Ultra-thin mobile phone support

A mobile phone holder, ultra-thin technology, applied in the direction of transportation and packaging, vehicle parts, etc., can solve the problems of large volume, thick mobile phone holder, occupying space in the car, etc. The effect of inner space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

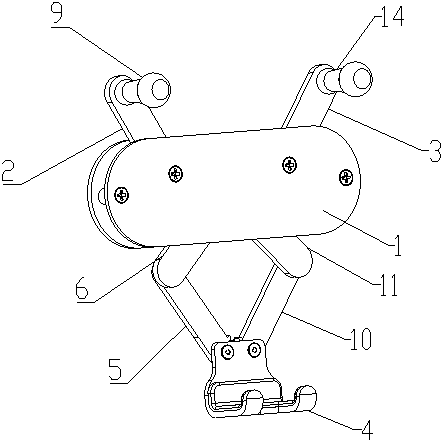

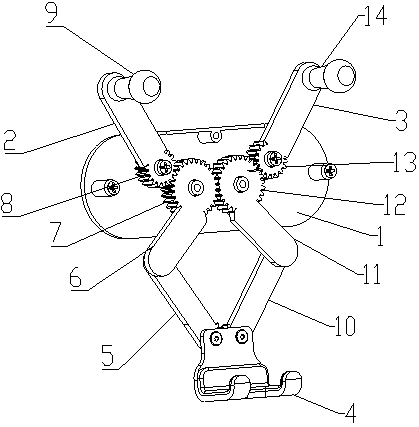

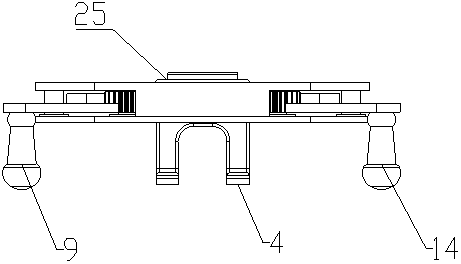

[0035] Such as Figure 1 to Figure 4 As shown, a kind of ultra-thin mobile phone holder, comprises housing 1, left clamping bar 2, right clamping bar 3, supporting claw 4, transmission mechanism, and described supporting claw 4 is arranged on described housing 1 below, and described The supporting claw 4 is connected with the left clamping rod 2 and the right clamping rod 3 through a transmission mechanism, and the transmission mechanism includes a left connecting rod 5, a left driving rod 6, a right connecting rod 10, a right driving rod 11, and the left One end of the connecting rod 5 is rotatably connected to the claw 4, the other end of the left connecting rod 5 is rotatably connected to one end of the left driving lever 6, and the other end of the left driving lever 6 is provided with a left driving gear 7 , one end of the left clamping rod 2 is provided with a left driven gear 8 meshing with the left driving gear 7, and the other end of the left clamping rod 2 is a left ...

Embodiment 2

[0042] Such as Figure 7As shown, embodiment 2 is the same as embodiment 1, the difference is that there is a rotating shaft at the connection between the claw 4 of embodiment 1 and the left connecting rod 5 and the right connecting rod 10 respectively, while the claw 4 of embodiment 2 is connected to the left connecting rod 5 and the right connecting rod 10 joints have only one rotating shaft, that is, the two rotating shafts at this place coincide in embodiment 1.

Embodiment 3

[0044] Such as Figure 8 As shown, embodiment 3 is the same as embodiment 2, and the difference is that the left driving gear 7 and the right driving gear 12 in embodiment 2 mesh with each other, while the left driven gear 8 and the right driven gear 12 in embodiment 3 The gears 13 mesh with each other.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com