Embossing device provided with tensioning structure and used for textile non-woven fabric production

A non-woven and tensioning technology, applied in textiles and papermaking, fabric surface trimming, thorn patterns, etc., can solve the problems of low production efficiency, low changing efficiency, no easy adjustment of the structure, etc., and achieves easy production and manufacturing. The structure is simple and reasonable, and the effect of high replacement efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to enable those skilled in the art to better understand the present invention, the technical solution of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

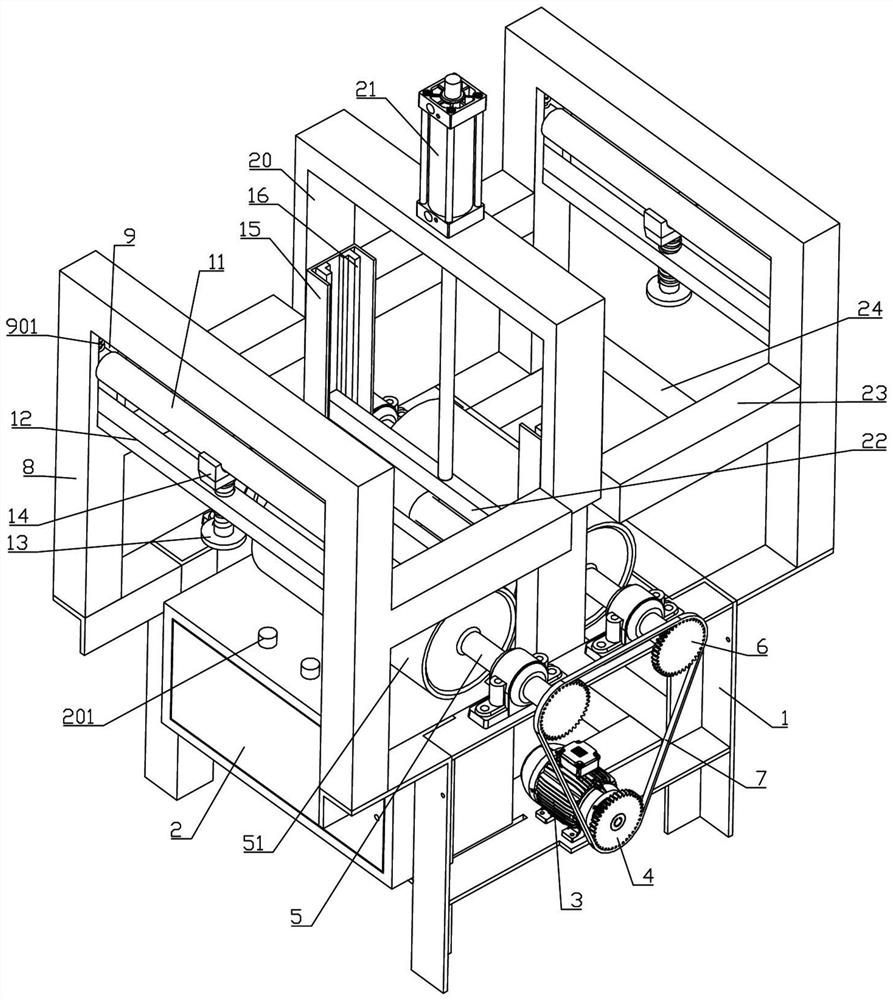

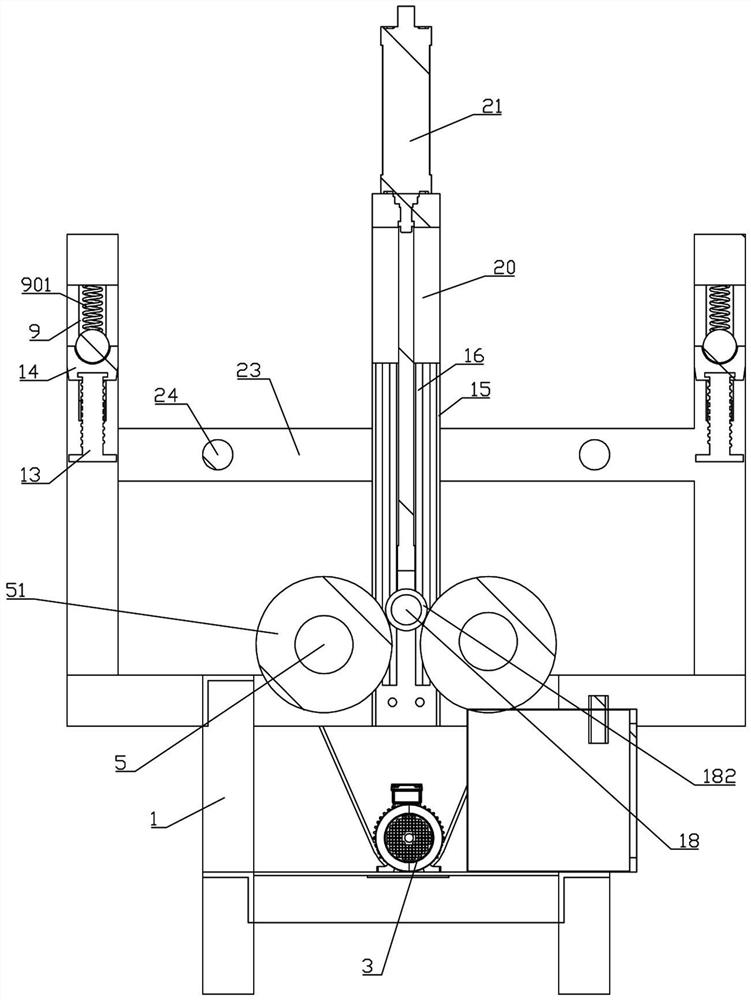

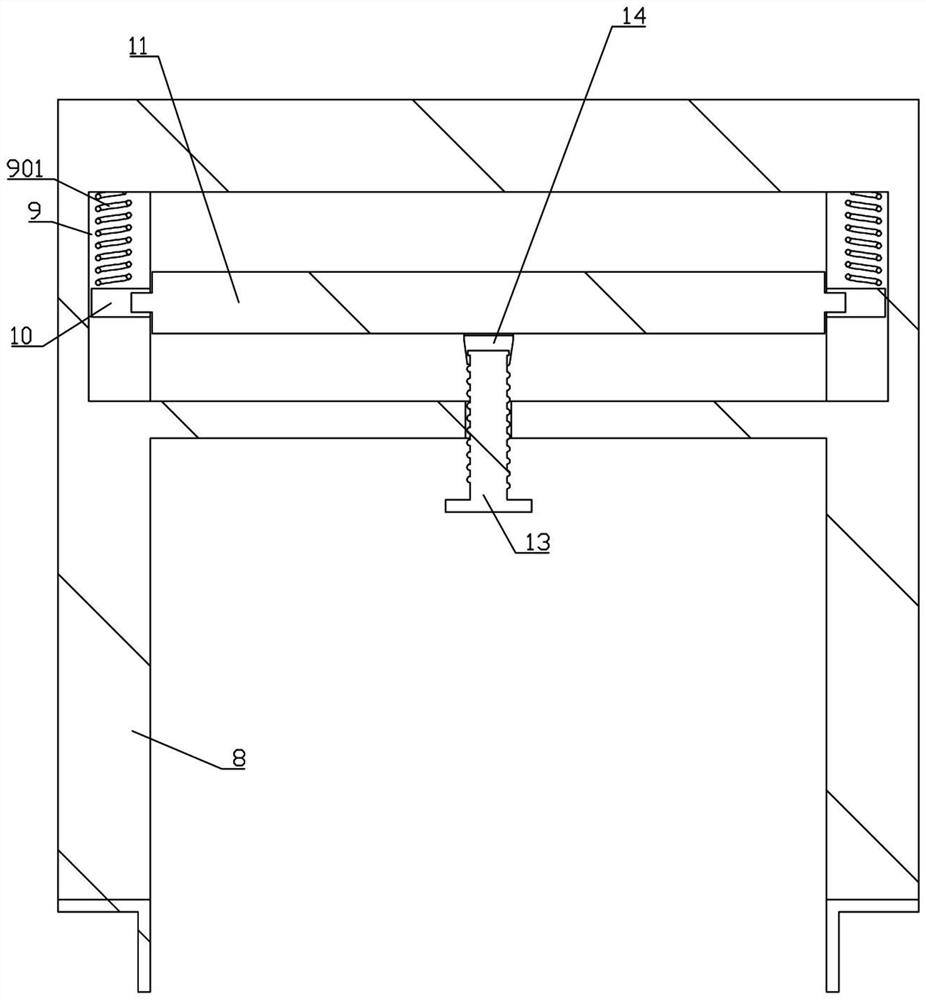

[0030] Such as Figure 1 to Figure 6 As shown, a kind of embossing device for weaving and non-woven fabric production that is provided with tension structure of the present invention comprises frame 1, and frame 1 is equipped with main control box 2, and frame 1 is equipped with motor 3, and motor 3 outputs The driving wheel 4 is connected to the end, and the frame 1 is rotatably connected with two rotating shafts 5. The rotating shaft 5 is equipped with a matching cylinder 51, and the ends of the two rotating shafts 5 are equipped with a driven wheel 6, and the driving wheel 4 and the driven wheel 6 are connected with a The belt 7 and the two ends of the frame 1 are connected with a tensioning bracket 8, the tensioning bracket 8 is provided...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com