Patents

Literature

34results about How to "Improve changeover efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

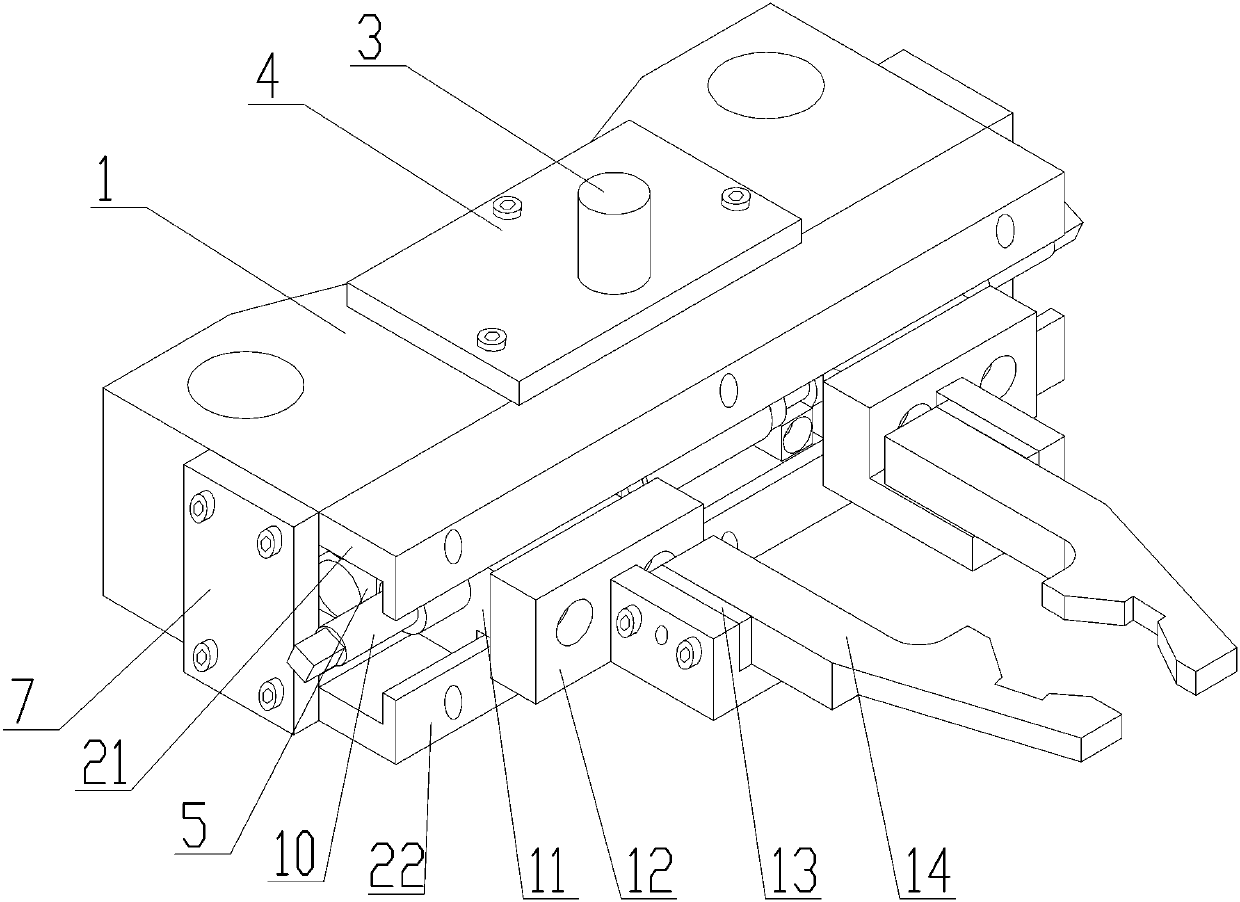

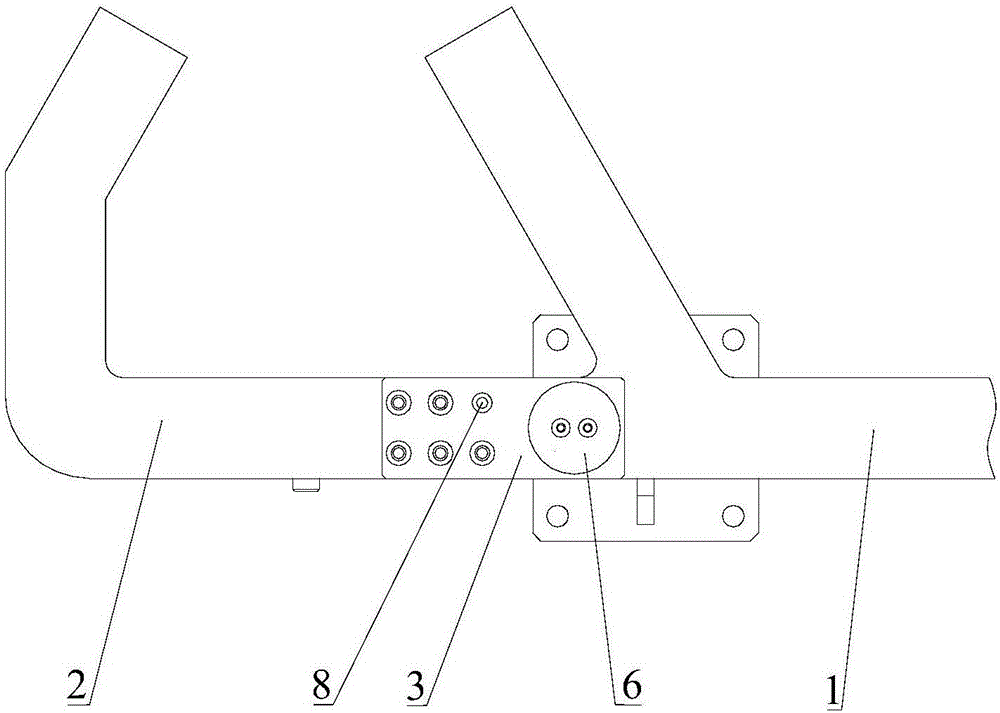

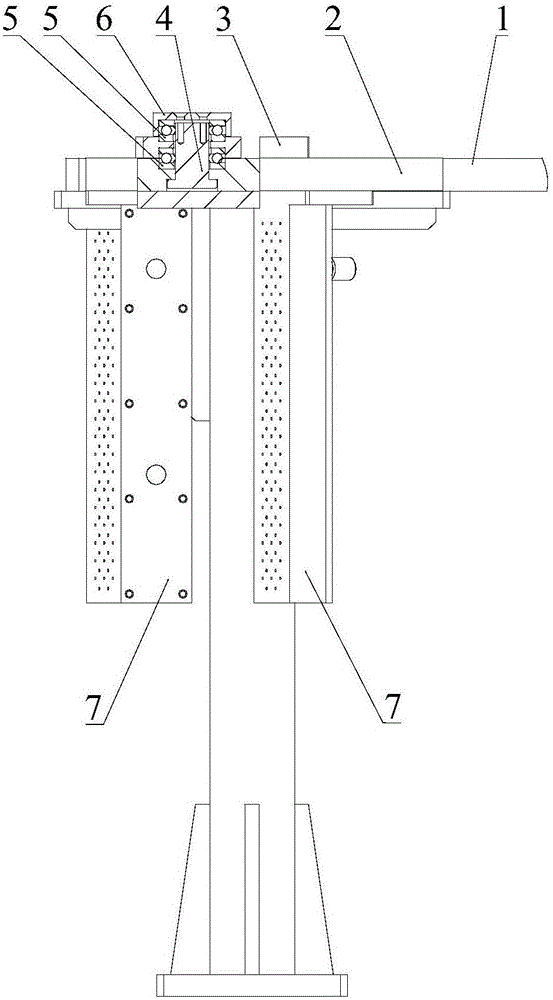

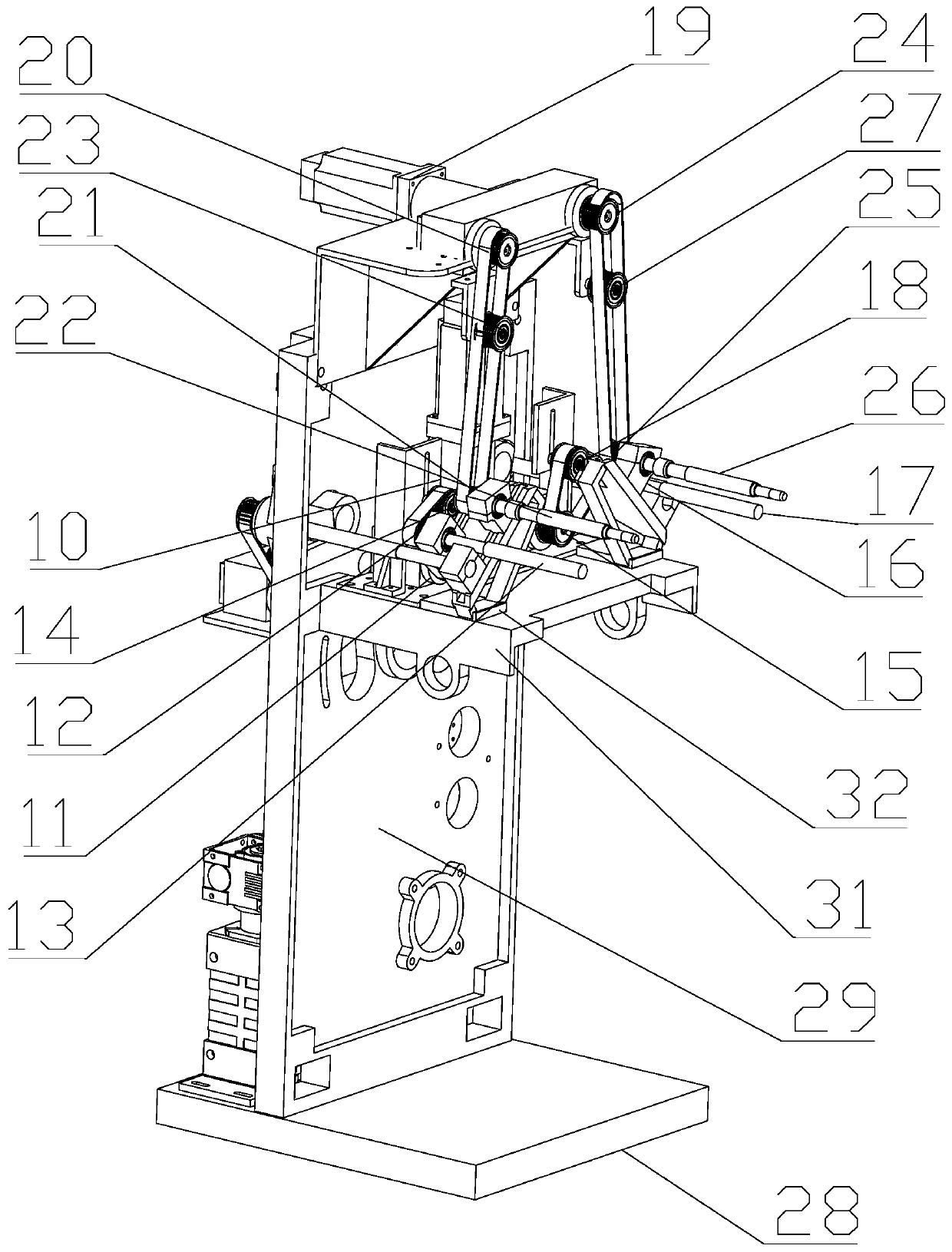

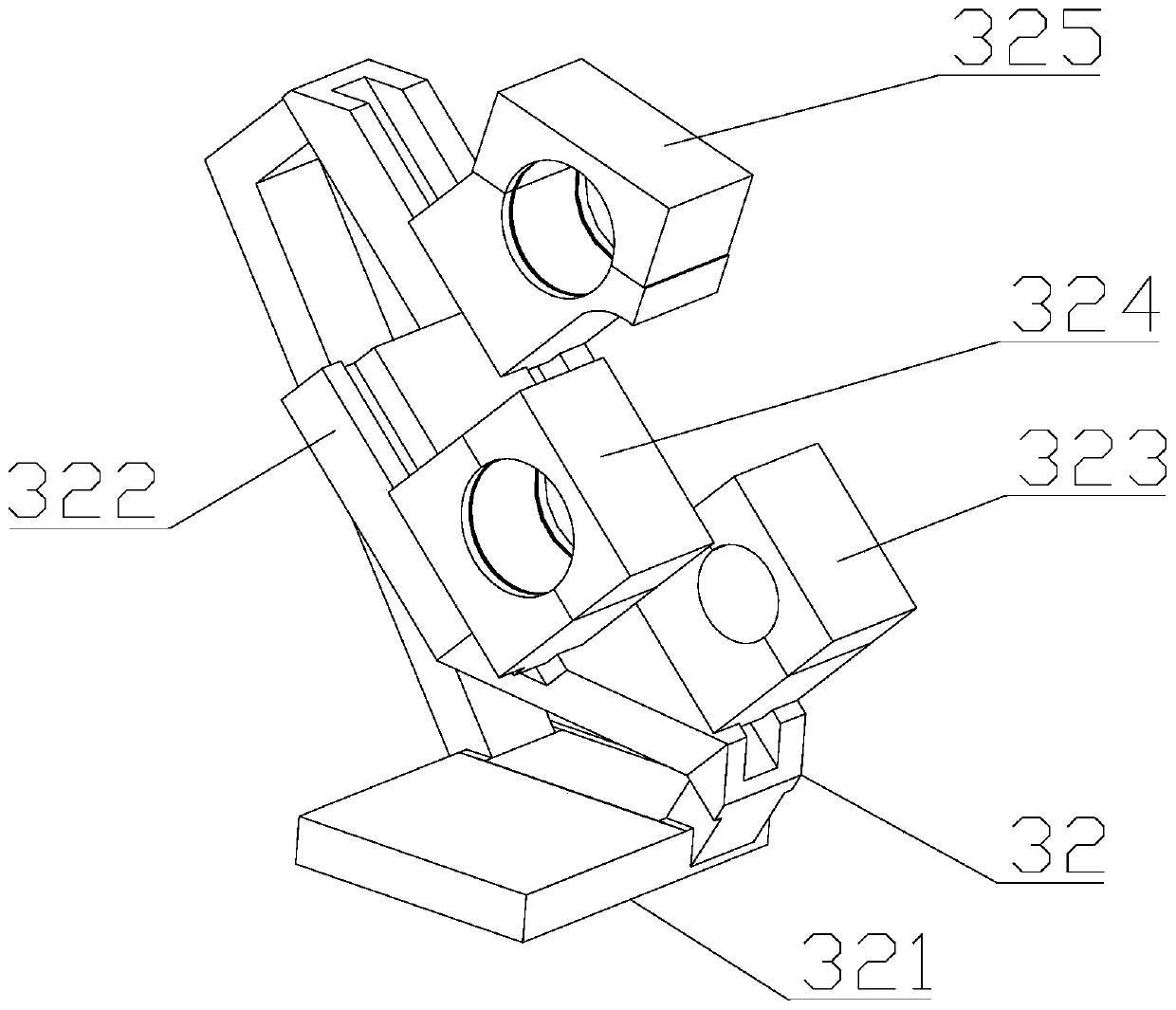

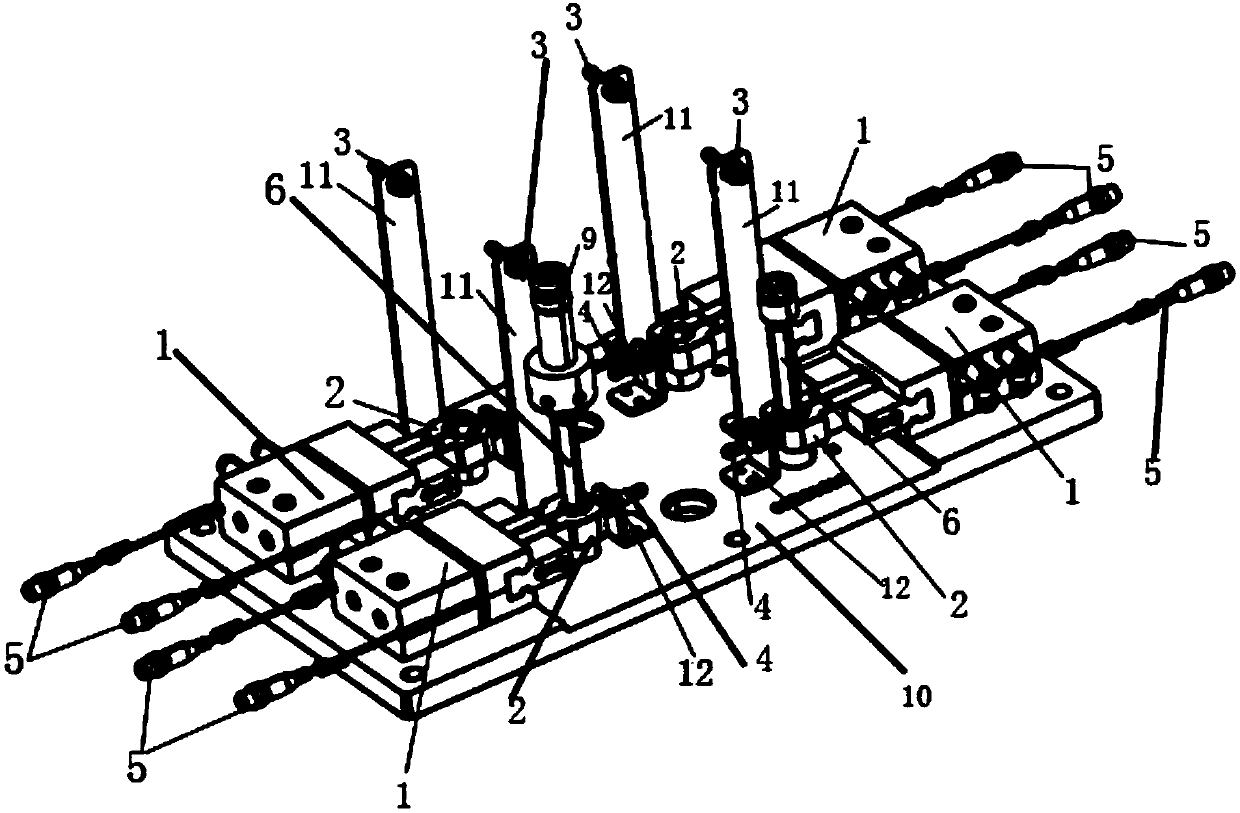

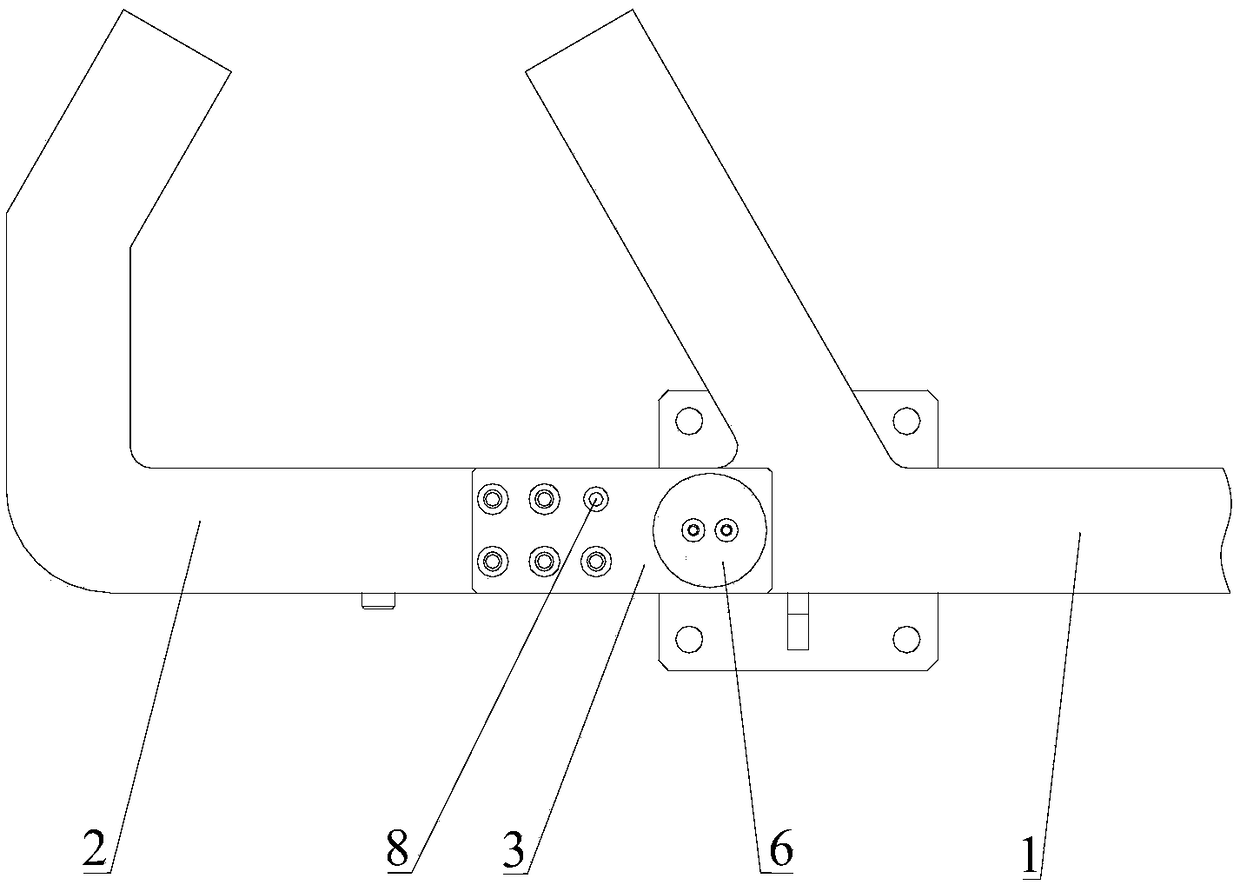

Grabbing mechanism capable of quickly adjusting positions of clamping jaws and using method thereof

The invention relates to a grabbing mechanism capable of quickly adjusting the positions of clamping jaws and a using method thereof. A chute penetrates through a base body; a first sliding inclined block and a second sliding inclined block are symmetrically and reversely arranged and are arranged on the chute in a sliding fit mode; the end face of the first sliding inclined block is in fit connection with a first adjusting screw; the end face of the second sliding inclined block is in fit connection with a second adjusting screw; a first sliding block is arranged on the first adjusting screwin a transmission fit mode through a right-hand thread; a second sliding block is arranged on the second adjusting screw in a transmission fit mode through a left-hand thread; a first clamping jaw isfixedly arranged on the first sliding block through a first clamping jaw mounting seat; a second clamping jaw is fixedly arranged on the second sliding block through a second clamping jaw mounting seat; and the first adjusting screw rod and the second adjusting screw rod match and are connected through an internal spline sleeve. According to the grabbing mechanism, the manipulator claws are rapidly adjustable clamping claws, so that the shape changing efficiency of the claws is greatly improved, and the repeated positioning precision is guaranteed.

Owner:宜昌长机科技有限责任公司

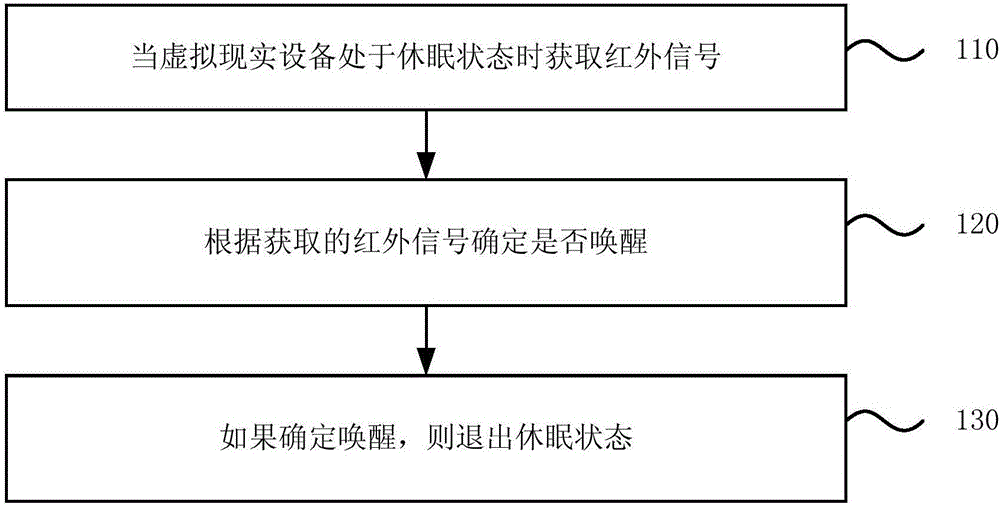

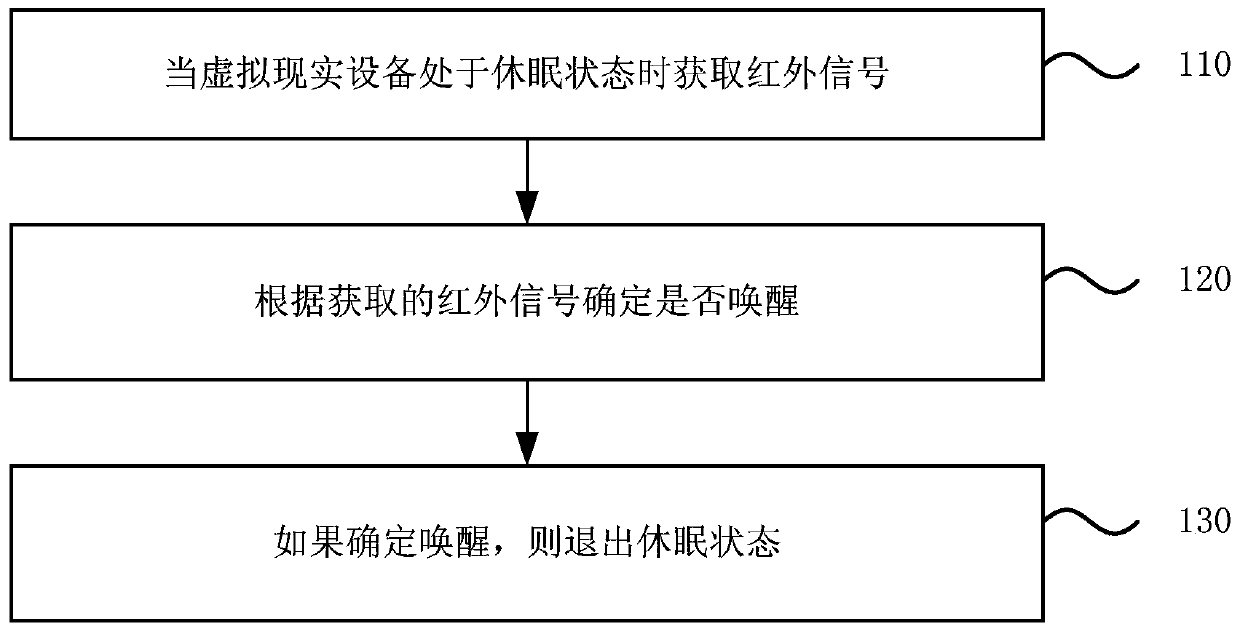

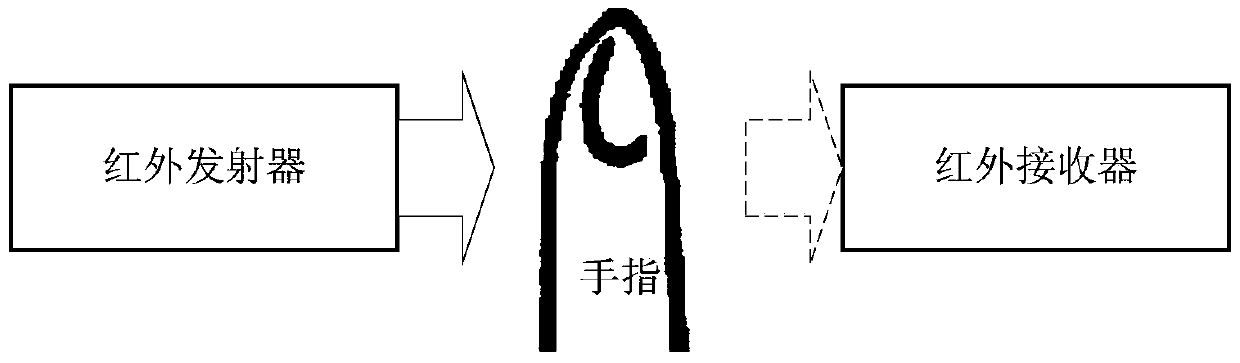

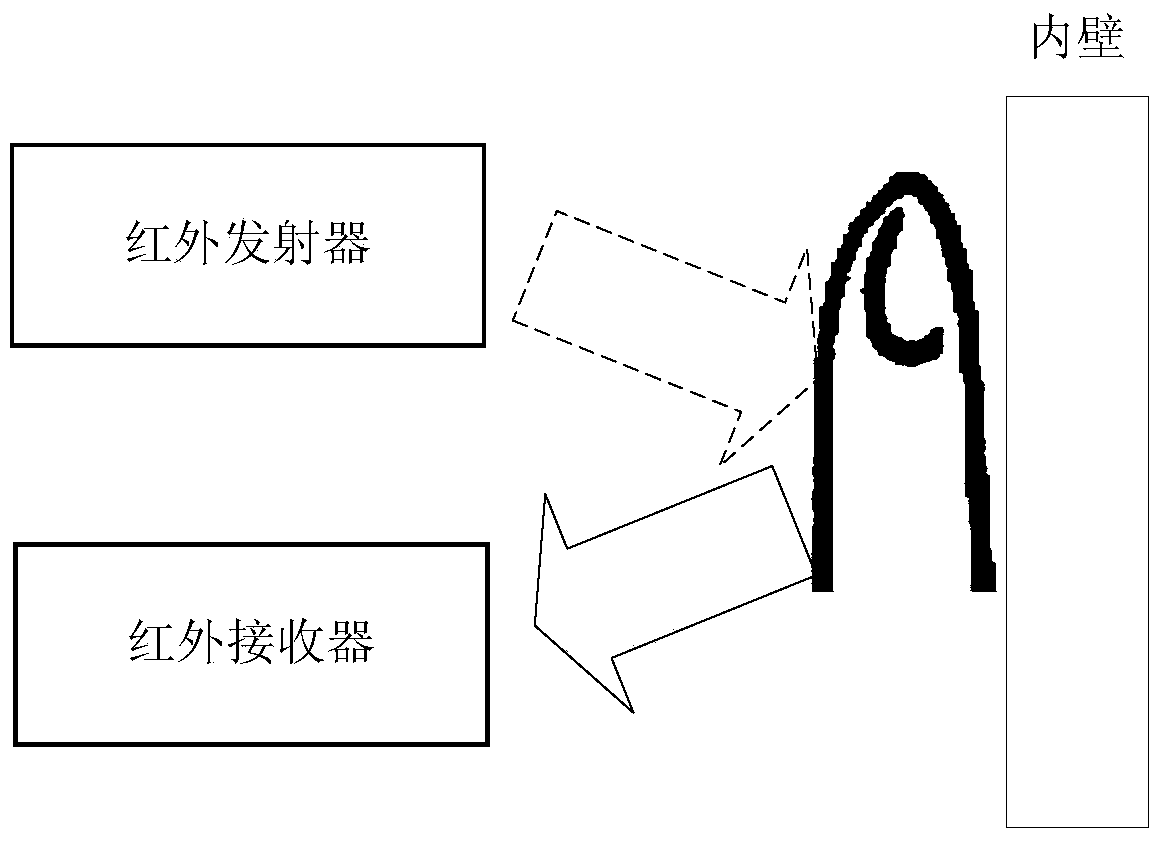

Control method and system for virtual reality device

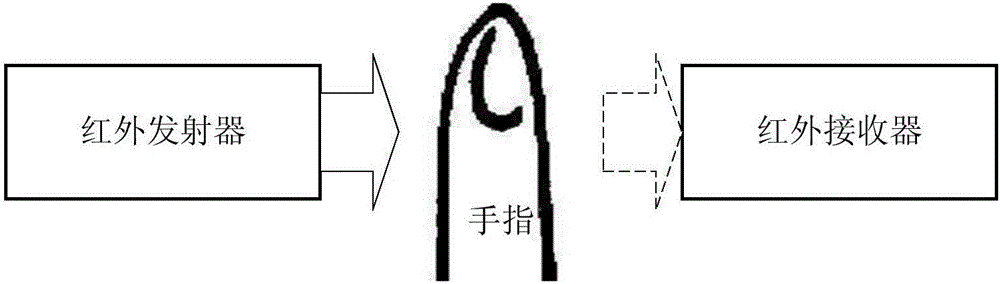

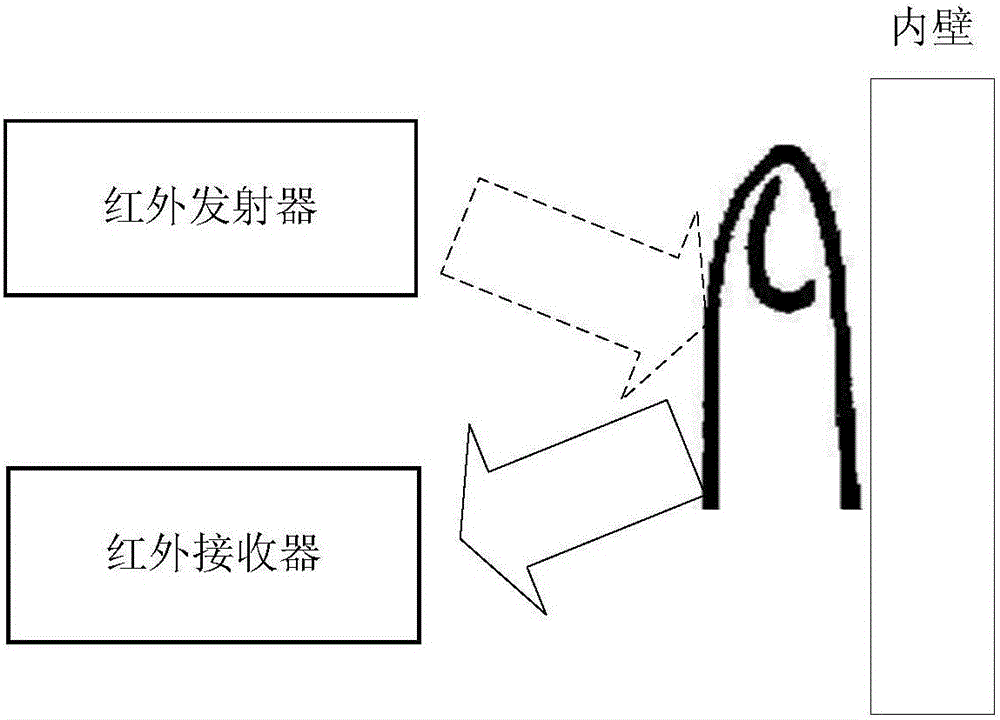

InactiveCN106095421AImprove changeover efficiencyImprove experienceInput/output for user-computer interactionGraph readingSleep stateUser experience design

The invention discloses a control method and system for a virtual reality device. The method comprises the steps of obtaining an infrared signal when the virtual reality device is in a sleep state; determining whether the virtual reality device is wakened or not according to the obtained infrared signal; and if it is determined that the virtual reality device is wakened, exiting from the sleep state. According to embodiments of the method and the system, whether the virtual reality device is wakened or not can be determined according to the obtained infrared signal when the virtual reality device is in the sleep state; after a user puts a finger in the virtual reality device, the infrared signal is reflected after meeting the finger of the user, an interruption is generated according to the reflected infrared signal, and the virtual reality device exits from the sleep state, so that the virtual reality device is wakened; and when the user wears the virtual reality device, the virtual reality device is determined to be wakened according to the obtained infrared signal, so that the user can waken the virtual reality device in a state of wearing the virtual reality device without taking off the virtual reality device, the changeover efficiency of the virtual reality device is improved, and the user experience is enhanced.

Owner:云南知识图谱科技有限公司

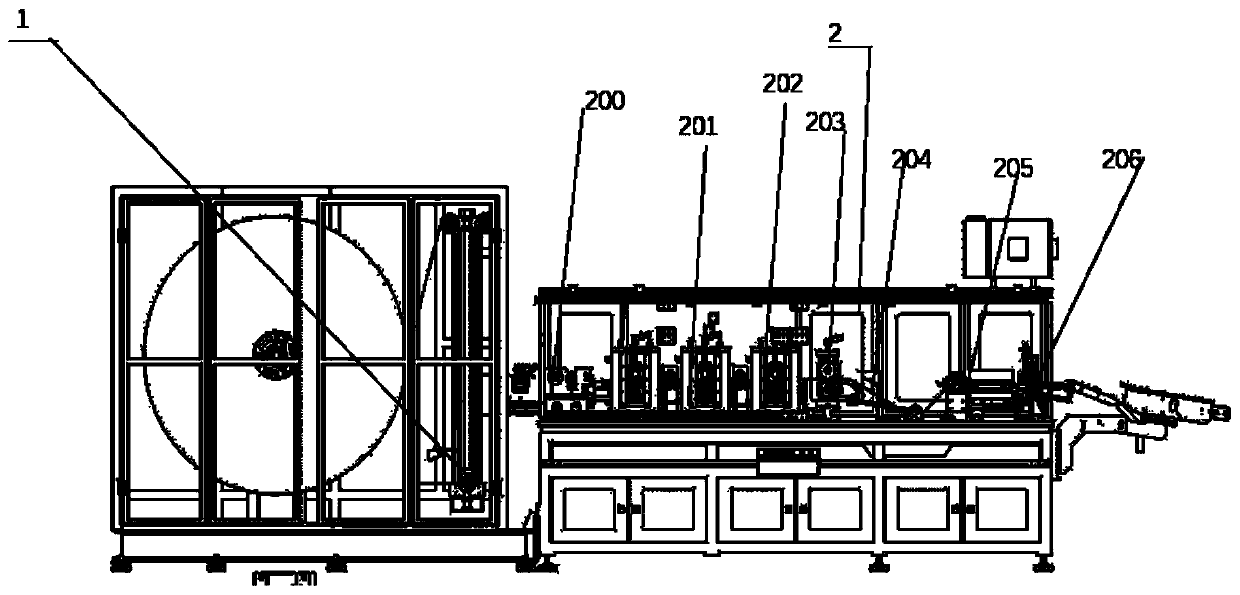

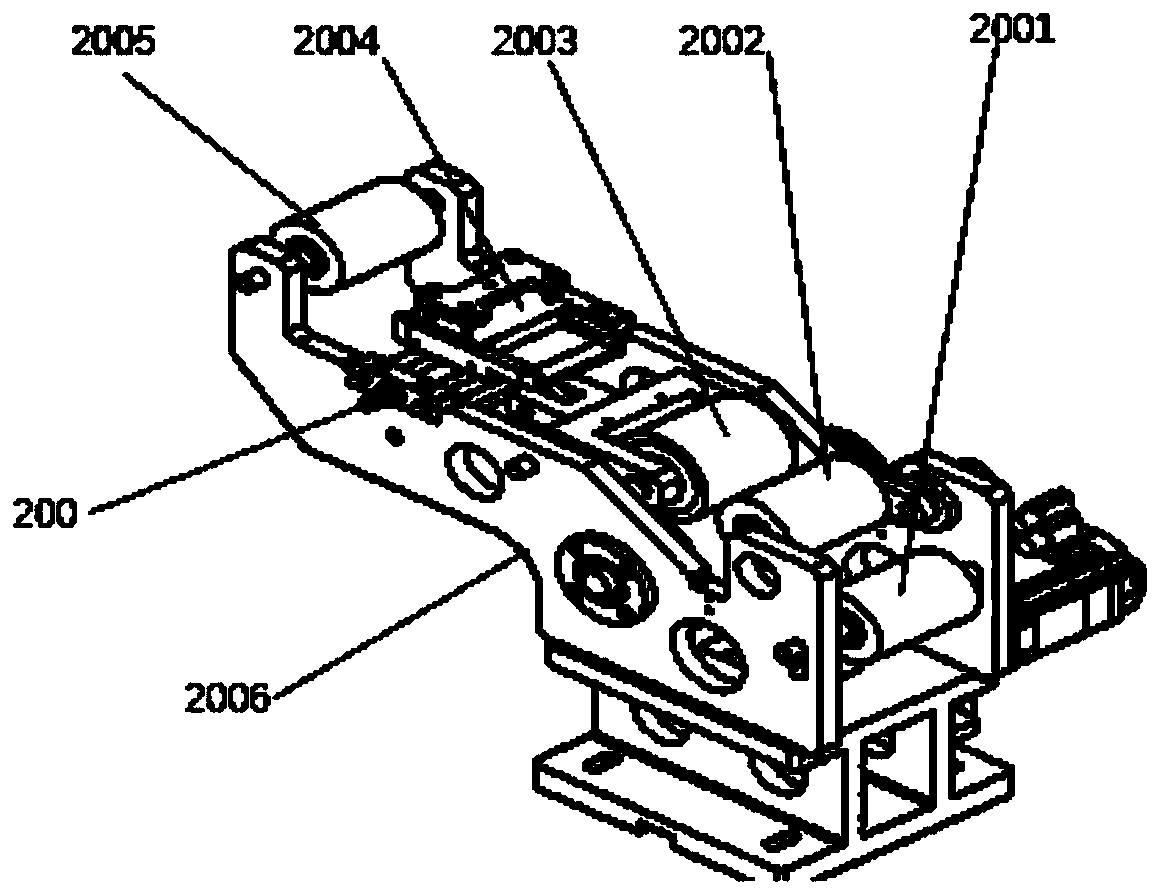

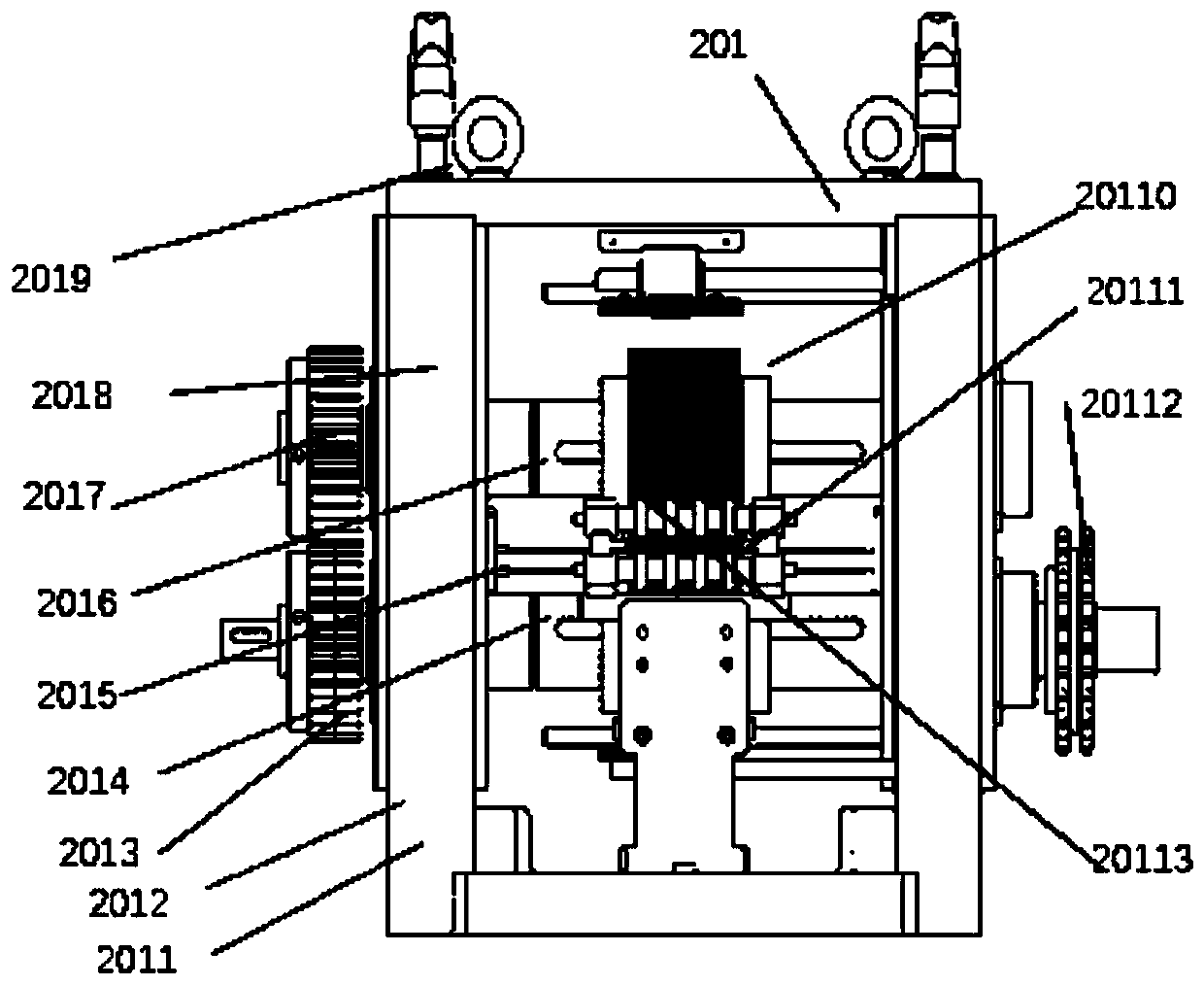

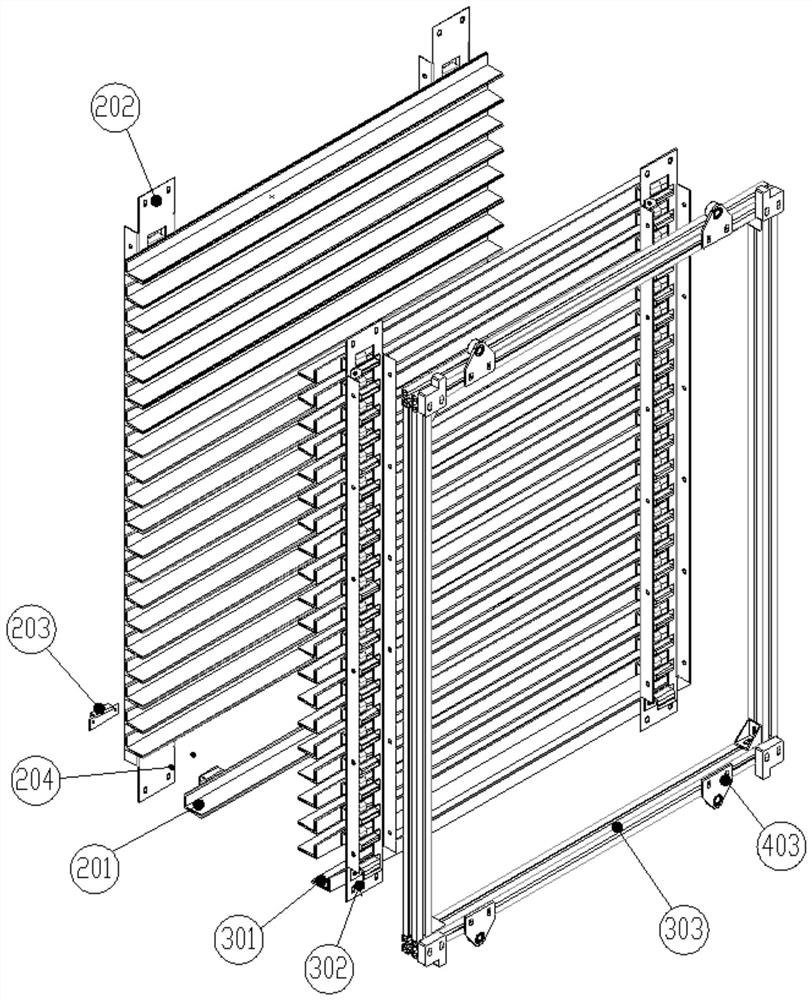

Automatic roll forming equipment for flat-top rectangular wave heat exchange fin

PendingCN111421074ALow costIncrease productivityMetal-working feeding devicesHeat exchange apparatusPhysicsEngineering

The present invention provides automatic roll forming equipment for a flat-top rectangular wave heat exchange fin. The automatic roll forming equipment comprises a strip tension guide unit (200), a first roller mold unit (201), a second roller mold unit (202), and a third roller mold unit (203), a fin shaping unit (204), the fin counting and cutting unit (205), and a fin outlet turning guide unit(206). The automatic roll forming equipment for the flat-top rectangular wave heat exchange fin adopts at least two forming steps. In the automatic roll forming equipment provided by the invention, the size and length changes of a product can be adjusted by only programmatically changing parameters; the width change of the fin can be adjusted by increasing or decreasing the number N of paired roller molds; the fin pitch and wave height changes can be adjusted by only replacing the paired roller molds; and each transmission and control drive system is unchanged. The mechanical adjustment and program adjustment of the entire transmission control system of the equipment system can adapt to the continuous production of heat radiating fins of various sizes and models, which greatly improves theproduction efficiency, also greatly improves the efficiency of model change and lowers the cost of various sizes of mold opening.

Owner:SHANGHAI JIUDUAN PRECISION ELECTROMECHANICAL TECH

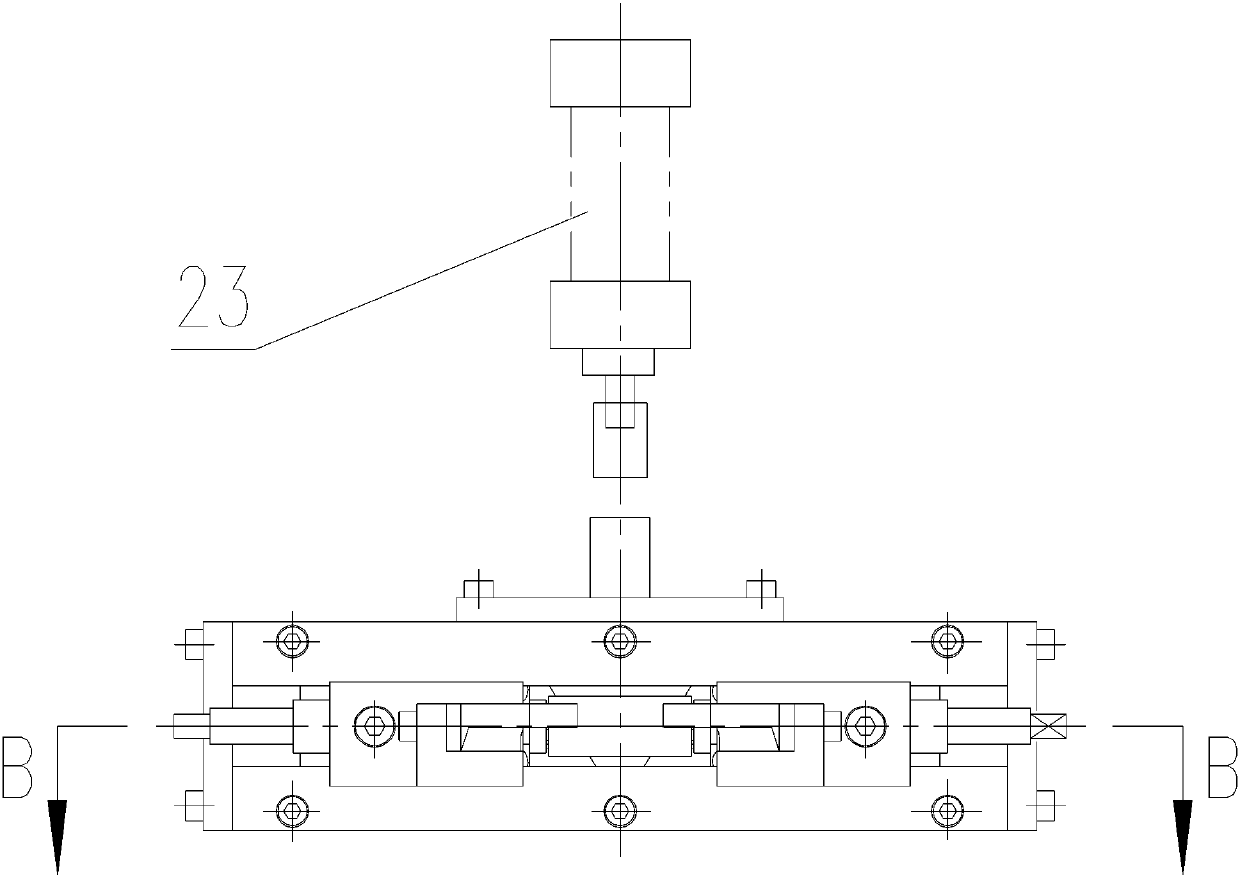

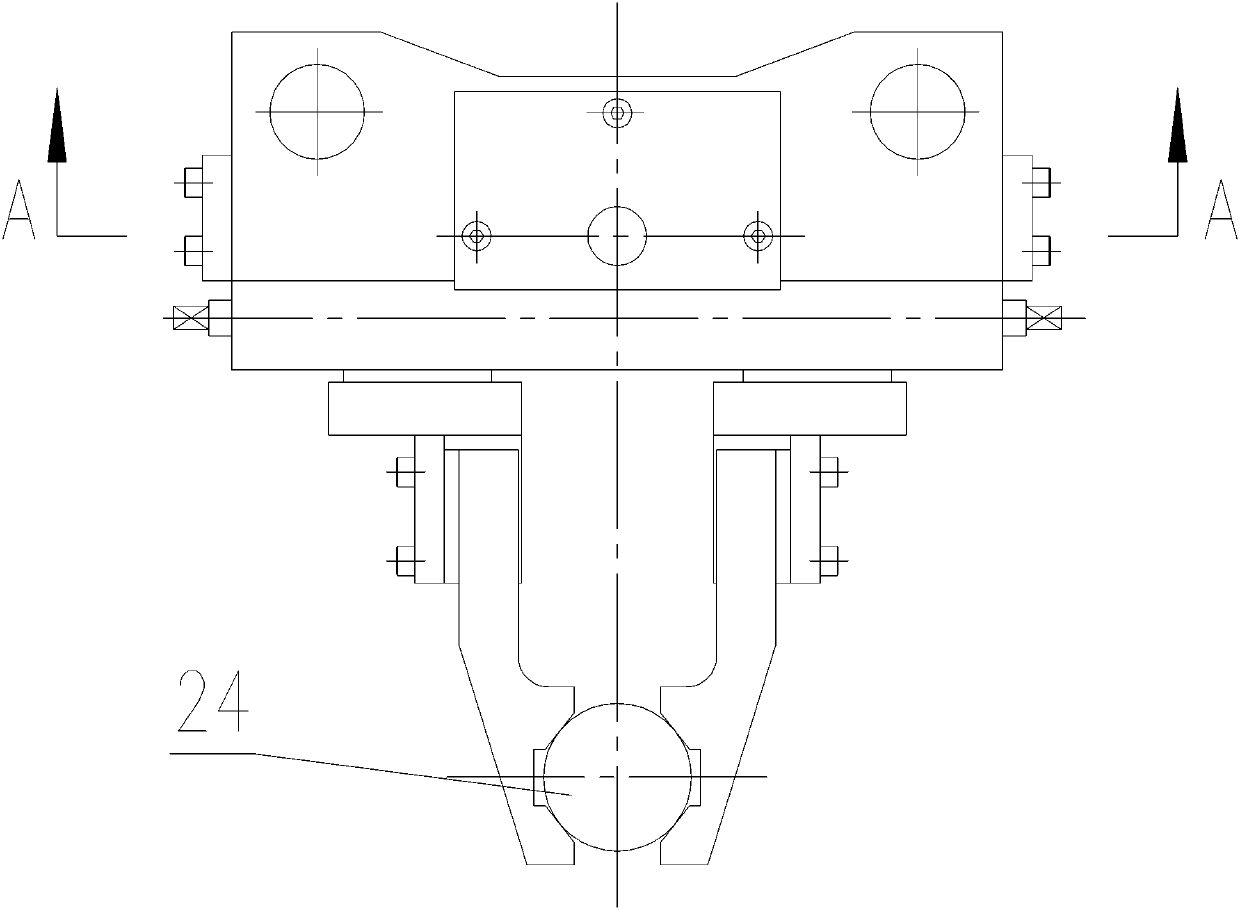

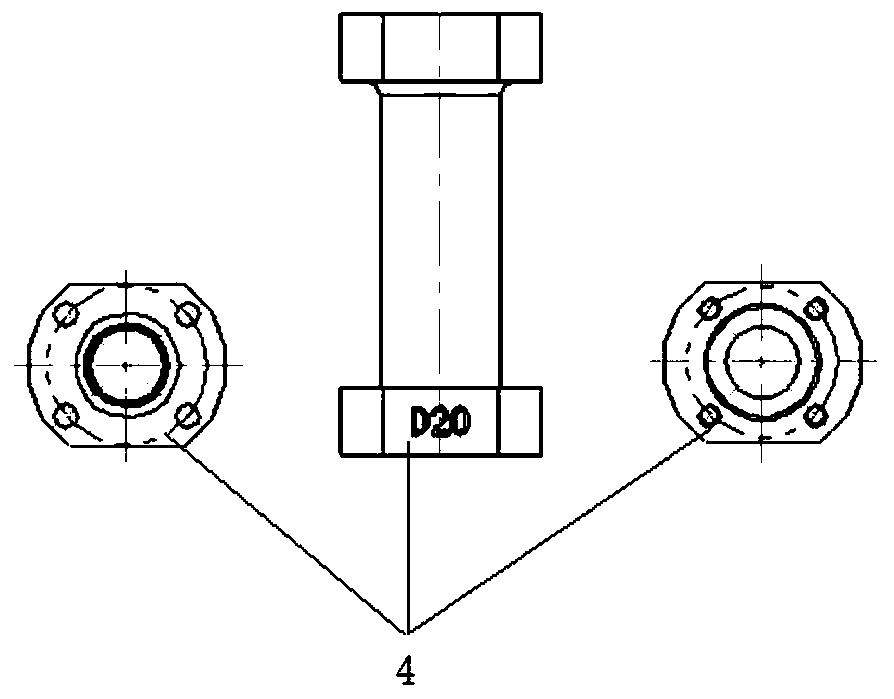

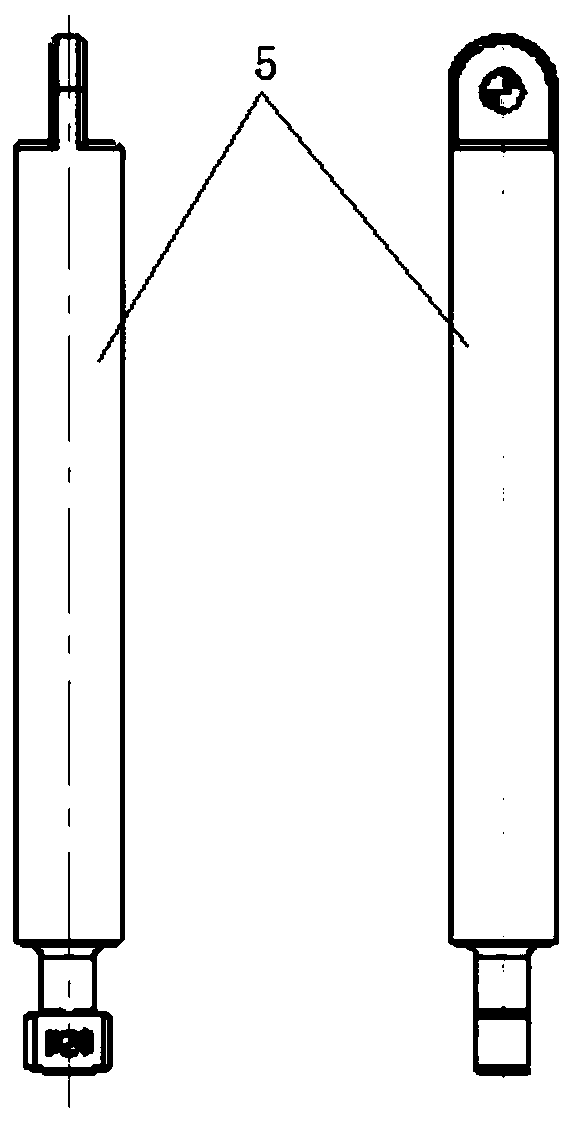

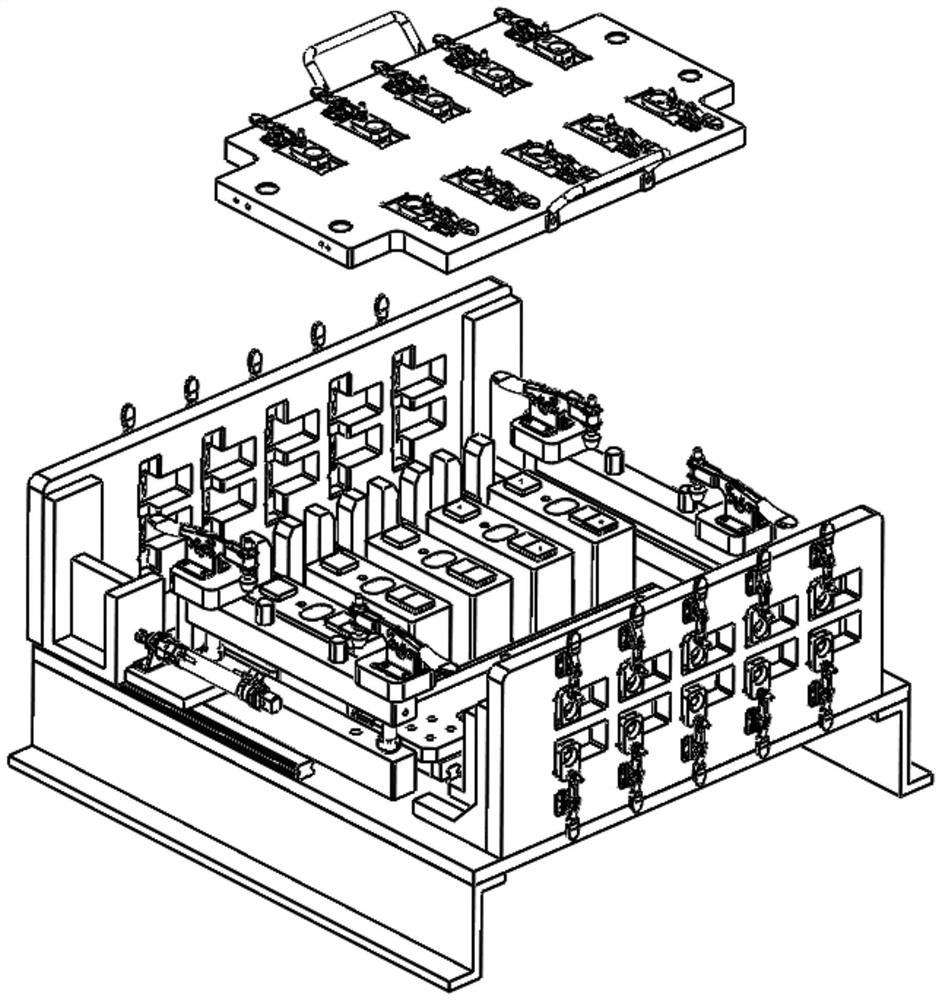

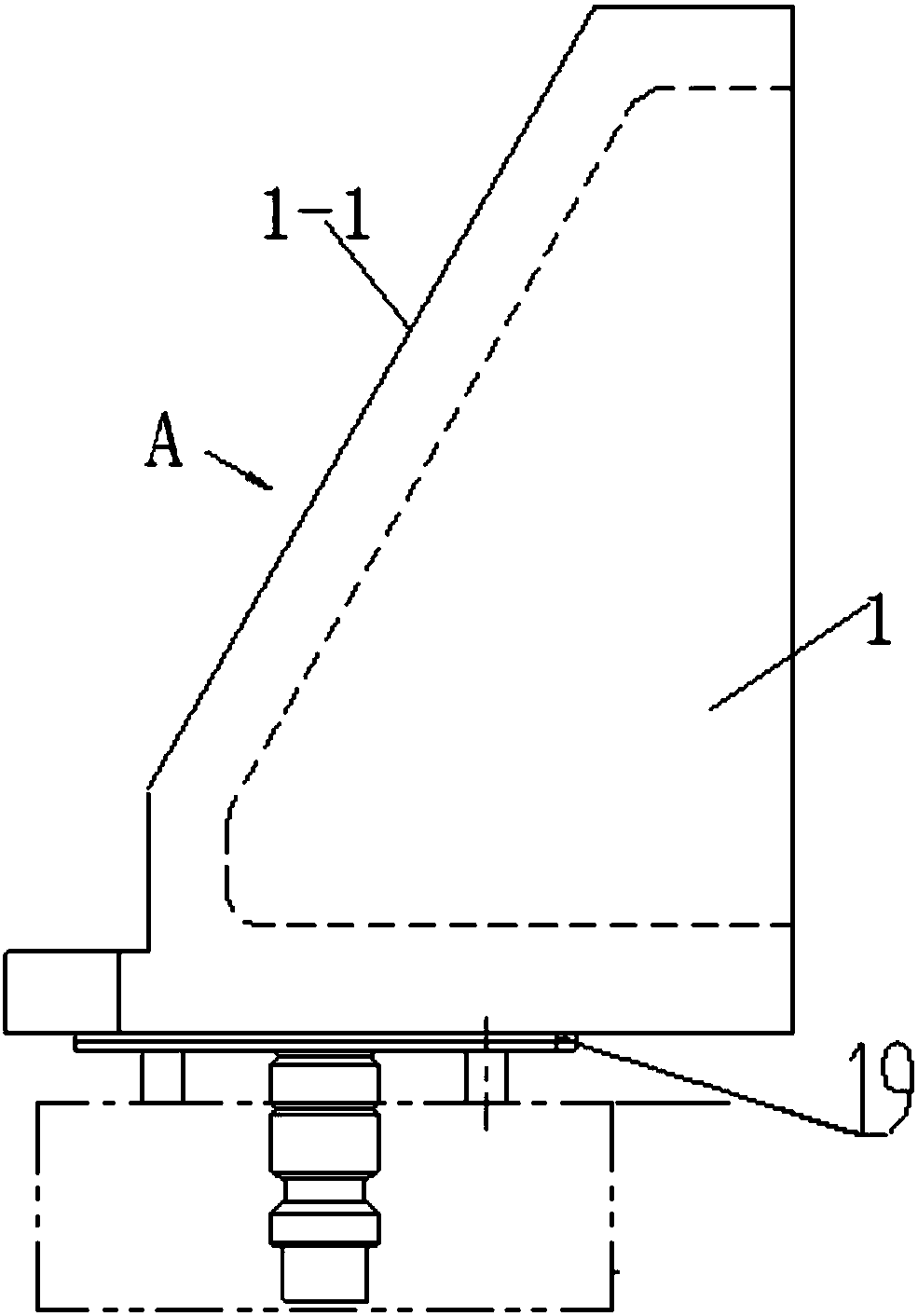

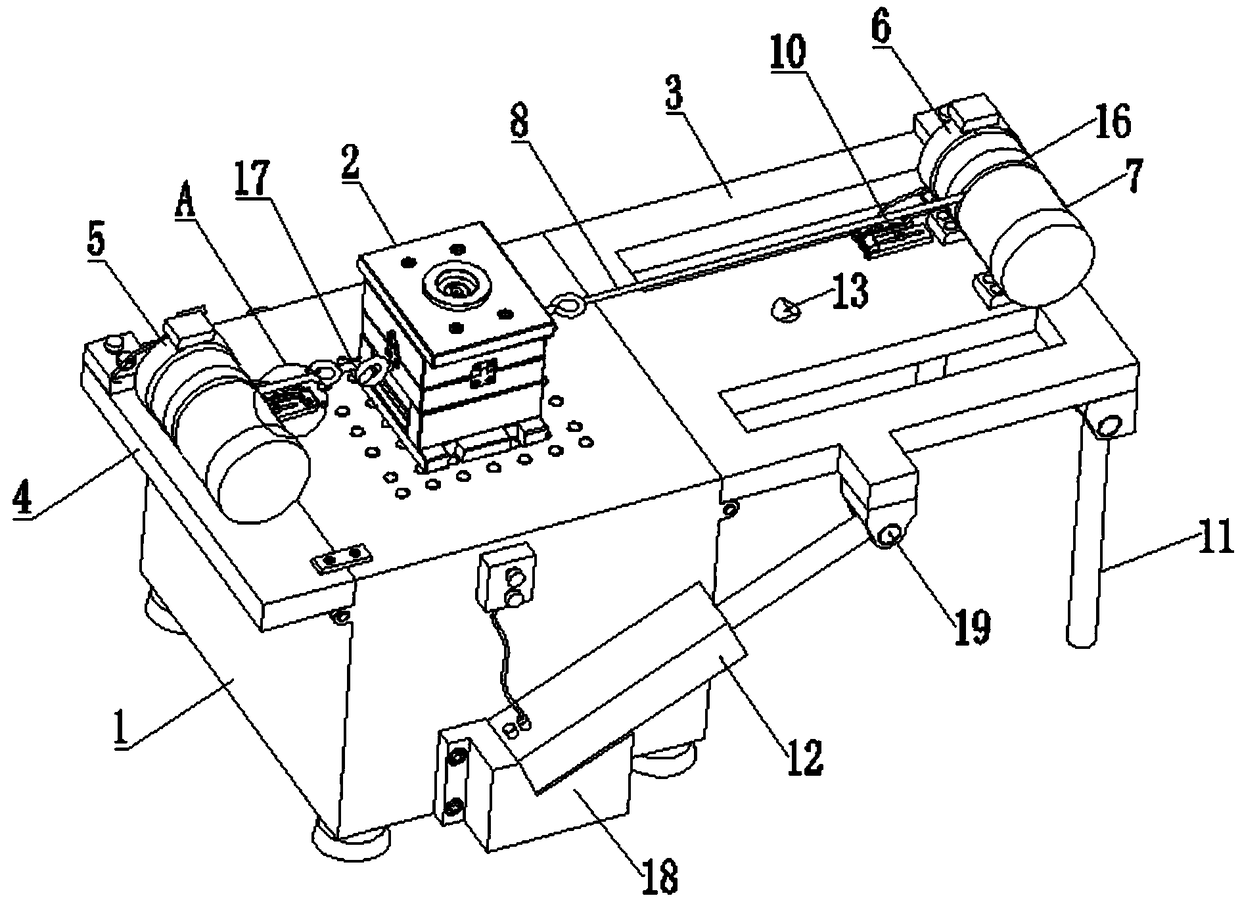

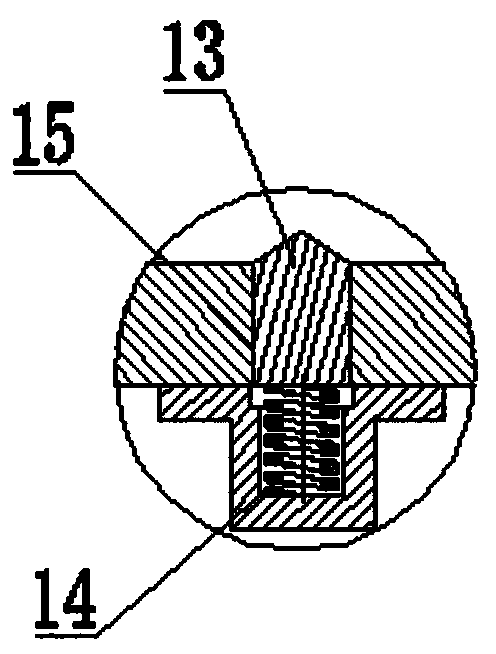

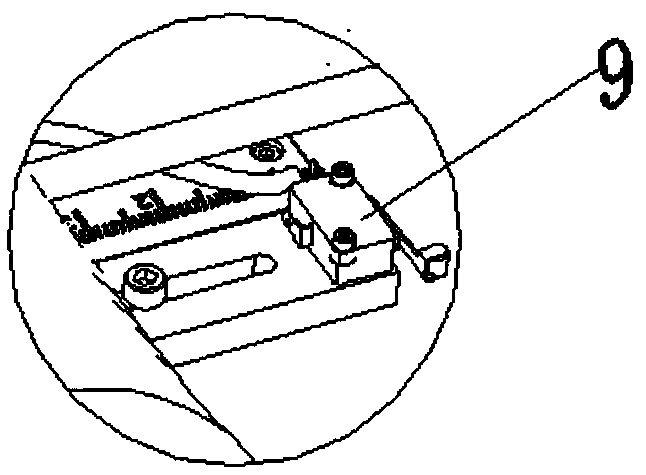

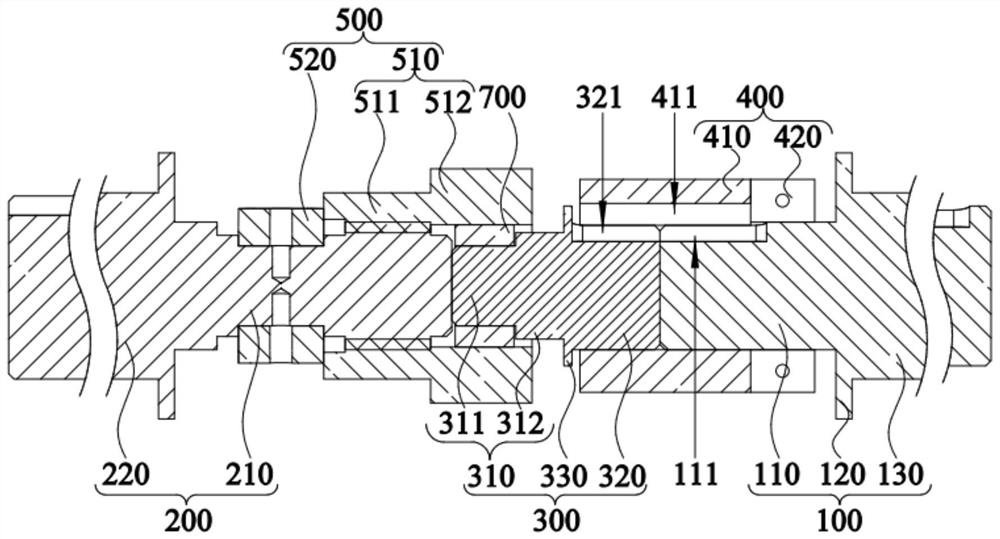

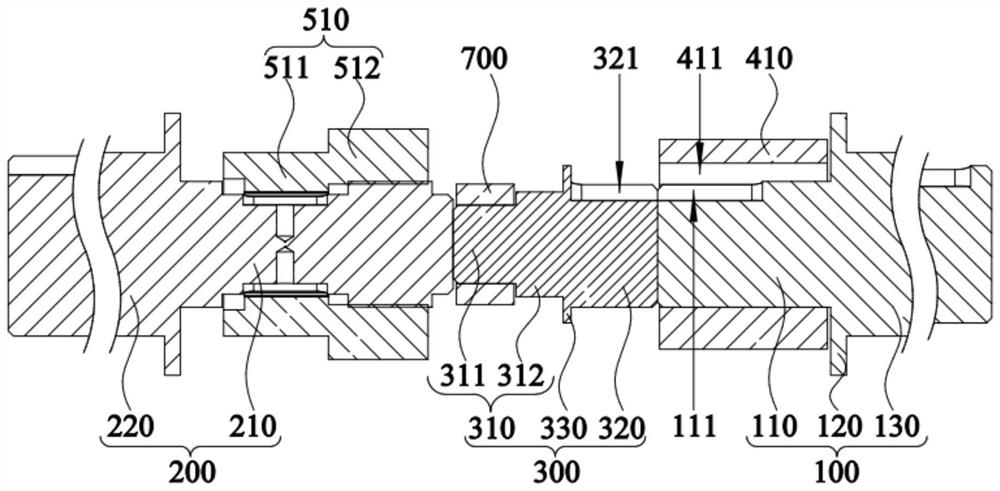

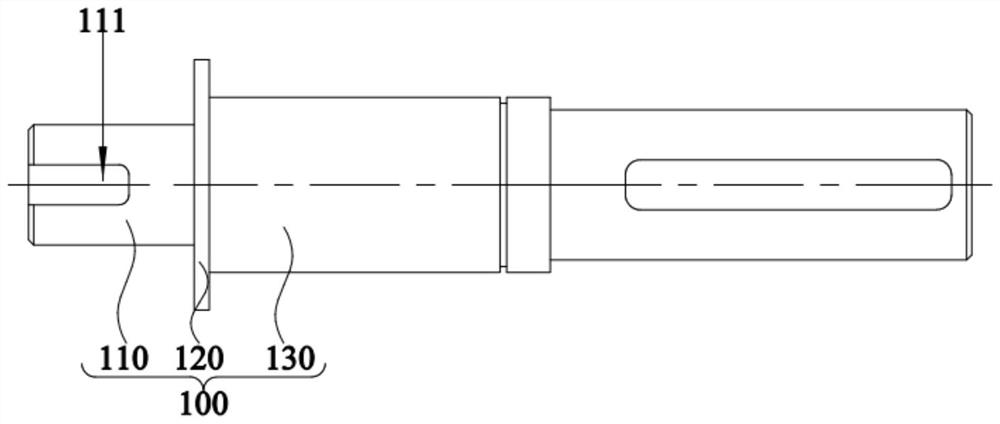

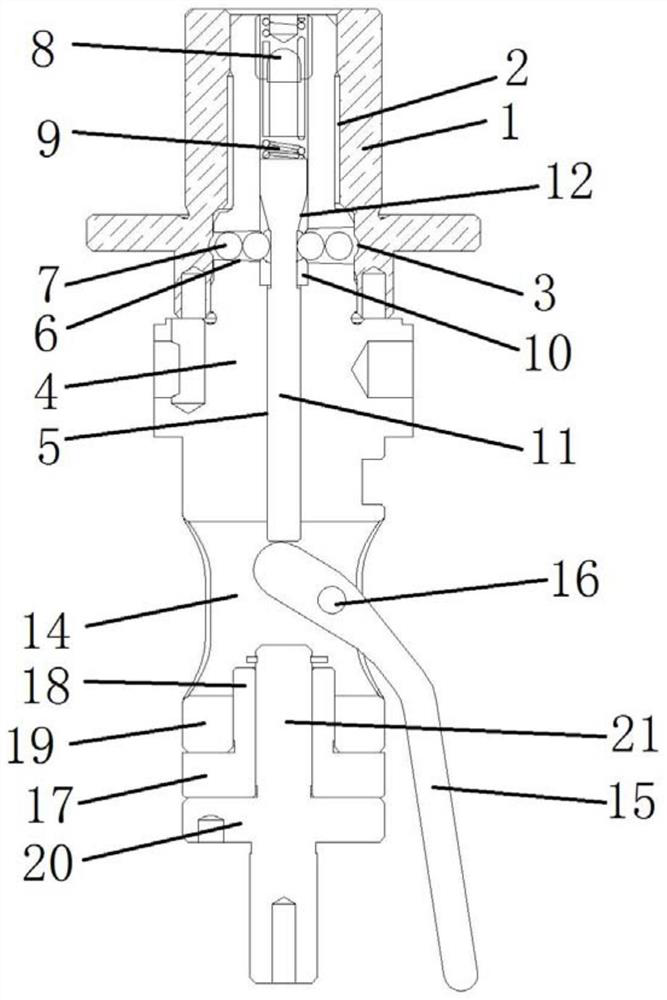

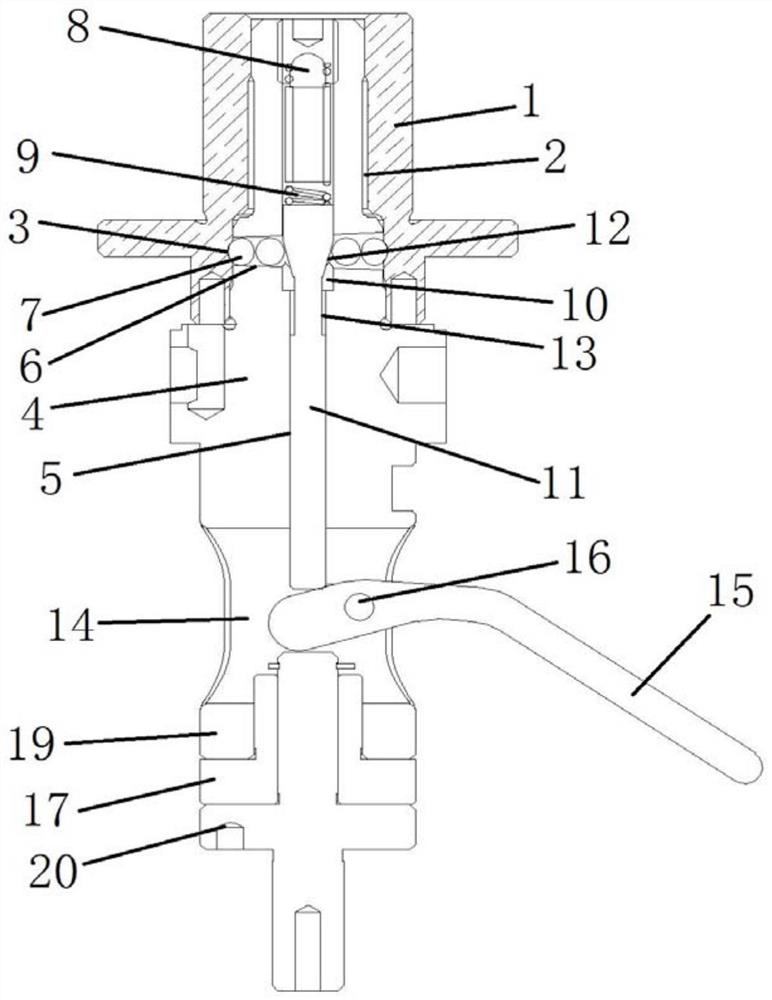

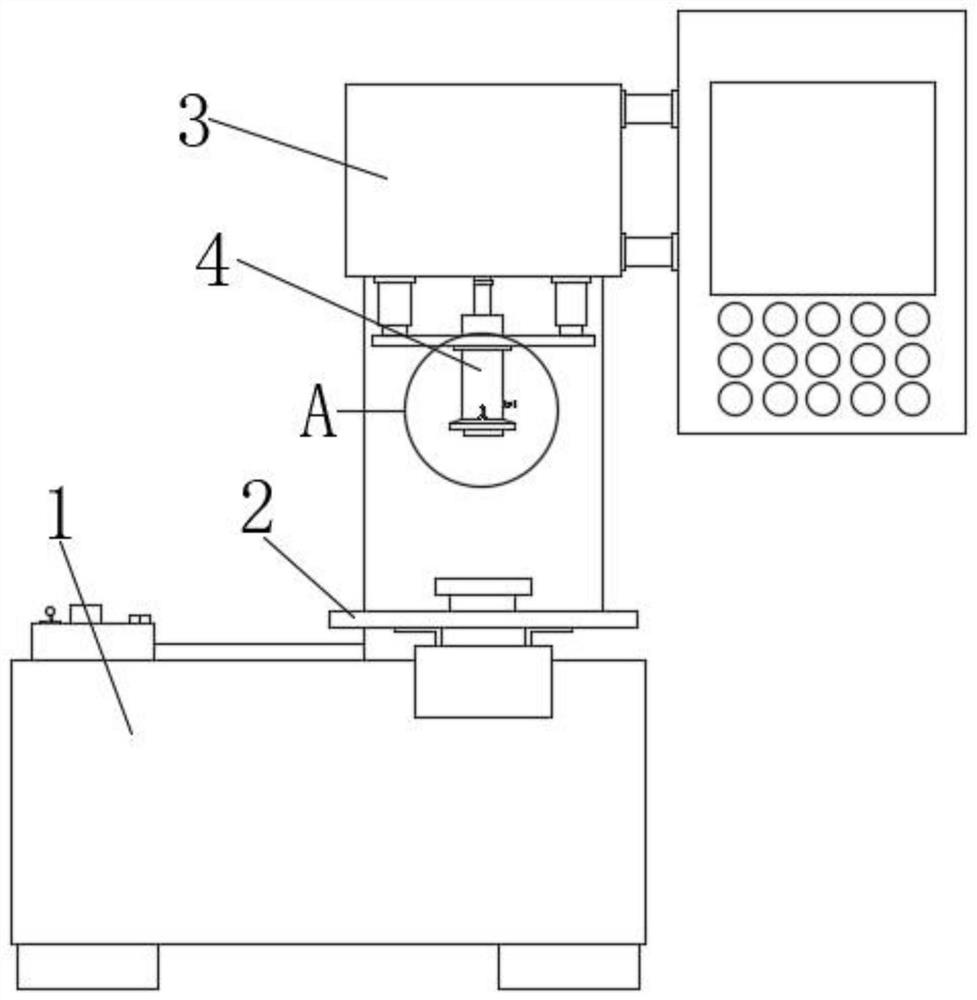

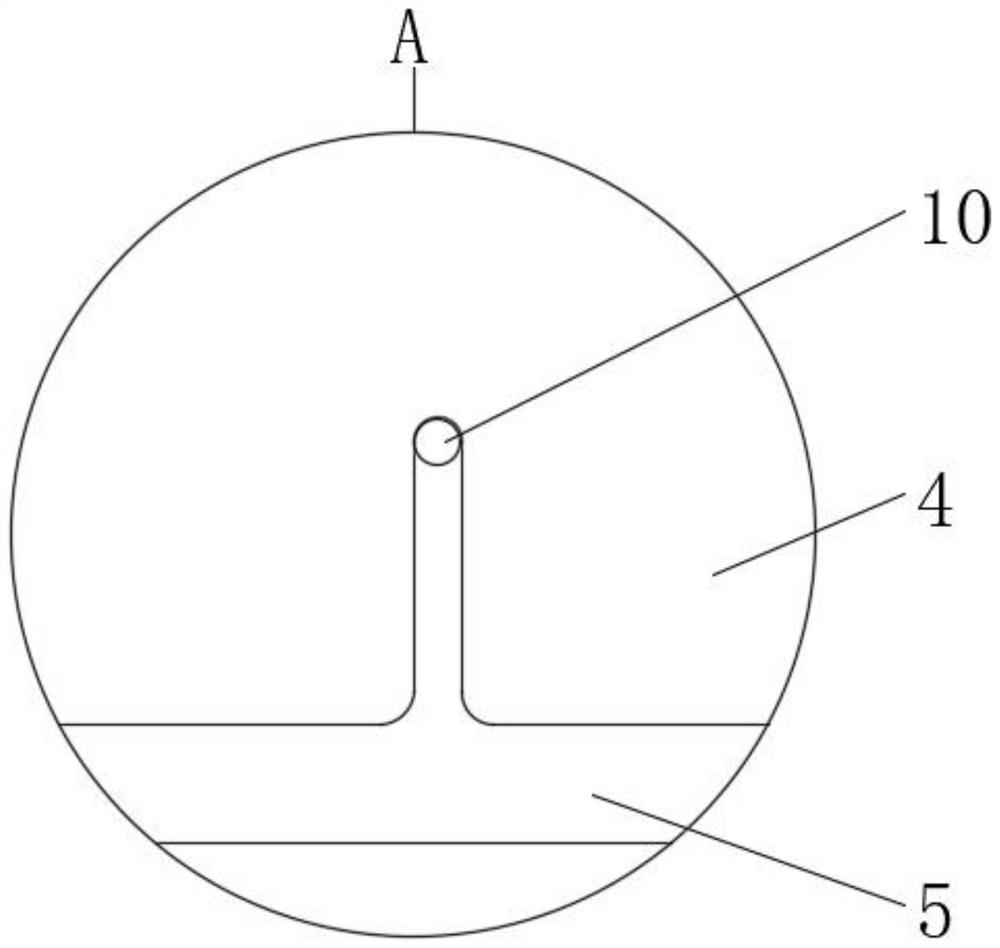

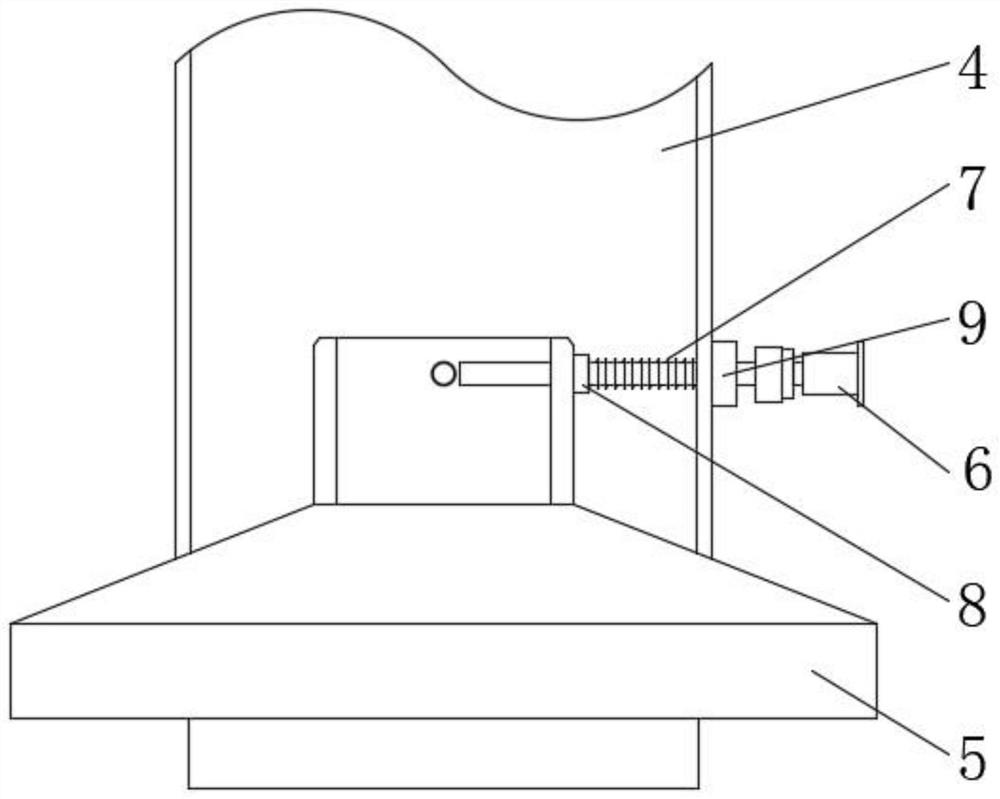

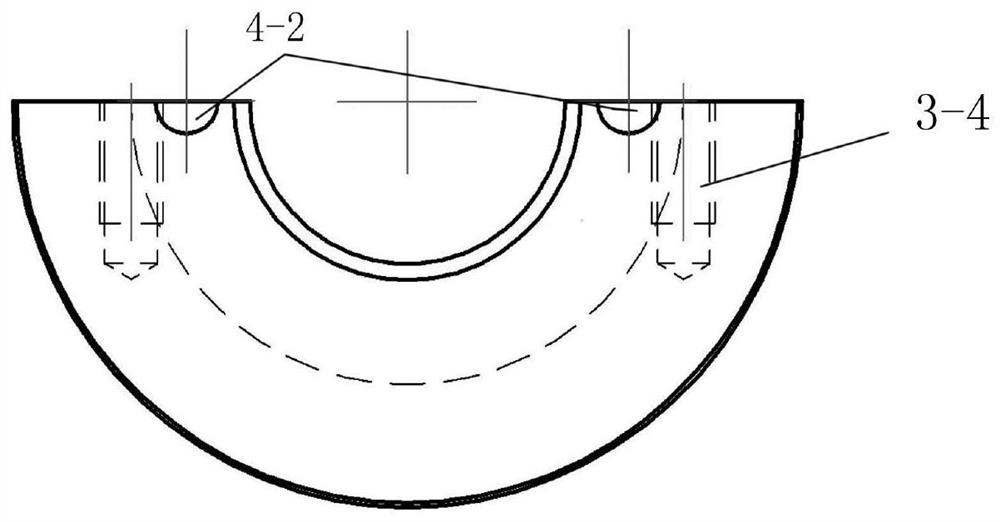

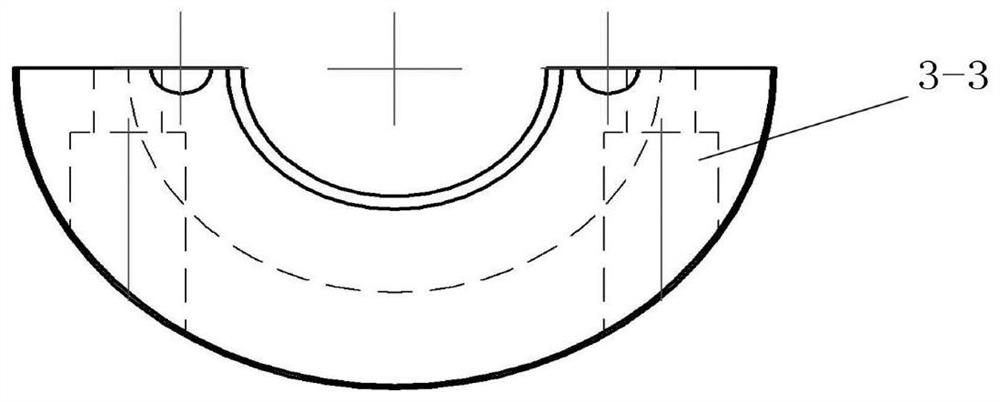

Cylinder body hydraulic clamp quick-change type pressing mechanism

ActiveCN111590360AIncrease productivitySimple and reliable structurePositioning apparatusMetal-working holdersPhysicsEngineering

The invention relates to a cylinder body hydraulic clamp quick-change type pressing mechanism which comprises a supporting assembly and a remodeling assembly. During remodeling, the remodeling assembly can be taken out by rotating the remodeling assembly by a certain angle. The cylinder body hydraulic clamp quick-change type pressing mechanism has the effects of being rapid in remodeling, simple in structure, easy to operate and high in flexibility, the purpose of being compatible with collinear production of different machine types can be achieved, and the working efficiency can be improved.

Owner:KUNMING YUNNEI POWER

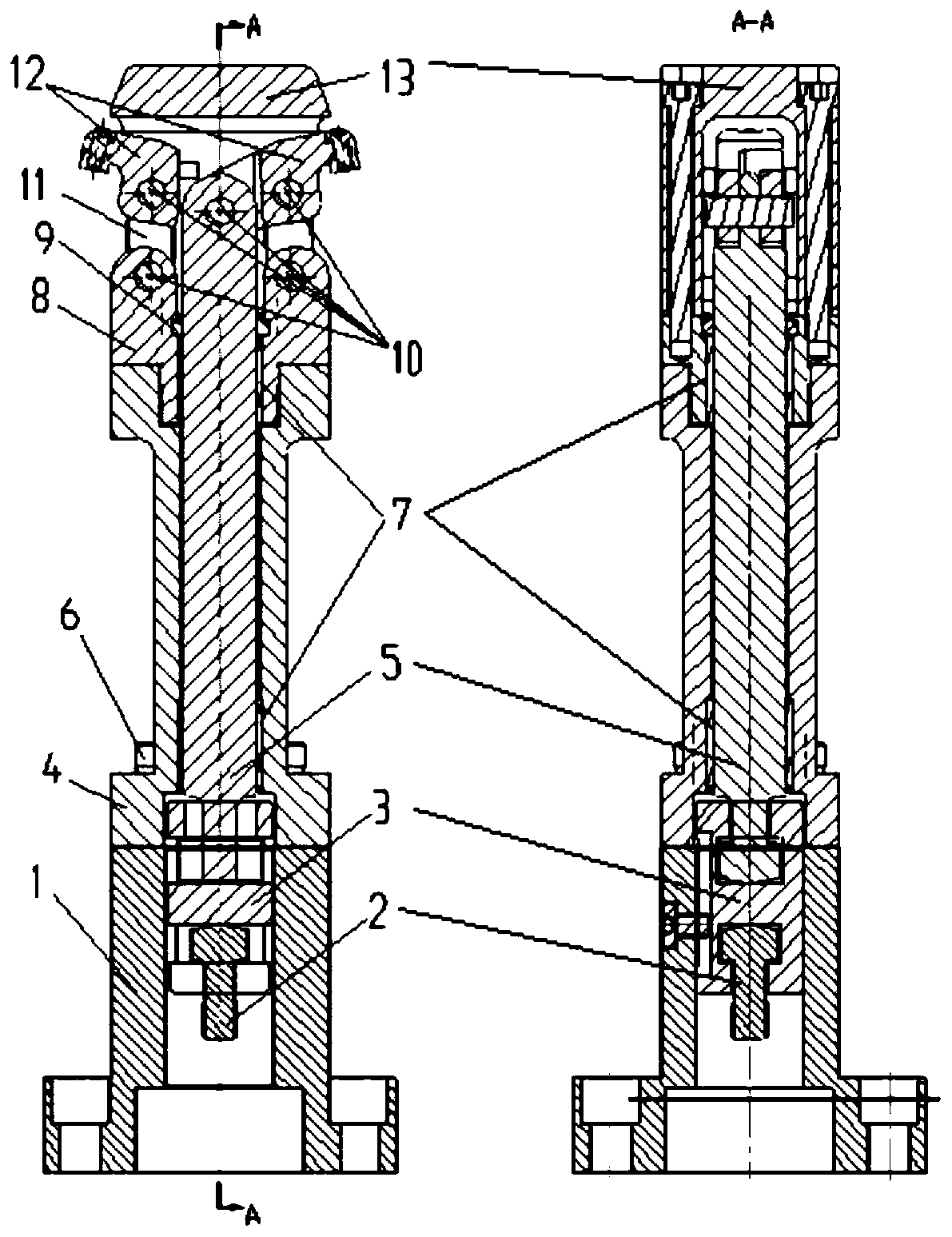

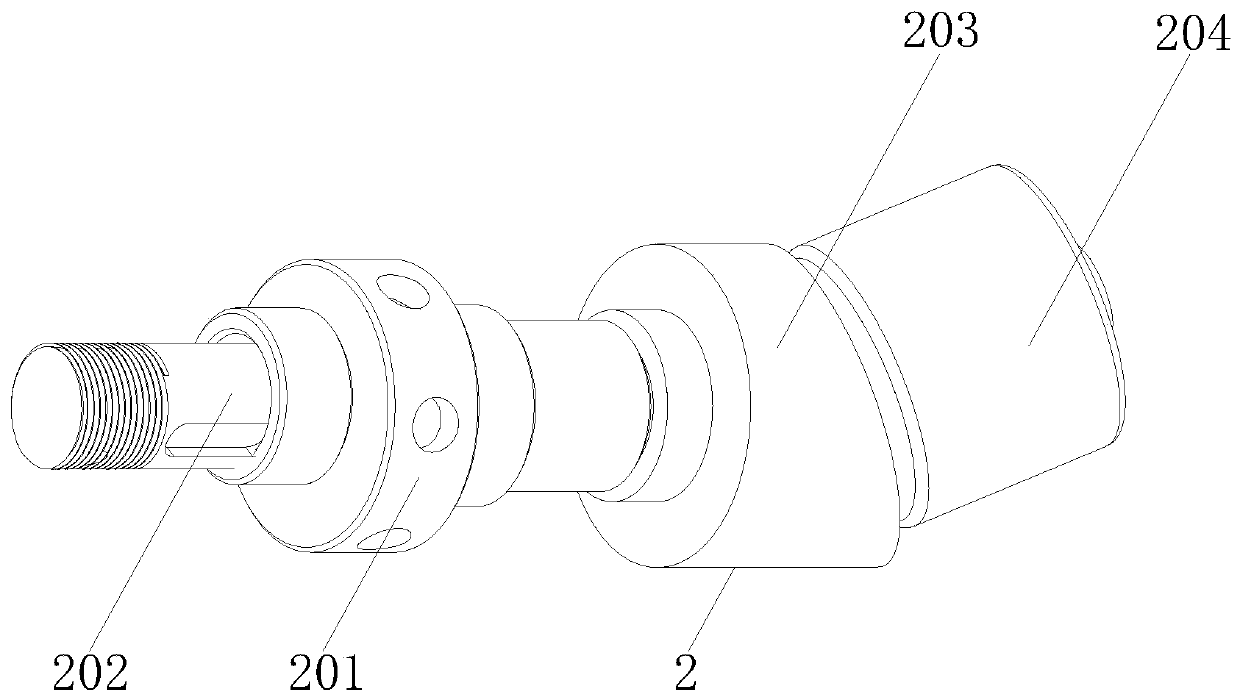

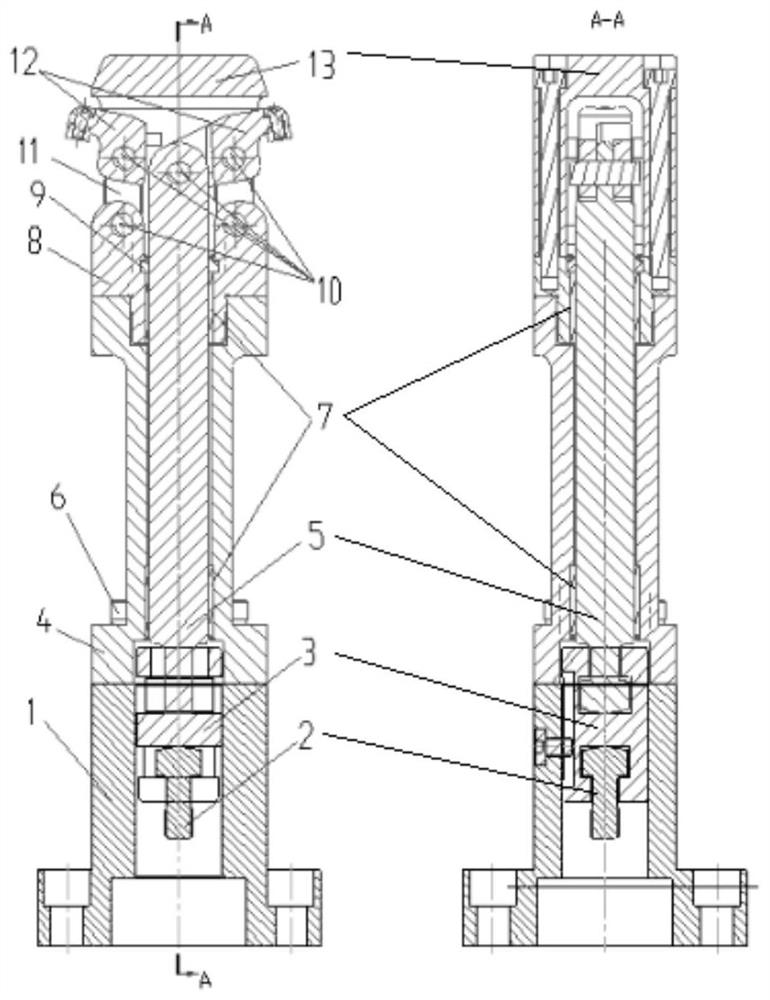

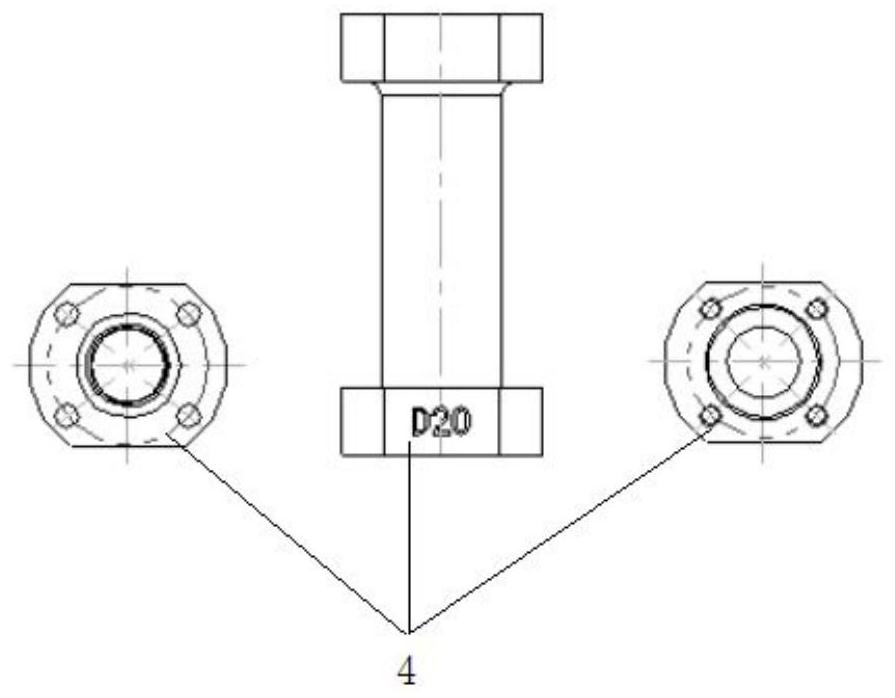

Coupler

The invention discloses a coupler. An axial inner hole is formed in the middle of the coupler. The coupler is partitioned into an upper half coupler body and a lower half coupler body through a planepassing through the center axis of the coupler; the upper half coupler body and the lower half coupler body are detachably combined; the coupler further comprises a plurality of positioning pins, anda first annular clamping groove and a second annular clamping groove are formed in the inner wall of the inner hole of the coupler; and a plurality of axial pin holes matched with the positioning pinsin a one-to-one correspondence mode are formed in each of the two end surfaces of the coupler. The coupler provided by the invention is simple in structure, an operating space is expanded, front faces of screwheads can be clearly seen during dismounting, the coupler can be fast dismounted and mounted conveniently, and the remodeling efficiency is improved.

Owner:GUANGXI YUCHAI MASCH CO LTD

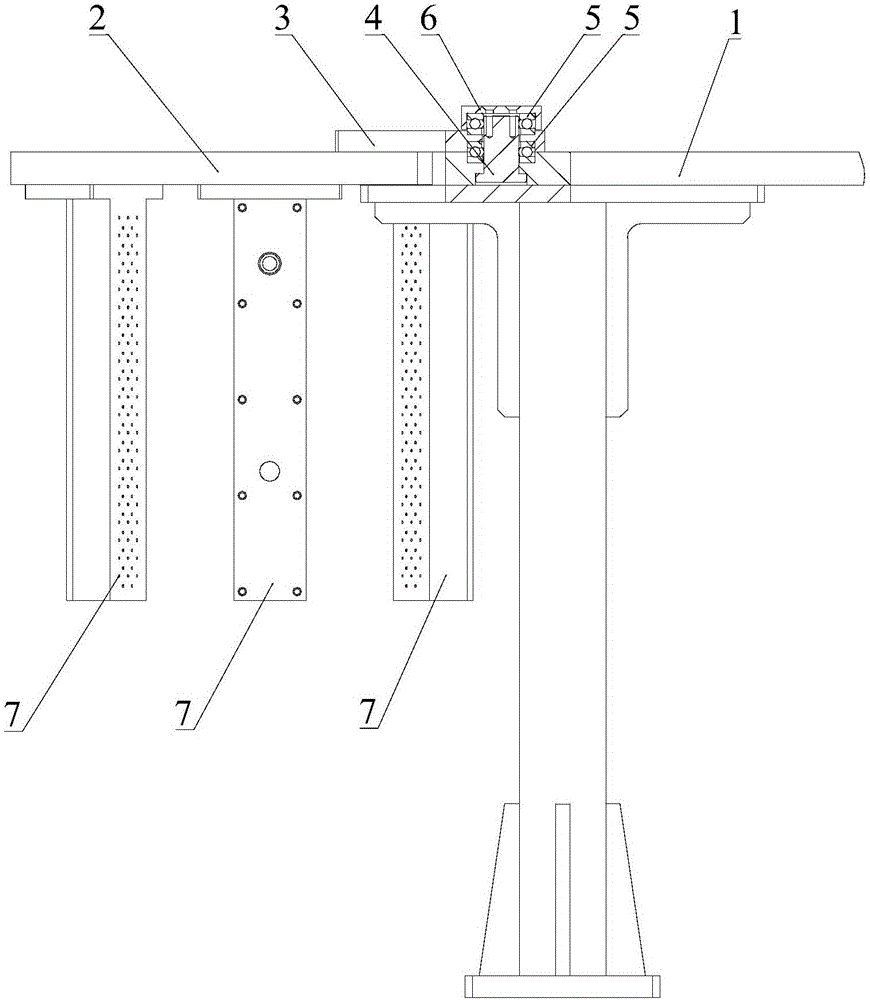

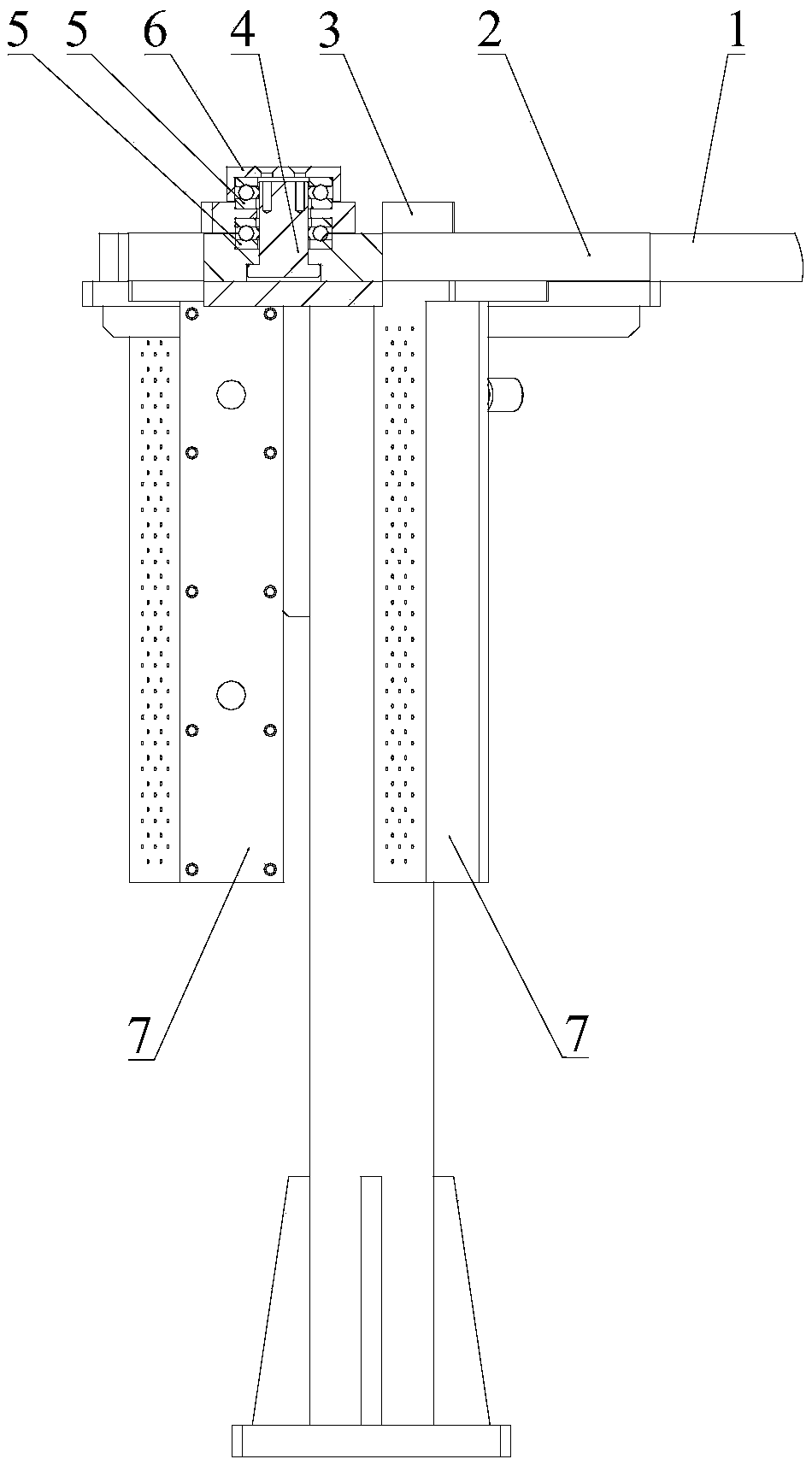

Movable swing arm type machine tool cooling spraying mechanism

ActiveCN106670891AQuick repairEasy maintenanceMaintainance and safety accessoriesBall bearingFixed frame

The invention discloses a movable swing arm type machine tool cooling spraying mechanism. The movable swing arm type machine tool cooling spraying mechanism comprises a fixing frame fixed to a machine tool, a movable swing arm, a transition plate, thrust ball bearings, spraying boxes and positioning screws, wherein the movable swing arm, the transition plate and the thrust ball bearings are in butt joint with the fixing frame, and the spraying boxes and the positioning screws are fixed to the movable swing arm; the transition plate is arranged above the fixing frame and the movable swing arm and is fixedly connected with the movable swing arm; shaft rings of the thrust ball bearings are connected and matched with the fixing frame, and base rings of the thrust ball bearings are connected and matched with the transition plate; and the corresponding positions on the transition plate and the fixing frame are provided with screw holes for installing the positioning screws. According to the movable swing arm type machine tool cooling spraying mechanism, when the machine tool performs machining, the movable swing arm can be fixed through the positioning screws, the positioning screws are detached when a rear mechanism needs to be maintained, the movable swing arm can swing relative to the fixing frame, and therefore a maintaining space is made, and the purpose of debugging or maintaining the rear mechanism is achieved.

Owner:WUHAN HEATKING MACHINE ELECTRICAL EQUIP

Bidirectional laser welding auxiliary jig

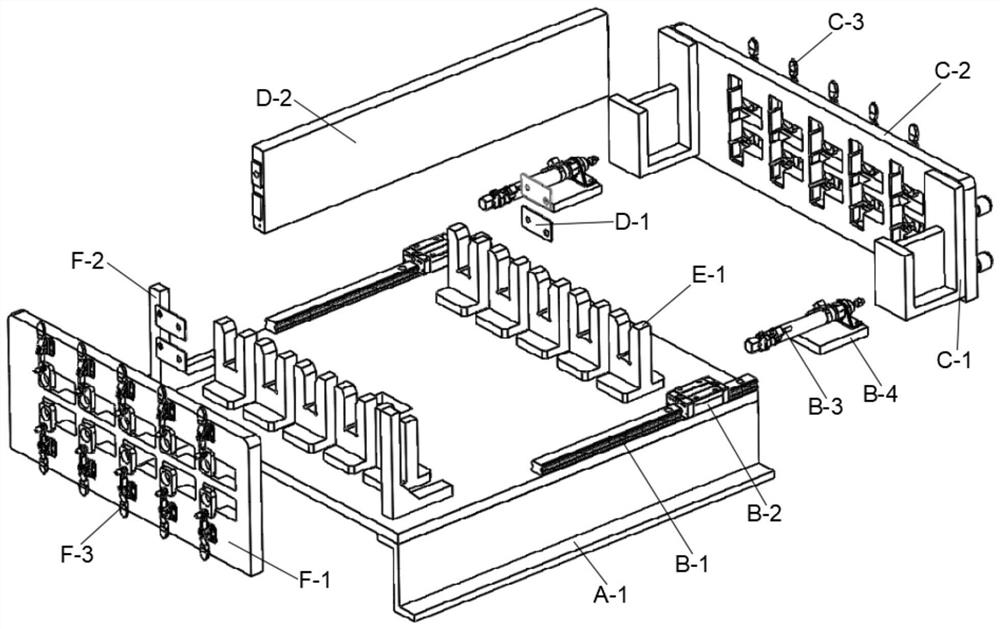

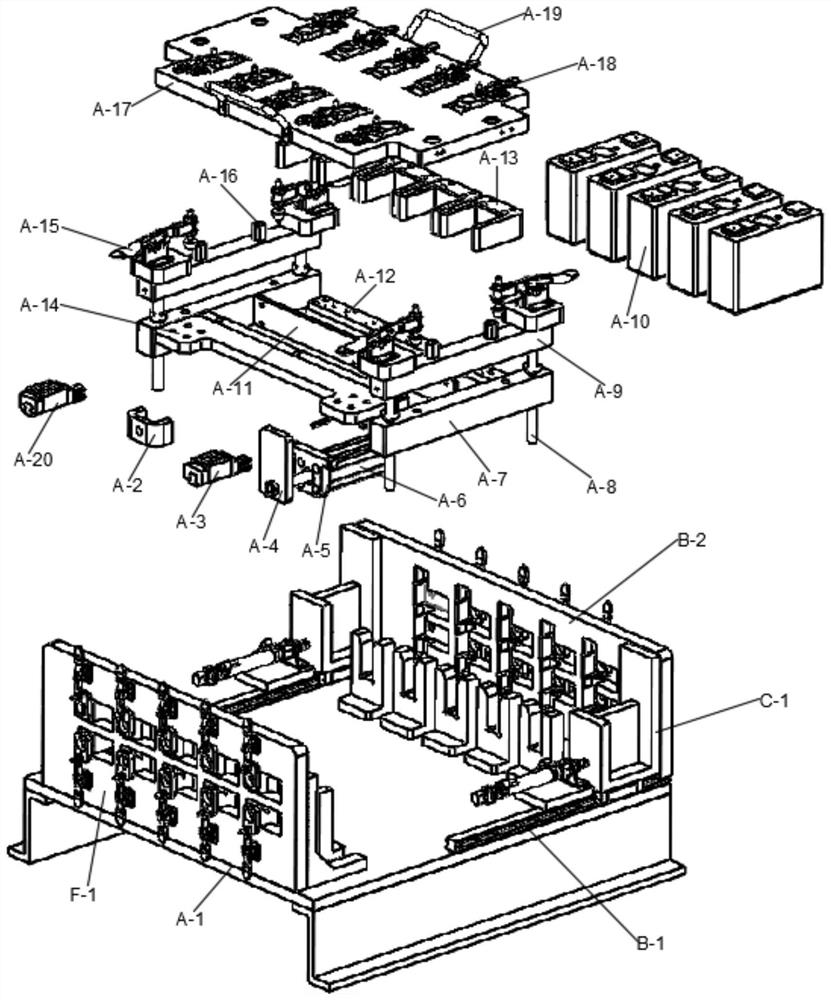

PendingCN114193013AEasy to operateImprove changeover efficiencyLaser beam welding apparatusBattery cellLaser soldering

The invention discloses a bi-directional laser welding auxiliary jig, and relates to the technical field of laser welding equipment, the bi-directional laser welding auxiliary jig comprises a jig main body and a welding battery cell, the jig main body comprises a welding mechanism, and the welding mechanism is used for horizontally welding the welding battery cell; the welding mechanism comprises a support assembly, a horizontal tensioning assembly, a horizontal welding jig movable end, a battery cell positioning clamping groove and a fixed end, the support assembly comprises a platform rack, the horizontal tensioning assembly comprises a first sliding rail and a first sliding block installed on the first sliding rail in a sliding mode, a pressing execution piece fixing block is fixed to the first sliding block, and the pressing execution piece fixing block is fixed to the platform rack. And a horizontal pressing execution piece is fixedly mounted at the top of the pressing execution piece fixing block. Two sets of positioning structures are adopted and are the horizontal welding positioning mechanism and the vertical welding positioning mechanism correspondingly. Welding paths in two different directions can be compatible in design, operation is convenient and easy, remodeling efficiency is high, and laser welding efficiency and takt are improved.

Owner:铭镭激光智能装备(河源)有限公司

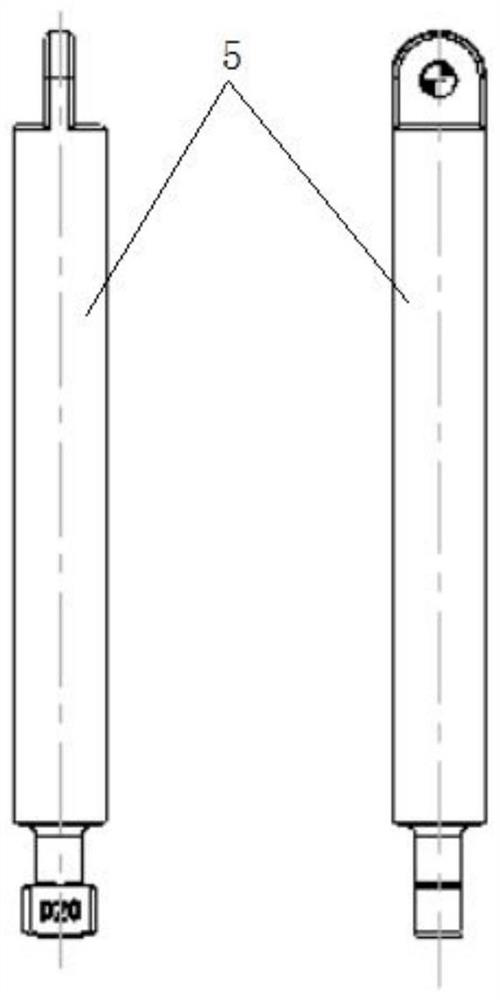

Embossing device provided with tensioning structure and used for textile non-woven fabric production

PendingCN114016243AImprove changeover efficiencySimple and reasonable structurePattern makingElectric machineryTelescopic cylinder

The invention belongs to the technical field of textile machinery, and discloses an embossing device provided with a tensioning structure and used for textile non-woven fabric production, the embossing device comprises a rack, the rack is provided with a main control box, the rack is provided with a motor, the output end of the motor is connected with a driving wheel, the rack is rotatably connected with two rotating shafts, the rotating shafts are provided with matching cylinders, and the end parts of the two rotating shafts are provided with driven wheels; a belt is connected between the driving wheels and the driven wheels, tensioning supports are connected to the two ends of the rack and provided with sliding grooves, the sliding grooves are in sliding fit with rectangular sliding blocks, the rectangular sliding blocks are rotationally connected with tensioning rollers, the tensioning supports are connected with cross beams, the cross beams are in threaded connection with adjusting screws, and the ends of the adjusting screws are rotationally connected with semicircular supporting blocks. Side plates are installed on the rack, the side plates are provided with slideways, the slideways are slidably matched with rectangular blocks, the rectangular blocks are rotatably connected with mounting columns, the mounting columns are fixedly provided with embossing cylinders, the side plates are fixedly provided with center supports, the center supports are provided with telescopic cylinders, and the output ends of the telescopic cylinders are connected with transverse plates.

Owner:河源市源城区创新创业科技服务中心 +1

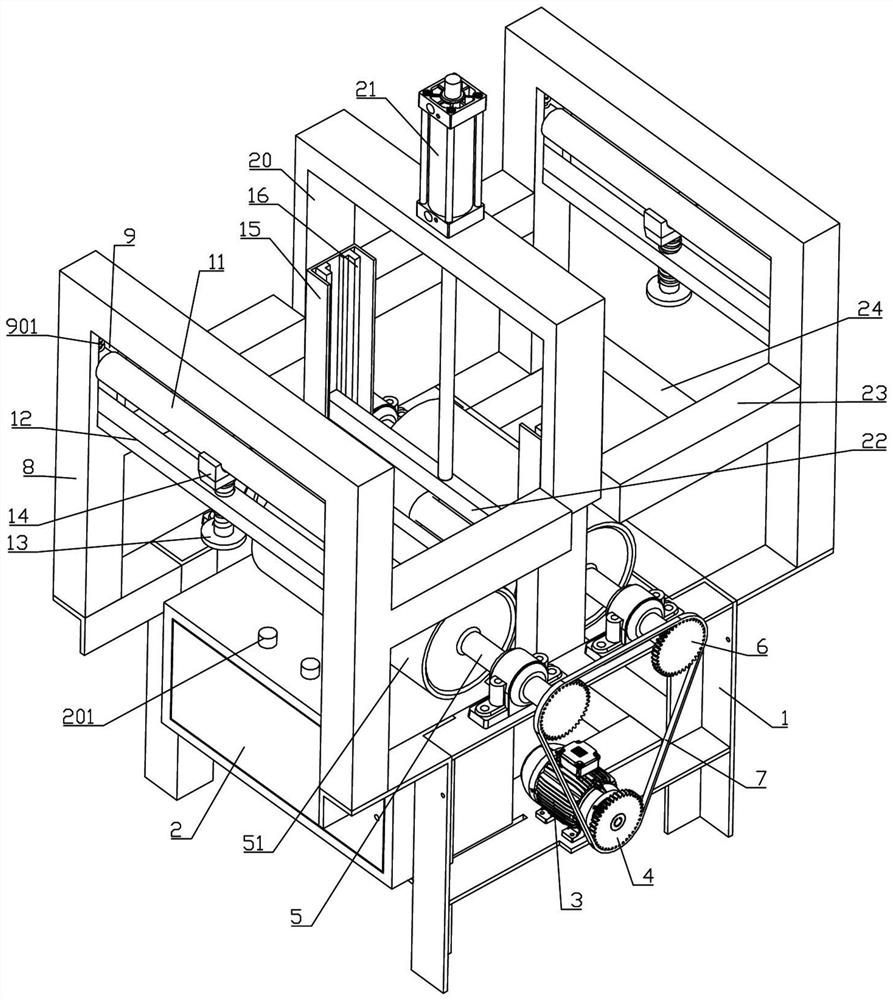

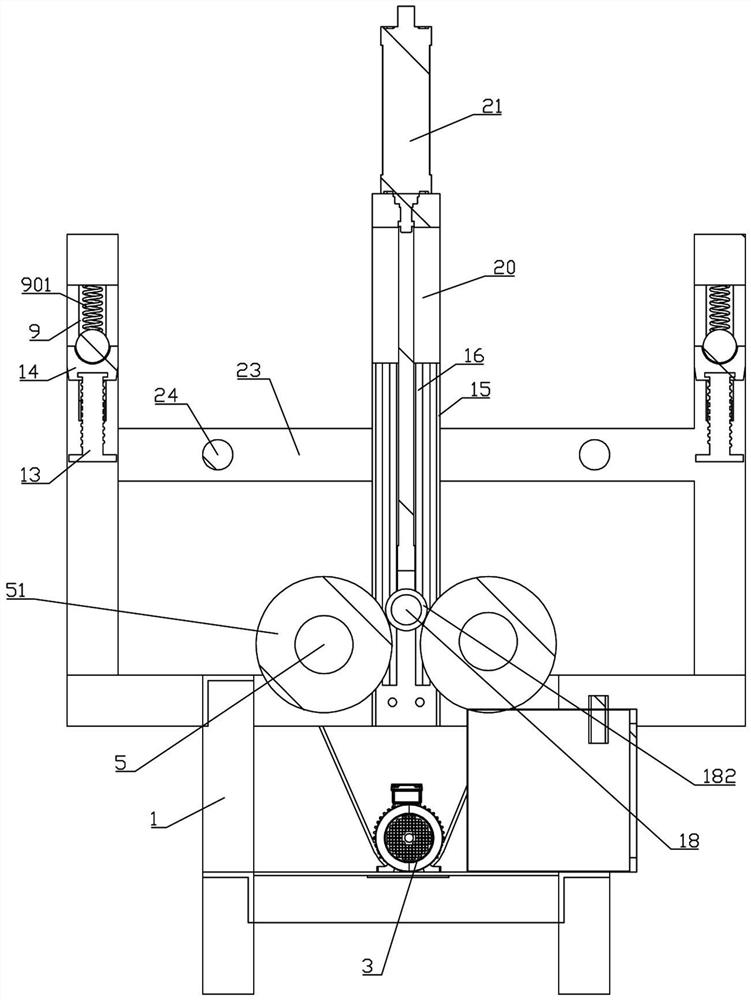

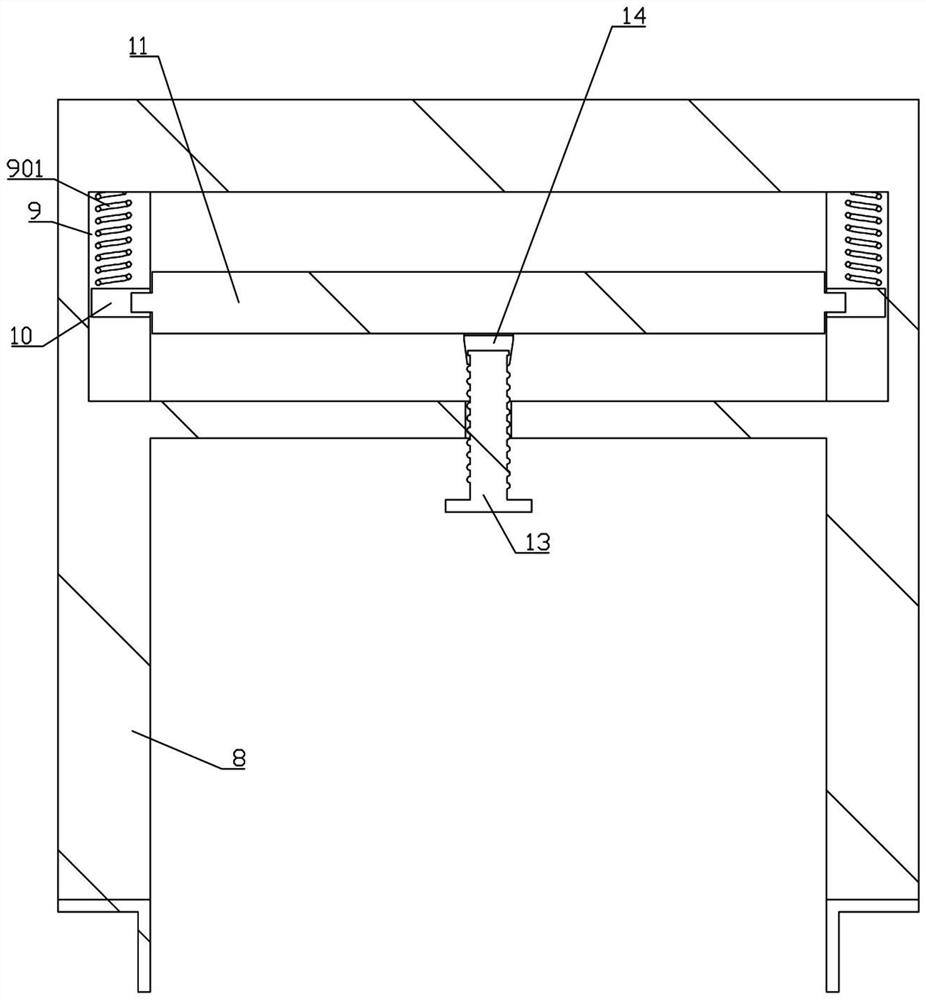

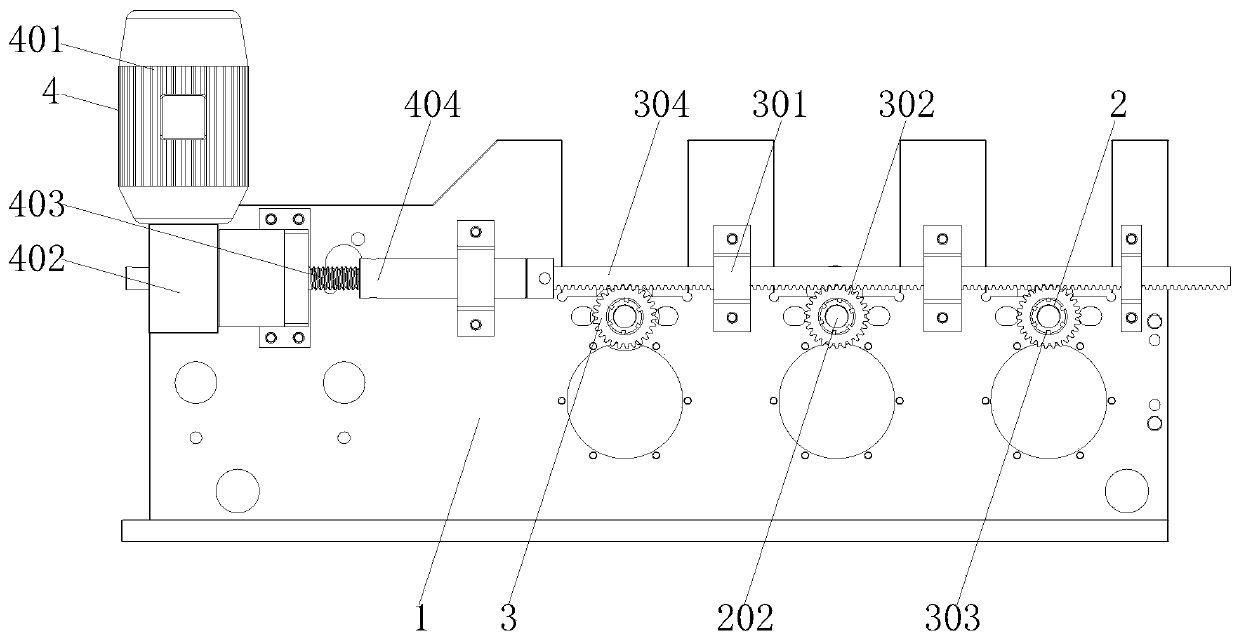

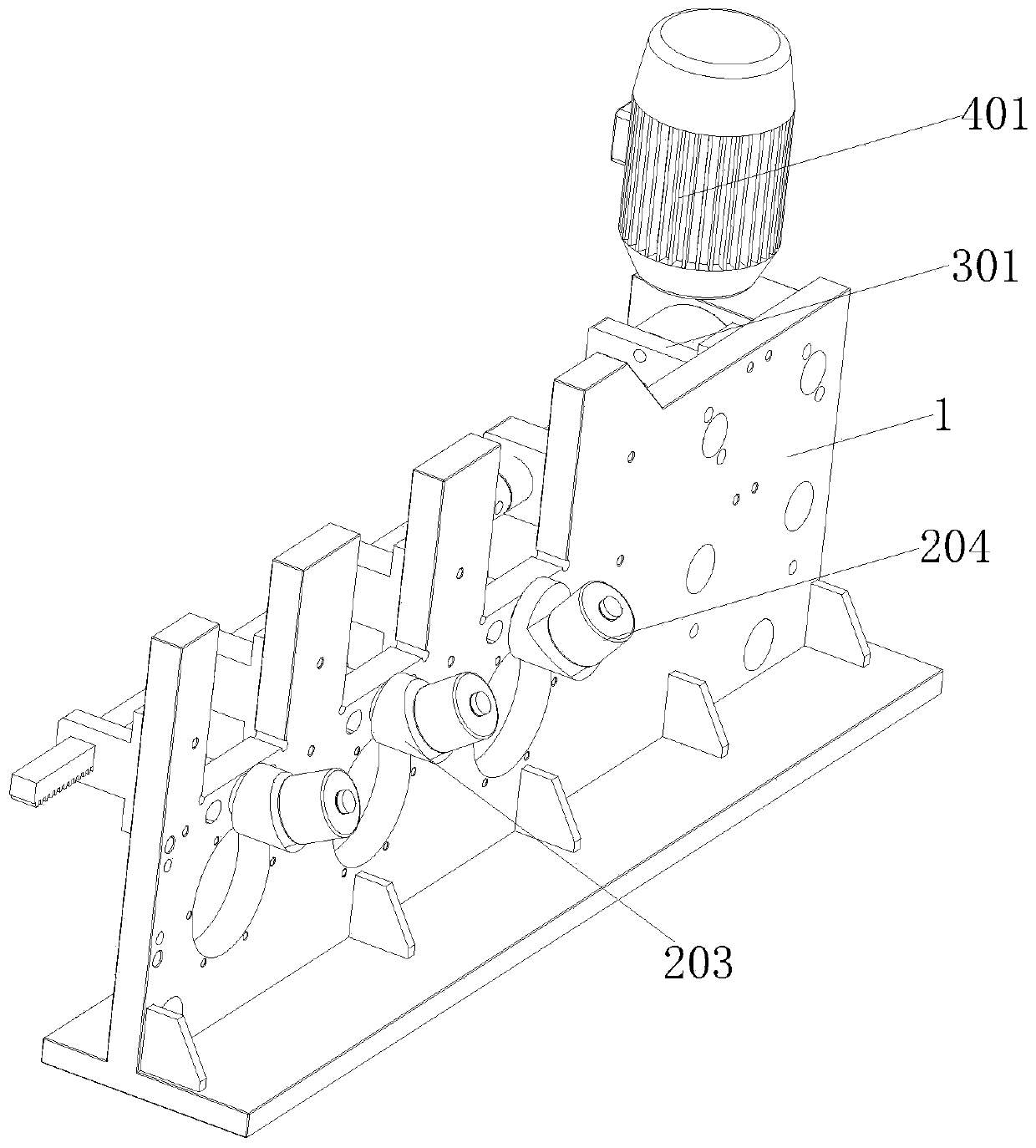

Turnover mechanism of numerical control CZ all-in-one machine

The invention belongs to the technical field of numerical control CZ all-in-one machines, and particularly relates to a turnover mechanism of a numerical control CZ all-in-one machine. The turnover mechanism comprises a rack, turnover assemblies, a transmission assembly and a power mechanism, wherein the turnover assemblies are fixedly connected with the rack and the transmission assembly and usedfor switching between C-shaped steel and Z-shaped steel and positioning the C-shaped steel or the Z-shaped steel; the transmission assembly is fixedly connected with the rack, the turnover assembliesand the power mechanism; and CZ remodeling adjustment can be completed through the turnover assemblies. Compared with the prior art, the design of the power mechanism and the transmission assembly isadded, an existing manual adjustment structure is replaced, the advantage of high speed adjusting is achieved through automatic adjustment, and the labor intensity of operators can be reduced; driving force is provided through the power mechanism, and therefore the locking effect can be achieved through the power mechanism; and the multiple turnover assemblies can be adjusted at the same time through the transmission assembly, the remodeling efficiency is improved, and therefore the turnover mechanism is suitable for being used on the CZ all-in-one machine and has the use value.

Owner:南通华恒智能科技有限公司

Double-symmetrical parallel shaft co-rotating reverse speed reducer and spinning frame with same

PendingCN111442070AImprove changeover efficiencyReduce in quantityGearingContinuous wound-up machinesClassical mechanicsElectric machinery

The invention provides a double-symmetrical parallel shaft co-rotating reverse speed reducer. The double-symmetrical parallel shaft co-rotating reverse speed reducer comprises a motor and a gear box,the output end of the motor is connected to the gear box, the gear box is provided with a first output shaft which is rotated anticlockwise, and a second output shaft which is rotated clockwise. A spinning frame with the double-symmetrical parallel shaft co-rotating reverse speed reducer comprises a bottom plate, a first vertical plate, a second vertical plate and a short machine beam, the bottomof the first vertical plate and the bottom of the second vertical plate are correspondingly and fixedly installed on the bottom plate, one side of the first vertical plate is connected to the second vertical plate through the short machine beam, the other side of the first vertical plate is provided with a first bracket for installing a first double-symmetrical parallel shaft co-rotating reverse speed reducer, the upper part of the short machine beam is provided with a second bracket for installing a second double-symmetrical parallel shaft co-rotating reverse speed reducer, and the top of thefirst vertical plate is provided with a third bracket for installing a third double-symmetrical parallel shaft co-rotating reverse speed reducer. According to the double-symmetrical parallel shaft co-rotating reverse speed reducer, the benefit of a spinning machine is improved, the cost is reduced, the environment is protected, the function of equipment is improved, automation, digitization, networking and intellectualization are achieved, the work intensity of workers is reduced, maintenance is avoided, the environment is protected, and the benefit is improved.

Owner:HEINLANZ TIANJIN IND TECH CO LTD

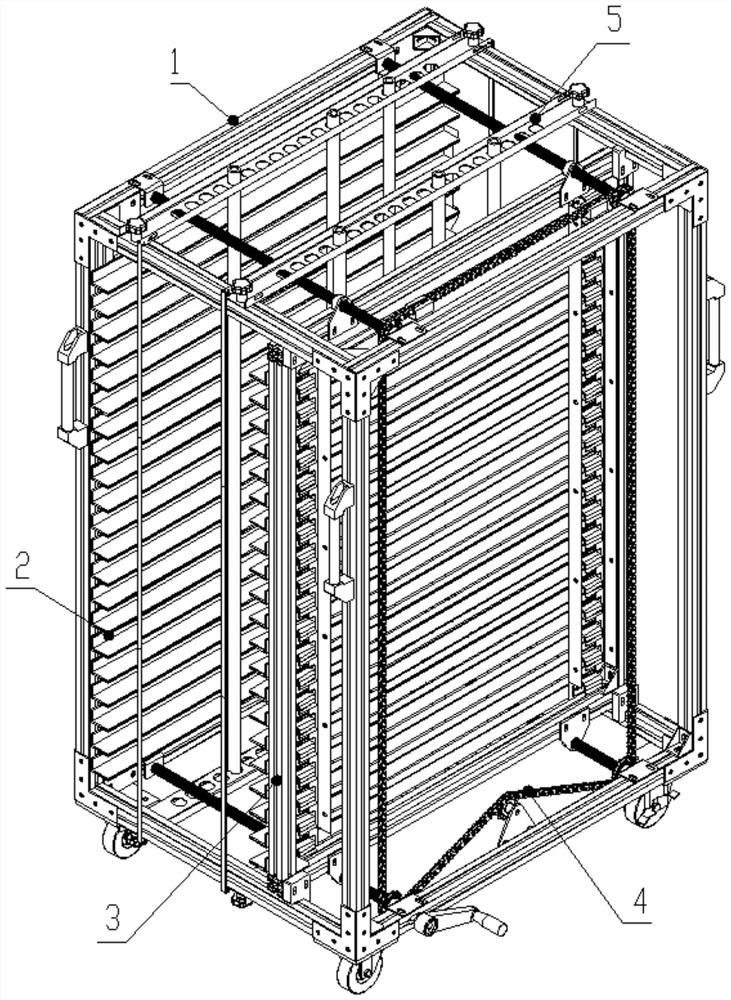

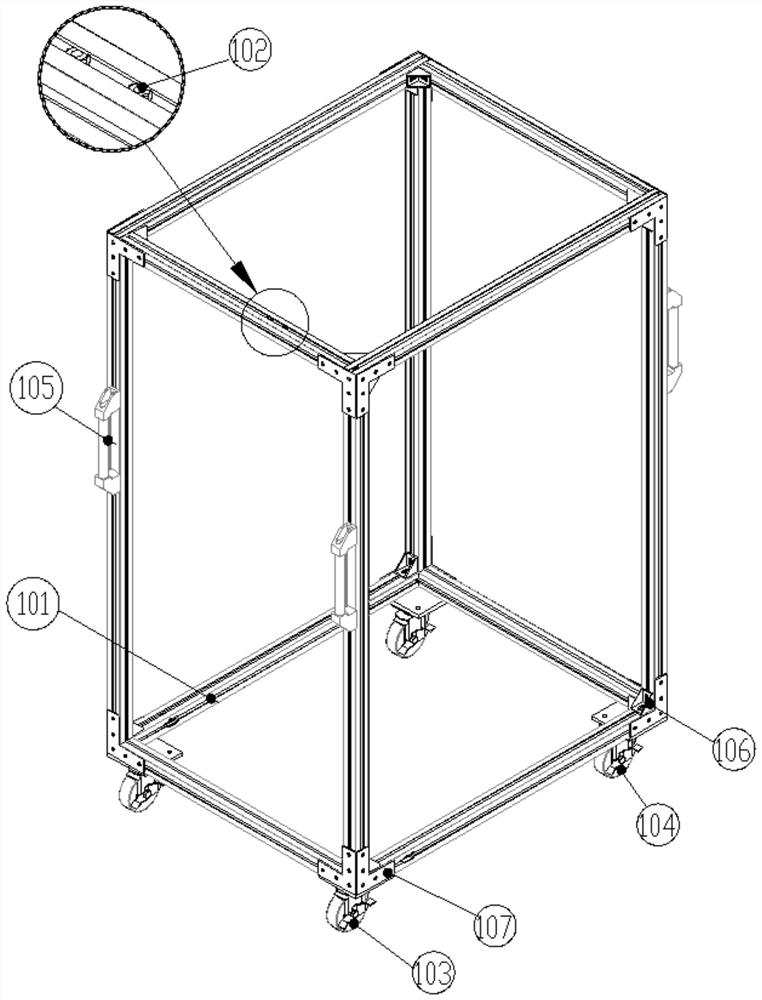

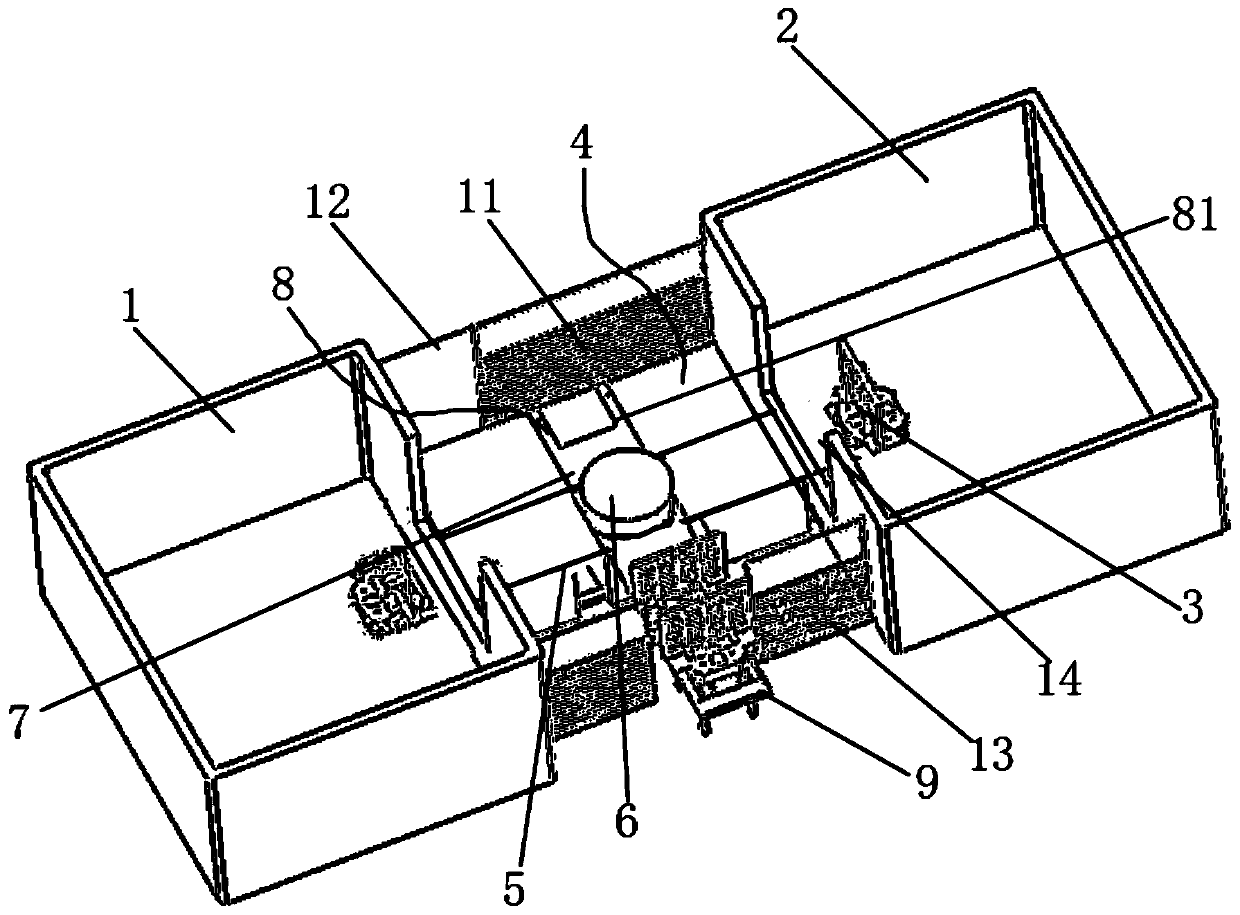

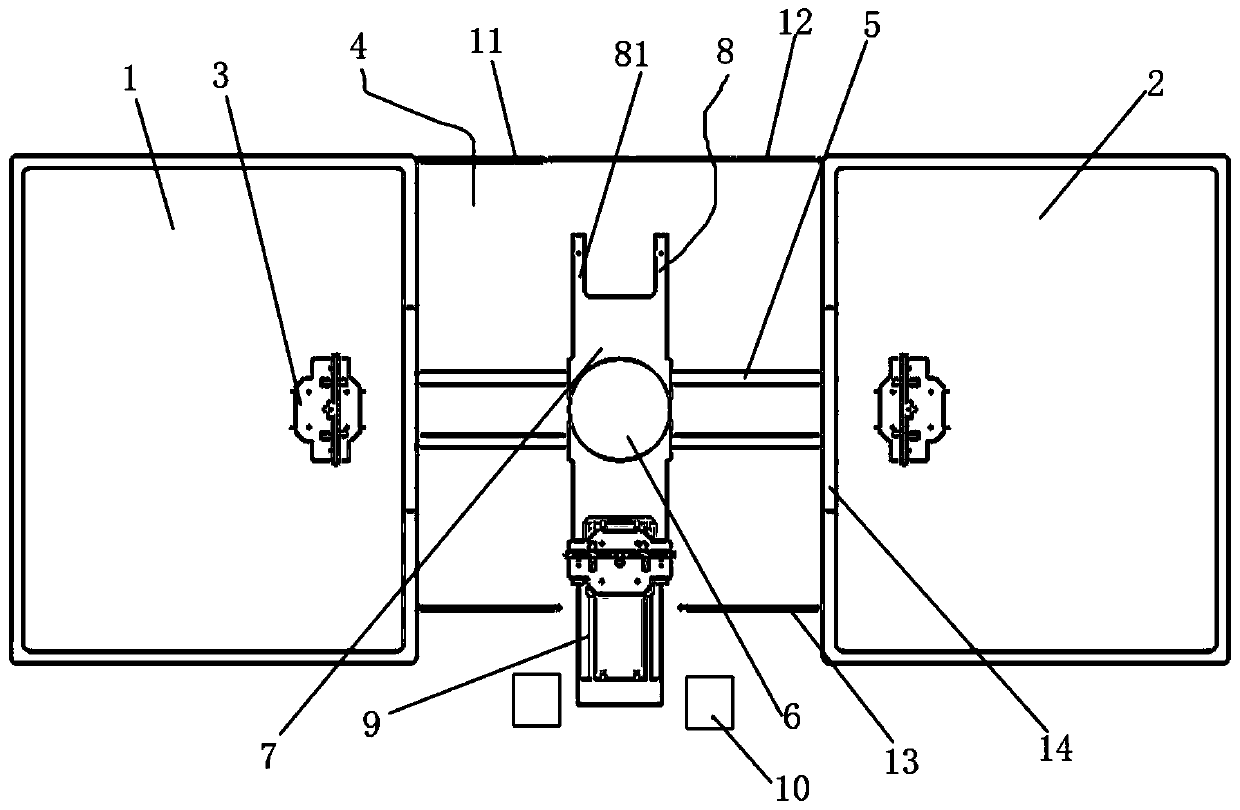

Universal type case material circulation frame

PendingCN112441307AComply with handling requirementsEasy to changeDischarging meansRigid containersProcess engineeringMechanical engineering

The invention provides a universal type case circulation material frame. The universal type case circulation material frame comprises an outer frame, a fixed side single-piece frame, an adjustable side single-piece frame, a width adjusting mechanism and a depth adjusting mechanism. The universal type case circulation material frame is used as a machine box type product in-process material transferring frame, is high in universality, can adapt to products of different sizes and models, is high in remodeling speed, and improves remodeling efficiency; and meanwhile, the universal type case circulation material frame is convenient to disassemble due to the adoption of an aluminum profile structure, saves storage space, can recycle materials, reduces cost and meets the environment-friendly requirement.

Owner:SHANGHAI SHENYAN COMM EQUIP MFR

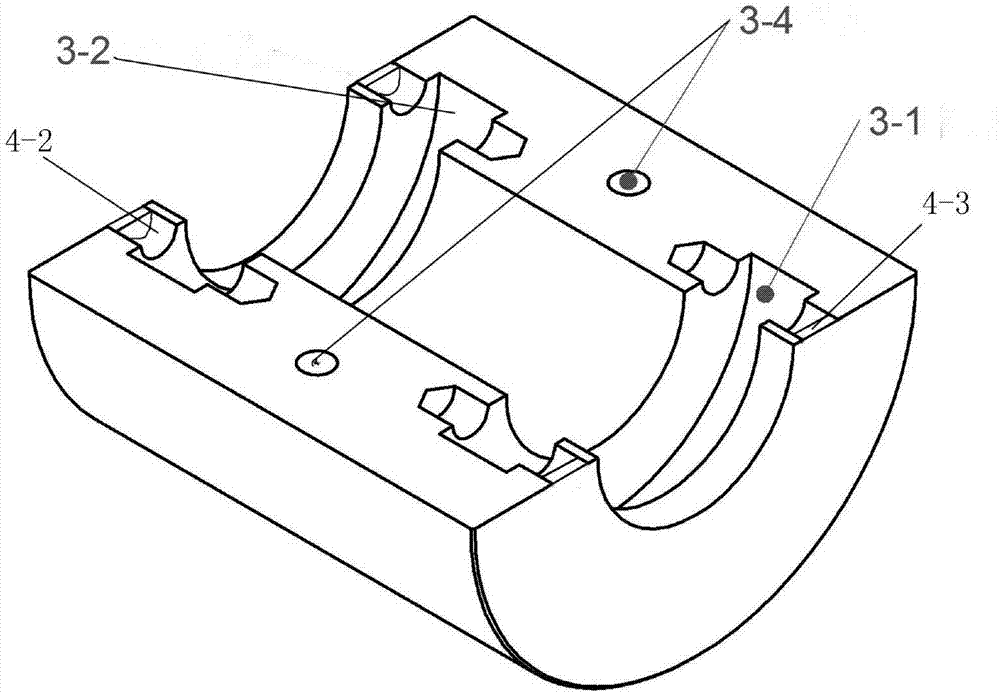

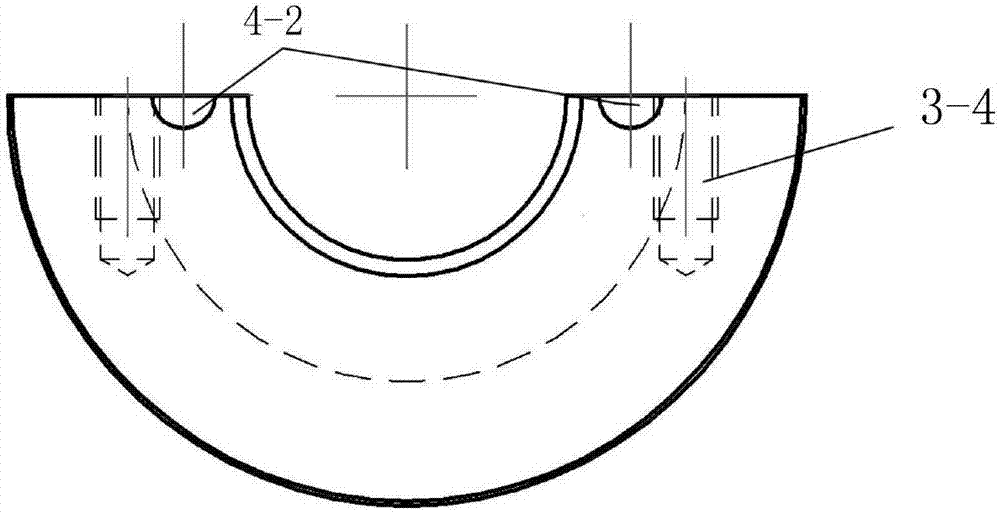

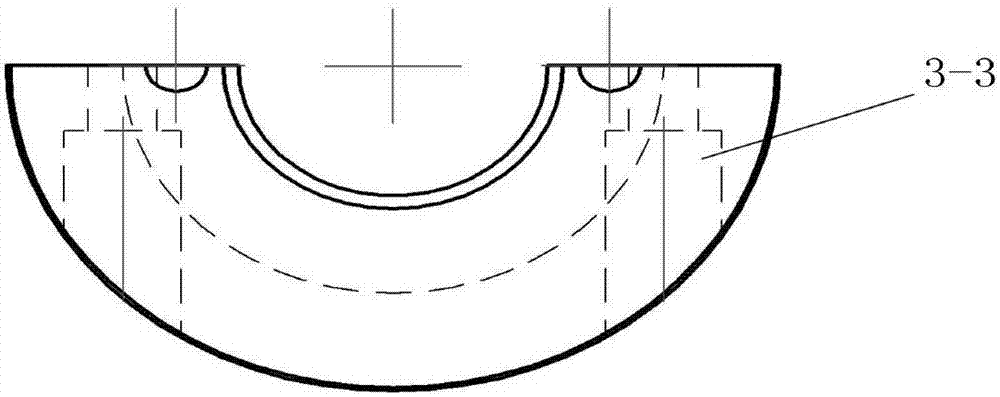

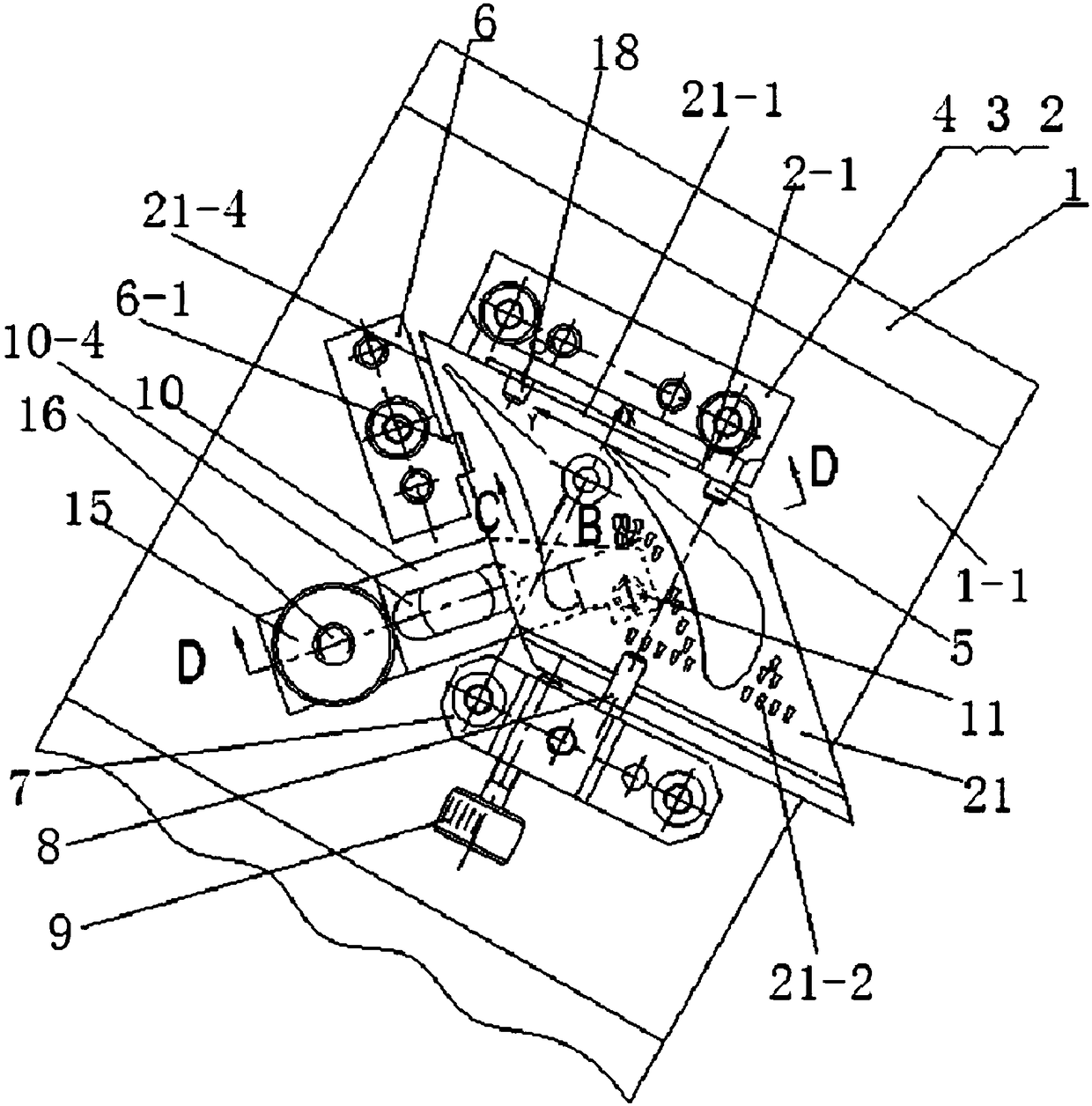

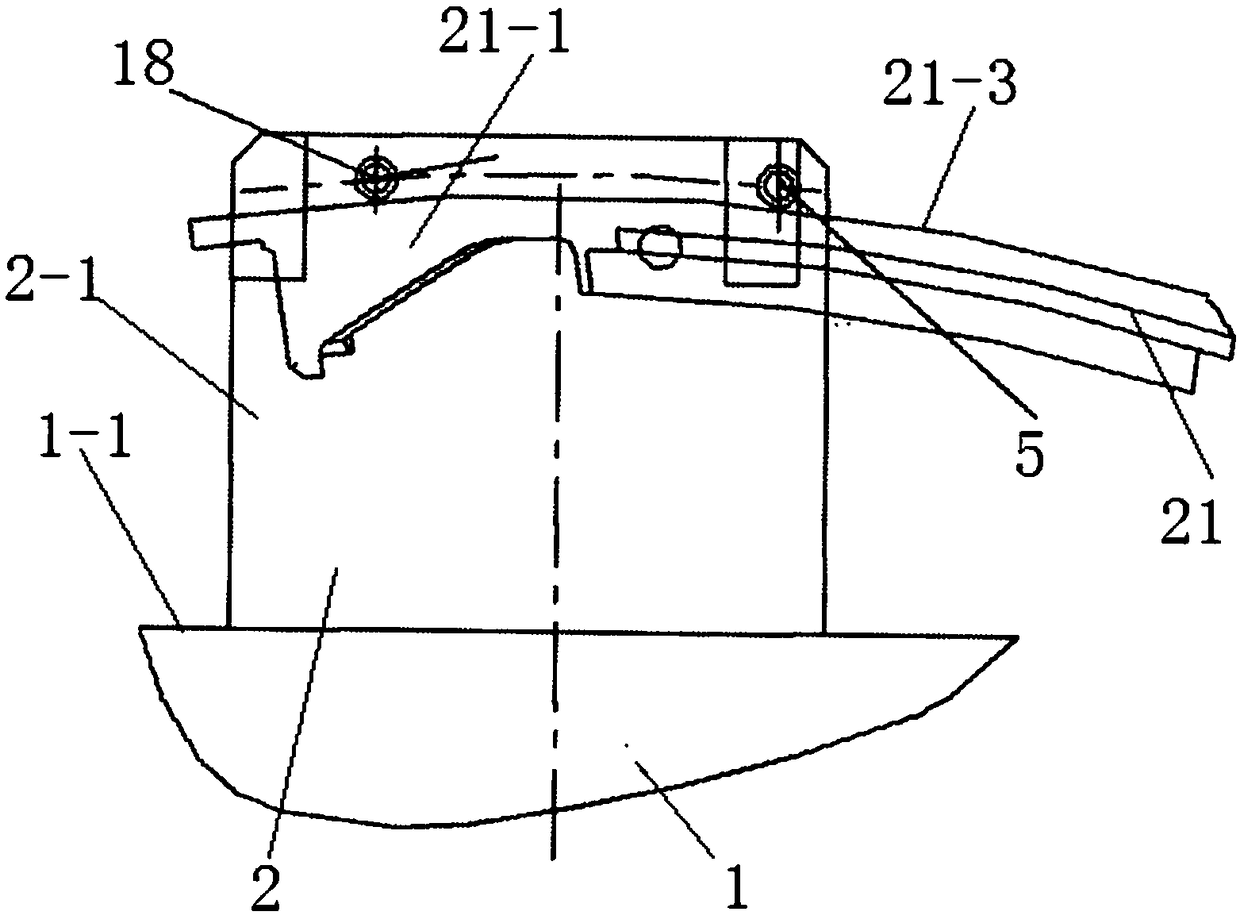

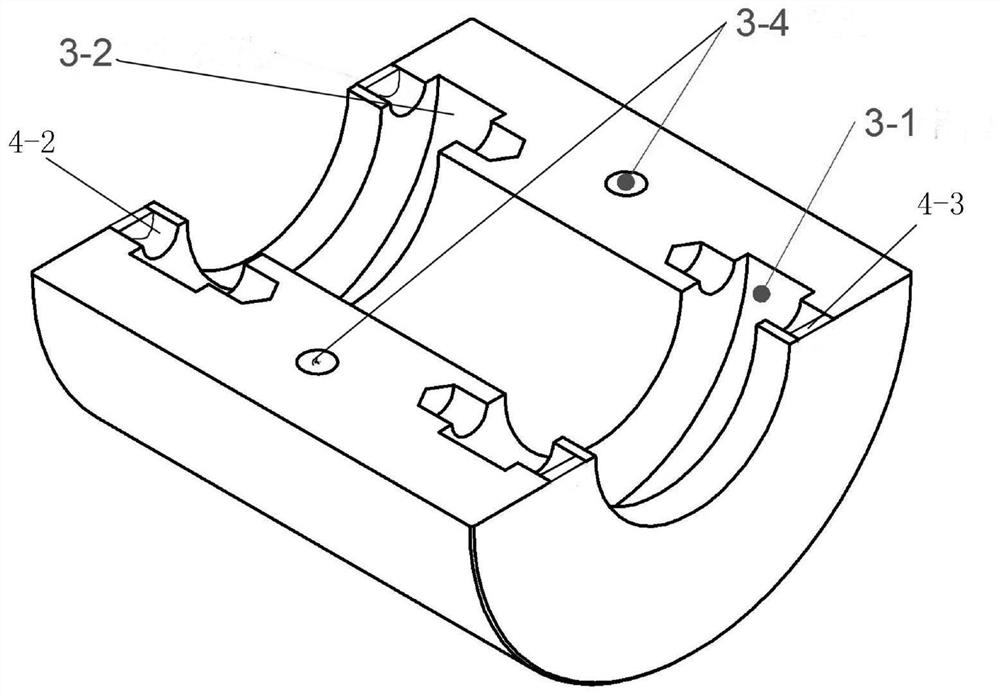

Device and method for quick changeover and clamping of guide vane edge plate dustpan hole processing

The invention belongs to the field of machining of aero-engine turbine guide blades, and relates to a guide blade edge plate dustpan hole machining rapid changing clamping device and method. The clamping device is in a whole type, a positioning block and a supporting plate are arranged on the angular face of a clamping device body, the direction of a guide blade edge plate is positioned through a positioning face on the positioning block, through two positioning pins on the positioning block and one positioning pin on the supporting plate, positioning of the circular-arc top face of the guide blade edge plate in the vertical height direction is achieved, and the guide blade edge plate is jacked upwards from the lower portion of the guide blade edge plate through a jacking mechanism so that the guide blade edge plate is clamped; the exhaust side end face and the positioning face of the positioning block are attached, the guide blade edge plate is jacked upwards by adjusting the jacking mechanism, the circular-arc top face of the guide blade edge plate is tightly attached to the first positioning pin, the second positioning pin and the third positioning pin, a uniform gap is arranged between the exhaust side end face and the positioning face, and the beneficial effects of being compact in structure and rapid and convenient to operate are achieved.

Owner:AECC AVIATION POWER CO LTD

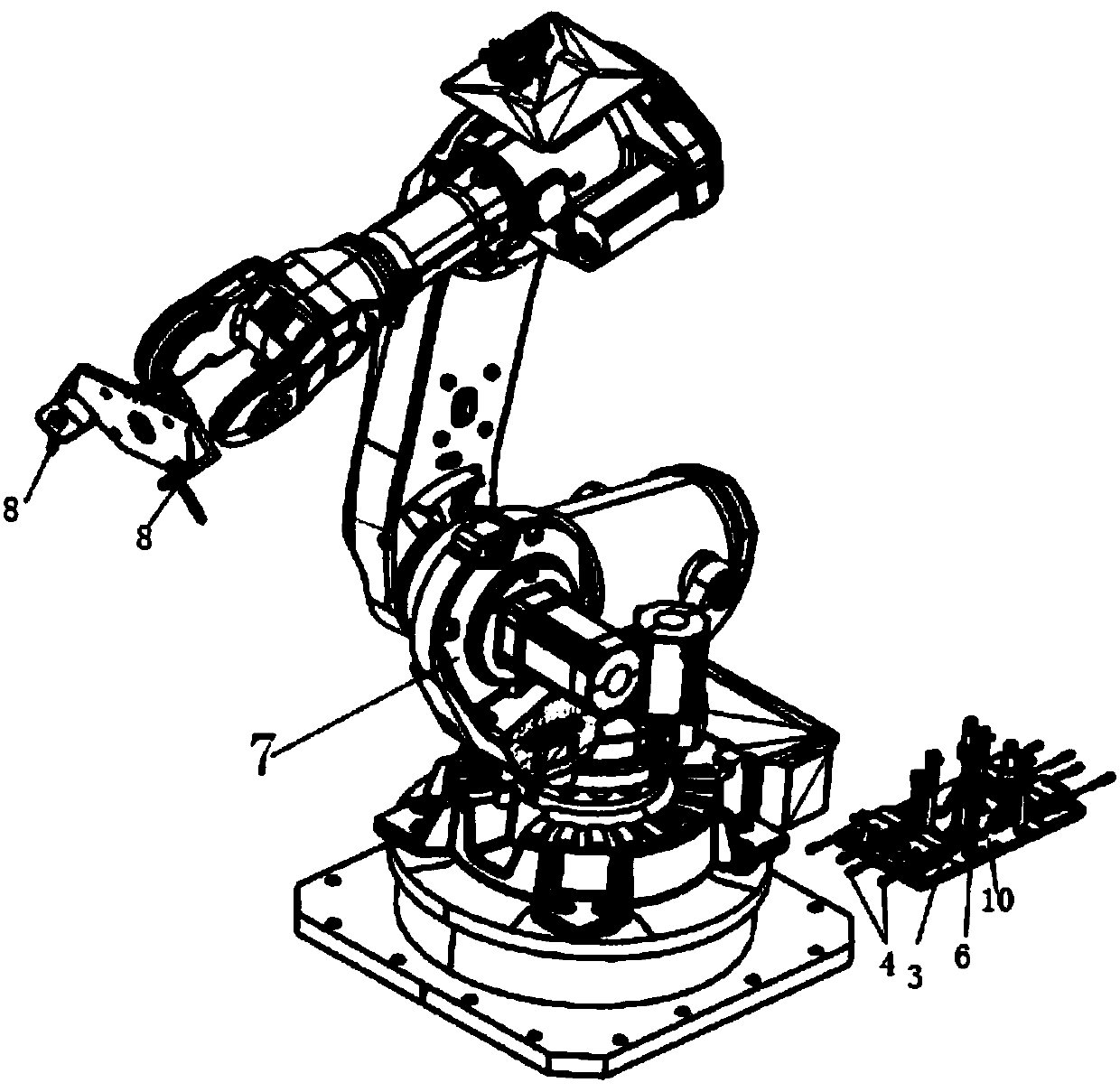

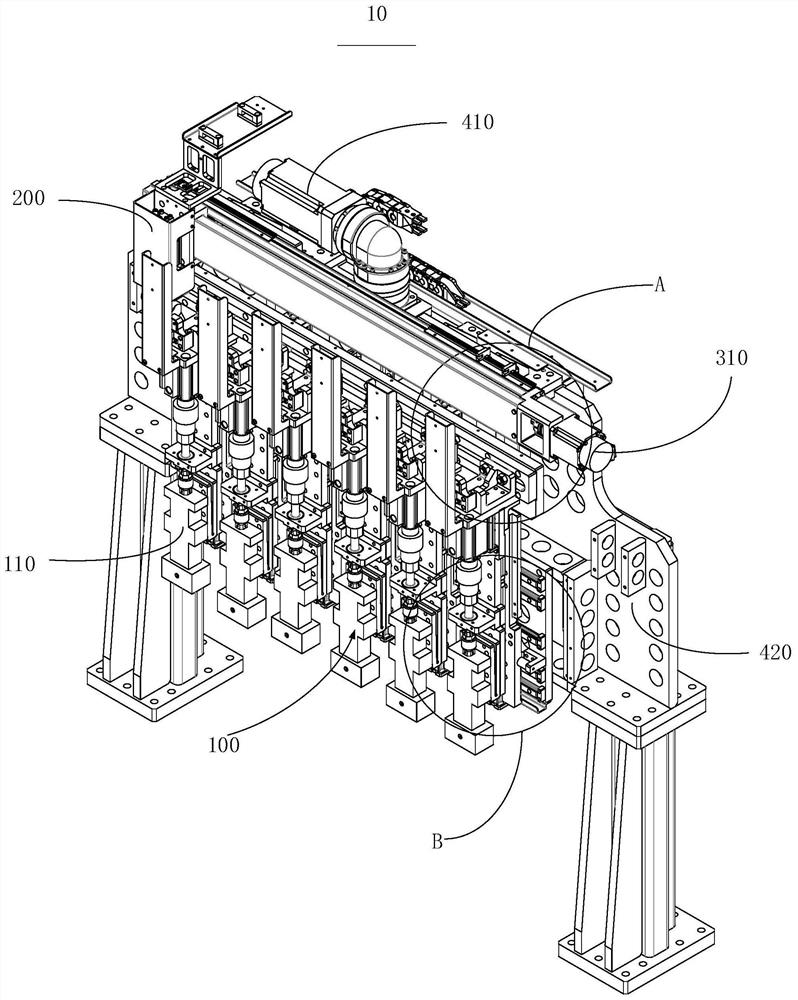

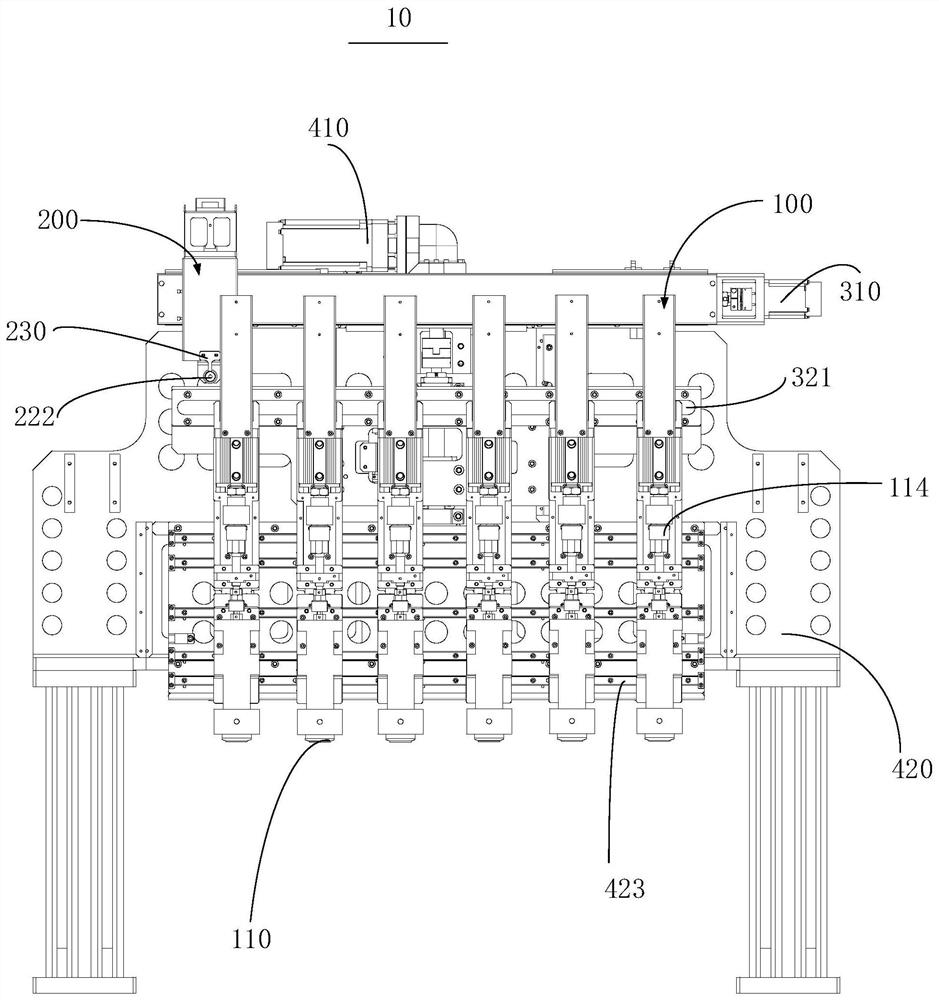

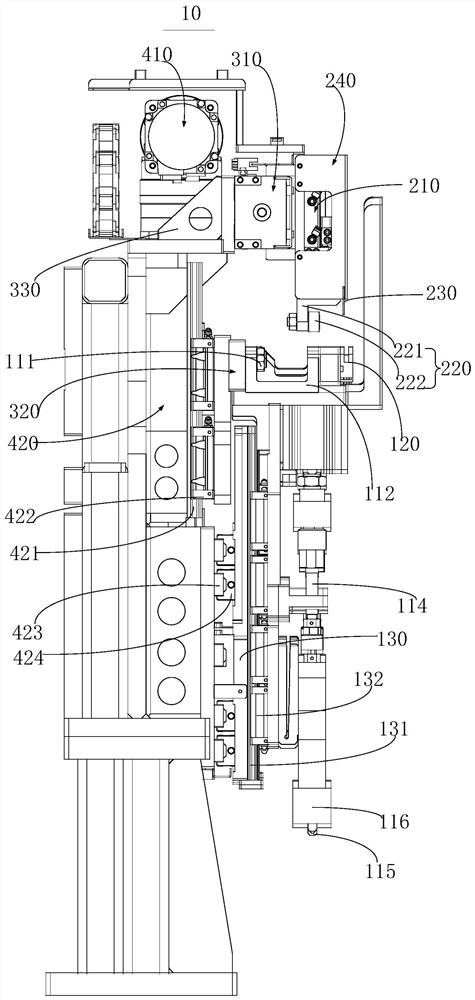

Automatic sleeve replacing mechanism

PendingCN110640444AAvoid risk of errorImplement error-proofingMetal working apparatusControl engineeringMachine

The invention discloses an automatic sleeve replacing mechanism. The automatic sleeve replacing mechanism comprises at least two driving and clamping assemblies and at least two sensing assemblies, and each driving and clamping assembly and each sensing assembly are fixed to a fixing base separately; each sensing assembly is connected with an electric control system, and the electric control system is connected with a tray data system; and each driving and clamping assembly comprises a driving device and a clamping device, the driving devices are connected with the corresponding clamping devices, each sensing assembly is connected with the corresponding clamping device, and each sleeve is detachably fixed to the corresponding clamping device through a machine fixing portion of a corresponding robot. According to the automatic sleeve replacing mechanism, the completely automatic sleeve replacing process is achieved, and the working efficiency is improved; and the potential sleeve type error risk is effectively prevented through sensing of the sensing assemblies, the automatic sleeve replacing function is achieved, the equipment stopping time is shortened, and a sleeve type error proofing function is achieved.

Owner:SAIC-GM-WULING AUTOMOBILE CO LTD

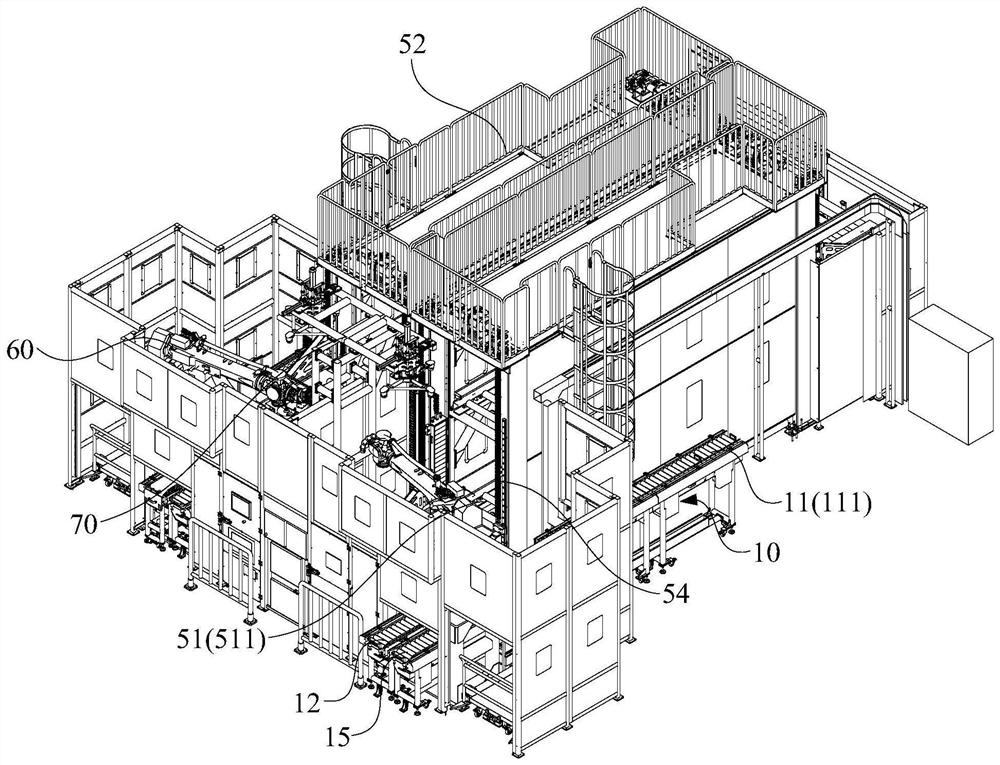

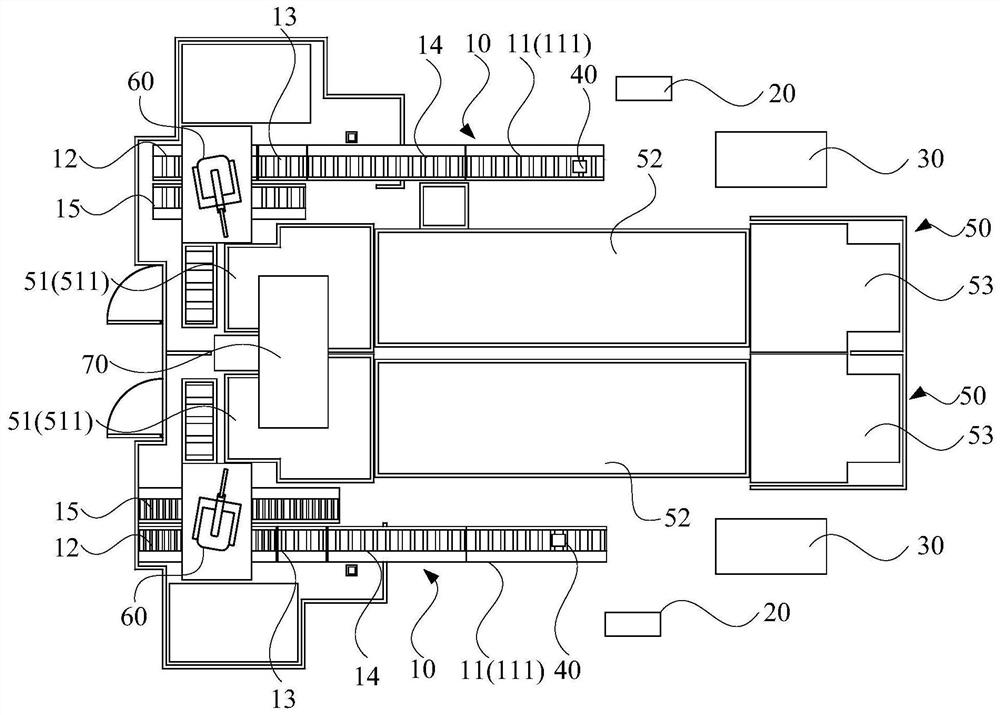

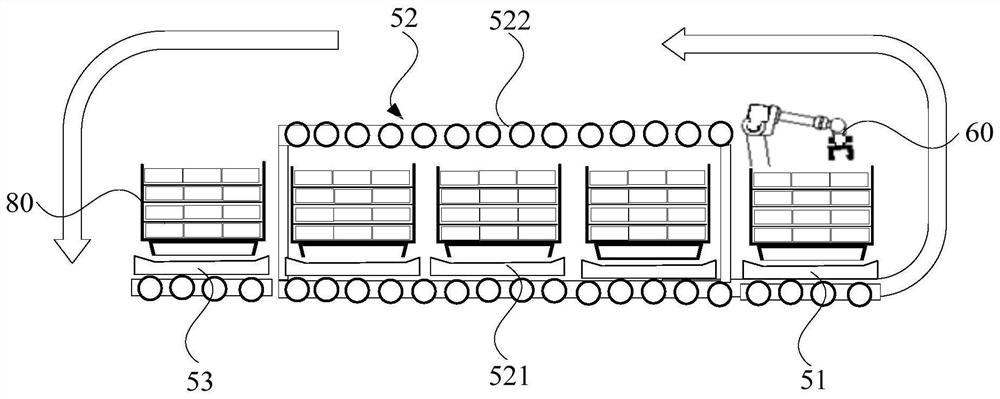

Automatic feeding device and method

PendingCN113071919AQuick changeSmooth replacementPackagingConveyor partsControl engineeringSimulation

The invention relates to an automatic feeding device and method. The automatic feeding device comprises a first conveying mechanism, a truss robot and a paw warehouse. The first conveying mechanism is provided with a first feeding area. The truss robot is provided with first inductive-type couplers. At least two different paws are stored in the paw warehouse, the at least two paws are provided with second inductor couplers, and the first inductive-type couplers are matched with the second inductor couplers, so that power sources and signals between the truss robot and the paws are communicated, and workpieces in the first feeding area are grabbed. And the truss robot is in non-contact butt joint with the paws so that the paws of the truss robot can be quickly replaced conveniently, the paw remodeling efficiency is improved, and automatic compatibility of all types of machines is realized. In addition, faults caused by abrasion, water inflow, oil inflow and the like of the paws of the truss robot are avoided, and high-cost stop is prevented. And moreover, the truss robot can be in power source and signal communication with the paws without a cable, so that motion interference is effectively avoided, and the effect that the paws of the truss robot can be smoothly replaced is guaranteed.

Owner:DONGFENG HONDA ENGINE

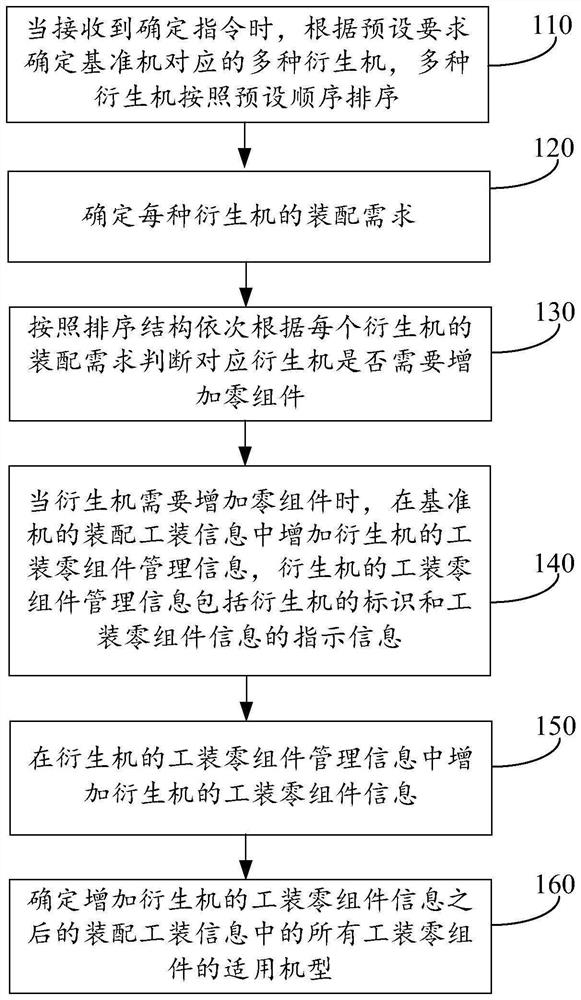

Multi-state configuration method for assembly tool

The invention discloses a multi-state configuration method for an assembly tool, belongs to the technical field of aeronautical manufacturing, and provides the multi-state configuration method for the assembly tool, so that the states of the assembly tool in multiple states can be well managed; according to the method, the positions and the number of the components corresponding to each state and the mutual relation between the components and other states can be clearly reflected, so that the time of process equipment is shortened and errors are reduced when the state of the tool entity is switched, the tool remodeling efficiency is improved, and the product quality is improved. And the occurrence of process equipment remodeling errors caused by unclear technical states is avoided, and the quality cost is reduced.

Owner:SHAANXI AIRCRAFT CORPORATION

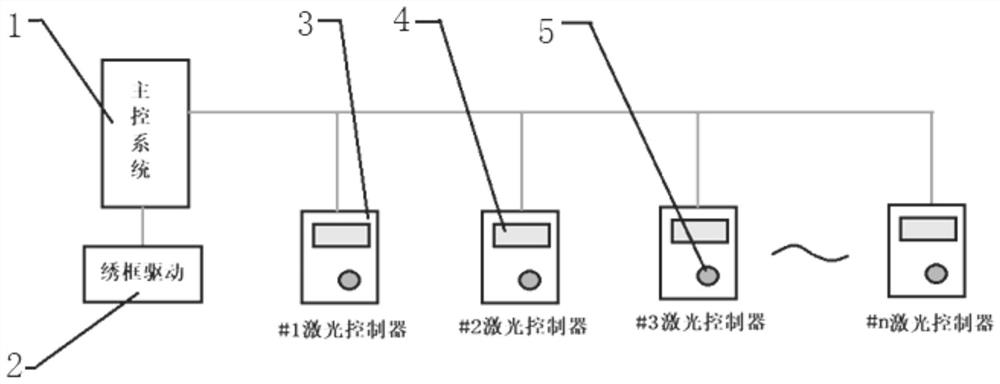

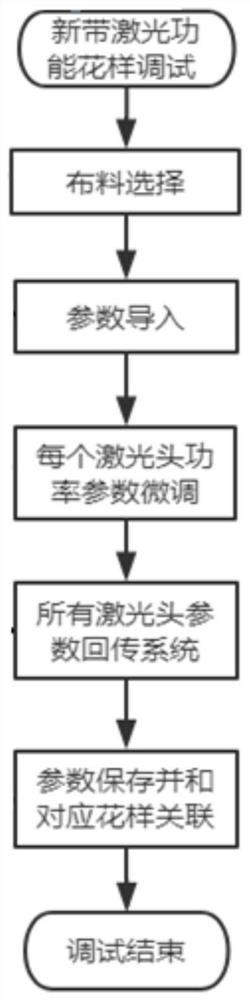

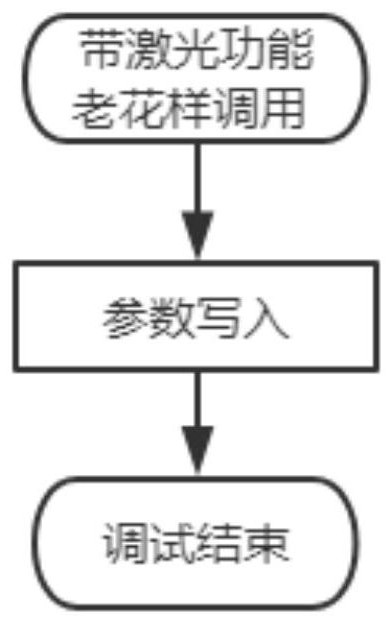

An embroidery machine laser control device and method

ActiveCN112411041BSimple parameter settingEasy to operateAutomatic machinesComputer hardwareControl system

The invention discloses an embroidery machine laser control device and method. The device comprises an embroidery machine main control system, an embroidery frame drive system communicated with the embroidery machine main control system, a communication connection with the embroidery machine main control system and corresponding to each machine control system. Laser controllers are set separately for the laser heads of the head. The main control system of the embroidery machine is equipped with an embroidery parameter storage module and a pattern parameter calling module. The power parameter and pattern parameter calling module writes the corresponding embroidery frame speed parameter into the embroidery frame drive system after any pattern is called, and writes the laser power parameter of each laser controller into the corresponding laser controller according to the address. The invention can directly call the old patterns processed before, and write the parameters to each machine head, which saves the process of resetting parameters and fine-tuning the laser head of each machine head, and significantly improves the efficiency of model change .

Owner:ZHEJIANG XINSHENG SEWING EQUIP

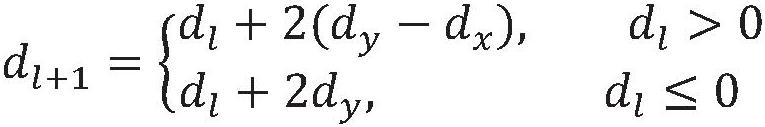

Embroidery machine frame movement control method and system

PendingCN114563984AAchieve unbiasedImprove mobile execution speedProgramme controlComputer controlControl engineeringElectric machinery

The invention provides an embroidery machine frame movement control method and system capable of improving frame movement efficiency and movement precision. The invention discloses an embroidery machine frame movement control method. The method specifically comprises the following steps: determining an original point of a machine; fixing a negative limit sensor; fixing a positive limit sensor; calculating an embroidery range of the embroidery machine according to the positive limit position and the negative limit position; reading parameters of patterns needing to be embroidered through a control device; setting an embroidery starting point; moving the frame according to the pattern parameters to carry out embroidery, and writing the number of stitches in the pattern and an absolute coding value corresponding to the current coordinate position information Ln into a control device every time one stitch in the pattern parameters is completed; and determining whether the absolute coded value of the current motor controller is consistent with the absolute coded value recorded by the control device when the needle is finished finally before shutdown, and controlling the framework to return to an embroidery stopping point by the control device to execute subsequent pattern embroidery. According to the invention, the remodeling efficiency is improved, and the frame movement execution speed of the embroidery machine is improved.

Owner:ZHEJIANG XINSHENG SEWING EQUIP

A control method and system for a virtual reality device

InactiveCN106095421BImprove changeover efficiencyImprove experienceInput/output for user-computer interactionBootstrappingSleep stateUser experience design

The invention discloses a control method and system for a virtual reality device. The method comprises the steps of obtaining an infrared signal when the virtual reality device is in a sleep state; determining whether the virtual reality device is wakened or not according to the obtained infrared signal; and if it is determined that the virtual reality device is wakened, exiting from the sleep state. According to embodiments of the method and the system, whether the virtual reality device is wakened or not can be determined according to the obtained infrared signal when the virtual reality device is in the sleep state; after a user puts a finger in the virtual reality device, the infrared signal is reflected after meeting the finger of the user, an interruption is generated according to the reflected infrared signal, and the virtual reality device exits from the sleep state, so that the virtual reality device is wakened; and when the user wears the virtual reality device, the virtual reality device is determined to be wakened according to the obtained infrared signal, so that the user can waken the virtual reality device in a state of wearing the virtual reality device without taking off the virtual reality device, the changeover efficiency of the virtual reality device is improved, and the user experience is enhanced.

Owner:云南知识图谱科技有限公司

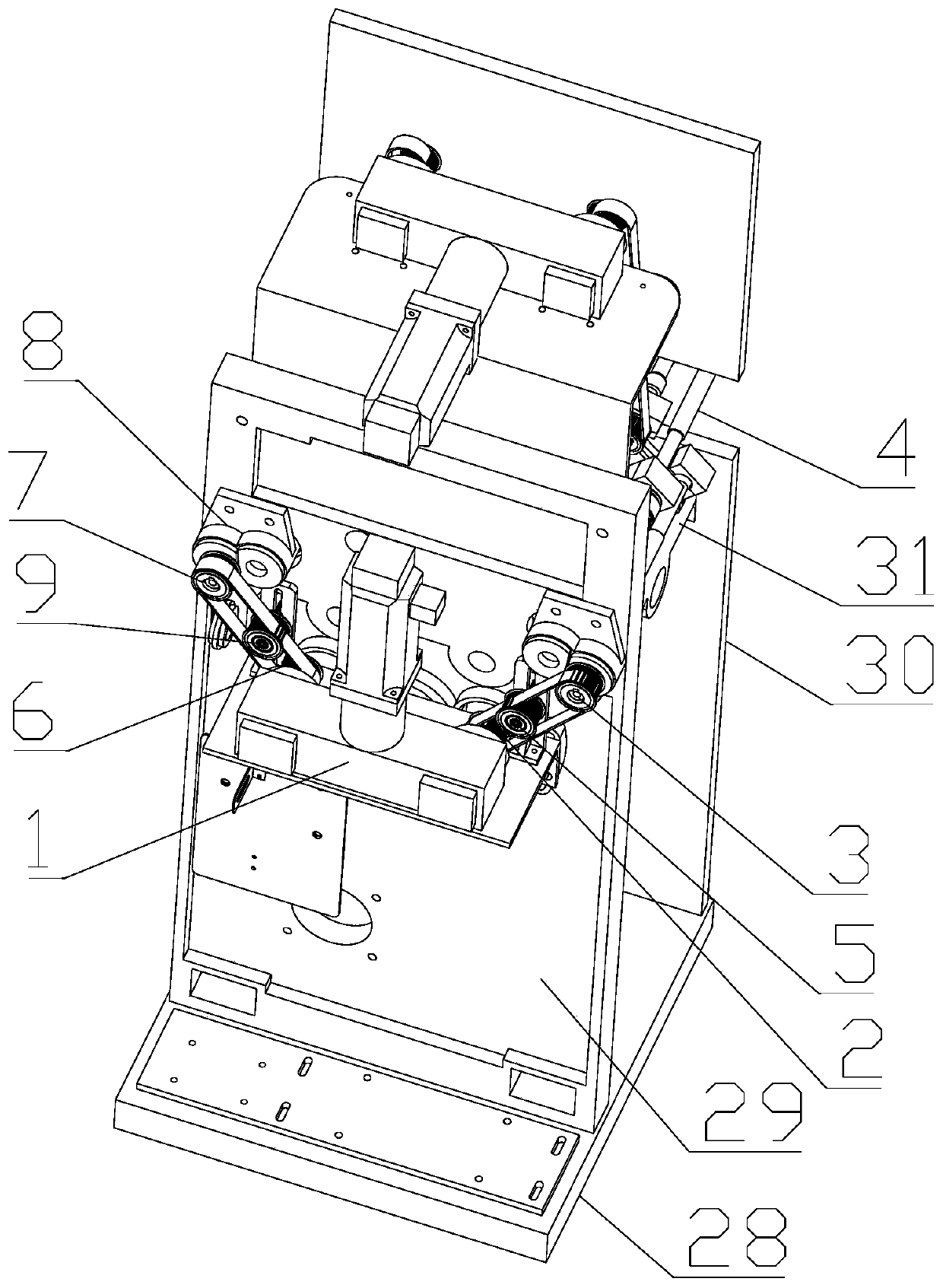

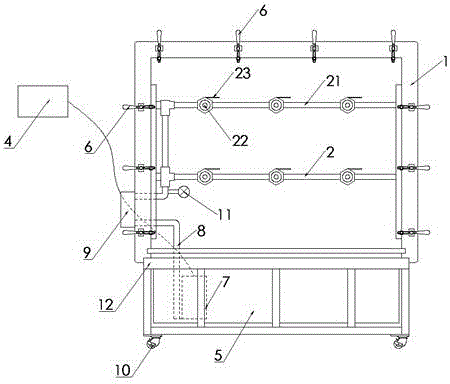

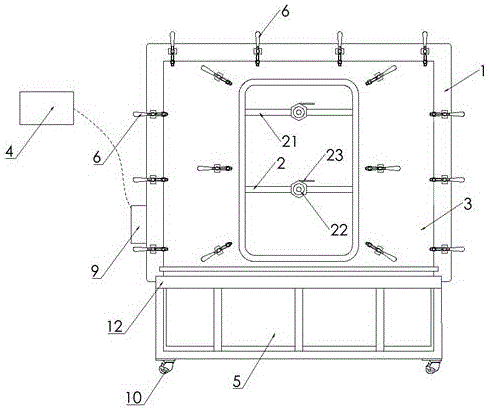

Rain test device for extremely-cold-resistant energy-saving vehicle window

InactiveCN105738132AEasy to install and fixImprove changeover efficiencyRailway vehicle testingPipingEngineering

A rain test device for an extremely-cold-resistant energy-saving vehicle window comprises a test framework (1), a water spray device(2), an installing plate (3) and a timer (4), wherein a water tank (5) is arranged in the bottom of the test framework (1), the water spray device(2) is fixedly installed on the test framework (1), a plurality of crimpers (6) are arranged on one side face of the test framework (1), the installing plate (3) is fixed on the side face of the test framework (1) through the crimpers (6), a water pump (7) is fixedly installed in the water tank (5), a water pipe (8) on the water pump (7) is connected with the water spray device(2) through a flow meter (9), and the flow meter (9) is fixed on the test framework (1). Test on vehicle windows of different sizes can be conducted, and the installation is fast and convenient. Water for rain test can be recycled for reuse to save water and ensure that a test work area is dry.

Owner:江苏申阳交通装备有限公司

Quick changing device for vertical injection molding machine

The invention discloses a quick changing device for a vertical injection molding machine. The quick changing device for the vertical injection molding machine comprises an injection molding machine body and a mold, wherein the mold is located on the injection molding machine body; a carrying table is connected to one side of the injection molding machine body; a motor fixing plate is connected tothe other side of the injection molding machine body; a first drawing die motor and a second drawing die motor are arranged on opposite positions of the motor fixing plate and the carrying table; winding rollers are connected onto the first drawing die motor and the second drawing die motor; and drawing die steel wire ropes wind on the two winding rollers and are connected with opposite vertical surfaces of the mold. The quick changing device for the vertical injection molding machine further comprises a switching assembly for controlling the mold to stop moving. The quick changing device is additionally arranged on the injection molding machine, and the electric motors are utilized for replacing manpower to move the mold, so that the manual operation can be reduced, and the changing efficiency is improved; the mold has no need to be lifted, so that the safety coefficient is high; and in addition, through additionally arranging the switching assembly, the mold can be ensured to accurately stop moving, so that the trouble of manual fine-adjusting is avoided.

Owner:SHANGHAI HENGNUO PLASTIC PROD CO LTD

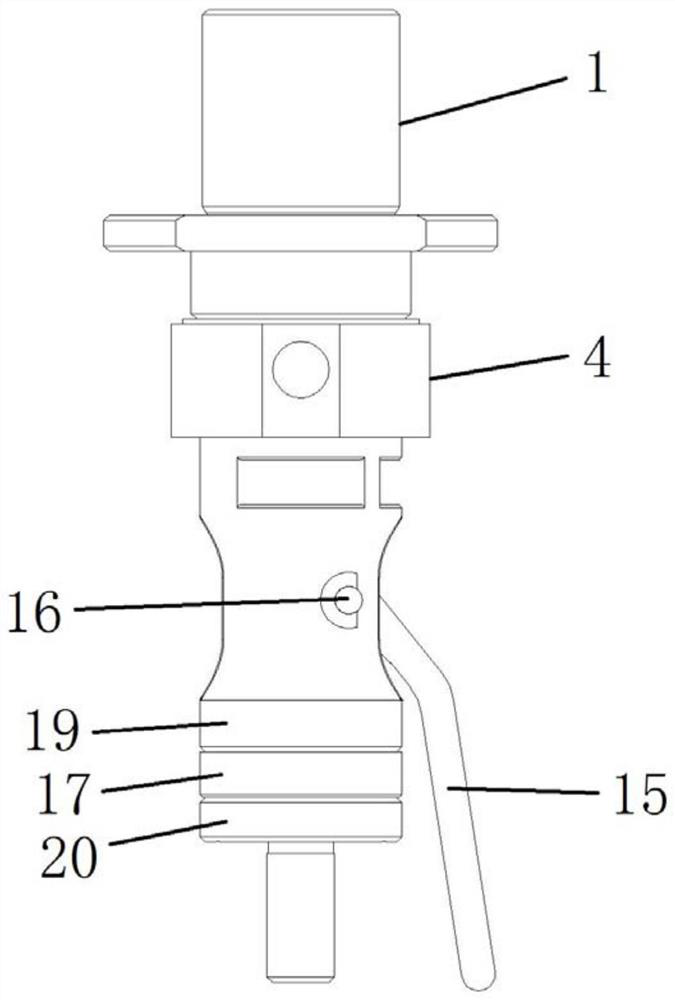

Clamp, clutch test equipment and clutch test method

PendingCN114199560AEasy to detectEasy to disassembleMachine part testingWork holdersDrive shaftControl engineering

The invention relates to the technical field of mechanical testing, in particular to a clamp, clutch testing equipment and a clutch testing method. The clamp comprises a driving shaft, a driven shaft, mounting shafts, a first fixing assembly and a second fixing assembly, the mounting shafts comprise multiple types, each type of mounting shaft corresponds to a to-be-tested clutch in a one-to-one mode, the mounting shafts are detachably arranged between the driving shaft and the driven shaft, the to-be-tested clutch is arranged on the mounting shafts in a sleeving mode, and the first fixing assembly is connected with the second fixing assembly. Therefore, the clamp can be suitable for clutches of different models by replacing the corresponding mounting shafts, and the application range of the clamp is widened. The clamp can be suitable for clutches of different specifications, the compatibility of the clamp is improved, and the working efficiency is improved. The invention further provides clutch testing equipment, the adaptability and compatibility of the clutch testing equipment are improved, and the detection efficiency is improved. The invention further provides a clutch testing method, the mounting shaft is convenient to assemble and disassemble, the remodeling time is shortened, and the remodeling efficiency is improved.

Owner:GUANGDONG GOBAO ELECTRONICS TECH CO LTD

Quick remodeling mechanism for automobile part detection

PendingCN113567144AReasonable structural designImprove stabilityVehicle testingWork holdersMotor vehicle partStructural engineering

Owner:上海欧博自控技术装备有限公司

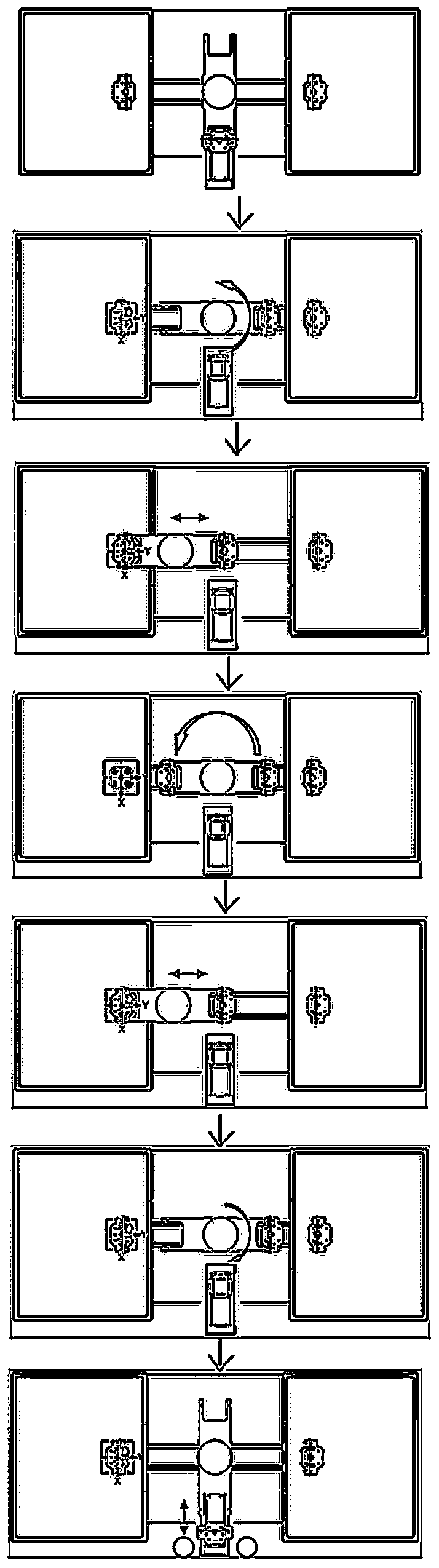

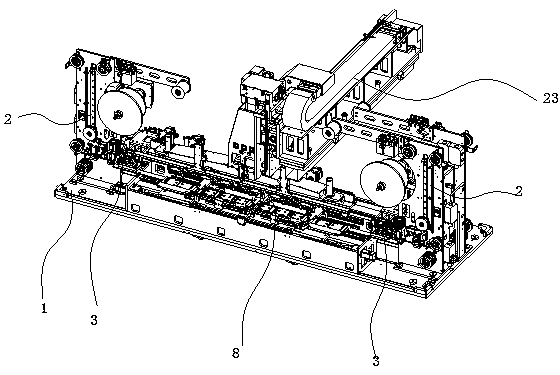

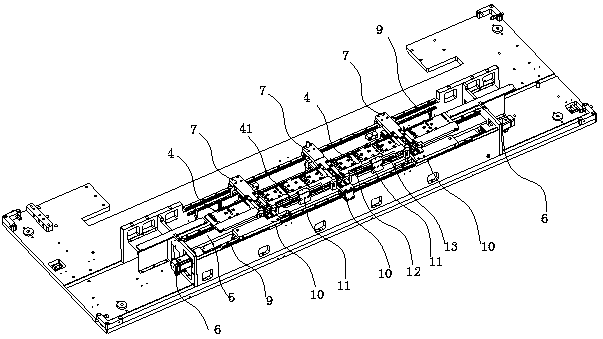

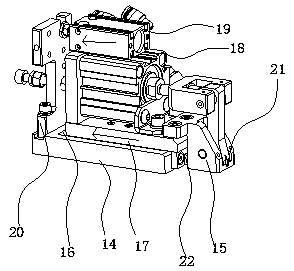

Tool quick replacing system for production line of 5G large die castings

The invention provides a tool quick replacing system for a production line of 5G large die castings. The tool quick replacing system can quickly convey needed tools to corresponding machine tables andthen quickly take out previous tools, the tools are quickly clamped, the replacement efficiency is high, safety of the tools and equipment is guaranteed, a work site is small, and site management isconvenient. The tool quick replacing system comprises the two adjacently-arranged machine tables, each machine table is provided with the corresponding tool, a quick replacing interval space is reserved between the two machine tables, a transverse track is formed in the quick replacing interval space, the two ends in the length direction of the transverse track are arranged facing tool clamp positions of the corresponding machine tables correspondingly, a sliding seat is arranged on the transverse track, a rotating table is integrated on the sliding seat, a linear supporting arm is arranged onthe rotating table, the two ends in the length direction of the linear supporting arm are provided with transferring mechanisms correspondingly, the center in the length direction of the linear supporting arm is arranged corresponding to the rotating table, and the linear supporting arm rotates relative to the center of the rotating table.

Owner:菲斯达精密工业部件(苏州)有限公司

Bus bar manufacturing equipment, bus bar manufacturing method and bus bar welding machine

PendingCN111555096AShorten the timeImprove changeover efficiencyContact member manufacturingEngineeringBus

The invention discloses bus bar manufacturing equipment, a bus bar manufacturing method and a bus bar welding machine. The bus bar manufacturing equipment is characterized in that the equipment comprises a bus bar manufacturing bracket, a discharging mechanism, a pulling mechanism and a cutting mechanism, the discharging mechanism, the pulling mechanism and the cutting mechanism are all fixed to the bus bar manufacturing bracket. A bus bar remodeling mechanism and a plurality of bus bar remodeling plates are arranged on the bus bar manufacturing bracket; the plurality of bus bar remodeling plates are sequentially arranged in the length direction of the bus bar manufacturing bracket, the plurality of bus bar remodeling plates are provided with a plurality of bus bar guide grooves with different widths in the width direction, and the bus bar remodeling mechanism is connected with the plurality of bus bar remodeling plates. The bus bar manufacturing equipment can automatically complete remodeling, the remodeling time is short, the efficiency is high, and the bus bar manufacturing equipment can adapt to manufacturing of bus bars of various models after remodeling.

Owner:苏州德睿联自动化科技有限公司

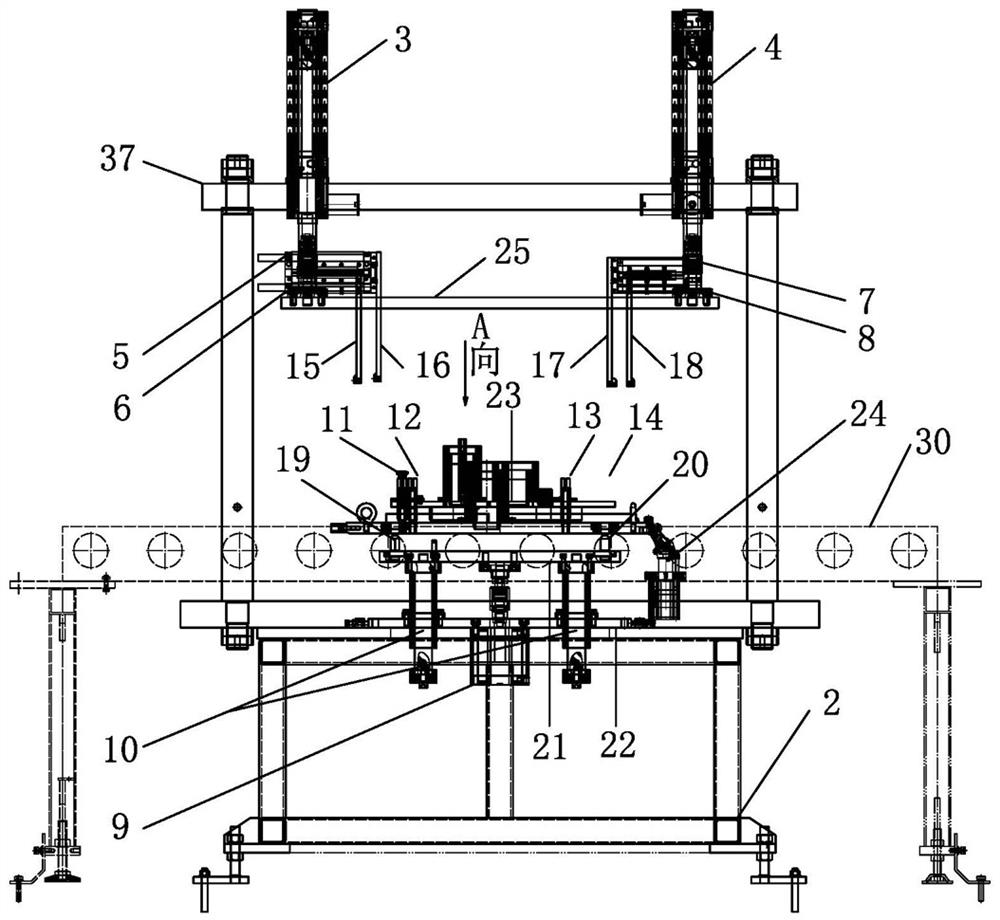

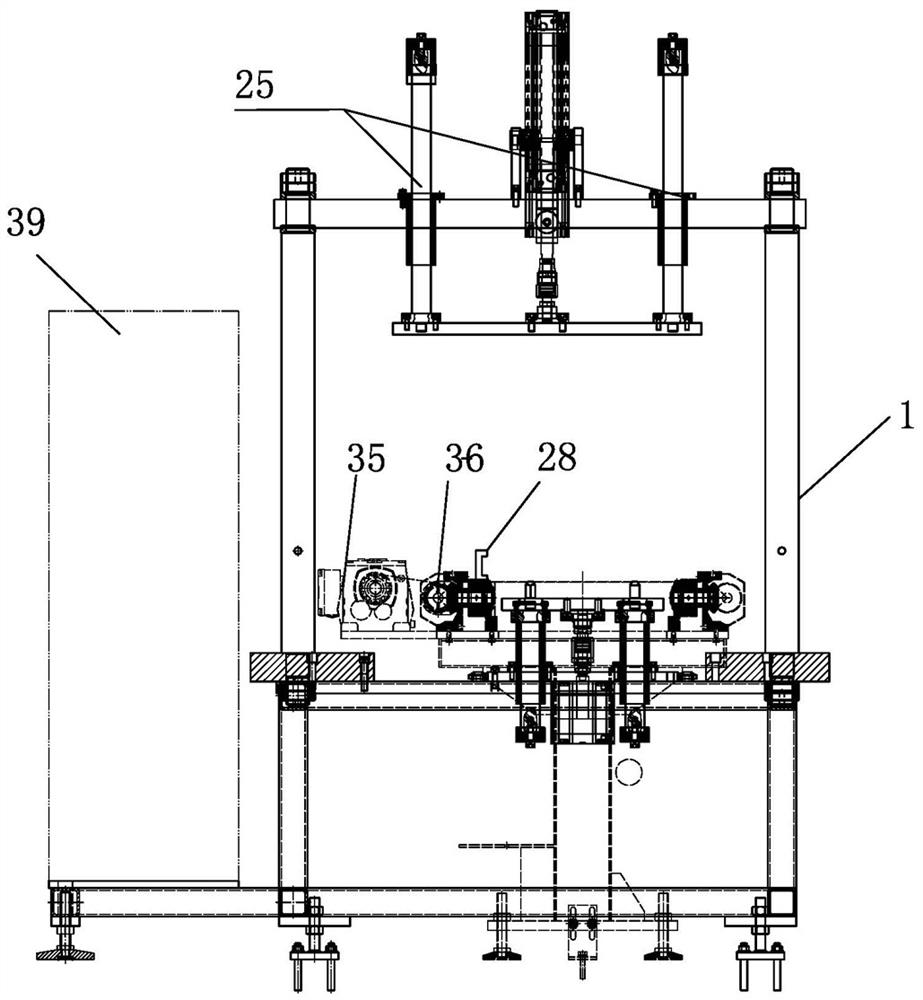

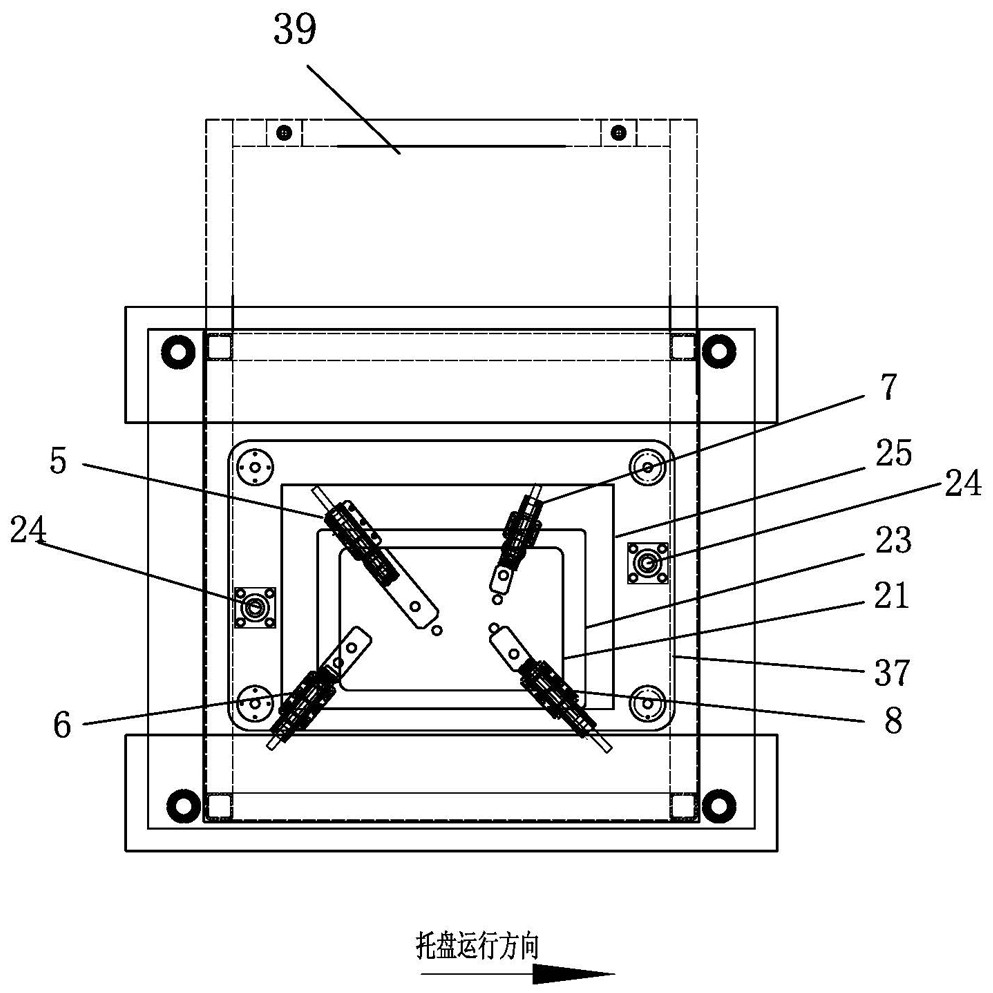

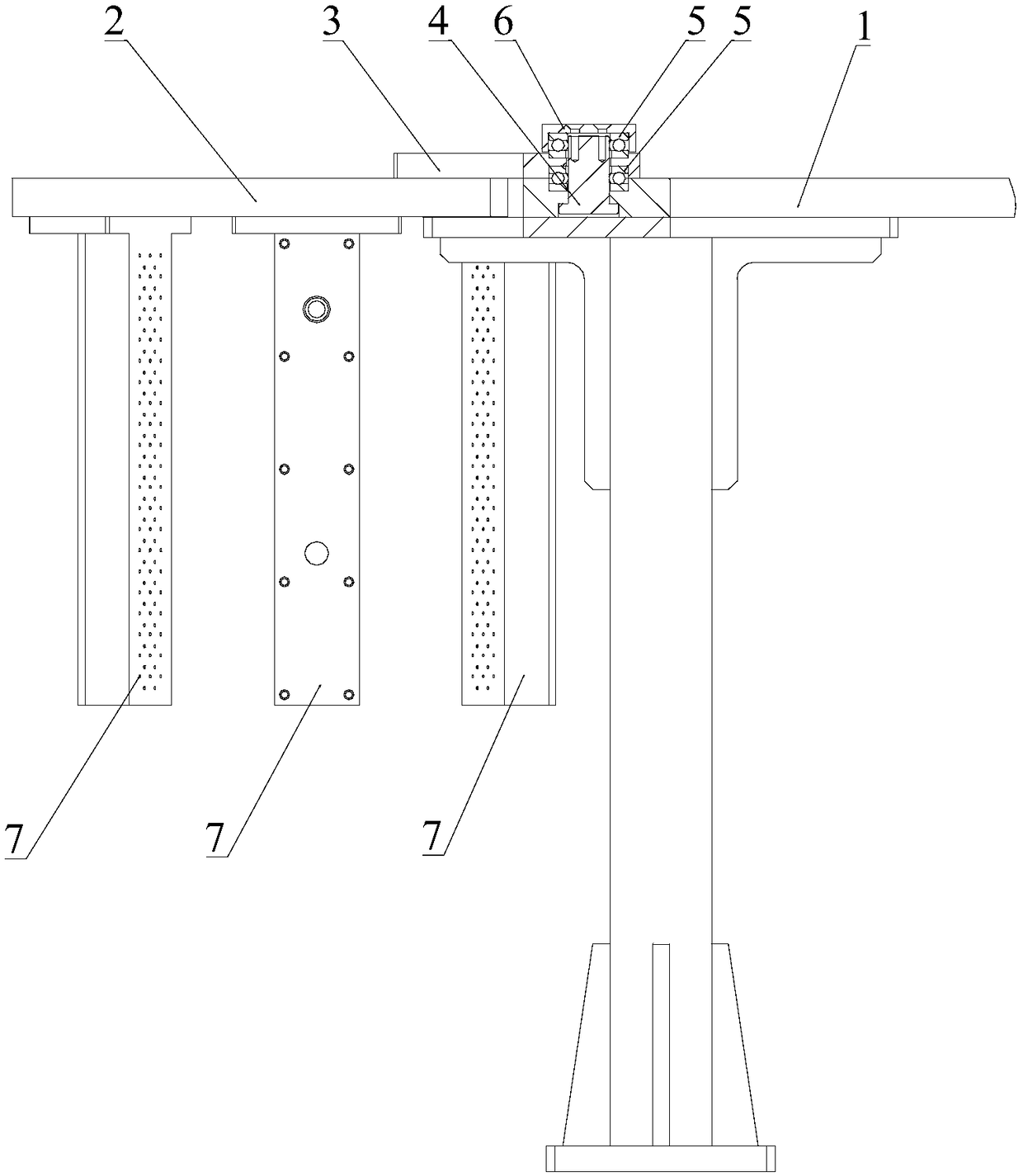

Tray reset device for transmission rear case assembly line

ActiveCN110961881BImprove pass rate FTQImprove changeover efficiencyMetal working apparatusControl engineeringStructural engineering

The invention discloses a tray resetting device for the assembly line of the transmission rear case. There is a support column on the base, and a lifting plate above the base. The lifting plate is connected to the base through the lifting guide column and the lifting cylinder. The mounting plate, the fork cylinder fixed mounting plate is respectively provided with the differential plug-in cylinder, the reverse gear shaft fork cylinder, the input shaft plug-in cylinder and the third / fourth gear fork shaft cylinder, and the fork cylinder is fixed above the mounting plate A lifting cylinder installation fixing plate is provided, and a first lifting cylinder and a second lifting cylinder are respectively arranged on the lifting cylinder installation fixing plate; the first lifting cylinder and the second lifting cylinder are respectively connected with the fixed installation plate of the fork cylinder. The present invention can solve the problems in the prior art that due to memory fatigue during manual reset, errors and missed resets of elastic positioning pins may occur, resulting in collision risks, ranging from knocking and scratching of the workpiece to severe damage to the gripper of the manipulator.

Owner:柳州上汽汽车变速器有限公司

Movable swing arm type machine tool cooling spray mechanism

ActiveCN106670891BQuick repairEasy maintenanceMaintainance and safety accessoriesBall bearingButt joint

The invention discloses a movable swing arm type machine tool cooling spraying mechanism. The movable swing arm type machine tool cooling spraying mechanism comprises a fixing frame fixed to a machine tool, a movable swing arm, a transition plate, thrust ball bearings, spraying boxes and positioning screws, wherein the movable swing arm, the transition plate and the thrust ball bearings are in butt joint with the fixing frame, and the spraying boxes and the positioning screws are fixed to the movable swing arm; the transition plate is arranged above the fixing frame and the movable swing arm and is fixedly connected with the movable swing arm; shaft rings of the thrust ball bearings are connected and matched with the fixing frame, and base rings of the thrust ball bearings are connected and matched with the transition plate; and the corresponding positions on the transition plate and the fixing frame are provided with screw holes for installing the positioning screws. According to the movable swing arm type machine tool cooling spraying mechanism, when the machine tool performs machining, the movable swing arm can be fixed through the positioning screws, the positioning screws are detached when a rear mechanism needs to be maintained, the movable swing arm can swing relative to the fixing frame, and therefore a maintaining space is made, and the purpose of debugging or maintaining the rear mechanism is achieved.

Owner:WUHAN HEATKING MACHINE ELECTRICAL EQUIP

A quick-change pressing mechanism for a hydraulic clamp for a cylinder block

ActiveCN111590360BMeet the requirements of flexible productionSatisfy the change production requirementsPositioning apparatusMetal-working holdersEngineeringCylinder block

Owner:KUNMING YUNNEI POWER

Press-fitting and quick-changing structure for front oil seal and rear oil seal of engine

PendingCN113770682AImprove changeover efficiencyEasy to useMetal working apparatusMachiningEngineering

The invention provides a press-fitting and quick-changing structure for a front oil seal and a rear oil seal of an engine. The press-fitting and quick-changing structure comprises a machining table and a changing and mounting mechanism, wherein a machining base and a control base are arranged on the outer surface of the top end of the machining table, a pressing head is arranged on the control base, and a press-fitting tool is arranged on the pressing head; and the changing and mounting mechanism is arranged on the pressure head and comprises a locking screw, a spring and a nut. By using the press-fitting and quick-changing structure disclosed by the invention, the press-fitting tool can be quickly changed through the arranged changing and mounting mechanism and can be quickly detached from the pressing head by pulling the locking screw through the arranged locking screw, the spring and the nut, the locking screw is inserted into a first through hole, and the press-fitting tool is quickly mounted on the press head, so that the remodeling efficiency of the device can be improved, the device is convenient to use by people, the whole device is simple in structure and convenient to operate, and the practicability of the whole press-fitting and quick-changing structure is improved.

Owner:GUANGXI YUCHAI MASCH CO LTD

Bonding device and automatic remodeling method

PendingCN113189800AImprove versatilityImprove changeover efficiencyPrinted circuit assemblingNon-linear opticsPhysicsEngineering

The invention relates to a bonding device and an automatic remodeling method based on the bonding device. The bonding device comprises a pressing head mechanism and a remodeling mechanism which are arranged at intervals in the vertical direction, wherein the pressing head mechanism comprises multiple sets of pressing head assemblies arranged at intervals, the remodeling assembly can be selectively connected with the multiple pressing head assemblies, the initial position and the target position of each pressing head assembly can be obtained, and a second driving piece drives the remodeling mechanism to move in the first direction, so that the multiple pressing head assemblies can be moved to the corresponding target positions in sequence, hot-pressing bonding can be conducted on products of different sizes and types, production and machining of various products are achieved, the universality of the bonding device is improved, the positions of the pressing head assemblies do not need to be adjusted many times, the remodeling efficiency can be improved, manual operation is not needed so as to reduce manual debugging errors, the bonding position accuracy of the pressing head assembly is ensured, and the remodeling precision and the production efficiency are improved.

Owner:SHENZHEN LIANDE AUTOMATION EQUIP

A method of assembling a coupling

The invention discloses a coupler. An axial inner hole is formed in the middle of the coupler. The coupler is partitioned into an upper half coupler body and a lower half coupler body through a planepassing through the center axis of the coupler; the upper half coupler body and the lower half coupler body are detachably combined; the coupler further comprises a plurality of positioning pins, anda first annular clamping groove and a second annular clamping groove are formed in the inner wall of the inner hole of the coupler; and a plurality of axial pin holes matched with the positioning pinsin a one-to-one correspondence mode are formed in each of the two end surfaces of the coupler. The coupler provided by the invention is simple in structure, an operating space is expanded, front faces of screwheads can be clearly seen during dismounting, the coupler can be fast dismounted and mounted conveniently, and the remodeling efficiency is improved.

Owner:GUANGXI YUCHAI MASCH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com