disperse into a silicon dioxide aqueous dispersion with a mass fraction of 25 wt%, And stirred by a stirrer to obtain 25wt% silica slurry;

[0051] S200, stirring and mixing 3 parts by mass of CNT aqueous solution and 30 parts by mass of silica slurry to form CNT-SiO 2 Mixed solution, and the dry glue mass fraction of 100 mass parts is that the centrifugal concentration nitrile latex of 60wt% adds CNT-SiO 2 In the mixture, stir the CNT-SiO with a blade stirrer 2 / NBRL mixture, complete CNT-SiO 2 Preparation of / NBRL mixture;

[0052] S300, the CNT-SiO to be prepared 2 / NBRL mixture is poured into the container tank, and the CNT-Si...

Embodiment 2

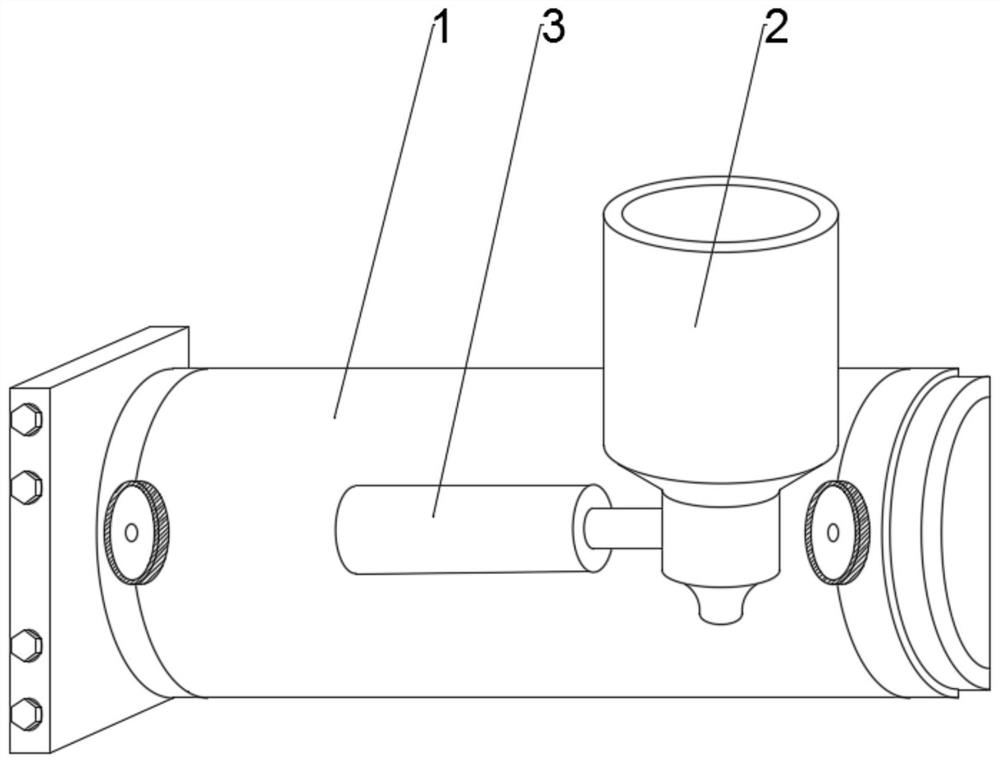

[0062] like Figure 2 to Figure 6 As shown, the present invention also provides a CNT-SiO 2 / NBR composite material ultrasonic atomization spray gun, including an assembly frame 1, and a batching bottle 2 arranged on the assembly frame 1, an air pump 3 is arranged on the assembly frame 1 located on one side of the batching bottle 2, and will be prepared The CNT / NBR mixed liquid is injected into the batching bottle 2, and the injection air pressure is provided by the air pump 3 and the pressure change in the batching bottle 2 is controlled to realize spraying under uniform pressure.

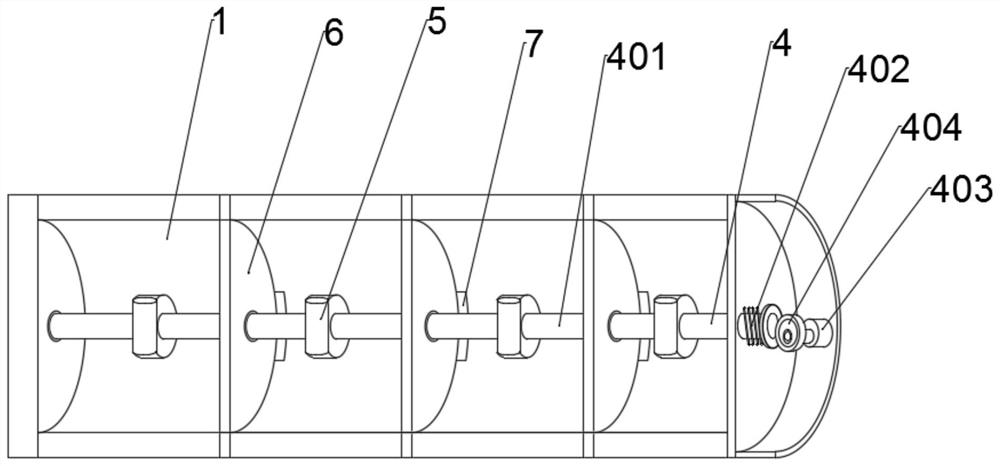

[0063] The inner side of the assembly frame 1 of the present invention is provided with a micro-movement assembly 4, and several atomizing nozzles 5 are arranged on the micro-motion assembly 4, and the left and right lateral vibrations of the atomizing nozzles are driven by the micro-motion assembly 4, thereby ensuring the stability of the atomizing nozzles 5. The spray surface moves slightly in ...

Embodiment 3

[0074] like Figure 7 , Figure 8 and Figure 9As shown, the ball mill used in the preparation of composite materials in Example 1 provided by the present invention includes a base B1 and a mounting groove B2 arranged on the base B1, and a planetary wheel B3 driven by a motor is arranged inside the mounting groove B2 , and there are at least three star wheels of the planetary wheel B3, the star wheel of the planetary wheel B3 is provided with a fixed bracket B4, the fixed bracket B4 is equipped with a grinding tank B6 through a movable hinge device B5, and a pressing rod device B7 is installed on the grinding tank B6 , the upper part of the grinding tank B6 is provided with a turntable B8, and the turntable B8 is fixedly connected to the installation groove B2 through a bracket, the turntable B8 includes an inner wheel B801 and an outer track ring B802, and the inner wheel B801 and the outer track ring The opposite surfaces of B802 are provided with racks, and the top of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com