Multi-station combined fixture

A combined fixture and multi-station technology, which is applied in the direction of manufacturing tools, clamping, positioning devices, etc., can solve the problem of cumulative error of multiple processing surfaces

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with accompanying drawings and embodiments.

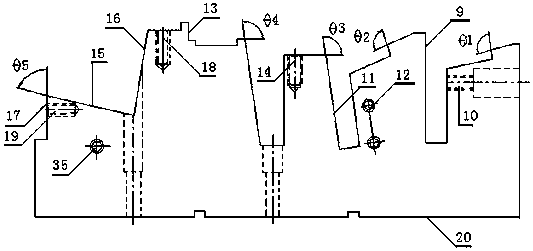

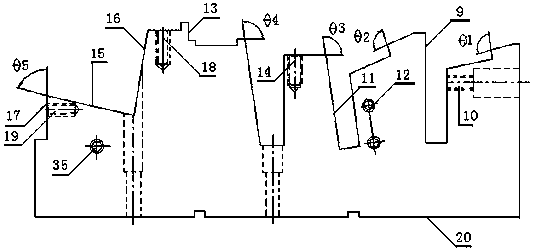

[0014] Examples, see attached figure 1 : The present invention relates to a multi-station combined fixture, comprising a first positioning surface 9, a first screw hole 10, a first matching angle θ1, a second positioning surface 11, a second screw hole 12, a second matching angle θ2, a first Three positioning surfaces 13, third screw holes 14, third matching angle θ3, fourth matching angle θ4, fourth positioning surfaces 15, fifth positioning surfaces 16, sixth positioning surfaces 17, fourth screw holes 18, fifth screw holes Hole 19 , sixth screw hole 35 , fifth matching angle θ5 , and bottom surface 20 . The multi-station means that there is more than one station in the combined fixture, and each station is signed by the surface to be processed, from right to left, including the outer plane station, theta bevel station, the outer vertical surface station...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com