Grabbing mechanism capable of quickly adjusting positions of clamping jaws and using method thereof

A grasping mechanism and quick adjustment technology, applied in the field of manipulators, can solve problems such as low efficiency of changeover, influence of repeated positioning accuracy, and inability to adjust jaws, etc., to achieve enhanced changeover efficiency, no change in clamping force, and small screw pitch Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

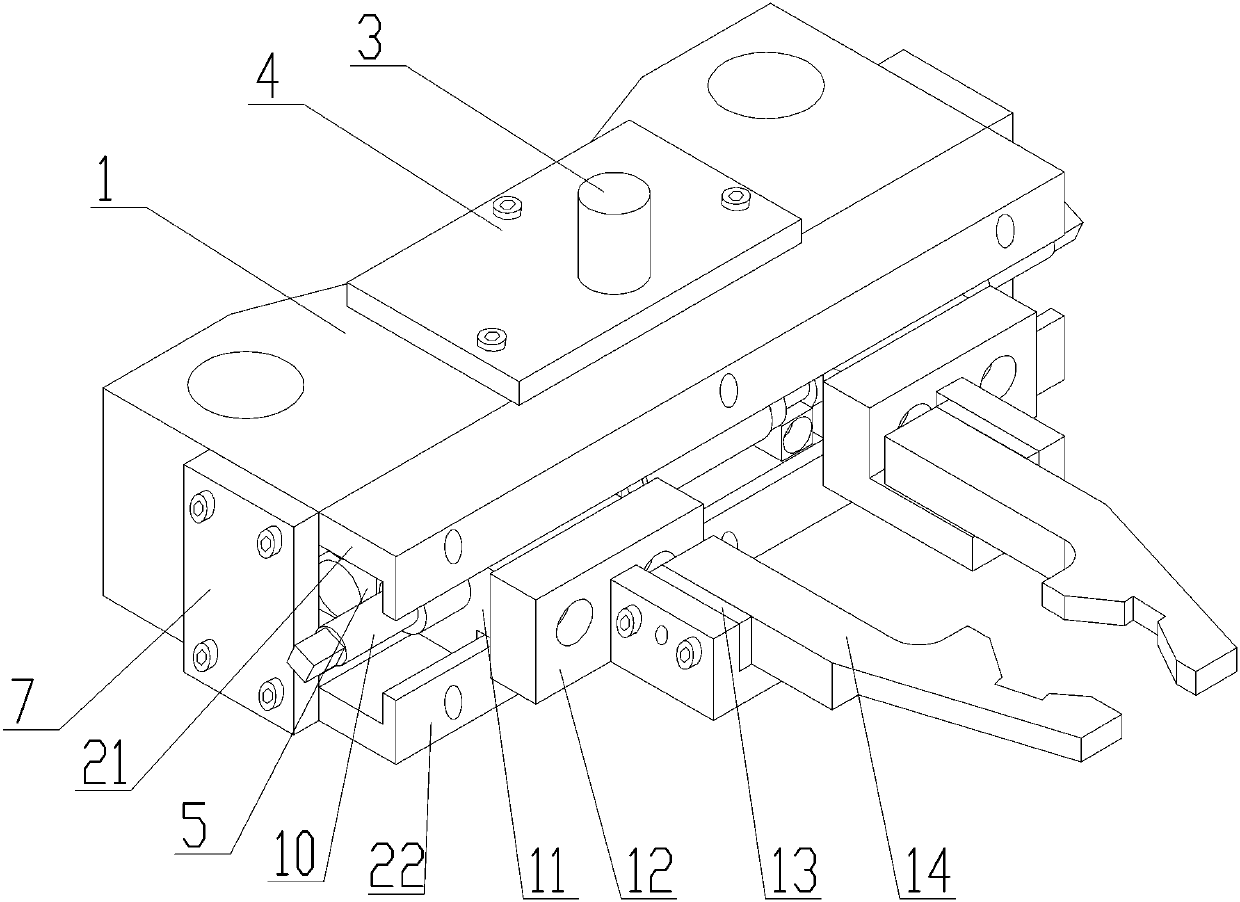

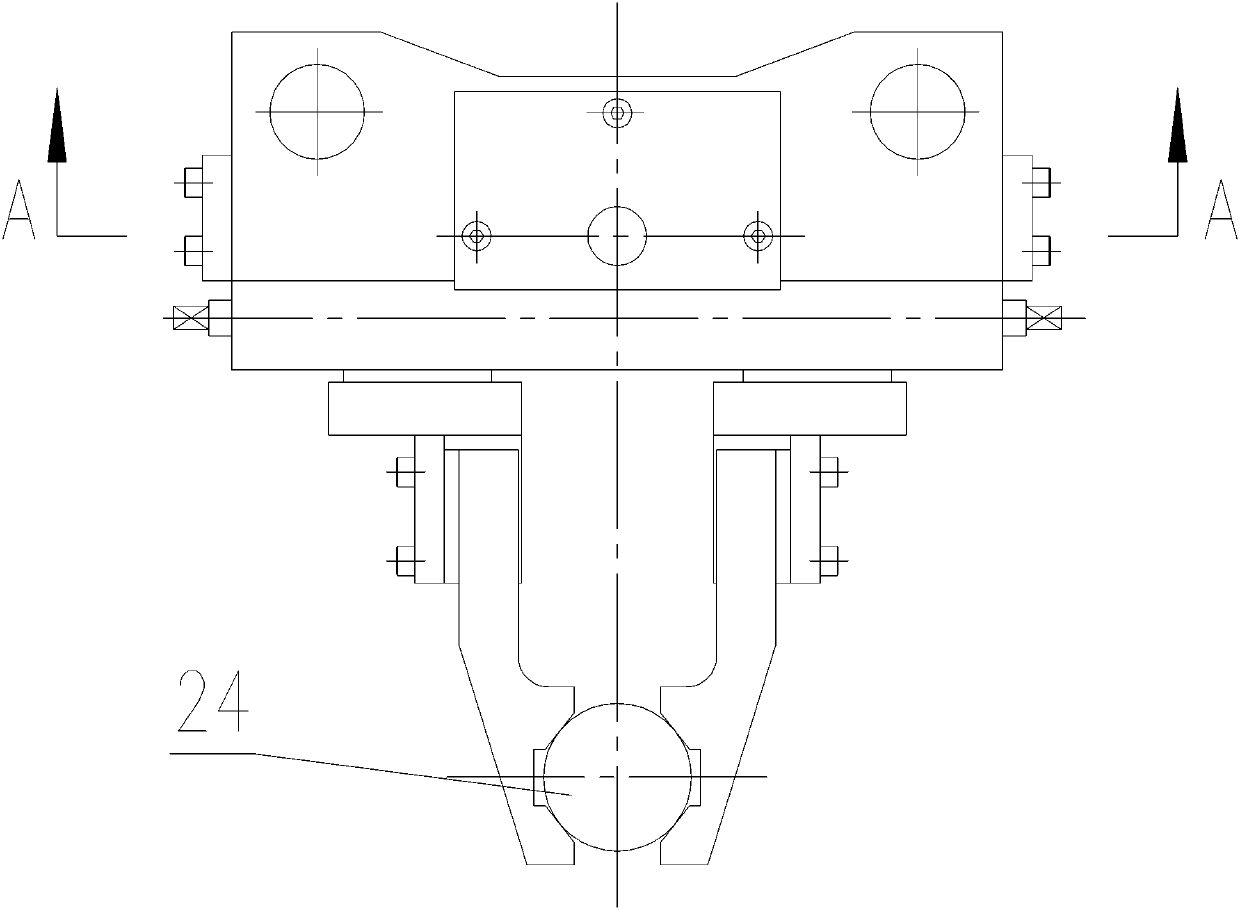

[0037] like Figure 1-8, a grabbing mechanism that can quickly adjust the position of the jaws, it includes a base body 1, the interior of the base body 1 is processed with a through chute, on the chute is installed a symmetrically reversed arrangement of the first sliding slant through sliding fit Block 5 and the second sliding block 8; the first sliding block 5 and the second sliding block 8 are matched with a power mechanism for driving both clamping and reverse release along the chute; The end face of the first sliding slant block 5 is connected with a first adjusting screw 10, and the end face of the second sliding slanting block 8 is connected with a second adjusting screw 19; The first slide block 11 is installed in transmission cooperation, and the second slide block 18 is installed on the second adjusting screw rod 19 through the left-hand thread transmission cooperation; the first slide block 11 is fixedly installed with the The first jaw 14, the second slider 18 is...

Embodiment 2

[0048] The use method of any one of the grasping mechanisms that can quickly adjust the position of the jaws is characterized in that:

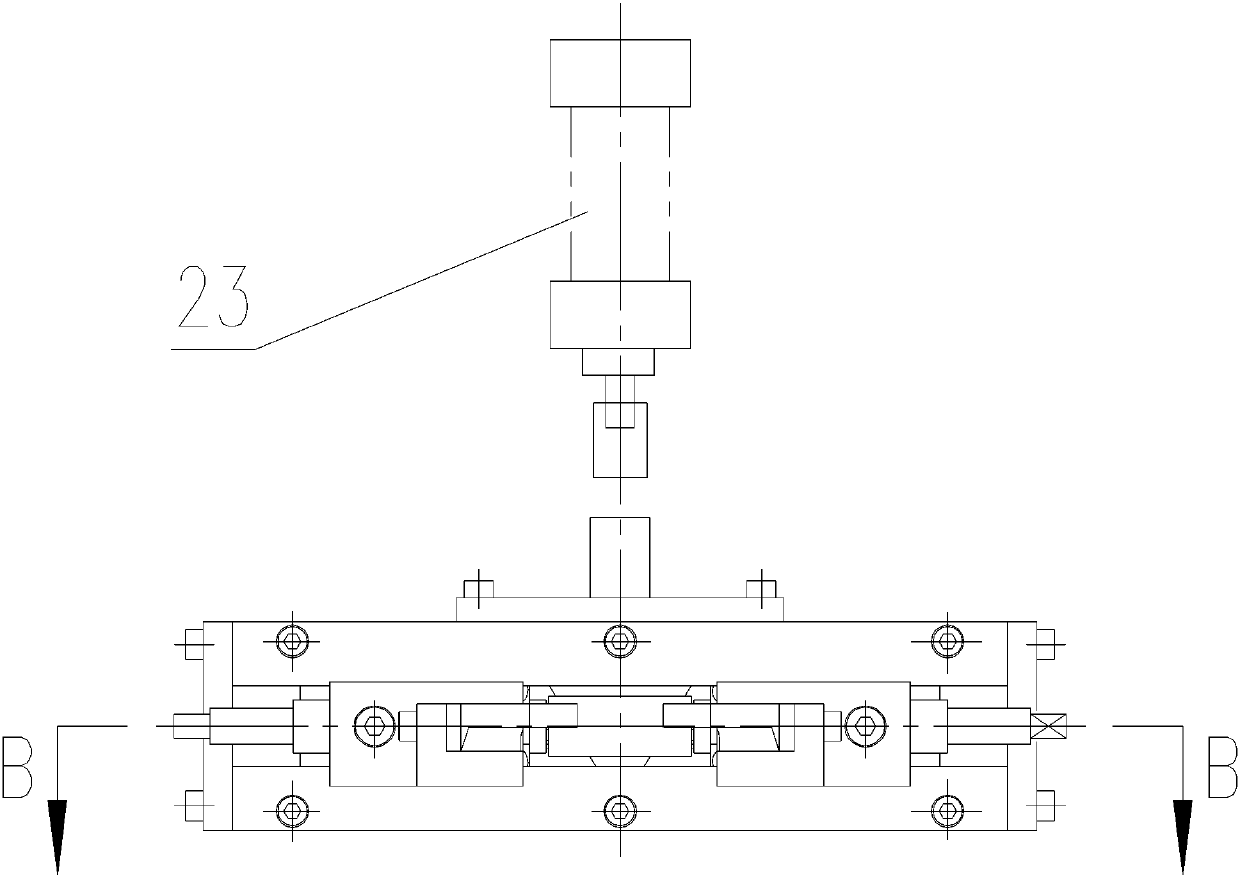

[0049] Loosening and clamping action: After the hydraulic cylinder 23 receives the signal, the piston rod descends, and the ejector rod 3 is pressed down for a certain distance, and at the same time, the guide slant block 2 also moves downward for the same distance, passing through the left and right slopes 27 of the guide slant block 2 , apply opposite forces to the first sliding block 5 and the second sliding block 8 respectively, thereby driving the first adjusting screw 10 and the second adjusting screw 19 to separate, passing through the first sliding block 11 and the second right sliding block 18, The first jaw mounting base 12 and the second jaw mounting base 17 realize the separation of the first jaw 14 and the second jaw 15, thereby releasing the workpiece;

[0050] On the contrary, when the hydraulic oil cylinder 23 receives the sig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com