Turnover mechanism of numerical control CZ all-in-one machine

A turning mechanism and integrated machine technology, applied in the field of CNC CZ integrated machine, can solve the problems of C-shaped steel and Z-shaped steel moving obstacles, long adjustment time, heavy operation workload, etc., and achieve the effect of improving the efficiency of type change and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

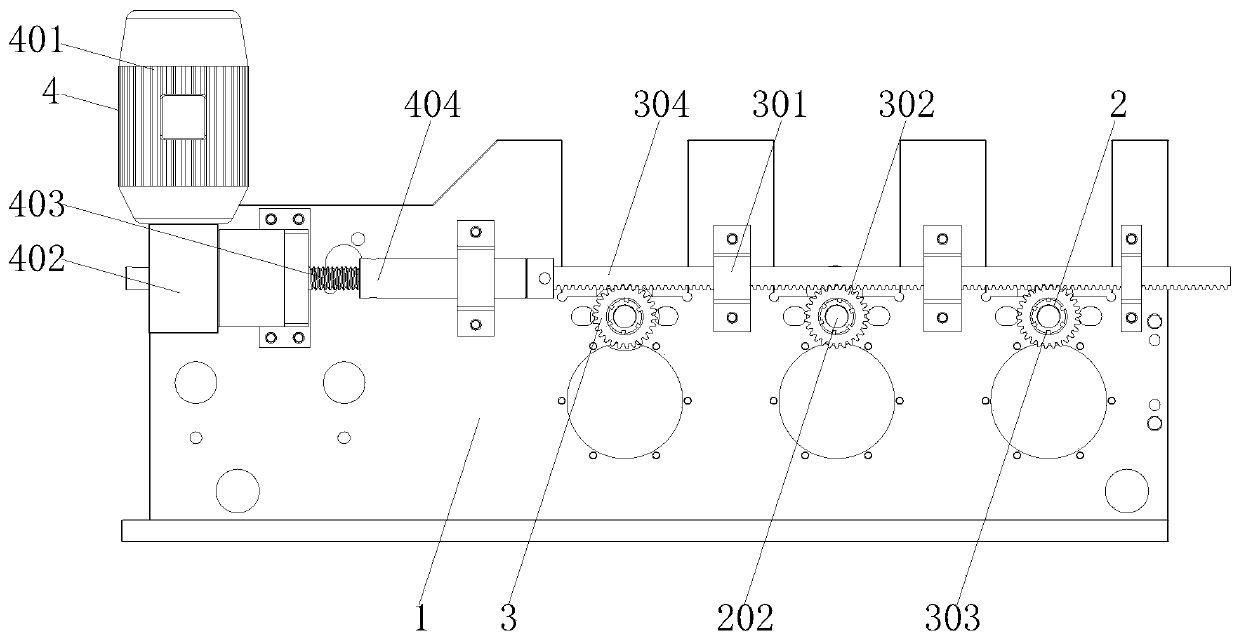

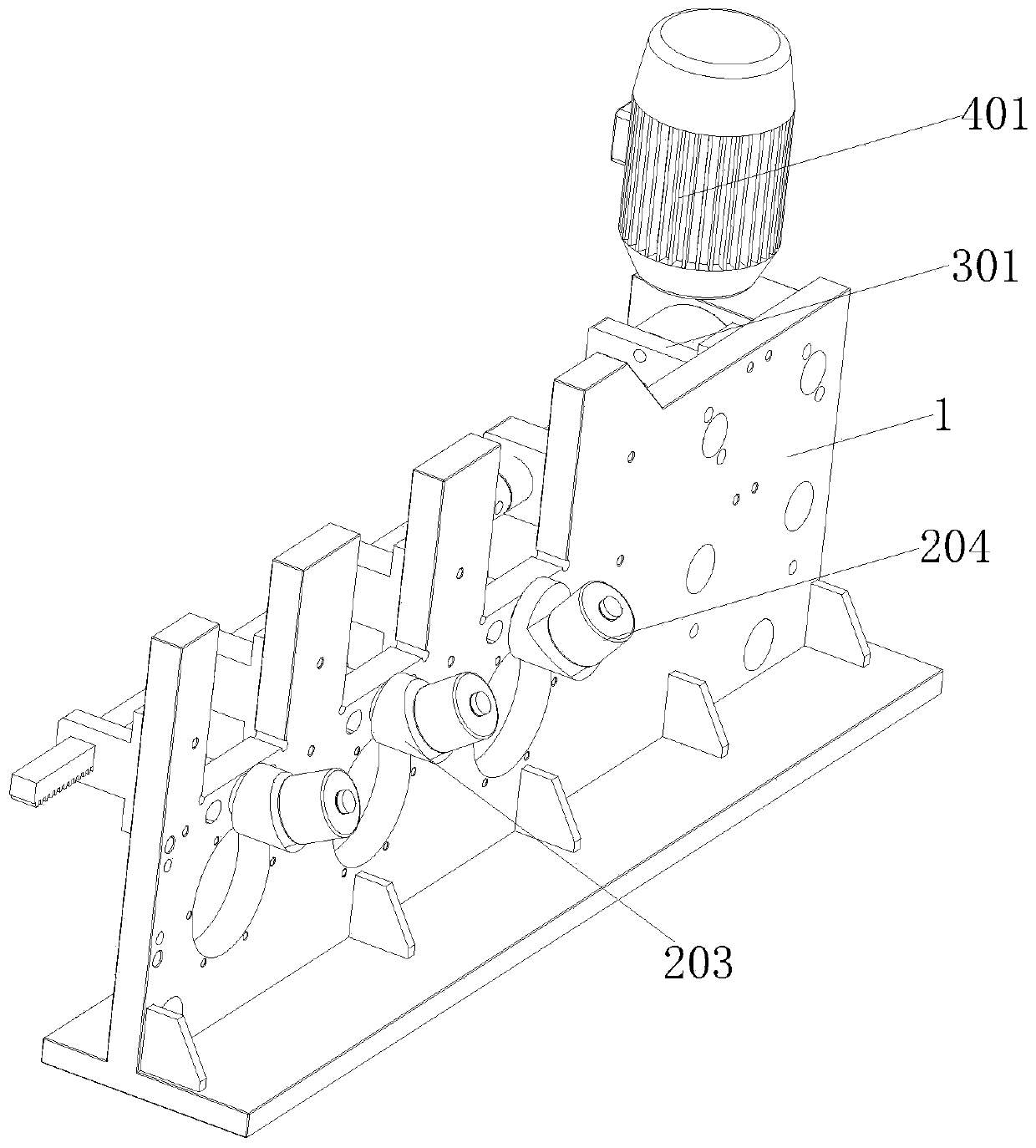

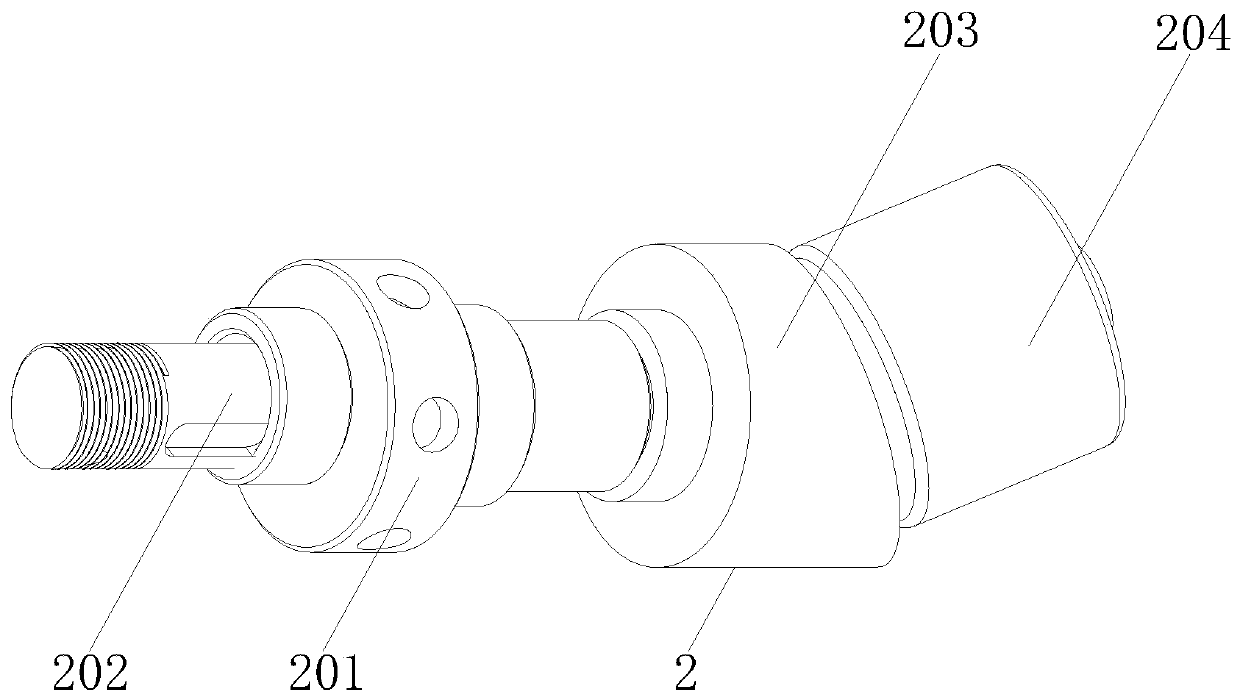

[0018] see Figure 1-3 , the present invention provides the following technical solutions: a turning mechanism of a CNC CZ all-in-one machine, including a frame 1, a turning component 2, a transmission component 3 and a power mechanism 4; the turning component 2 is fixedly connected to the frame 1 and the transmission component 3, and its It is used to switch between C-shaped steel and Z-shaped steel and to position C-shaped steel or Z-shaped steel; the transmission component 3 is fixedly connected with the frame 1, the turning component 2 and the power mechanism 4, and is used to cooperate with the power mechanism 4 to drive the turning component 2 rotates; the power mechanism 4 cooperates with the frame 1 and the transmission assembly 3, and is used to provide driving force for the rotation of the turning assembly 2 with the transmission assembly 3.

[0019] In this embodiment, there are multiple turning components 2, and the transmission connection between multiple turning ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com