A packaging device for plastic granules using centrifugal drop

A plastic granule and subpackaging technology, which is applied in packaging, solid materials, transportation and packaging, etc., can solve the problems of reducing bagging efficiency, bagging volume reduction, waste, etc., to improve the quality of subpackaging, improve work efficiency, reduce workload effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

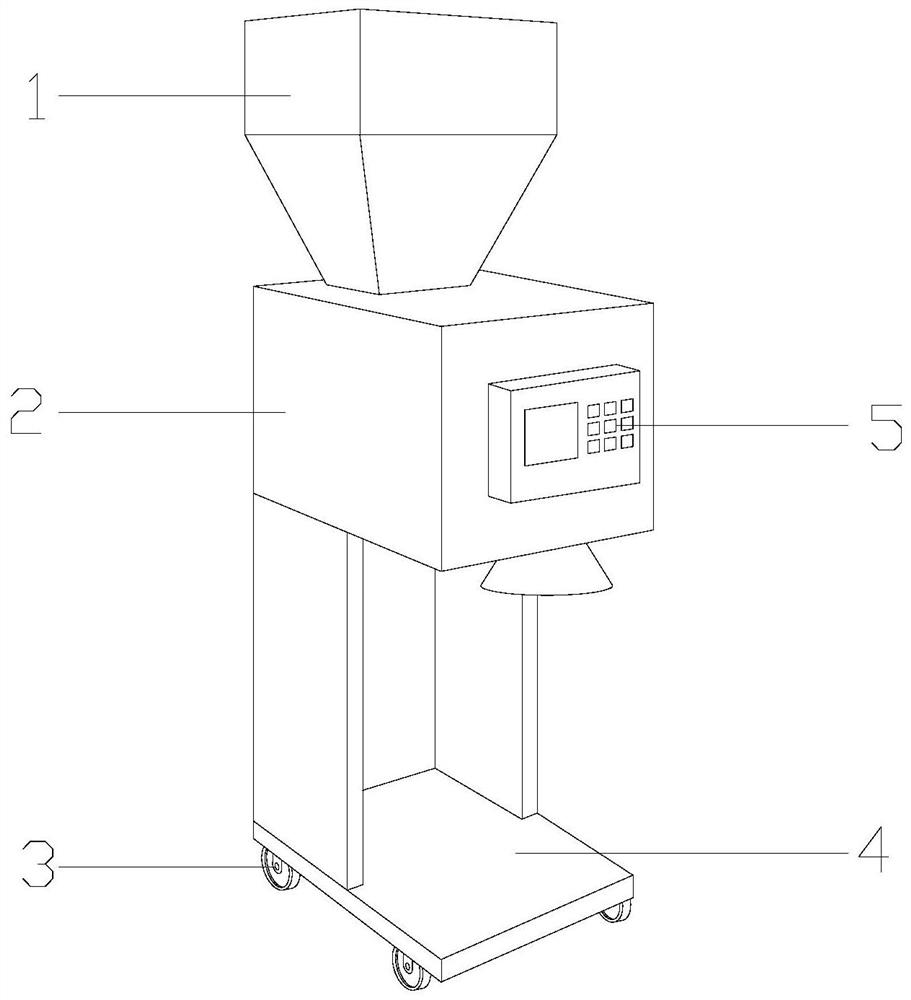

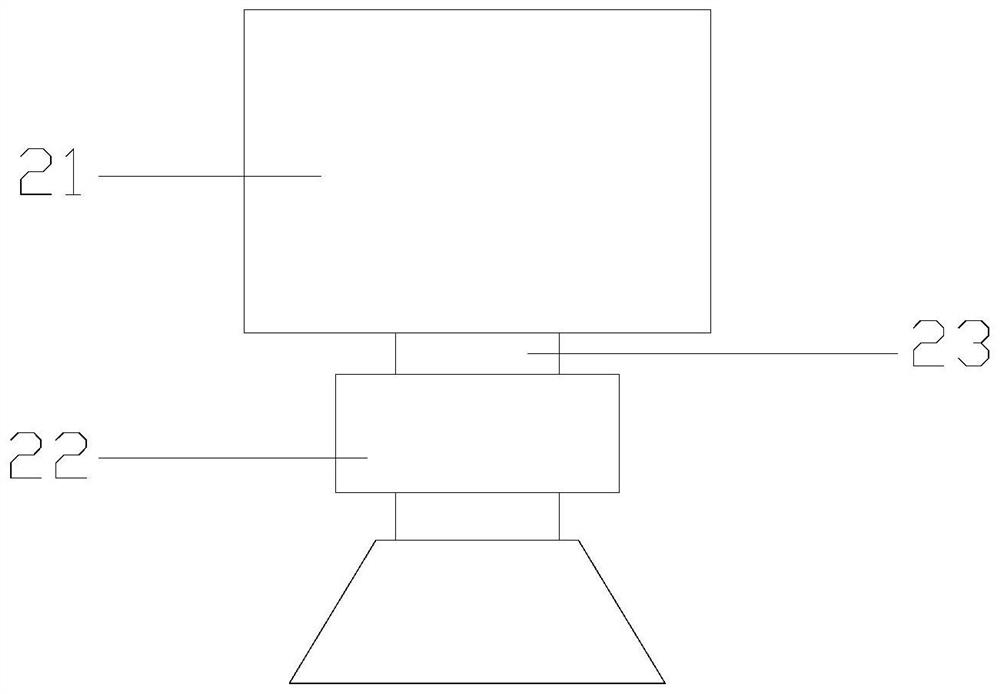

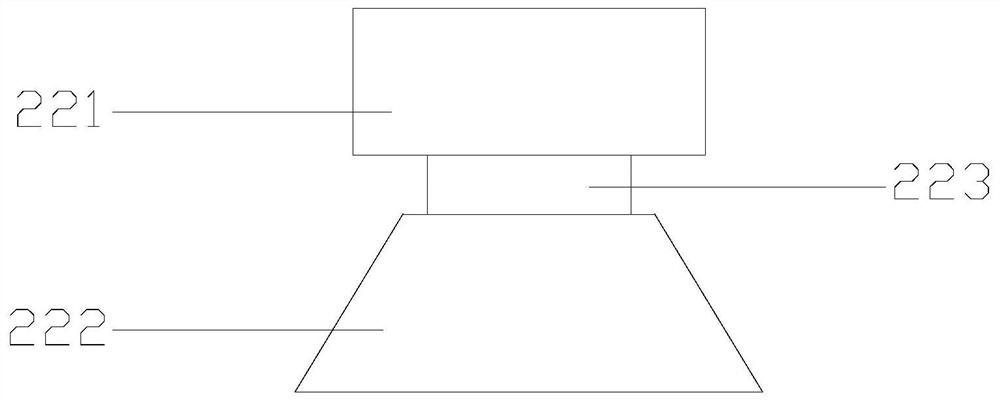

[0027] see Figure 1-Figure 2 , the present invention provides a packaging device for plastic granules that utilizes centrifugal drop-off. The fixing frame 4 is vertically placed on the ground, and the universal driving wheel 3 is provided with four corners which are respectively fixed with the four corners of the bottom surface of the fixing frame 4 by bolts. The upper surface of the fixing frame 4 is welded together, the hopper 1 is an inverted cone structure and the bottom surface is interlocked with the upper surface of the sub-package processing device 2, and the front four corners of the control panel 5 pass through the front of the sub-package processing device 2 The bolts are fixed together, and the sub-packaging processing device 2 is composed of a screw feeding barrel 21, a plastic pellet filling head 22, and a connecting pipe 23, and the bottom surface of the screw feeding barrel 21 is welded together with the upper surface of the sub-packaging fixing frame 4 , the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com