Quick changing device for vertical injection molding machine

An injection molding machine and fast technology, which is applied in the field of rapid changing device of vertical injection molding machine, can solve the problems of unable to guarantee normal production and product quality, high safety risk, low changing efficiency, etc., to facilitate promotion and reduce personnel operation. , Improve the effect of changing the efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

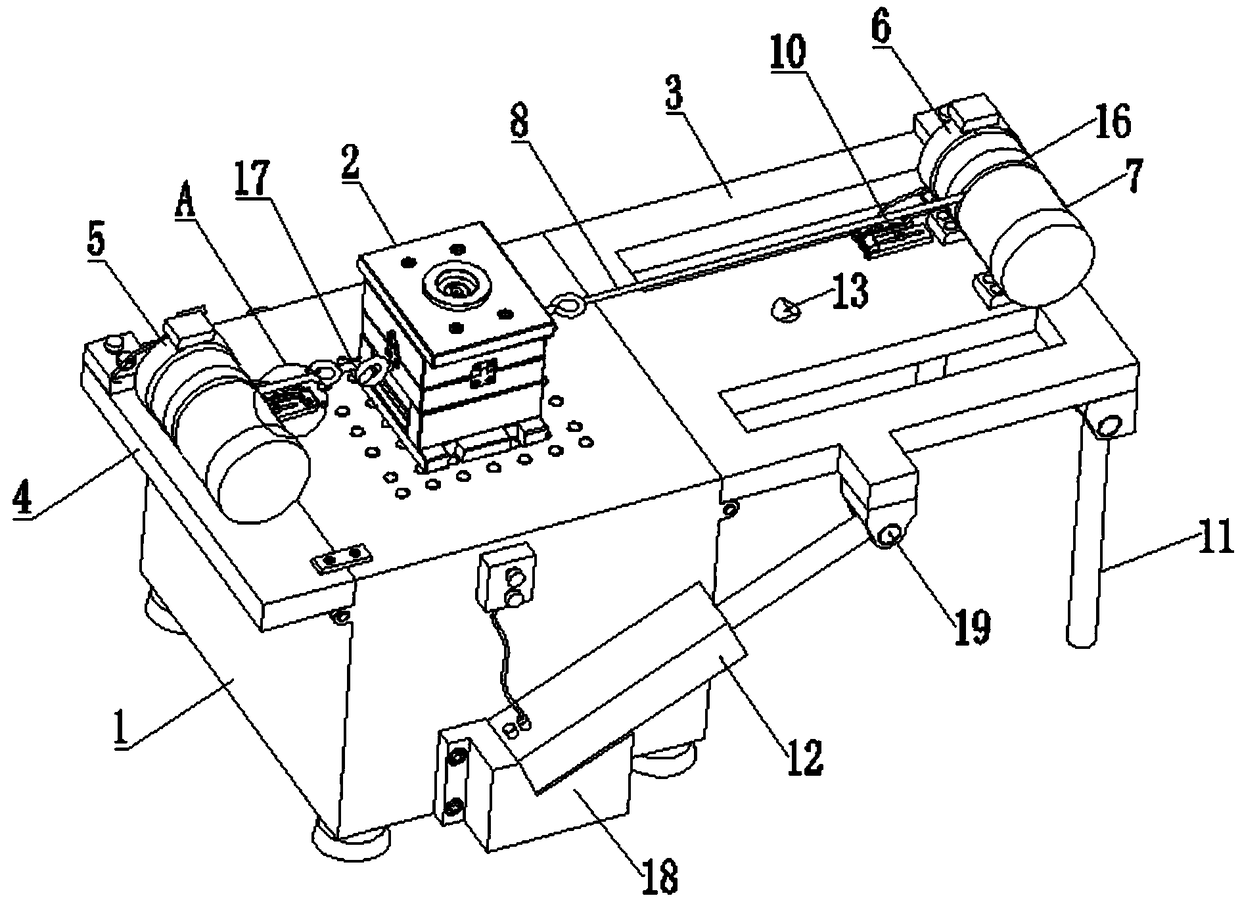

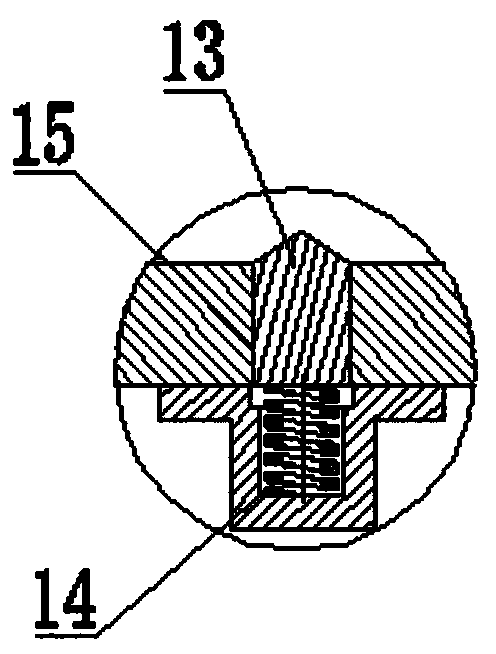

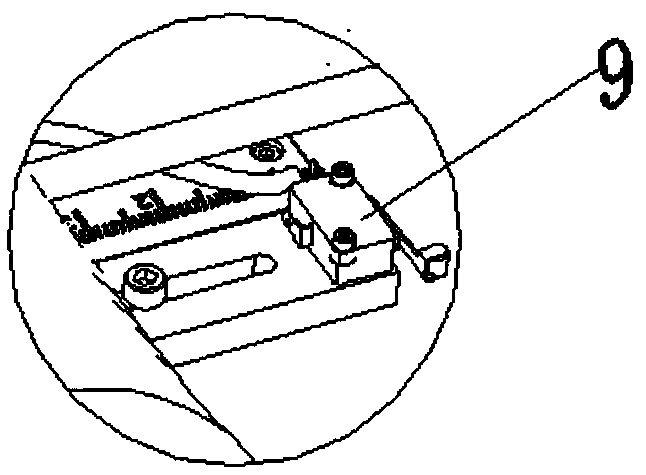

[0021] see Figure 1 to Figure 3 , the present invention provides a quick-change device for a vertical injection molding machine, comprising an injection molding machine body 1 and a mold 2, the mold 2 is located on the injection molding machine body 1, and a receiving platform 3 is connected to one side of the injection molding machine body 1 , the other side of the injection molding machine body 1 is connected with a motor fixing plate 4, and a first drawing motor 5 and a second drawing motor 6 are respectively arranged on the position where the motor fixing plate 4 is opposite to the receiving platform 3 , the first drawing motor 5 and the second drawing motor 6 are connected with winding rollers 7, and the two winding rollers 7 are respectively wound with drawing steel wire ropes 8, and the two drawing Die wire ropes 8 are respectively connected to opposite sides of the mold 2; a switch assembly for controlling the movement of the mold 2 to stop is also included.

[0022]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com