Tray reset device for transmission rear case assembly line

A reset device and rear case technology, which is applied in the field of pallet reset devices on the rear case assembly line of transmissions, can solve problems such as collision risk, missing reset, and damage to manipulator fixtures, so as to improve the pass rate, reduce manufacturing costs, and improve The effect of product changeover efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Below in conjunction with accompanying drawing and embodiment the present invention is described in further detail:

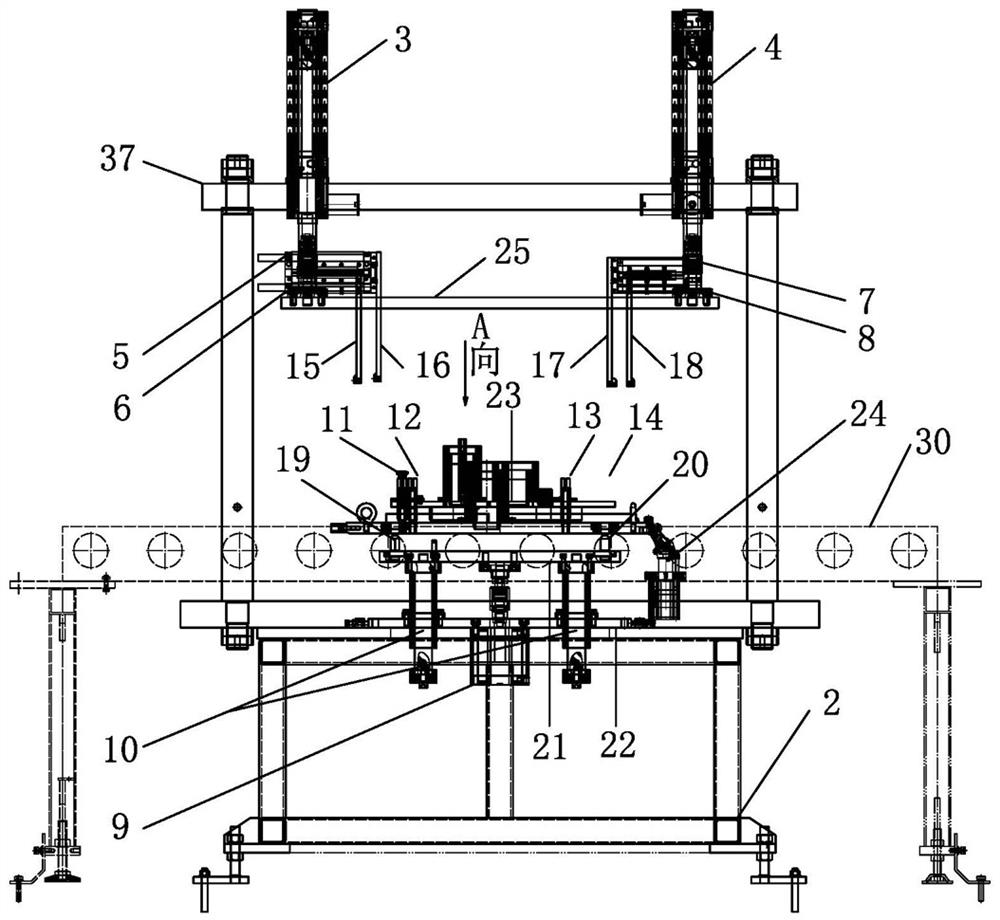

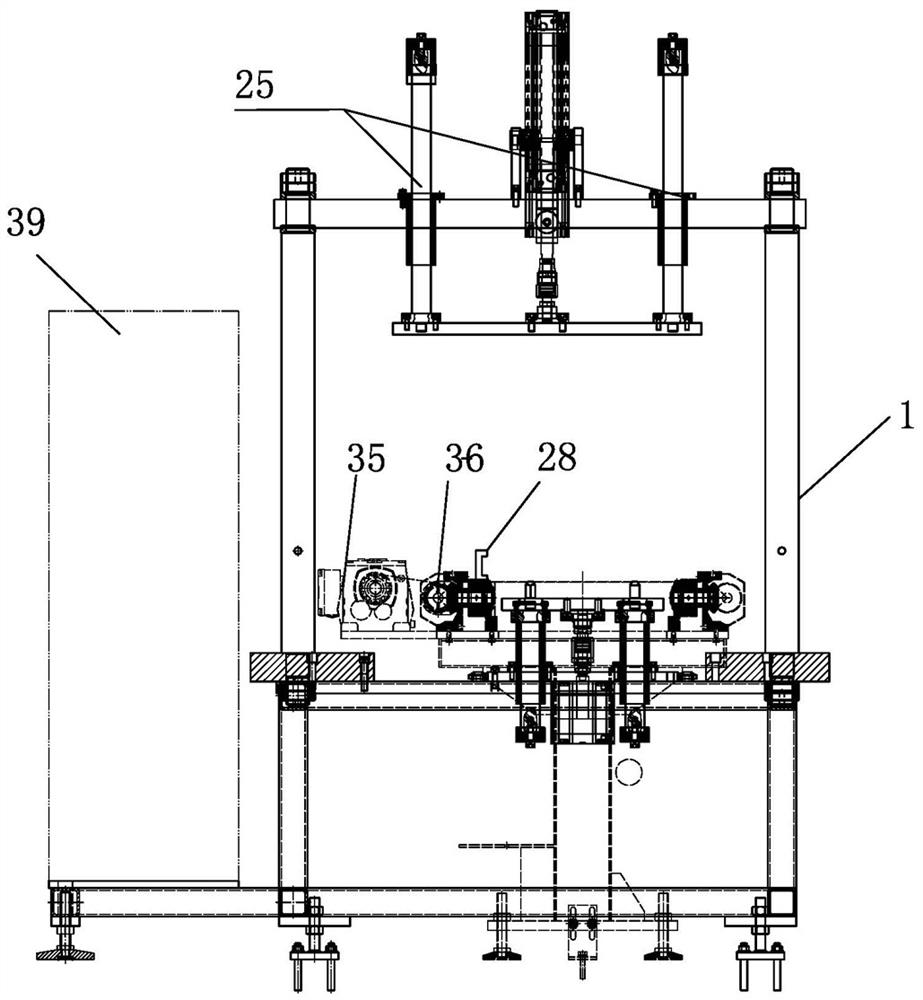

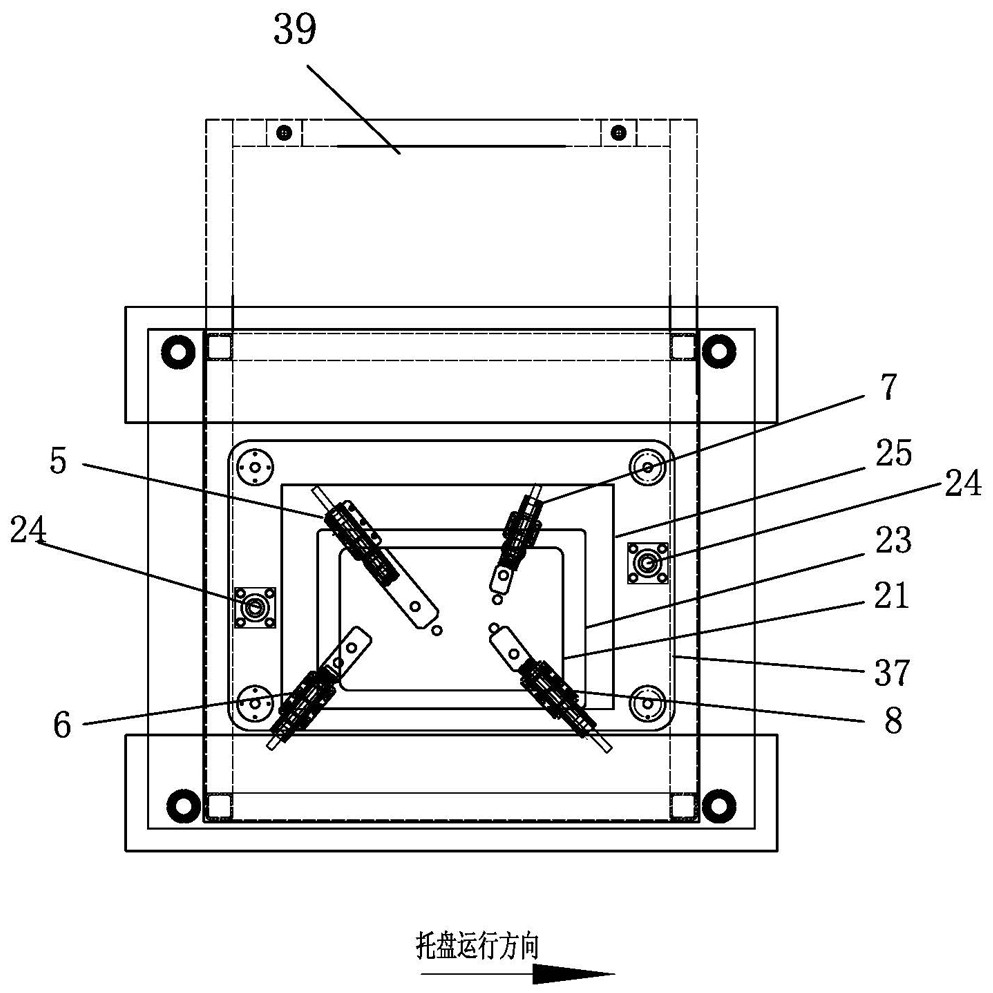

[0017] figure 1 , figure 2 , image 3 , Figure 4 and Figure 5 The pallet reset device for the rear case assembly line of the transmission shown includes a base 2, and support columns 1 are respectively provided on both sides of the base 2, and a lifting plate 21 is provided above the base 2, and the lifting plate 21 passes through the lifting guide column 10 Connect with the lifting cylinder 9 and the base 2, the upper end of the lifting plate 21 is provided with a tray 23 that is movably connected with the lifting plate, and the top of the lifting plate 21 is provided with a plug-in cylinder fixed mounting plate 25, and the plug-in cylinder is fixedly installed Plate 25 is respectively provided with differential gear plug-in cylinder 5, reverse gear shaft plug-in cylinder 6, input shaft plug-in cylinder 7 and third / fourth gear shift fork shaft cy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com